Professional Documents

Culture Documents

Masterseal 333

Uploaded by

Doby YuniardiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Masterseal 333

Uploaded by

Doby YuniardiCopyright:

Available Formats

MASTERSEAL® 333 Interim Datasheet

Formerly Silaseal

Dust Arresting Treatment

DESCRIPTION The application of the first coat should continue until no

more solution will penetrate the surface. Allow to dry for

nd rd

MASTERSEAL 333 is a deep penetrating silicate 24 hours. Repeat procedure for 2 and 3 coats.

solution for sealing and dust-proofing powdery or friable During application do not allow puddles to form or

concrete and masonry surfaces. significant surface build with occur. A glaze of sheen

should not form on the surface.

RECOMMENDED FOR MASTERSEAL 333 is formulated to penetrate, not form

a surface coating. 24 hours after the completion on the

• Old concrete floors that are soft and starting to dust 3rd coat, wash and broom any excess surface material

due to inadequate curing and/or low cement away.

content. NOTE : surfaces treated with MASTERSEAL 333 can

• Powdery or friable concrete and masonry surfaces. exhibit a whitish, blotchy appearance. Where the treated

• New concrete surface to seal against oil, grease surface has been allowed to become wet up to seven

and many chemical solutions. dyas after the final coat, it can become slippery. To

overcome these surface conditions, neutralise by

FEATURES AND BENEFITS brooming a solution of 1 part hydrochloric acid diluted in

15 parts of water onto the floor.

• Dust arresting treatment. Seals and dust proofs new Hose down after 10 minutes and allow to dry.

or old concrete, floors, walls, masonry or stonework. The above procedure is also necessary before

Deep penetrating liquid hardener. Prolongs the considering overcoating with paints, render, etc. A small

serviceable life of “problem” concrete floors before test area is recommended prior to application of any

retoping is required. subsequent surface finish.

• Protects concrete surfaces by sealing and hardening Treated surface may be opened to traffic when the

concrete surfaces, providing increased durability and surface has dried completely and no tackiness remains,

resistance to abrasion. usually after 24 hours.

• Dense surface. Resists penetration of oil and grease.

Protects concrete from the corrosive effects of smoke CLEANING

fumes, mild acids, salts and many other aggressive

chemical solutions. Clean equipment promptly after use with clean water.

APPLICATION DIRECTIONS ESTIMATING DATA

Preparation Coverage will vary greatly depending on the porosity and

Correct surface preparation is essential to ensure a texture of the surface of the concrete and its age. Old

successful application. Surfaces must be dry and concrete can take double the quantity of MASTERSEAL

absorbent, free from oil, grease, paint, cring compounds 333 of new concrete as will a vary rough profile at the

and other contaminants. surface.

New concrete floors As a guide:

New concrete floors that required hardening sealing or Concrete finish Old/New Coverage

dust arresting treatment should be left until they are at Wood float Old 0.17 litre/m2 (6 m2/litre)

2 2

least 28 days old then dilute MASTERSEAL 333 1 : 1 Wood float New 0.10 litre/m (10m /litre)

2 2

with clean potable water, and carefully apply by broom, Steel float Old 0.12 litre/m (8 m /litre)

2 2

mop, spray or squeegee until absorption ceases and all Steel float New 0.08 lutre/m (12m /litre)

pores are filled. Do not allow MASTERSEAL 333 to

PACKAGING

puddle. Liquid membrane curing compound should NOT

be used when using MASTERSEAL 333, use alternative MASTERSEAL 333 is packed in 20 and 205 litre

method such as polythene film or water curing. containers.

Old concrete floors, soft stone, masonry

After surface preparation, apply 3 coats, at 24 hour SHELF LIFE

intervals.

st

1 coat diluted 1 : 3 with potable water MASTERSEAL 333 can be stored under cover in tightly

nd

2 coat diluted 1 : 2 with potable water closed original container for 24 months at moderate

rd

3 coat diluted 1 : 1 with potable water temperature.

Head Office Factories Representative Offices

Plaza GRI 10th & 11th Floor Jl. Daan Mogot Km.14 Jl. Jababeka V Blok I-1 Grand Residence Office Park, Komp. Pertokoan Royal Sunggal

Jl. HR Rasuna Said Blok X-2 No.1 Cengkareng, Cikarang Industrial Estate 1st Floor Jl. Gagak Hitam No. A-12

Jakarta 12950 Jakarta 11750 Bekasi 17530 Jl. Darmo Harapan Complex 1 Ring Road – Sunggal

Tel.: (6221) 5262481, 5262505 Tel.: (6221) 6190007 Tel.: (6221) 8934339 Surabaya 60187 Medan, Sumatera Utara 20128

Fax: (6221) 5262493, 5262515 Fax: (6221) 6190741 Fax: (6221) 8934342 Tel.: (6231) 7326705 Tel.: (6261) 8447110

Fax: (6231) 7326730 Fax: (6261) 8444072

MASTERSEAL® 333 Interim Datasheet

PRECAUTIONS

1) MASTERSEAL 333 is strongly alkaline. Avoid

contact with skin and eyes. Wear protective

goggles, impervious footwear and gloves when

handling.

2) If poisoning occurs seek medical advice. If

swallowed, do not induce vomiting – give a glass of

water.

3) Refer to Material safety Data Sheet for full safety

and First Aid instructions.

I M333/1/0597

The technical information and application advice given in this BASF Construction Chemicals

publication are based on the present state of our best scientific and practical knowledge. As the

STATEMENT OF information herein is of a general nature, no assumption can be made as to a product's suitability for a

RESPONSIBILITY particular use or application and no warranty as to its accuracy, reliability or completeness either

expressed or implied is given other than those required by law. The user is responsible for checking the

suitability of products for their intended use.

Field service where provided does not constitute supervisory responsibility. Suggestions made by

BASF Construction Chemicals either orally or in writing may be followed, modified or rejected by the

NOTE owner, engineer or contractor since they, and not BASF Construction Chemicals, are responsible for

carrying out procedures appropriate to a specific application.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Group 2 (ME 03) - Hoa Phat GroupDocument42 pagesGroup 2 (ME 03) - Hoa Phat GroupLê Thành DanhNo ratings yet

- Masterflex 828: Hot Pour Joint Sealant, ASTM D1190Document2 pagesMasterflex 828: Hot Pour Joint Sealant, ASTM D1190Doby YuniardiNo ratings yet

- Intercure 99Document4 pagesIntercure 99Doby YuniardiNo ratings yet

- Tabel Konversi SatuanDocument1 pageTabel Konversi SatuanSutopo AhmadNo ratings yet

- HIT Rebar Fatigue enDocument7 pagesHIT Rebar Fatigue enWalter CastilloNo ratings yet

- HIT Rebar Fatigue enDocument7 pagesHIT Rebar Fatigue enWalter CastilloNo ratings yet

- ProdukDocument3 pagesProdukDoby YuniardiNo ratings yet

- HIT Rebar Fatigue enDocument7 pagesHIT Rebar Fatigue enWalter CastilloNo ratings yet

- Renderoc HB25: Constructive SolutionsDocument4 pagesRenderoc HB25: Constructive SolutionsDoby YuniardiNo ratings yet

- Masterflex 3000Document2 pagesMasterflex 3000Doby YuniardiNo ratings yet

- Intercryl 520Document4 pagesIntercryl 520Doby YuniardiNo ratings yet

- MBrace Putty ASEANDocument2 pagesMBrace Putty ASEANDoby YuniardiNo ratings yet

- Preco EAC-SDocument2 pagesPreco EAC-SDoby YuniardiNo ratings yet

- Mastertop Primer 9Document3 pagesMastertop Primer 9Doby YuniardiNo ratings yet

- Interlac 826Document4 pagesInterlac 826Doby YuniardiNo ratings yet

- Intergard 774Document4 pagesIntergard 774Doby YuniardiNo ratings yet

- ) Fi Puoqqsnrg: LZVX LselduocDocument2 pages) Fi Puoqqsnrg: LZVX LselduocDoby YuniardiNo ratings yet

- Preco EAC-SDocument2 pagesPreco EAC-SDoby YuniardiNo ratings yet

- Mastertop 566: Self Smoothing Cementitious Based Floor LevellerDocument2 pagesMastertop 566: Self Smoothing Cementitious Based Floor LevellerDoby YuniardiNo ratings yet

- Nitoplate FRC: Constructive SolutionsDocument2 pagesNitoplate FRC: Constructive SolutionsDoby YuniardiNo ratings yet

- Backer RodDocument2 pagesBacker RodDoby YuniardiNo ratings yet

- Conbextra EUW: Water Insensitive Epoxy MaterialDocument2 pagesConbextra EUW: Water Insensitive Epoxy MaterialDoby YuniardiNo ratings yet

- Mastertop 102: Natural Aggregate Concrete Surface HardenerDocument2 pagesMastertop 102: Natural Aggregate Concrete Surface HardenerDoby YuniardiNo ratings yet

- Masterflex 3000: Masterflex Sealing System For Irregular and Unconventional JointsDocument3 pagesMasterflex 3000: Masterflex Sealing System For Irregular and Unconventional JointsDoby YuniardiNo ratings yet

- Mastertop 1240 AseanDocument2 pagesMastertop 1240 AseanDoby YuniardiNo ratings yet

- Intergard 774Document4 pagesIntergard 774Doby YuniardiNo ratings yet

- Mastertop 1240 AseanDocument2 pagesMastertop 1240 AseanDoby YuniardiNo ratings yet

- Masterflex 3000: Masterflex Sealing System For Irregular and Unconventional JointsDocument3 pagesMasterflex 3000: Masterflex Sealing System For Irregular and Unconventional JointsDoby YuniardiNo ratings yet

- Ucrete Ud200 AseanDocument2 pagesUcrete Ud200 AseanDoby YuniardiNo ratings yet

- Mastertop 1220 AseanDocument3 pagesMastertop 1220 AseanDoby YuniardiNo ratings yet

- Intergard 774Document4 pagesIntergard 774Doby YuniardiNo ratings yet

- Fema 154 FormsDocument3 pagesFema 154 FormslesgiuNo ratings yet

- Pyroelectric Array CameraDocument7 pagesPyroelectric Array Cameraziggie_lenzNo ratings yet

- Elevated Intz Tank 279Document23 pagesElevated Intz Tank 279Navasivayam Sankar100% (2)

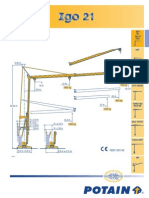

- Potain Igo 21 PDFDocument4 pagesPotain Igo 21 PDFMarco CruzNo ratings yet

- Brain Controlled Car For Disabled Using Artificial IntelligenceDocument17 pagesBrain Controlled Car For Disabled Using Artificial IntelligenceMdkhanzNo ratings yet

- Training CoursesDocument16 pagesTraining CoursesFeroz KhanNo ratings yet

- Código BoogaDocument138 pagesCódigo BoogaJazmin SeguelNo ratings yet

- Chemistry, Intermediate II Year Model Question PapersDocument3 pagesChemistry, Intermediate II Year Model Question PapersAkshay PandeyNo ratings yet

- Pravin Yesubon.Y: and Social Responsibility (PSSR) and Personal Survival Techniques (PST)Document2 pagesPravin Yesubon.Y: and Social Responsibility (PSSR) and Personal Survival Techniques (PST)shaNo ratings yet

- Concrete Mix Design 10Document1 pageConcrete Mix Design 10Rexter UnabiaNo ratings yet

- American University of Beirut Aub Thesis TemplateDocument12 pagesAmerican University of Beirut Aub Thesis TemplateHassane EzzeddineNo ratings yet

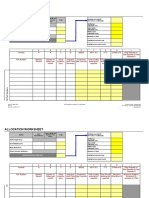

- Supplier Run Rate CalculatorDocument9 pagesSupplier Run Rate CalculatordcevipinNo ratings yet

- Roland Sands Design US CatalogDocument56 pagesRoland Sands Design US Catalogsema2210No ratings yet

- Raman Spectroscopy SetupDocument13 pagesRaman Spectroscopy SetupRafael RamosNo ratings yet

- Amadeus Web ServicesDocument2 pagesAmadeus Web ServicesBoris ChoiNo ratings yet

- Water and Environmental Sanitation Strategic Plan BihacDocument53 pagesWater and Environmental Sanitation Strategic Plan BihacEddiemtongaNo ratings yet

- Vector VII 104-561kVA User Manual 6.6.1Document165 pagesVector VII 104-561kVA User Manual 6.6.1juliocanel2009100% (3)

- ReportDocument13 pagesReportMamta SindhuNo ratings yet

- SAES-A-102 Ambient Air Quality and Source Emissions StandardsDocument21 pagesSAES-A-102 Ambient Air Quality and Source Emissions StandardsFlorante NoblezaNo ratings yet

- 115 Test Out Study GuideFeb2017Document16 pages115 Test Out Study GuideFeb2017Ashish MalikNo ratings yet

- AIP Puducherry Aerodrome, IndiaDocument13 pagesAIP Puducherry Aerodrome, Indiass khadriNo ratings yet

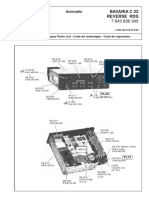

- Bavaria Reverse RdsDocument15 pagesBavaria Reverse RdsDušan JovanovićNo ratings yet

- FMS 2009 Question Paper and Answer KeyDocument6 pagesFMS 2009 Question Paper and Answer KeyHarish PotterNo ratings yet

- Catapult Ref ManDocument372 pagesCatapult Ref ManBiplab RoyNo ratings yet

- PCMX Data Eng 01Document13 pagesPCMX Data Eng 01spamNo ratings yet

- Curriculam Vitae: ObjectiveDocument4 pagesCurriculam Vitae: ObjectiveSachin DeoNo ratings yet

- ASTM Data and ControlDocument141 pagesASTM Data and ControlYohanes Ronny100% (1)

- DW-143 - Leakage Factor As Per Calculation FormulaDocument2 pagesDW-143 - Leakage Factor As Per Calculation Formulasandeep7426No ratings yet

- Oracle E-Business Suite Release 11 Discoverer & XML PublisherDocument32 pagesOracle E-Business Suite Release 11 Discoverer & XML PublisherVijay KishanNo ratings yet