Professional Documents

Culture Documents

Ulman Phosgene Uses English

Uploaded by

Priska Dewi AnjarsariCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ulman Phosgene Uses English

Uploaded by

Priska Dewi AnjarsariCopyright:

Available Formats

Its many different reactions makes phosgene an important starting compound in the production of

intermediates and end products in many branches of large-scale industrial chemistry.

Diisocyanates. Mostphosgeneisusedforthe production of diisocyanates as starting materials of

polyurethane chemistry. The most important compounds are toluene diisocyanate (TDI) [1321-38-6]

as well as monomeric [101-68-8] (MDI) and polymeric methylenediphenyl diisocyanate [9016-87-9]

(PMDI) (→Isocyanates, Organic, Chap. 3.).

The production of toluene diisocyanate (TDI) starts from toluene, which is converted in a continuous

process to a mixture of 2,4and 2,6-dinitrotoluene. This mixture is hydrogenated with hydrogen to

give 2,4- and 2,6toluenediamine(TDA).Thereactionwithphosgene is usually carried out in a

continuous process, using e.g., toluene, chlorobenzene, or 1,2dichlorobenzene as solvents, at 65–

180◦C and at excess pressure. In the course of this process hydrogen chloride (reaction product),

phosgene (excessreactant),andfinallythesolventaresuccessively separated. The end product TDI is

purified by distillation.

For the production of methylenediphenyl diisocyanate (MDI), aniline is used as the starting material.

It is condensed with formaldehyde to form a mixture of isomeric methylenediphenyldiamines

(MDA). The subsequent reaction of this amine mixture with phosgene is

similartothatdescribedaboveforTDI.Theend product is a mixture of isomeric MDI and various PMDI

types. Distillative purification is not carried out.

Thehightoxicityofphosgenehasresultedin intensiveworkonthedevelopmentofphosgenefree processes

for diisocyanate manufacture. These processes start from the corresponding dinitro compounds,

which react with CO to form diisocyanates [57–62]. The reaction of the amines with compounds

other than phosgene such as dimethyl carbonate [63] or methanol and carbon monoxide with

oxygen [64], is another line of development. The development of phosgene-

freeprocesseshasbeensuccessfulfor only a few aliphatic diisocyanates; the production of other

diisocyanates by this route suffers from a lack of profitability or process engineering difficulties

(→Isocyanates, Organic, Chap. 4.3.) [65], [66].

Aliphatic diisocyanates are important starting materials for polyurethanes used in coatings.

Monoisocyanates, such as isopropyl isocyanate, phenyl isocyanate, and chlorophenyl isocyanates,

are important intermediates in the manufacture of herbicides and insecticides.

Polycarbonates. The next largest phosgene consumers are polycarbonate plastics

(→Polycarbonates). They are produced by reaction of 2,2-bis(4-hydroxyphenyl)propane (bisphenolA)

with phosgene, either directly or indirectly via diphenyl carbonate.

Chloroformic Esters. The reaction of phosgenewithalcoholstoformchloroformicestersis

veryimportantforindustrialapplications.These esters are exceptionally versatile intermediates, e.g.,

for the production of carbonic esters, polycarbonates, and polyurethanes, and for many other

applications (→Chloroformic Esters).

Urea Azo Dyes. The treatment of aminoazo dyes with phosgene in aqueous solution to produce

symmetrical urea azo dyes, has been practiced since the end of the 19th century (→Azo Dyes, Chap.

4.1.6.).

Carbonate Esters. Among the carbonate esters,dimethylanddiethylcarbonatesinparticular are used in

the pharmaceutical industry and in the production of pesticides. Diphenyl carbonate is an

intermediate in the production of polycarbonates.

Friedel–Crafts Acylations. Friedel–Crafts acylations with phosgene are important reactions, e.g., for

the dye industry, yielding importantketonessuchasbenzophenone(→Ketones, Chap. 7.3.) or 4,4-

bis(dimethylamino)benzophenone (Michler’s ketone) (→ Acylation and Alkylation, Chap. 2.2.).

Benzoyl chloride can also be obtained in this way from benzene. The production of 2,5-

dichlorobenzoic acid from 1,4-dichlorobenzeneandphosgeneinanAlCl3 – sodium formate melt is

described in [67].

Other Uses. Phosgene undergoes commercially important cyclization reactions with aminocarboxylic

acids, aminophenols, and diamines. Acid chlorides are often prepared by reaction of carboxylic acids

with phosgene (for suitable catalysts see [68]). Examples are the production of isophthaloyl

dichloride and terephthaloyl dichloride on the large industrial scale.

Phosgene disproportionates to form carbon tetrachloride and carbon dioxide at high temperatures

(→Chlorinated Hydrocarbons).

In inorganic chemistry, phosgene is used as anintermediateforthelarge-scaleproductionof

aluminumchloride(→AluminumCompounds, Inorganic, Chap. 4.1.2.). The production of zirconium

chloride is described in [69].

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- APIC Template For Report On Nitrosamine Risk Assessment-FinalDocument9 pagesAPIC Template For Report On Nitrosamine Risk Assessment-FinalNgoc Sang Huynh100% (2)

- Castor Oil A Vital Industrial Raw MaterialDocument6 pagesCastor Oil A Vital Industrial Raw Materialonemahmud100% (2)

- Analysisof Silicon Carbide Abrasive Grainand Abrasive CrudeDocument23 pagesAnalysisof Silicon Carbide Abrasive Grainand Abrasive CrudeCristiano Cabral MüllerNo ratings yet

- SPM Chemistry Form 5Document5 pagesSPM Chemistry Form 5Aileen PoLyNo ratings yet

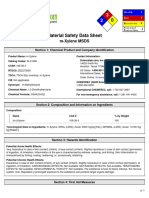

- Msds P XyleneDocument6 pagesMsds P XylenePriska Dewi AnjarsariNo ratings yet

- Msds o Xylene PDFDocument6 pagesMsds o Xylene PDFPriska Dewi AnjarsariNo ratings yet

- Msds MxyleneDocument5 pagesMsds MxylenePriska Dewi AnjarsariNo ratings yet

- Phosgenation A Handbook Hal 20 EnglishDocument3 pagesPhosgenation A Handbook Hal 20 EnglishPriska Dewi AnjarsariNo ratings yet

- Activated Carbon MSDS PDFDocument6 pagesActivated Carbon MSDS PDFRIANG TRIANDONONo ratings yet

- IAL Chemistry Unit-02 Samplepaper - 03 PDFDocument17 pagesIAL Chemistry Unit-02 Samplepaper - 03 PDFDimuthu SandaruwanNo ratings yet

- Staining - Practical and Theoretical (1962) by GurrDocument654 pagesStaining - Practical and Theoretical (1962) by GurrDan JohnsonNo ratings yet

- Organic Chemistry: Course Code: SKO 3033 Semester 2 Sessions 2020/2021 Id Number and NameDocument6 pagesOrganic Chemistry: Course Code: SKO 3033 Semester 2 Sessions 2020/2021 Id Number and NameSITI HUMAIRAH BINTI HAMZAHNo ratings yet

- Vihasifene Chem PVT LTD, Hyderabad (Vihasi.m@gmail - Com)Document36 pagesVihasifene Chem PVT LTD, Hyderabad (Vihasi.m@gmail - Com)vihasibioNo ratings yet

- Lab 7Document7 pagesLab 7Dana Georgiana CrivoiNo ratings yet

- Catalog PurinovaDocument8 pagesCatalog Purinovamostafa shafizadehNo ratings yet

- Questions About DensityDocument8 pagesQuestions About DensityJohn OsborneNo ratings yet

- Acetyl AcetoneDocument11 pagesAcetyl AcetonePanneerselvam DhanushkodiNo ratings yet

- Handprint - YellowDocument17 pagesHandprint - YellowfrazNo ratings yet

- Expt On Solubility of Organic CompoundsDocument4 pagesExpt On Solubility of Organic CompoundsJasmine Juit100% (1)

- ISO/WD xxxxx-1: © ISO 2010 - All Rights ReservedDocument19 pagesISO/WD xxxxx-1: © ISO 2010 - All Rights ReservedAnanda Ganesh MadheswaranNo ratings yet

- Full Length Article: J. Greco-Duarte, E.D. Cavalcanti-Oliveira, J.A.C. Da Silva, R. Fernandez-Lafuente, D.M.G. FreireDocument10 pagesFull Length Article: J. Greco-Duarte, E.D. Cavalcanti-Oliveira, J.A.C. Da Silva, R. Fernandez-Lafuente, D.M.G. FreireAna Cristina CollaçoNo ratings yet

- API Product ListDocument4 pagesAPI Product ListpstindiaNo ratings yet

- Class 10 Science Chapter 4 Carbon and Its Compounds Revision NotesDocument30 pagesClass 10 Science Chapter 4 Carbon and Its Compounds Revision NotesNanhe SinghNo ratings yet

- Reactions of Copper (Edited, 10 Sept 2023)Document5 pagesReactions of Copper (Edited, 10 Sept 2023)Rose-AnnMirambilNo ratings yet

- Sulfate AttackDocument19 pagesSulfate AttackIrvebry Ayu WulandaryNo ratings yet

- Chemistry 2 QuestionsDocument23 pagesChemistry 2 QuestionsRozilah YunusNo ratings yet

- Solid StateDocument16 pagesSolid StatePrahasNo ratings yet

- Alkene Practice QuestionDocument10 pagesAlkene Practice Questionscsa31619No ratings yet

- Fe Analysis by REDOX Titration PDFDocument4 pagesFe Analysis by REDOX Titration PDFarun231187No ratings yet

- Oxidaciones Con KMnO4Document9 pagesOxidaciones Con KMnO4Cristian Camilo Sanin VillamilNo ratings yet

- The Logic of Chemical Synthesis Corey E J Amp Cheng X M 271 330Document60 pagesThe Logic of Chemical Synthesis Corey E J Amp Cheng X M 271 330bann tvNo ratings yet

- Lab Report Experiment 1 Chm624Document11 pagesLab Report Experiment 1 Chm624Hazwan HamimNo ratings yet

- Ece3204 Group 2Document14 pagesEce3204 Group 2HendrixNo ratings yet

- Apple PectinDocument14 pagesApple PectinNyan Lin HtetNo ratings yet

- Exp1 Sic180033 PDFDocument6 pagesExp1 Sic180033 PDFfara basar100% (1)