Professional Documents

Culture Documents

04 - HDPE Pipe Laying - REV 000

Uploaded by

Venkadesh PeriathambiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

04 - HDPE Pipe Laying - REV 000

Uploaded by

Venkadesh PeriathambiCopyright:

Available Formats

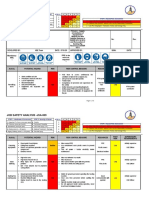

DATE:

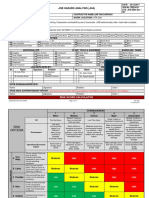

JOB HAZARD ANALYSIS (JHA)

JHA No:

EPCM: BPJV CONTRACTOR NAME:SAIF BIN DARWISH

PROJECT: Al TAWEELAH WORK LOCATION: Al Taweelah Refinery site

JOB DESCRIPTION:

Use of mobile Crane or HIAB crane for loading and unloading of HDPE pipes at site/ storage yard and laying inside the excavation

EMERGECY PLAN (include First Response):

Make the area safe , Inform EGA emergency response team (02-5092111) , Follow site emergency protocol

PERMITS

Confined Space Excavation Floor/Wall opening Hot Work HV Access Isolation (LOTO) Lift Study NDT Workbox Working at heights

PLANNED HIGH RISK CONSTRUCTIONACTIVITIES

Confined Space Entry Excavation <1.2m Isolation (LOTO) Road Work Work at Heights

Crane Activities Flammable / Contaminated atmosphere Mobile Plant Movement Tilt Up / Precast Installation NDT

Energised Electrical Work Gas / Chemical Fuel Line Work Pressure testing Vertical Rebar Other:

ADDITIONAL PPE PLANT, TOOLS & EQUIPMENT BARRICADE / SIGNS

Goggles Sun Screen Compactor Hand Tools Excavator Barrier Mesh

Face Shield Welding Jacket Drill Ladder Backhoe Yellow & Black Chain

Hearing Protection Welding Helmet Extension Leads Scaffold Crane Concrete Barriers

Safety Harness Other- Fans Power Source EWP / Scissor Lift Hard Barricade

Respirator Other - Fire Extinguisher Welding Machine Shade Red & White

Other - Other - Other – Telehandler , Other -

Hand Protection Grinder

flatbed trailer

JHA DEVELOPED BY: JHAAPPROVAL:

No Name Signature Position Date No Name Signature Position Date

1 1

2 2

3 3

4 4

5 5

EPCM ESHMANAGERREVIEW:

Name: Signature: Position: Date //

EPCM AREA SUPERINTENDENT REVIEW:(work shall not proceed until the JHA is signed &dated by the EPCMESH and Area Superintendent other designees)

25875-000-GFX-GHX-00040 Page 1 of 6 Rev 000

14 June 2014

Name: Signature: Position: Date://

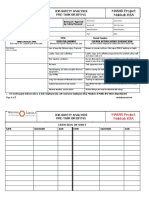

RISK SCORE CALCULATOR

CONSEQUENCES

1 2 3 4 5

Minor Medium Serious Major Catastrophic

Medical Treatment Multiple Fatalities or

Single Fatality or

`1C1 First Aid Injury Injury or restricted Lost Time Injury Multiple Permanent

Permanent Impairment

work day case Impairment

Low level

Major environmental Catastrophic

environmental Minor effects on Moderate short-term

RISK impact, biological or physical environmental impact,

event, e.g. pollution - environmental event,

impact that is e.g. pollution – impact

CRITERIA e.g.pollution– environment, e.g. e.g. pollution – near

unconfined &requiring that is widespread,

Environment Near source pollution – near source source confined &

long term recovery, unconfined &requiring

confined & confined &short-term medium term recovery

leaving residual long term recovery,

promptly reversible impact. impact.

damage. leaving major residual

reversible impact.

damage.

Minor damage to Major damage; loss of Serious problems with

Easily fixed up Loss of less than one

Operational/Economic equipment; no loss of less than six months future operation of the

straight away weeks production

Impact production production facility

<$10k $100k - $1M

$10k - $100k $1M - $10M >$10M

Occurs several times per

year at similar

Very projects/reasonably

A Moderate High High High High

likely expected to occur under

normal operating

conditions

Has occurred several

LIKELIHOOD

times / likely to occur at

B Likely some time under normal

Moderate Moderate High High High

operating conditions

Has occurred/may occur

C Possible under normal operating Low Moderate Moderate High High

conditions

Known to have occurred

in the construction

D Rare industry/unlikely to occur Low Low Moderate Moderate High

under normal operating

conditions

25875-000-GFX-GHX-00040 Page 2 of 6 Rev 000

14 June 2014

Unheard of/not known to

E Unlikely have occurred

Low Low Low Moderate Moderate

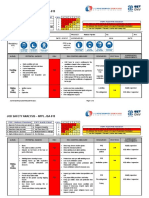

Inherent Control Methods & Monitoring Residual

Step Hazard Risk Risk Action By

What control measures will be used?

Describe the job step by step What are the hazards of each step?

Score How will the effectiveness of the controls be determined? Score

All traffic shall be kept to designated roads.

Load should be secured with guard rails and cargo

belts

Escort should be in place to guide the vehicle

Vehicle routes planned to avoid danger to pedestrians

and clear of excavations.

Roads shall be wetted to suppress dust, as required.

Collision/Impact Vehicles will be subject to a planned maintenance Supervisor

programme. Operator

Transporting of HDPE pipes to site/storage

Overturning High All heavy equipment must be fitted with reverse Moderate Manual

area by flatbed trailers

audible alarm. workers

Persons struck by trailers The maximum allowable speed limit is 30km/hr.,

unless otherwise advised.

Continues supervision and monitoring the equipment

operation.

Unloading checklist should be followed for all

delivery vehicles

25875-000-GFX-GHX-00040 Page 3 of 6 Rev 000

14 June 2014

BPJV approved Traffic controller shall be in place to

control the equipment movement

Telehandler/ JCB backhoe operational area should be

barricaded with level 2 barricades

Competent and BPJV authorized banks man in place

to guide the telehandler / JCB backhoe at the time

dumping bedding materials inside the excavation

Collision/Impact No personal allowed to stand inside the excavation

Supervisor

Competent supervision in place

Operator

Placing of Pipe bedding materials (Soft sand) Overturning Safe distance should be maintain at the time dumping

High Moderate Manual

inside the excavation by Telehandler / JCB, etc. materials by telehandler / JCB backhoe

workers

Persons struck by material / Bedding materials shall be loader <70 percentage

telehandler from the telehandler/ JCB backhoe bucket to avoid

falling materials from bucket

At the time dumping bedding material telehandler

jacks must be placed in level base

Proper communication in place between operator and

banks man

The SWL must be indicated on telehandler / JCB

backhoe bucket and never exceeded

All lifting operations must be under control of an

‘appointed person’ who will be competent to take

overall responsibility and possess a method statement

for the work activities.

An assessment of the ground conditions must be

carried out by a competent person.

Crane must have firm level base with load bearing

checks made on ground to support weight of crane and

Collision/Collapse

load, shock loading, wind stress and slewing torques. Lifting

Lifting zone should be identified and cordoned off to Supervisor

Overturning of Mobile Crane/ Hiab prevent lifting over people. Crane

crane Crane out riggers must be placed away from the operator

Unloading and Laying of HDPE pipes High

excavation solid barriers Moderate

wrong slinging, Serious injuries, Rigger

Possible fatality ASLI’s, radius load indicators and motion limit Manual

switches must be fitted and operational by audio- workers

visual methods. The SWL must be indicated on crane

and never exceeded.

Oversized loads must be tagline to be guided safely.

A Plan must be produced that considers weight of

load, radius of lift, overhead clearance, ground

conditions, positioning of crane, and lifting equipment

required.

lifting zones must be barricaded with red and white

chain

25875-000-GFX-GHX-00040 Page 4 of 6 Rev 000

14 June 2014

Operation of mobile cranes must be carried out by a

competent and BPJV authorized person

Competent and BPJV authorized rigger only allowed

the perform the slinging and rigging

Competent and BPJV authorized lifting supervisor in

place

Load must be correctly slung and secured.

Loosed materials must be carried in boxes/containers.

All lifting equipment must be maintained to

manufactures instructions, generally weekly

inspections by operative required. After 12 months a

thorough examination (T.E.) or For lifting accessories

(chains, slings) must have a thorough examination

after 6 months and weekly inspection. Each rope must

identify SWL

Lifting equipment and lifting gears must inspected

and colour coded as per RBGY

25875-000-GFX-GHX-00040 Page 5 of 6 Rev 000

14 June 2014

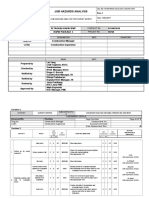

NOTE: If the conditions or controls used to conduct the job changes work group members are together use the re-

STARRT process (for one off changes) or amend and re-sign onto the JHA (for permanent changes).

NOTE: Any significant change requires Contractor & EPCM Management authorisation prior to continuing the job.

PRINCIPAL CONTRACTOR: BPJV CONTRACTOR NAME:SBD

PROJECT: Project Shaheen SUPERVISOR NAME:

JOB DESCRIPTION:

JHA SIGN OFF REGISTER

I have read and understood this JHA …

No. First Name Surname Employer Signature Date

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

25875-000-GFX-GHX-00040 Page 6 of 6Rev 000 14 June 2014

You might also like

- 001 - JHA Survey Setting Out - REV000Document5 pages001 - JHA Survey Setting Out - REV000Venkadesh Periathambi100% (2)

- Risk Assessment - Construction of Manholes at Landscape Node P1Document4 pagesRisk Assessment - Construction of Manholes at Landscape Node P1逍逾No ratings yet

- Job Hazard Analysis (Jha) : Contractor: Date: Doc. No. & Rev. No.: 00Document6 pagesJob Hazard Analysis (Jha) : Contractor: Date: Doc. No. & Rev. No.: 00poovazhaganNo ratings yet

- Copy (4) of JSA For HDPE Liner Fusion Welding Includes Night WorksDocument7 pagesCopy (4) of JSA For HDPE Liner Fusion Welding Includes Night WorksMohammed Minhaj75% (4)

- Project No. 074-10 JHA No. 1Document20 pagesProject No. 074-10 JHA No. 1Adel SukerNo ratings yet

- Risk Assessment For Installation of Toilet Exhaust FanDocument10 pagesRisk Assessment For Installation of Toilet Exhaust FanMaria Carmela Rachel GazilNo ratings yet

- RETAIL PERMIT WORK HAZARDDocument7 pagesRETAIL PERMIT WORK HAZARDSanthosh Kumar100% (1)

- Risk Assessment - Drain Pipe Connection at MLSDocument8 pagesRisk Assessment - Drain Pipe Connection at MLS逍逾No ratings yet

- DR - Rescue Plan Water Tank Cleaning (002) Rev-With LayoutDocument4 pagesDR - Rescue Plan Water Tank Cleaning (002) Rev-With LayoutSachin DharneNo ratings yet

- Pre-Job Safety Assessment ChecklistDocument2 pagesPre-Job Safety Assessment Checklistgueettaf faresNo ratings yet

- JSA-009 Sand Blasting - Coating 2Document6 pagesJSA-009 Sand Blasting - Coating 2Omar DhiebNo ratings yet

- JHA For Steam PipingDocument17 pagesJHA For Steam PipingM8Rskn6wcNo ratings yet

- Job Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Document3 pagesJob Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Sreeraj Reghunathan Nair Vanmazhy100% (1)

- JsaDocument39 pagesJsajithin shankar100% (3)

- JSA Mechanical Activity Risk AssessmentDocument1 pageJSA Mechanical Activity Risk Assessmentjithin shankarNo ratings yet

- Revised JHA HDDDocument12 pagesRevised JHA HDDHariharan RajaramanNo ratings yet

- JSA-049 Valves & Support Installation and DismantlingDocument4 pagesJSA-049 Valves & Support Installation and DismantlingMoaatazz Nouisri100% (3)

- Risk Assessment Rib Erection & FabricationDocument2 pagesRisk Assessment Rib Erection & FabricationAkash SharmaNo ratings yet

- Loading and Unloading Pile Pipes SafelyDocument4 pagesLoading and Unloading Pile Pipes SafelyOsiobe Ewomazino100% (1)

- WMSRA For Loading Unloading of Office Containers and Installation of Office Containers - FinalDocument17 pagesWMSRA For Loading Unloading of Office Containers and Installation of Office Containers - FinalAnandu Ashokan50% (2)

- 8 B Pick and Carry Hydra Crane Daily ChecklistDocument1 page8 B Pick and Carry Hydra Crane Daily Checklistjohn raj100% (1)

- 008 JSA - Manual BoringDocument3 pages008 JSA - Manual BoringMohammed MinhajNo ratings yet

- Diesel RefuelingDocument3 pagesDiesel RefuelingAMINNo ratings yet

- Risk Asses 65-Piping Fabricated and Assembly - H03Document11 pagesRisk Asses 65-Piping Fabricated and Assembly - H03Rochdi BahiriNo ratings yet

- Trial Pit During ExcavationDocument3 pagesTrial Pit During Excavationmujahid1137No ratings yet

- Job Safety Analysis - Clinker StorageDocument4 pagesJob Safety Analysis - Clinker StorageMohammed MinhajNo ratings yet

- PVCMS-BMV-HSE-JSA-001 InsulationDocument6 pagesPVCMS-BMV-HSE-JSA-001 InsulationBkdn DungNo ratings yet

- Ehs Risk AssessmentDocument2 pagesEhs Risk AssessmentRohit Singh100% (1)

- Hydro Testing On Piping System Utility and Plant Piping Jsa 2012Document4 pagesHydro Testing On Piping System Utility and Plant Piping Jsa 2012AldrinNo ratings yet

- INSTALLATION SAFETY ANALYSISDocument22 pagesINSTALLATION SAFETY ANALYSISSyed Yousuf Ali100% (1)

- Mobilization of CabinDocument1 pageMobilization of CabinRashidi RahmanNo ratings yet

- Incident Accident RegisterDocument2 pagesIncident Accident RegisterMuruganNo ratings yet

- Risk Assisment For Fence WorkDocument2 pagesRisk Assisment For Fence Workashishakare100% (1)

- Job Safety Analysis Pre-Task Briefing: MASAR Project Makkah KSADocument2 pagesJob Safety Analysis Pre-Task Briefing: MASAR Project Makkah KSAmahammed saleem100% (2)

- JHA - Survey WorksDocument3 pagesJHA - Survey WorksNazirul Syazwan100% (3)

- Jha For CCB CommissioningDocument6 pagesJha For CCB CommissioningChinedu AchilikeNo ratings yet

- Job Safety Analysis: Trench Preparation & Thrust Boring Activity Required References Jsa ReviewDocument4 pagesJob Safety Analysis: Trench Preparation & Thrust Boring Activity Required References Jsa ReviewMoaatazz Nouisri100% (1)

- BargeDocument4 pagesBargeanon_222140886No ratings yet

- Ra For Fire Protection Piping Installation WorksDocument7 pagesRa For Fire Protection Piping Installation WorksprinceNo ratings yet

- Pipe Lowering JHADocument6 pagesPipe Lowering JHASalam AlkataluniNo ratings yet

- JSO Cable Drum (02 Sept.'07)Document2 pagesJSO Cable Drum (02 Sept.'07)Francis Enriquez TanNo ratings yet

- (Potential/existing) (Permits, Safety Precautions, Equipment, PPE, Recommended Actions)Document3 pages(Potential/existing) (Permits, Safety Precautions, Equipment, PPE, Recommended Actions)krisNo ratings yet

- Risk Assessment - 4500018082-Testing of Slab To Earth Resistance (Potrooms)Document3 pagesRisk Assessment - 4500018082-Testing of Slab To Earth Resistance (Potrooms)nsadnan0% (1)

- Chennai Metro Rail Project Safe Gas Cutting & Welding ProcedureDocument12 pagesChennai Metro Rail Project Safe Gas Cutting & Welding ProcedureRmr ReyesNo ratings yet

- Chipping Work by MCDocument1 pageChipping Work by MCChandruNo ratings yet

- Cold Cutting PDFDocument9 pagesCold Cutting PDFAshraf BottaniNo ratings yet

- Coshh Risk Assessemnt PDFDocument29 pagesCoshh Risk Assessemnt PDFerwinNo ratings yet

- Manual Handling (Building) : S W M S (SWMS) P 1Document20 pagesManual Handling (Building) : S W M S (SWMS) P 1bubele pamlaNo ratings yet

- New Pta Complex: Jsa For Reinforcing Steel BarsDocument12 pagesNew Pta Complex: Jsa For Reinforcing Steel BarsUMUTNo ratings yet

- JSA-019 Manual WeldingDocument5 pagesJSA-019 Manual WeldingMoaatazz Nouisri0% (1)

- Risk Assessment For Refurbishment of Civil Assets in Pump Station Rev 00Document12 pagesRisk Assessment For Refurbishment of Civil Assets in Pump Station Rev 00Sachwin SachuNo ratings yet

- JSA For Piping-Hydro TestDocument10 pagesJSA For Piping-Hydro TestMuthu AlaguRajNo ratings yet

- 3-REV.1 - Hot Work - Risk Assessment JHADocument16 pages3-REV.1 - Hot Work - Risk Assessment JHAnaiyar100% (1)

- Brazing (Oxygen and Acetylene)Document6 pagesBrazing (Oxygen and Acetylene)My Zain100% (1)

- 007 - Risk Ass. - CE-0994-MEP WorksDocument9 pages007 - Risk Ass. - CE-0994-MEP Worksnsadnan50% (2)

- Machine excavation hazard analysisDocument7 pagesMachine excavation hazard analysisVenkadesh Periathambi100% (1)

- Soft Landscaping ROW Area Risk AssessmentDocument11 pagesSoft Landscaping ROW Area Risk AssessmentSIBIN100% (2)

- Risk Assessment High Strain Dynamic Testing of PilesDocument4 pagesRisk Assessment High Strain Dynamic Testing of PilesYaba88% (8)

- JHEA Loading and Offloading FENCEDocument13 pagesJHEA Loading and Offloading FENCEStansilous Tatenda NyagomoNo ratings yet

- Phase 3 Hardscape RA R0Document14 pagesPhase 3 Hardscape RA R0SIBIN100% (1)

- Adhesive-Bonded Joints Method Statement (TB-TS) : Field Services DepartmentDocument25 pagesAdhesive-Bonded Joints Method Statement (TB-TS) : Field Services DepartmentVenkadesh PeriathambiNo ratings yet

- Site Office BOQDocument4 pagesSite Office BOQVenkadesh PeriathambiNo ratings yet

- Rescue Plan Working at HeightDocument11 pagesRescue Plan Working at HeightHernandito Rahmat Kusuma100% (1)

- Civil Demolition Work East of PL3 Rev01Document30 pagesCivil Demolition Work East of PL3 Rev01Venkadesh PeriathambiNo ratings yet

- Grade:8 Date: 12/12/19 Choose The Correct Vocabulary To Complete The SentencesDocument2 pagesGrade:8 Date: 12/12/19 Choose The Correct Vocabulary To Complete The SentencesVenkadesh PeriathambiNo ratings yet

- Key Preventive Measures - COVID 19Document2 pagesKey Preventive Measures - COVID 19Venkadesh PeriathambiNo ratings yet

- JSS International School Dubai document on mole concept and stoichiometryDocument3 pagesJSS International School Dubai document on mole concept and stoichiometryVenkadesh PeriathambiNo ratings yet

- Stress Management Policy: Occupational Health and Safety StaffDocument2 pagesStress Management Policy: Occupational Health and Safety StaffVenkadesh PeriathambiNo ratings yet

- Read The Following Passages and Then Answer The Questions That FollowDocument9 pagesRead The Following Passages and Then Answer The Questions That FollowVenkadesh PeriathambiNo ratings yet

- Adverse Weather Condition HIRADocument5 pagesAdverse Weather Condition HIRAVenkadesh PeriathambiNo ratings yet

- Asset Practice QuestionsDocument6 pagesAsset Practice QuestionsVenkadesh PeriathambiNo ratings yet

- Clarification # 1Document1 pageClarification # 1Venkadesh PeriathambiNo ratings yet

- Method Statement For Laying of MCC Duct and Civil Works For MCC NetworkDocument26 pagesMethod Statement For Laying of MCC Duct and Civil Works For MCC NetworkVenkadesh PeriathambiNo ratings yet

- Web Sling DetailsDocument2 pagesWeb Sling DetailsVenkadesh PeriathambiNo ratings yet

- Portion 1A Summary Sheet BreakdownDocument46 pagesPortion 1A Summary Sheet BreakdownVenkadesh PeriathambiNo ratings yet

- 1578771297224924501Document2 pages1578771297224924501Venkadesh PeriathambiNo ratings yet

- Drug and Alcohol PolicyDocument1 pageDrug and Alcohol PolicyVenkadesh PeriathambiNo ratings yet

- Scanned by CamscannerDocument12 pagesScanned by CamscannerVenkadesh PeriathambiNo ratings yet

- Pro Forma Change Approval FormDocument1 pagePro Forma Change Approval FormVenkadesh PeriathambiNo ratings yet

- Pro Forma Change Approval FormDocument1 pagePro Forma Change Approval FormVenkadesh PeriathambiNo ratings yet

- Daily AttendanceDocument2 pagesDaily AttendanceVenkadesh PeriathambiNo ratings yet

- Summer Projects - 2020-21: Jss International School, DubaiDocument6 pagesSummer Projects - 2020-21: Jss International School, DubaiVenkadesh PeriathambiNo ratings yet

- Sri Ram Kushwaha Incident Report at 08 July 19.45Document1 pageSri Ram Kushwaha Incident Report at 08 July 19.45Venkadesh PeriathambiNo ratings yet

- Meeting Details: # Notes and Actions Arising Action Date 1. HSEDocument6 pagesMeeting Details: # Notes and Actions Arising Action Date 1. HSEVenkadesh PeriathambiNo ratings yet

- Jss International School-Dubai Second Term Portions - 2020-21Document22 pagesJss International School-Dubai Second Term Portions - 2020-21Venkadesh PeriathambiNo ratings yet

- Site Observation Report: Infrastructure & Streetscape Works - Neighborhood-6&7Document2 pagesSite Observation Report: Infrastructure & Streetscape Works - Neighborhood-6&7Venkadesh PeriathambiNo ratings yet

- Contact NumberDocument1 pageContact NumberVenkadesh PeriathambiNo ratings yet

- Greetings, Your Test Result From 02-07-2020 Is Negative. Please StaysafeDocument1 pageGreetings, Your Test Result From 02-07-2020 Is Negative. Please StaysafeVenkadesh PeriathambiNo ratings yet

- Incident Investigation Meeting MinutesDocument2 pagesIncident Investigation Meeting MinutesVenkadesh PeriathambiNo ratings yet

- Riyadh City South Phase 5 - Infrastructure and Streetscape - C 418Document2 pagesRiyadh City South Phase 5 - Infrastructure and Streetscape - C 418Venkadesh PeriathambiNo ratings yet

- Liste Des Normes API: Item Réf. Normes Domaines D'applicationDocument3 pagesListe Des Normes API: Item Réf. Normes Domaines D'applicationAbdelkader DraïNo ratings yet

- Motor - Cycle .MechanicDocument19 pagesMotor - Cycle .MechanicRaja Umar Javaid100% (1)

- WS 3Document9 pagesWS 3Eddie SantillánNo ratings yet

- Hewlett Packard 78670, 78671 Defibrillator - Service ManualDocument265 pagesHewlett Packard 78670, 78671 Defibrillator - Service ManualMarckus BrodyNo ratings yet

- MSDS - Oxidized BitumenDocument6 pagesMSDS - Oxidized BitumenbenzeneinternationalNo ratings yet

- MJF Edeqwerwe 11 FDocument21 pagesMJF Edeqwerwe 11 FVulebg VukoicNo ratings yet

- DEVA CatalogueDocument12 pagesDEVA CataloguepietroNo ratings yet

- Paraiso PDFDocument6 pagesParaiso PDFNorazmi Abdul RahmanNo ratings yet

- NES-147 Requirements Building Accuracy Const SsDocument78 pagesNES-147 Requirements Building Accuracy Const Sssalman GtrNo ratings yet

- Rise of The FSRU and Market OutlookDocument15 pagesRise of The FSRU and Market OutlookKalipada SenNo ratings yet

- Ms. Anjali Kitchen DetailDocument6 pagesMs. Anjali Kitchen DetailChetna JoshiNo ratings yet

- CATALOG Uniweld-Products TYPE17-2Document13 pagesCATALOG Uniweld-Products TYPE17-2Máy cầm tay Hoàng TrungNo ratings yet

- CIP Session I Quiz-2Document5 pagesCIP Session I Quiz-2sahadik bahadurNo ratings yet

- Basic FormulaeDocument4 pagesBasic FormulaeRiki AsmadiNo ratings yet

- Frame Contained PDF File, Click To ViewDocument62 pagesFrame Contained PDF File, Click To ViewdzymytchNo ratings yet

- Submerged Arc Welding Consumables GuideDocument19 pagesSubmerged Arc Welding Consumables GuideMarleneLopesNo ratings yet

- Compact PCB Power Relay Spec SheetDocument2 pagesCompact PCB Power Relay Spec SheetJORGENo ratings yet

- Elevator Inquiry Form-EPSSDocument1 pageElevator Inquiry Form-EPSSJavier Vasquez100% (1)

- HIPS (Supreme) Sh731Document2 pagesHIPS (Supreme) Sh731avi.singh849291No ratings yet

- Bitzer - 4GE-30-40P X 2comp - (1'C) - r407c - 070917 PDFDocument7 pagesBitzer - 4GE-30-40P X 2comp - (1'C) - r407c - 070917 PDFAgus CahyonoNo ratings yet

- FP3.0 INT TablerosDocument24 pagesFP3.0 INT TablerossueNo ratings yet

- Se 747Document16 pagesSe 747Roohian Ali100% (1)

- Mira ESDocument371 pagesMira ESBilal Ilyas75% (4)

- YPV6 Mobile Air Conditioner ManualDocument18 pagesYPV6 Mobile Air Conditioner ManualTecnicas Metalicas100% (1)

- Basics of Power Generation Sources and India's Future OutlookDocument13 pagesBasics of Power Generation Sources and India's Future Outlookk rajendraNo ratings yet

- One Point LessonDocument8 pagesOne Point LessonVenkatesanNo ratings yet

- Learning RSLogix 5000 Programming1Document10 pagesLearning RSLogix 5000 Programming1alimohebbi1361No ratings yet

- Coppus Steam Turbine BrochureDocument6 pagesCoppus Steam Turbine Brochuredevdown100% (2)

- Aguado Valencia Jose Roberto M06s2ai3Document7 pagesAguado Valencia Jose Roberto M06s2ai3Karim Villa RedkenNo ratings yet

- Quality of Work Life in B.H.E.L.Document90 pagesQuality of Work Life in B.H.E.L.DESH RAJ BHANDARI82% (17)