Professional Documents

Culture Documents

Metoda Kerja Kerucut Tangki PDF

Uploaded by

gitaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Metoda Kerja Kerucut Tangki PDF

Uploaded by

gitaCopyright:

Available Formats

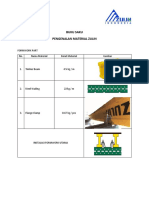

METHODE OF WORK FOR CONE CUT TANK

PELINTUNG, DUMAI. WILLMAR GROUP.

NO DESCRIPTION AND EXPLICIT

I PREPARATION OF WORK

1.1 Welder test (do by third party)

1.2 Submission and approval WPS (welding procedure specification)

1.3 Handling material on the "medan" workshop

1.4 Allotment the of plate as thickness and as the activity workers group

II ENGINEERING PREPARATION

2.1 Draw and calculate the pola of the material cutting for cone cut tank before cutting activity

2.2 Send the WPS to Chief of worker as guidence welder do to works

III FITTER WORKERS

3.1 Make temporary Joint to the plate (two plate to be join make it one plate assembly whit the same thicknes)

3.2 Do mark the pola cutting on the plate and cutting the plate as the mark (as engineering order)

3.3 after finish point 3.2 make separated and continues whit bevel and grinding

3.4 Do the work repeatedly for the activity as the above as the thickness allotment

IV SANDBLAST AND COATING

Do point 3.4 continue whit sandblasting and coating for first coat only

V MECHANICAL OF WORK

After sandblasting and coating first coat finish

5.1 Bending of the plate, to maked shape of plate become as curve as computation of the cone cut

5.2 Do the permanent welding joint to every plate as appropriate the thickness and allotment of the plate

5.3 Do the work repeatedly the activity as the above as the thickness allotment

VI MOBILISATION OF MATERIAL (all the plate already sandblast and first coating)

6.1 Send of the plate to site as the priority concern to follow the civil action work

6.2 Continue whit the another plate as formation thicknes of the cone plate structure

VII MATERIAL ON SITE

7.1 Allotment the material as the group of number tank or the structure of the cone cut

7.2 Coordination whit the civil people to arrange erection of the plate

7.3 Preparing equipment, tools and support for erection the plate

VIII EXCECUTION OF WORK

This under activity is do it's whit the more than one's group

8.1 Joint embaded plate whit anchor

8.2 Install of support temporary for handling joint of the embaded plate to concrete column

8.3 Fit up the embaded plate to the concrete column and jointed the anchor by weld whit the reinforced bar

8.4 Do the activity as the above by weld until the circle of the embaded plate make it join totaly

8.5 Install of support temporary for handling join of the embaded plate whit the under formation plate

8.6 Do it repeatedly thats the work as the formation plate, until the formation of plate of the cone cut finish

8.7 Do it test joint weld whit the NDT test, as confirm as consideration the owner people

IX SITE COATING ACTIVITY

All the weld actvity for each cone cut already finish and approved by owner consideration

CONE CUT TANK STRUCTURE PLATE COMPOSITION EQUIPMENT SCHEDULE

1 No 1 Embaded Plate 16 mm 9 sheet 1 Crane service erection 1 unit

2 No 2 Plate Cone 16 mm 9 sheet 2 Crane service material 1 unit

3 No 3 Plate Cone 14 mm 6 sheet 3 Welding Machine 5 unit

4 No 4 Plate Cone 14 mm 6 sheet 4 Tool's supporting 1 lots

5 No 5 Plate Cone 14 mm 5 sheet 5 Scaffolding for support 1 lots

6 No 6 Plate Cone 14 mm 5 sheet 6 Safety tools

7 No 7 Plate Cone 12 mm 2 sheet

8 No 8 Plate Cone 12 mm 2 sheet

9 No 9 Plate Cone 12 mm 1 sheet

You might also like

- Buku Saku - Formwork ZULINDocument5 pagesBuku Saku - Formwork ZULINgitaNo ratings yet

- Brosur Katalog Fire Alarm HOOSEKIDocument6 pagesBrosur Katalog Fire Alarm HOOSEKIAris SucahyoNo ratings yet

- VIKING - General Catalog 2017Document40 pagesVIKING - General Catalog 2017gitaNo ratings yet

- Jump Formwork PDFDocument92 pagesJump Formwork PDFgitaNo ratings yet

- Jump Formwork PDFDocument92 pagesJump Formwork PDFgitaNo ratings yet

- Fire Pumps Testing & CommissioningDocument6 pagesFire Pumps Testing & CommissioninggitaNo ratings yet

- CIG WELD Deposition Rate PDFDocument7 pagesCIG WELD Deposition Rate PDFgitaNo ratings yet

- K FactorDocument5 pagesK Factorgita100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Ingles - 1 - Bach - Modulo - 2 (20 - 21)Document32 pagesIngles - 1 - Bach - Modulo - 2 (20 - 21)John Alex Almeida50% (2)

- MAF 451 Suggested Solutions - A) I) Process 1Document9 pagesMAF 451 Suggested Solutions - A) I) Process 1anis izzatiNo ratings yet

- Module 5: Number Systems: Introduction To Networks v7.0 (ITN)Document16 pagesModule 5: Number Systems: Introduction To Networks v7.0 (ITN)Mihai MarinNo ratings yet

- Barista TestDocument7 pagesBarista Testwinnie chanNo ratings yet

- Datasheet d801001Document6 pagesDatasheet d801001Hammad HussainNo ratings yet

- Dpco 151223080520 PDFDocument23 pagesDpco 151223080520 PDFSiva PrasadNo ratings yet

- LAB - Testing Acids & BasesDocument3 pagesLAB - Testing Acids & BasesRita AnyanwuNo ratings yet

- Packet Tracer - VLSM Design and Implementation Practice TopologyDocument3 pagesPacket Tracer - VLSM Design and Implementation Practice TopologyBenj MendozaNo ratings yet

- User Manual of CHISON IVis 60 EXPERT PDFDocument164 pagesUser Manual of CHISON IVis 60 EXPERT PDFJuan Carlos GoyzuetaNo ratings yet

- Cell Signaling - The ComponentsDocument7 pagesCell Signaling - The Componentsk10 Lớp Dinh DưỡngNo ratings yet

- Math912 2Document7 pagesMath912 2Mbq ManbriquaNo ratings yet

- Matter and Materials (Grade 6 English)Document80 pagesMatter and Materials (Grade 6 English)Primary Science Programme100% (5)

- Management of Odontogenic Infection of Primary Teeth in Child That Extends To The Submandibular and Submental Space Case ReportDocument5 pagesManagement of Odontogenic Infection of Primary Teeth in Child That Extends To The Submandibular and Submental Space Case ReportMel FANo ratings yet

- Product Management Software Director in Austin TX Resume Chad ThreetDocument2 pagesProduct Management Software Director in Austin TX Resume Chad ThreetChad ThreetNo ratings yet

- Cognitive InfocommunicationsDocument229 pagesCognitive Infocommunicationsradhakodirekka8732No ratings yet

- Ventilation WorksheetDocument1 pageVentilation WorksheetIskandar 'muda' AdeNo ratings yet

- Popis Na OK KoziDocument325 pagesPopis Na OK KoziViktor ArsovNo ratings yet

- Clostridium BotulinumDocument37 pagesClostridium Botulinummaria dulceNo ratings yet

- Router Board Performance TestsDocument2 pagesRouter Board Performance TestsedkaviNo ratings yet

- Beg 2018 XXDocument42 pagesBeg 2018 XXFranz Gustavo Vargas MamaniNo ratings yet

- Improving Radar Echo Lagrangian Extrapolation Nowcasting by Blending Numerical Model Wind Information: Statistical Performance of 16 Typhoon CasesDocument22 pagesImproving Radar Echo Lagrangian Extrapolation Nowcasting by Blending Numerical Model Wind Information: Statistical Performance of 16 Typhoon CasesLinh DinhNo ratings yet

- 17 Samss 518Document20 pages17 Samss 518Mohamed H. ShedidNo ratings yet

- 2.fundamentals of MappingDocument5 pages2.fundamentals of MappingB S Praveen BspNo ratings yet

- Factors Influencing The Selection Of: MaterialsDocument22 pagesFactors Influencing The Selection Of: MaterialsMaulik KotadiyaNo ratings yet

- 9.LearnEnglish Writing A2 Instructions For A Colleague PDFDocument5 pages9.LearnEnglish Writing A2 Instructions For A Colleague PDFوديع القباطيNo ratings yet

- Getting Started HANADocument86 pagesGetting Started HANAAr RazaNo ratings yet

- Install Sensor Lsi Fl061Document14 pagesInstall Sensor Lsi Fl061AlterSon Grafi KalayNo ratings yet

- SPE-171076-MS The Role of Asphaltenes in Emulsion Formation For Steam Assisted Gravity Drainage (SAGD) and Expanding Solvent - SAGD (ES-SAGD)Document14 pagesSPE-171076-MS The Role of Asphaltenes in Emulsion Formation For Steam Assisted Gravity Drainage (SAGD) and Expanding Solvent - SAGD (ES-SAGD)Daniel FelipeNo ratings yet

- Maruti FinalDocument23 pagesMaruti FinalYash MangeNo ratings yet

- Set B Cluster 3 (Final) (Aug102015)Document4 pagesSet B Cluster 3 (Final) (Aug102015)Kuo Sarong100% (1)