Professional Documents

Culture Documents

BIS0148 - C2L9P2 - Spec Sheet - Wear 450 Steel - Web

Uploaded by

idontlikeebooksOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BIS0148 - C2L9P2 - Spec Sheet - Wear 450 Steel - Web

Uploaded by

idontlikeebooksCopyright:

Available Formats

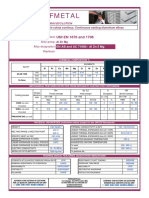

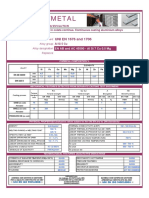

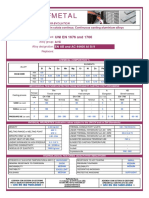

TECHNICALBULLETIN 01

COMPARISON SUMMARY BETWEEN

BISALLOY® WEAR 450 STEEL AND IMPORTED PLATES

CHARACTERISTIC BISALLOY® WEAR 450 STEEL HARDOX 450* QUARD 450+

HARDNESS 425 - 475 425 - 475 420 - 480

Brinell Through hardened to 50mm

IMPACT PROPERTIES Sample Size Energy Sample Size Energy Sample Size Energy

Charpy Impact (Longitudinal)

-40˚C (10mm x 10mm) 10x10mm 35 J 10x10mm 50 J 10x10mm 35 J

STEEL TYPE Low Alloy, Heat Treated Low Alloy, Heat Treated Low Alloy, Heat Treated

Plate Thickness

CHEMICAL COMPOSITION (mm) Typical Avg Typical Avg Typical Avg

Carbon Equivalent CE (IIW) 6 - 20 0.46 0.49 - 0.52 -

CE= C+Mn+Cr+Mo+V+Cu+Ni 25 - 50 0.58 0.60 0.56

6 5 15 >50 - 100 0.62 0.74 0.64

Carbon Equivalent CET 6 - 20 0.30 0.38 - 0.39 -

CET= C+Mn+Mo+Cr+Cu+Ni 25 - 50 0.36 0.41 0.37

10 20 40 >50 - 100 0.40 0.43 0.40

Grain Refined, Low Sulphur Grain Refined, Low Sulphur Desulphurisation in a ladle

STEEL MAKING PROCESS Vacuum Degassed Vacuum Degassed furnace, fine grain treated

WELDING CONSUMABLES Low Hydrogen Low Hydrogen Low Hydrogen

Pre-Heat Joint Combined Nil Nil Room Temperature

Thickness ≤40

>40mm ≤60mm 100°C 100°C 100°C

>60mm ≤100mm 125°C 125°C -

Maximium Interpass Temps 150 - 175°C 150 - 175°C 225°C

Maximium Heat Input 2.0 - 2.5 kJ/mm 2.0 - 2.5 kJ/mm 1.0 - 1.75 kJ/mm

CUTTING

Oxy Methods OK OK OK

Plasma OK OK OK

Laser OK OK OK

Water Jet OK OK OK

BENDING 6 - 50mm Thickness 6 - 50mm Thickness 8 - 20mm Thickness

Minimium R/T 4.0 4.0 4.0

Transverse Bend

Longitudinal Bend 5.0 5.0 5.0

Minimium Die Opening W/t 10.0 10.0 12.0

Transverse Bend

Longitudinal Bend 12.0 12.0 14.0

DRILLING

Cobalt Type HSS OK OK OK

Solid Carbide Type OK OK OK

Replaceable Carbide OK OK OK

Countersinking & Counterboring OK OK OK

MACHINING

Milling OK OK OK

Turning OK OK OK

*Data for Hardox 450 is taken from the SSAB website. +Data without investigation and verification as to its accuracy,

for QUARD 450 is taken from the Quard website. Please refer suitability and applicability by a competent professional person

to full specifications and fabrication data in BISALLOY® Wear in this regard.

steel product brochure. Bisalloy cannot accept any responsibility for any loss, damage

or consequence resulting from the use of this publication.

Disclaimer: Whilst every effort has been made and all

Images included in this publication are for illustrative

reasonable care taken to ensure the accuracy of the

02 4272 0444 information contained in this publication, this information

purposes only. Images are indicative only of the type of

applications which may use a Bisalloy product.

www.bisalloy.com.au should not be used or relied upon for any specific application

BIS0148 - TB01 - BISALLOY® WEAR 450 STEEL - OCTOBER 2016

BISALLOY is a registered trade mark of Bisalloy Steels Group Limited, ABN 22 098 674 545

You might also like

- Crane Rail Welding 978Document3 pagesCrane Rail Welding 978Jurie_sk3608No ratings yet

- American Fastener - ASTM, SAE, and ISO Grade Markings PDFDocument6 pagesAmerican Fastener - ASTM, SAE, and ISO Grade Markings PDFnate anantathatNo ratings yet

- Epoxy Floor Coating MethodologyDocument6 pagesEpoxy Floor Coating MethodologyYbanez Marc80% (5)

- 2017-91 Heat Treatment of SteelDocument74 pages2017-91 Heat Treatment of SteelJen Megah Bremanda SembiringNo ratings yet

- Offset ProblemiDocument34 pagesOffset ProblemiMica IvanovicNo ratings yet

- SAE Ferrous Materials Standards Manual - 2004Document3 pagesSAE Ferrous Materials Standards Manual - 2004Xin Yu50% (2)

- OECD Future of Education and Skills 2030Document12 pagesOECD Future of Education and Skills 2030I Gusti Nyoman Anton Surya DiputraNo ratings yet

- Principles of Heat TreatmentDocument17 pagesPrinciples of Heat TreatmentManoranjan Nayak100% (2)

- Gold Medallion Assessors Guide v1.2 2023Document9 pagesGold Medallion Assessors Guide v1.2 2023idontlikeebooksNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Raj RajeshNo ratings yet

- Zinc AG40A (Zinc Alloy 3 Zn-4Al-0.4Mg Zamak 3), Cast - SAE 903Document2 pagesZinc AG40A (Zinc Alloy 3 Zn-4Al-0.4Mg Zamak 3), Cast - SAE 903Hari Tej AvvaruNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706satheeskumar VikramasingarajNo ratings yet

- Casting Material WCBDocument9 pagesCasting Material WCBHazim HazimNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Hareth MRAIDINo ratings yet

- Brand, Source, Tests Etc. Units RequirementDocument1 pageBrand, Source, Tests Etc. Units RequirementNandika MilindaNo ratings yet

- EN71000 From ReinferdenDocument2 pagesEN71000 From ReinferdenJason WuNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Amandeep SinghNo ratings yet

- Copper Alloy C14200 PDFDocument9 pagesCopper Alloy C14200 PDFNut AssanaiNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Sachin JawaleNo ratings yet

- ASTM A453 Grade 660 Stud - Bolt.nut - WasherDocument1 pageASTM A453 Grade 660 Stud - Bolt.nut - WasherTdk DallasNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Martin DuarteNo ratings yet

- EN47100Document2 pagesEN47100tsonjayaNo ratings yet

- Material Chemical Composition - Cast Analysis: Brand, Source, Tests Etc. Units RequirementDocument3 pagesMaterial Chemical Composition - Cast Analysis: Brand, Source, Tests Etc. Units RequirementNandika MilindaNo ratings yet

- Componemtes e Aleaccion ExactobondDocument1 pageComponemtes e Aleaccion ExactobondNatanael F'dezNo ratings yet

- A.S.T.M. B584-09a: WWW - Okendo.mxDocument4 pagesA.S.T.M. B584-09a: WWW - Okendo.mxShariq KhanNo ratings yet

- Material Chemical Composition - Cast Analysis: Brand, Source, Tests Etc. Units RequirementDocument4 pagesMaterial Chemical Composition - Cast Analysis: Brand, Source, Tests Etc. Units RequirementNandika MilindaNo ratings yet

- SilcoTek Coatings For High Purity ApplicationsDocument30 pagesSilcoTek Coatings For High Purity ApplicationsKommu RohithNo ratings yet

- NIC Component Series NTIDocument4 pagesNIC Component Series NTINICCompNo ratings yet

- Astm A325Document1 pageAstm A325Alberto CárdenasNo ratings yet

- Cu ZN 15 TombacDocument2 pagesCu ZN 15 TombacPetrus UngureanuNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document1 pageRaffmetal: UNI EN 1676 and 1706swaroop NalamNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Raj RajeshNo ratings yet

- ASTM A540 Grade B24 Tensile ClassDocument8 pagesASTM A540 Grade B24 Tensile ClassJhenny HerediaNo ratings yet

- Tiginox 385: Classification: en Iso 14343-ADocument1 pageTiginox 385: Classification: en Iso 14343-AJagannath SahuNo ratings yet

- Cuzn37-Pna 243 enDocument2 pagesCuzn37-Pna 243 enAbrahan Tinco PariNo ratings yet

- Alloy 276 Spec SheetDocument3 pagesAlloy 276 Spec SheetJAYA BHARATHA REDDYNo ratings yet

- Forged Engineering DataDocument4 pagesForged Engineering DataretrogradesNo ratings yet

- Arsenical Admiralty Copper, Uns C44300, Oso25 Temper Tubing: Advertise With Matweb!Document2 pagesArsenical Admiralty Copper, Uns C44300, Oso25 Temper Tubing: Advertise With Matweb!David LluguinNo ratings yet

- DH 40Document1 pageDH 40saswattNo ratings yet

- House WiresDocument1 pageHouse Wiresrobinknit2009No ratings yet

- Copper Cu-Dhp / Sf-Cu: Page 1/2Document2 pagesCopper Cu-Dhp / Sf-Cu: Page 1/2gemilanglpNo ratings yet

- Cumirex: - Ceramics Aluminium Copper Iron & SteelDocument2 pagesCumirex: - Ceramics Aluminium Copper Iron & SteeldebasisNo ratings yet

- BS en 1706 - En44100 PDFDocument2 pagesBS en 1706 - En44100 PDFDhamodaran RNo ratings yet

- NIC Components NTL SeriesDocument4 pagesNIC Components NTL SeriesNICCompNo ratings yet

- En 44100Document2 pagesEn 44100hiren_mistry55No ratings yet

- Hussey Copper Electrolytic Tough Pitch CDA Copper C 110 00Document1 pageHussey Copper Electrolytic Tough Pitch CDA Copper C 110 00Michael DoyleNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Hareth MRAIDINo ratings yet

- Plate A36 (2016)Document4 pagesPlate A36 (2016)eko kusumoNo ratings yet

- 36CrB4 Rod - Wire Rev4 PDFDocument6 pages36CrB4 Rod - Wire Rev4 PDFKarthi KeyanNo ratings yet

- Industrial Application of CVD and PVDDocument18 pagesIndustrial Application of CVD and PVDYong Jae Kwon50% (2)

- CuZn30-PNA 226 - ENDocument2 pagesCuZn30-PNA 226 - ENNHadesNo ratings yet

- Soft Magnetic Iron-Cobalt Alloy Hiperco 27: Xi'An Gangyan Special Alloy Co.,LtdDocument10 pagesSoft Magnetic Iron-Cobalt Alloy Hiperco 27: Xi'An Gangyan Special Alloy Co.,LtdMohammadehsan SalarpourNo ratings yet

- AISI 1040 Carbon Steel (UNS G10400)Document4 pagesAISI 1040 Carbon Steel (UNS G10400)عابد زاهدNo ratings yet

- AISI 4130: Category Type Steel GradeDocument2 pagesAISI 4130: Category Type Steel Gradetjt4779No ratings yet

- Alloyed: Case-Hardening Steels Rn3 - Rn3PbDocument2 pagesAlloyed: Case-Hardening Steels Rn3 - Rn3PbSaba AhmedNo ratings yet

- Copper-Nickel Cu-Ni 90/10 Alloy (UNS C70600) : Heanjia Super-Metals Co., LTD, Call-12068907337. WebDocument7 pagesCopper-Nickel Cu-Ni 90/10 Alloy (UNS C70600) : Heanjia Super-Metals Co., LTD, Call-12068907337. Webboydoc inspectionNo ratings yet

- 94B15, 94B15HDocument2 pages94B15, 94B15HGil CabreraNo ratings yet

- Material Characteristics PDFDocument4 pagesMaterial Characteristics PDFELTIPAZONo ratings yet

- Tenalloy 125: LOW ALLOY STEEL (High Strength)Document1 pageTenalloy 125: LOW ALLOY STEEL (High Strength)satnamNo ratings yet

- Fora 400Document4 pagesFora 400PeterWayNo ratings yet

- Uk 506 - Fita GuiaDocument5 pagesUk 506 - Fita GuiaAlessandro OliveiraNo ratings yet

- Physical Properties Metric English: @strain 2.00 % @strain 2.00 %Document1 pagePhysical Properties Metric English: @strain 2.00 % @strain 2.00 %Rahul SanjayanNo ratings yet

- Oaisdokas 123123Document5 pagesOaisdokas 123123Justine Lloyd BautistaNo ratings yet

- FJ Product Data Hydraulic Wiper Seal Beca 485 037253700 1631 08122015Document5 pagesFJ Product Data Hydraulic Wiper Seal Beca 485 037253700 1631 08122015Phan Đức NgọcNo ratings yet

- Metal Composition PDFDocument3 pagesMetal Composition PDFVijendra Singh JhalaNo ratings yet

- AISI Type W2 Tool Steel, Water Quenched at 775°C (1425°F), and TemperedDocument2 pagesAISI Type W2 Tool Steel, Water Quenched at 775°C (1425°F), and TemperedidontlikeebooksNo ratings yet

- SMPC Delivery and Assessment Guide v1 June 2022Document37 pagesSMPC Delivery and Assessment Guide v1 June 2022idontlikeebooksNo ratings yet

- Psar35 m5 Rescue V December 2022Document37 pagesPsar35 m5 Rescue V December 2022idontlikeebooksNo ratings yet

- Bronze Medallion (BM) Theory Questions (Assessment Task 1)Document23 pagesBronze Medallion (BM) Theory Questions (Assessment Task 1)idontlikeebooksNo ratings yet

- Water Safety Risk Assessment Guide v1.0Document4 pagesWater Safety Risk Assessment Guide v1.0idontlikeebooksNo ratings yet

- 2023 State Age Championships Final Event Information 1Document10 pages2023 State Age Championships Final Event Information 1idontlikeebooksNo ratings yet

- AISI Type W2 Tool Steel, Water Quenched at 775°C (1425°F), and TemperedDocument2 pagesAISI Type W2 Tool Steel, Water Quenched at 775°C (1425°F), and TemperedidontlikeebooksNo ratings yet

- AISI Type W2 Tool Steel, Water Quenched at 775°C (1425°F), and TemperedDocument2 pagesAISI Type W2 Tool Steel, Water Quenched at 775°C (1425°F), and TemperedidontlikeebooksNo ratings yet

- NL48Document1 pageNL48idontlikeebooksNo ratings yet

- STT Vertimill Retrofit 03282022Document2 pagesSTT Vertimill Retrofit 03282022idontlikeebooksNo ratings yet

- WEG Indústrias S.A.: Performance Curves Related To SpeedDocument1 pageWEG Indústrias S.A.: Performance Curves Related To SpeedidontlikeebooksNo ratings yet

- AISI Type W2 Tool Steel, Water Quenched at 775°C (1425°F), and TemperedDocument2 pagesAISI Type W2 Tool Steel, Water Quenched at 775°C (1425°F), and TemperedidontlikeebooksNo ratings yet

- Lime Slaking 101 Whitepaper 4-06-22Document8 pagesLime Slaking 101 Whitepaper 4-06-22idontlikeebooksNo ratings yet

- WEG Indústrias S.A.: Performance Curves Related To SpeedDocument1 pageWEG Indústrias S.A.: Performance Curves Related To SpeedidontlikeebooksNo ratings yet

- CA6 ContactorsDocument36 pagesCA6 ContactorsAbhishek mishraNo ratings yet

- Memo 2023 Age Championships Water Safety RosterDocument3 pagesMemo 2023 Age Championships Water Safety RosteridontlikeebooksNo ratings yet

- WEG Indústrias S.A.: Performance Curves Related To SpeedDocument1 pageWEG Indústrias S.A.: Performance Curves Related To SpeedidontlikeebooksNo ratings yet

- WEG Indústrias S.A.: Performance Curves Related To SpeedDocument1 pageWEG Indústrias S.A.: Performance Curves Related To SpeedidontlikeebooksNo ratings yet

- WEG Indústrias S.A.: Performance Curves Related To SpeedDocument1 pageWEG Indústrias S.A.: Performance Curves Related To SpeedidontlikeebooksNo ratings yet

- WEG Indústrias S.A.: Performance Curves Related To SpeedDocument1 pageWEG Indústrias S.A.: Performance Curves Related To SpeedidontlikeebooksNo ratings yet

- WEG Indústrias S.A.: Performance Curves Related To SpeedDocument1 pageWEG Indústrias S.A.: Performance Curves Related To SpeedidontlikeebooksNo ratings yet

- WEG Indústrias S.A.: Performance Curves Related To SpeedDocument1 pageWEG Indústrias S.A.: Performance Curves Related To SpeedidontlikeebooksNo ratings yet

- TeSys Giga Contactors - LC1G225KUENDocument5 pagesTeSys Giga Contactors - LC1G225KUENidontlikeebooksNo ratings yet

- WEG Indústrias S.A.: Performance Curves Related To SpeedDocument1 pageWEG Indústrias S.A.: Performance Curves Related To SpeedidontlikeebooksNo ratings yet

- WEG Indústrias S.A.: Performance Curves Related To SpeedDocument1 pageWEG Indústrias S.A.: Performance Curves Related To SpeedidontlikeebooksNo ratings yet

- WEG Indústrias S.A.: Performance Curves Related To SpeedDocument1 pageWEG Indústrias S.A.: Performance Curves Related To SpeedidontlikeebooksNo ratings yet

- WEG Ieee 841 2001 Nema Premium Efficiency Motors With Inproseal Usa841 Brochure EnglishDocument8 pagesWEG Ieee 841 2001 Nema Premium Efficiency Motors With Inproseal Usa841 Brochure EnglishidontlikeebooksNo ratings yet

- WEG Indústrias S.A.: Performance Curves Related To SpeedDocument1 pageWEG Indústrias S.A.: Performance Curves Related To SpeedidontlikeebooksNo ratings yet

- WEG Indústrias S.A.: Performance Curves Related To SpeedDocument1 pageWEG Indústrias S.A.: Performance Curves Related To SpeedidontlikeebooksNo ratings yet

- Proper Brazing ProcedureDocument8 pagesProper Brazing ProcedureQuek Keng LengNo ratings yet

- Material 1.2738 - 40CrMnNiMo8-6-4Document1 pageMaterial 1.2738 - 40CrMnNiMo8-6-4johnnydoe90100% (1)

- BoringDocument15 pagesBoringSreehari VpNo ratings yet

- Datasheet For Steel Grades Carbon Steel AFNOR XC 48Document2 pagesDatasheet For Steel Grades Carbon Steel AFNOR XC 48Arpad SzeriNo ratings yet

- Taimanin V0.9Document40 pagesTaimanin V0.9Doutor RodinhasNo ratings yet

- Nichita Gabriela Georgeta 1Document5 pagesNichita Gabriela Georgeta 1pill strigNo ratings yet

- CycloneDocument4 pagesCyclonedante224No ratings yet

- Bridgman-Stockbarger TechniqueDocument2 pagesBridgman-Stockbarger TechniqueSuraj SutarNo ratings yet

- Heat TreatmentDocument9 pagesHeat TreatmentsvsddsdsNo ratings yet

- Foundry LabDocument4 pagesFoundry LabChidiebere JohnNo ratings yet

- European Steel and Alloy Grades: HDT560F (1.0959)Document2 pagesEuropean Steel and Alloy Grades: HDT560F (1.0959)farshid KarpasandNo ratings yet

- Climatronic Self DiagnosticsDocument12 pagesClimatronic Self DiagnosticsAnonymous jcvsaT9No ratings yet

- Phoscopper 0 (BCuP-2) TDSDocument2 pagesPhoscopper 0 (BCuP-2) TDS顏煥杰No ratings yet

- Use of Rapid Prototyping For Rapid Tooling - PPTDocument17 pagesUse of Rapid Prototyping For Rapid Tooling - PPTSudhanwa KulkarniNo ratings yet

- On Gating SystemDocument19 pagesOn Gating SystemMurali Krishnan SelvarajaNo ratings yet

- Unit 4:-Heat Treatment of MetalsDocument52 pagesUnit 4:-Heat Treatment of MetalsRushikesh KaleNo ratings yet

- LKPD Procedure Text X TJKTDocument7 pagesLKPD Procedure Text X TJKTChaozi SoulNo ratings yet

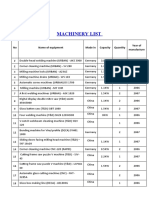

- Machinery List-1Document2 pagesMachinery List-1Hồng HạnhNo ratings yet

- DFMA Rules For WeldingDocument17 pagesDFMA Rules For WeldingArunNo ratings yet

- YBS Grades For Difficult-To-Cut MaterialsDocument4 pagesYBS Grades For Difficult-To-Cut MaterialsGastonBalcarcelNo ratings yet

- METS Mineral Processing Course PresentationDocument17 pagesMETS Mineral Processing Course PresentationAdham ElbrawyNo ratings yet

- 47-DeVEREAUX - Superfinish & Grinding - ASETS Defense '11Document22 pages47-DeVEREAUX - Superfinish & Grinding - ASETS Defense '11dimitrisNo ratings yet

- Abrasives Selection Guide: Choose From Our Extensive Range of Discs, Wheels, Burrs and Sanding ProductsDocument27 pagesAbrasives Selection Guide: Choose From Our Extensive Range of Discs, Wheels, Burrs and Sanding Productsagniva dattaNo ratings yet