Professional Documents

Culture Documents

Esab, Atom Arc 9018 (29-En - US-FactSheet - Main-01, 2016.10.26)

Uploaded by

RodrigoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Esab, Atom Arc 9018 (29-En - US-FactSheet - Main-01, 2016.10.26)

Uploaded by

RodrigoCopyright:

Available Formats

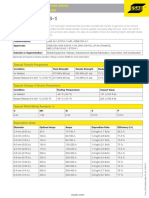

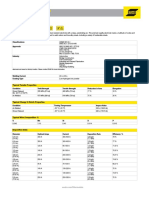

COVERED (STICK) ELECTRODES (SMAW)

LOW HYDROGEN/LOW ALLOY ELECTRODES

Atom Arc 9018

Atom Arc 9018 electrodes are used for attachment welds on T-1, HY-80 and HY-90 steels and other high tensile,

quenched and tempered steels.

Classifications: AWS A5.5:E9018M H4R, ASME SFA 5.5

Approvals: QPL-22200/1 MIL-9018-M, ABS 3Y, LR 3Ym(H15)

Industry or Segmentation: Bridge Construction, Ship/Barge Building, Mobile Equipment,

Industrial and General Fabrication, Railcars, Civil Construction

Approvals are based on factory location. Please contact ESAB for more information.

Typical Tensile Properties

Condition Yield Strength Tensile Strength Reduction in Area Elongation

As Welded 580 MPa (84 ksi) 655 MPa (95 ksi) 69 % 28 %

Stress Relieved 24 hr 593 °C (1100 °F) 470 MPa (68 ksi) 635 MPa (92 ksi) 72 % 27 %

Typical Charpy V-Notch Properties

Condition Testing Temperature Impact Value

As Welded -51 °C (-60 °F) 81 J (60 ft-lb)

Stress Relieved 24 hr 593 °C (1100 °F) -51 °C (-60 °F) 92 J (66 ft-lb)

Typical Weld Metal Analysis %

C Mn Si S P Ni Mo

0.043 1.00 0.26 0.01 0.012 1.60 0.29

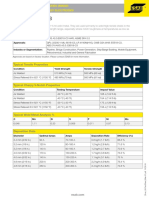

Deposition Data

Diameter Optimal Amps Amps Deposition Rate Efficiency (%)

2.4 mm (3/32 in.) 90 A 70-100 A 0.8 kg/h (1.7 lb/h) 66.3 %

3.2 mm (1/8 in.) 120 A 90-160 A 1.2 kg/h (2.6 lb/h) 71.6 %

3.2 mm (1/8 in.) 140 A 90-160 A 1.2 kg/h (2.7 lb/h) 70.9 %

4.0 mm (5/32 in.) 170 A 130-220 A 1.7 kg/h (3.8 lb/h) 73.5 %

4.0 mm (5/32 in.) 140 A 130-220 A 1.1 kg/h (3.1 lb/h) 75 %

4.8 mm (3/16 in.) 200 A 200-300 A 2.2 kg/h (4.9 lb/h) 76.4 %

4.8 mm (3/16 in.) 250 A 200-300 A 2.4 kg/h (5.4 lb/h) 74.6 %

29-en_US-FactSheet_Main-01.pdf 10/26/16

esab.com

You might also like

- Electrodo Aws 7018-1 EsabDocument1 pageElectrodo Aws 7018-1 EsabHORACIONo ratings yet

- Esab, Atom Arc 8018 (26-En - US-FactSheet - Main-01, 2016.10.26)Document1 pageEsab, Atom Arc 8018 (26-En - US-FactSheet - Main-01, 2016.10.26)RodrigoNo ratings yet

- ESAB Filler Metal GuideDocument1 pageESAB Filler Metal GuidekapsarcNo ratings yet

- Dual Shield II 101H4MDocument2 pagesDual Shield II 101H4Madanmeneses1No ratings yet

- Atom Arc 7018-1: Covered (Stick) Electrodes (Smaw) Low Hydrogen ElectrodesDocument2 pagesAtom Arc 7018-1: Covered (Stick) Electrodes (Smaw) Low Hydrogen ElectrodesFranklin Aranda ChacónNo ratings yet

- FICHADocument2 pagesFICHAadmisecoinperuNo ratings yet

- Coreweld 70: Metal-Cored Wires (Mcaw) Mild Steel WiresDocument2 pagesCoreweld 70: Metal-Cored Wires (Mcaw) Mild Steel WiresJerald GuevarraNo ratings yet

- Esab, Coreshield 40 (275-En - US-FactSheet - Main-01) (26.10.16)Document1 pageEsab, Coreshield 40 (275-En - US-FactSheet - Main-01) (26.10.16)RodrigoNo ratings yet

- Dual Shield 710X: Gas-Shielded Flux-Cored Wires (Fcaw) Mild Steel WiresDocument3 pagesDual Shield 710X: Gas-Shielded Flux-Cored Wires (Fcaw) Mild Steel WiresPhilippe TrudelNo ratings yet

- Atom Arc 7018-B2L: Typical Tensile PropertiesDocument1 pageAtom Arc 7018-B2L: Typical Tensile PropertiesPubcrawlNo ratings yet

- Dual Shield II 101 1.6 MMDocument2 pagesDual Shield II 101 1.6 MMadanmeneses1No ratings yet

- Atom Arc 7018: Covered (Stick) Electrodes (Smaw) Low Hydrogen ElectrodesDocument2 pagesAtom Arc 7018: Covered (Stick) Electrodes (Smaw) Low Hydrogen ElectrodesKrishna VachaNo ratings yet

- Dual Shield 810X-NI1: Gas-Shielded Flux-Cored Wires (Fcaw) Low Alloy WiresDocument2 pagesDual Shield 810X-NI1: Gas-Shielded Flux-Cored Wires (Fcaw) Low Alloy Wiresadanmeneses1No ratings yet

- OK Autrod 2209: Typical Tensile PropertiesDocument1 pageOK Autrod 2209: Typical Tensile PropertiesjavadmohammadiNo ratings yet

- Atom Arc 8018Document2 pagesAtom Arc 8018Jagan TnNo ratings yet

- Dual Shiel Ii 101Document2 pagesDual Shiel Ii 101Robin carcamoNo ratings yet

- Esab, Dual Shield 810X Ni1 (248 en - US FactSheet - Main 01)Document2 pagesEsab, Dual Shield 810X Ni1 (248 en - US FactSheet - Main 01)RodrigoNo ratings yet

- Dual Shield 7100 Ultra: Gas-Shielded Flux-Cored Wires (Fcaw) Mild Steel WiresDocument3 pagesDual Shield 7100 Ultra: Gas-Shielded Flux-Cored Wires (Fcaw) Mild Steel Wiresadanmeneses1No ratings yet

- Covered (Stick) Electrodes (SMAW)Document5 pagesCovered (Stick) Electrodes (SMAW)Hanny Dewi SaragihNo ratings yet

- Dual Shield II 70T-12H4: Gas-Shielded Flux-Cored Wires (Fcaw) Mild Steel WiresDocument2 pagesDual Shield II 70T-12H4: Gas-Shielded Flux-Cored Wires (Fcaw) Mild Steel WiresPhilippe TrudelNo ratings yet

- Dual Shield II 81-K2: Gas-Shielded Flux-Cored Wires (Fcaw) Low Alloy WiresDocument2 pagesDual Shield II 81-K2: Gas-Shielded Flux-Cored Wires (Fcaw) Low Alloy WiresMOhammed PatelNo ratings yet

- Tech Data Sheet: Dual Shield T-115Document3 pagesTech Data Sheet: Dual Shield T-115carlosNo ratings yet

- Dual Shield T-115: Gas-Shielded Flux-Cored Wires (Fcaw) Low Alloy WiresDocument2 pagesDual Shield T-115: Gas-Shielded Flux-Cored Wires (Fcaw) Low Alloy WiresPEPITO GRILLO2No ratings yet

- Esab Welding RodDocument1 pageEsab Welding Rodv ictor manuel MunozNo ratings yet

- 274 en - US FactSheet - Main 01Document2 pages274 en - US FactSheet - Main 01Luisa FernandaNo ratings yet

- Esab, Dual Shield II 110 (265-En - US-FactSheet - Main-01) (26.10.16)Document2 pagesEsab, Dual Shield II 110 (265-En - US-FactSheet - Main-01) (26.10.16)RodrigoNo ratings yet

- Sureweld 6010: Covered (Stick) Electrodes (Smaw) Mild Steel ElectrodesDocument1 pageSureweld 6010: Covered (Stick) Electrodes (Smaw) Mild Steel ElectrodesGibbs PerNo ratings yet

- COR-1076C Coreweld Brochure 141118Document28 pagesCOR-1076C Coreweld Brochure 141118Thanh TamNo ratings yet

- Esab, Dual Shield T-115 (24!02!17, 266-En - US-FactSheet - Main-01)Document2 pagesEsab, Dual Shield T-115 (24!02!17, 266-En - US-FactSheet - Main-01)RodrigoNo ratings yet

- 278 en US FactSheet Main 01Document1 page278 en US FactSheet Main 01Jorge Manuel GuillermoNo ratings yet

- Dual Shield 7100 Ultra: Typical Tensile PropertiesDocument3 pagesDual Shield 7100 Ultra: Typical Tensile PropertiesDino Paul Castro HidalgoNo ratings yet

- Tech Data Sheet: Dual Shield Ii 100-D1Document3 pagesTech Data Sheet: Dual Shield Ii 100-D1carlosNo ratings yet

- Dual Shield T-75: Typical Tensile PropertiesDocument2 pagesDual Shield T-75: Typical Tensile PropertiescfloresNo ratings yet

- MD250MW CAN DataSheet 1642812289Document1 pageMD250MW CAN DataSheet 1642812289masNo ratings yet

- OK Weartrode 30: Covered (Stick) Electrodes (Smaw) Hardfacing ElectrodesDocument1 pageOK Weartrode 30: Covered (Stick) Electrodes (Smaw) Hardfacing Electrodesraghubhaimantra4136No ratings yet

- Ok 74.86 Tensitrode: A Basic Coated Electrode For Steels and Castings With U.T.S. of Min. 690 MpaDocument1 pageOk 74.86 Tensitrode: A Basic Coated Electrode For Steels and Castings With U.T.S. of Min. 690 Mpamitesh prajapatiNo ratings yet

- ESB 255051815 SpecSheetDocument2 pagesESB 255051815 SpecSheetanupmenon menonNo ratings yet

- Typical Tensile Properties: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationDocument1 pageTypical Tensile Properties: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationKukuh YuonoNo ratings yet

- Ultracore 360 M81: Conformances Key FeaturesDocument3 pagesUltracore 360 M81: Conformances Key FeaturesDaniel Lvqve GarciaNo ratings yet

- Tech Data Sheet: DUAL SHIELD 8000-Ni2Document3 pagesTech Data Sheet: DUAL SHIELD 8000-Ni2carlosNo ratings yet

- Versaflow 80 C Plus: Product DataDocument2 pagesVersaflow 80 C Plus: Product DataMuhammad victoryan nadezulNo ratings yet

- Glaistytieji Elektrodai (Smaw) Žemos Vandenilio Jonų Koncentracijos ElektrodaiDocument2 pagesGlaistytieji Elektrodai (Smaw) Žemos Vandenilio Jonų Koncentracijos ElektrodaiKiranNo ratings yet

- Pipeweld 6010 Plus: Covered (Stick) Electrodes (Smaw) Mild Steel ElectrodesDocument1 pagePipeweld 6010 Plus: Covered (Stick) Electrodes (Smaw) Mild Steel ElectrodesRys Multiventas SacNo ratings yet

- SFTPreal10 Cat6A 6x4p Loom 650MHz AWG26Document2 pagesSFTPreal10 Cat6A 6x4p Loom 650MHz AWG26Slobodan ĐenićNo ratings yet

- FabCO 811N1Document2 pagesFabCO 811N1Sleyda MunozNo ratings yet

- F11TSVDocument2 pagesF11TSVBryan CustodioNo ratings yet

- OK Tigrod 13.32Document1 pageOK Tigrod 13.32Paulo CorreiaNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile PropertiesNibin OdukkathilNo ratings yet

- Versaflow 45 Plus: Product DataDocument2 pagesVersaflow 45 Plus: Product DataHendra AriefNo ratings yet

- Metalshield Clarity MC - 707: Conformances Key FeaturesDocument2 pagesMetalshield Clarity MC - 707: Conformances Key FeaturesRumman Ul AhsanNo ratings yet

- Atom Arc 8018: Features Typical Mechanical PropertiesDocument2 pagesAtom Arc 8018: Features Typical Mechanical PropertiesFranklin Aranda ChacónNo ratings yet

- Medidores AMERICAN METERSDocument17 pagesMedidores AMERICAN METERSRaúl PalomoNo ratings yet

- ESM Inert Support BallsDocument1 pageESM Inert Support BallsBamrung SungnoenNo ratings yet

- Neema 34 Geared PDFDocument1 pageNeema 34 Geared PDFMimo AbduNo ratings yet

- FFCDocument2 pagesFFCCesar ZarateNo ratings yet

- CSF-71T Technical Report EN - V2Document7 pagesCSF-71T Technical Report EN - V2Miroslav ThôngNo ratings yet

- Fabcor 86 RDocument2 pagesFabcor 86 RAnonymous fj4iRr1No ratings yet

- GM - 6000 20000 - L-242 41 15000 3 D - 200 24 2500 GBDocument1 pageGM - 6000 20000 - L-242 41 15000 3 D - 200 24 2500 GBEduardo Garcia SaraviaNo ratings yet

- RS 250 M Welding MachineDocument1 pageRS 250 M Welding MachineLucioNo ratings yet

- Zeron 100 Brochure Rolled AlloysDocument8 pagesZeron 100 Brochure Rolled AlloysRodrigoNo ratings yet

- Beyond A1 Plus SB Unit 8 SML PDFDocument11 pagesBeyond A1 Plus SB Unit 8 SML PDFAlex Rödriguez R50% (2)

- Lincoln, Tech-Rod ® 99 (c141022)Document2 pagesLincoln, Tech-Rod ® 99 (c141022)RodrigoNo ratings yet

- Lincoln, TECHALLOY® 606 (c14107)Document2 pagesLincoln, TECHALLOY® 606 (c14107)RodrigoNo ratings yet

- Unibraze Er80s-B2 (Tig)Document1 pageUnibraze Er80s-B2 (Tig)RodrigoNo ratings yet

- Lincoln, Superarc LA-90Document2 pagesLincoln, Superarc LA-90RodrigoNo ratings yet

- 2015 KOBELCO Defect PDFDocument25 pages2015 KOBELCO Defect PDFayushNo ratings yet

- Steel Castings, Carbon, For General ApplicationDocument4 pagesSteel Castings, Carbon, For General ApplicationJuan Carlos Chura QuispeNo ratings yet

- Espesificaciones de MaterialesDocument2 pagesEspesificaciones de MaterialesDanyAlex GarciaNo ratings yet

- Lincoln GMAW Welding GuideDocument96 pagesLincoln GMAW Welding GuideМич БјукенонNo ratings yet

- Essential Factors in Gas Shielded Metal Arc Welding GMAW - 5edDocument33 pagesEssential Factors in Gas Shielded Metal Arc Welding GMAW - 5edCarlo MonsalveNo ratings yet

- Esab, Coreshield 40 (275-En - US-FactSheet - Main-01) (26.10.16)Document1 pageEsab, Coreshield 40 (275-En - US-FactSheet - Main-01) (26.10.16)RodrigoNo ratings yet

- Verticalshrouds Proteccion VerticalDocument4 pagesVerticalshrouds Proteccion VerticalRodrigoNo ratings yet

- ABC 5edDocument93 pagesABC 5edJuan Diego Garcia EsquenNo ratings yet

- Dual Shield 7100 Ultra: Typical Tensile PropertiesDocument3 pagesDual Shield 7100 Ultra: Typical Tensile PropertiesDino Paul Castro HidalgoNo ratings yet

- Esab, OK Autrod 12.10 (A345311)Document1 pageEsab, OK Autrod 12.10 (A345311)RodrigoNo ratings yet

- Esab, OK Flux 10.71 (30.06.16), 420014-En - US-FactSheet - Main-01Document2 pagesEsab, OK Flux 10.71 (30.06.16), 420014-En - US-FactSheet - Main-01RodrigoNo ratings yet

- Esab, Dual Shield T-115 (24!02!17, 266-En - US-FactSheet - Main-01)Document2 pagesEsab, Dual Shield T-115 (24!02!17, 266-En - US-FactSheet - Main-01)RodrigoNo ratings yet

- Esab, OK Autrod 12.10 (A345311)Document1 pageEsab, OK Autrod 12.10 (A345311)RodrigoNo ratings yet

- Esab, OK Autrod 12.22 (1222252800)Document1 pageEsab, OK Autrod 12.22 (1222252800)RodrigoNo ratings yet

- Dual Shield 7100 Ultra: Typical Tensile PropertiesDocument3 pagesDual Shield 7100 Ultra: Typical Tensile PropertiesDino Paul Castro HidalgoNo ratings yet

- Esab, Dual Shield 810X Ni1 (248 en - US FactSheet - Main 01)Document2 pagesEsab, Dual Shield 810X Ni1 (248 en - US FactSheet - Main 01)RodrigoNo ratings yet

- Esab, Dual Shield II 110 (265-En - US-FactSheet - Main-01) (26.10.16)Document2 pagesEsab, Dual Shield II 110 (265-En - US-FactSheet - Main-01) (26.10.16)RodrigoNo ratings yet

- Esab, OK Flux 10.71 (30.06.16), 420014-En - US-FactSheet - Main-01Document2 pagesEsab, OK Flux 10.71 (30.06.16), 420014-En - US-FactSheet - Main-01RodrigoNo ratings yet

- Hobart, Hoballoy - 8018b2 (Aws E8018-B2 h4r)Document2 pagesHobart, Hoballoy - 8018b2 (Aws E8018-B2 h4r)RodrigoNo ratings yet

- Esab, OK Tigrod NiCr-3 (21.06.16) (411170-En - US-FactSheet - Main-01)Document1 pageEsab, OK Tigrod NiCr-3 (21.06.16) (411170-En - US-FactSheet - Main-01)RodrigoNo ratings yet

- Fillet Weld DesignDocument2 pagesFillet Weld Designsaj0205037No ratings yet

- Portafolio SoldDocument1 pagePortafolio SoldRodrigoNo ratings yet

- 2001 - New Porcelainized Stoneware Materials Obtained by Recycling of MSW Incinerator Fly Ashes and Granite Sawing ResiduesDocument8 pages2001 - New Porcelainized Stoneware Materials Obtained by Recycling of MSW Incinerator Fly Ashes and Granite Sawing ResiduesFURY FURIONNo ratings yet

- 12th Chemistry Vol.1 Book Back One Mark Questions English Medium PDF DownloadDocument19 pages12th Chemistry Vol.1 Book Back One Mark Questions English Medium PDF Downloadteddygamingyt201No ratings yet

- Reverse Engineering Project ReportDocument53 pagesReverse Engineering Project ReportMKAMRANBHATTI100% (6)

- Catálogo de Insertos MccoyDocument48 pagesCatálogo de Insertos MccoyEdgar Moreira FernandezNo ratings yet

- Cambridge International AS & A Level: CHEMISTRY 9701/23Document20 pagesCambridge International AS & A Level: CHEMISTRY 9701/23nickole.taruc022807No ratings yet

- Fpso Piping Material Datasheet SO17033 PESDMCPF999001 A2 10 of 23Document1 pageFpso Piping Material Datasheet SO17033 PESDMCPF999001 A2 10 of 23alouisNo ratings yet

- Extraction of Nonferrous Metals by H S Ray PDFDocument2 pagesExtraction of Nonferrous Metals by H S Ray PDFMichael22% (23)

- OBJECTIVEDocument3 pagesOBJECTIVEGautam Singh RajputNo ratings yet

- Protective Coatings For MetalsDocument53 pagesProtective Coatings For MetalsSiddharth Khorwal50% (2)

- IV. Oxidation and Secondary Enrichment of Gold Deposits: General PrinciplesDocument15 pagesIV. Oxidation and Secondary Enrichment of Gold Deposits: General PrinciplesHAMZA LAMSALAHNo ratings yet

- 8 Different Types of Metal Cutting Tools and Their UsesDocument31 pages8 Different Types of Metal Cutting Tools and Their UsesAlexander MwauraNo ratings yet

- Astm B584Document6 pagesAstm B584Lucas Mlb100% (1)

- Geology QuestionsDocument25 pagesGeology QuestionsGera VillaNo ratings yet

- Chemical Formula Writing WorksheetDocument4 pagesChemical Formula Writing Worksheetprabhu4321100% (1)

- Deepak 2017 IOP Conf. Ser.: Mater. Sci. Eng. 197 012067 PDFDocument9 pagesDeepak 2017 IOP Conf. Ser.: Mater. Sci. Eng. 197 012067 PDFMakeshNo ratings yet

- Stellram Turning Cat2013 Threading Inserts Holders MetricDocument58 pagesStellram Turning Cat2013 Threading Inserts Holders MetricFrederich Bear RiverNo ratings yet

- Astm A350 LF2Document1 pageAstm A350 LF2anjangandak2932100% (1)

- ASTM A480-A480M-99bDocument24 pagesASTM A480-A480M-99bmgmqro100% (1)

- Thermal & Chemical Kilb 2006Document40 pagesThermal & Chemical Kilb 2006mustaf100% (1)

- Astm A 506 - 00Document4 pagesAstm A 506 - 00Alvaro HernandezNo ratings yet

- Gamma Titanium Aluminide Alloys Science andDocument5 pagesGamma Titanium Aluminide Alloys Science andkorkmazmailNo ratings yet

- Online Metals IndiaDocument2 pagesOnline Metals IndiaRISHABH MEHTANo ratings yet

- QQ-A-250 - 12F - Aluminum Alloy 7075, Plate and Sheet - StandardDocument7 pagesQQ-A-250 - 12F - Aluminum Alloy 7075, Plate and Sheet - StandardSüleymanNo ratings yet

- Corrosion Resistance of Nickel-Containing Alloys in Phosphoric Acid (CEB-4)Document41 pagesCorrosion Resistance of Nickel-Containing Alloys in Phosphoric Acid (CEB-4)GagrigoreNo ratings yet

- Astm A358Document10 pagesAstm A358Swapnil ModakNo ratings yet

- KV45 R45S R45PB - C45E Nr.1.1191 C45R Nr.1.1201 ENGDocument2 pagesKV45 R45S R45PB - C45E Nr.1.1191 C45R Nr.1.1201 ENGNarimane BentyNo ratings yet

- 4G 2G 2F 3G Uphill 3G DownhillDocument1 page4G 2G 2F 3G Uphill 3G Downhillamit singhNo ratings yet

- Chapter 16Document5 pagesChapter 16dervis berk congerNo ratings yet

- Cold Rolled Steel Sheet-JFE PDFDocument32 pagesCold Rolled Steel Sheet-JFE PDFEduardo Javier Granados SanchezNo ratings yet

- STEELDocument6 pagesSTEELRico BelledoNo ratings yet