Professional Documents

Culture Documents

Forta 316L/4404 Stainless Steel Properties

Uploaded by

pcman147Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Forta 316L/4404 Stainless Steel Properties

Uploaded by

pcman147Copyright:

Available Formats

Forta 316L/4404

EN 1.4404, ASTM TYPE 316L / UNS S31603

General characteristics Typical applications

Outokumpu grade 4404 is an austenitic stainless steel, which • pulp & paper industry

belongs to the family of the standard CrNiMo stainless steels. • stack liners

Grade 4404 is the variant with low carbon content for improved • heat exchangers

resistance against intergranular corrosion after welding. • storage tanks

Due to their molybdenum content, the austenitic CrNiMo • process equipment

standard grades can be used in applications with increased • tank containers

demand for corrosion resistance. Their well

well--balanced material • piping

properties make them suitable for the fabrication of many • swimming pools

products. • food & beverage industry

Grade 4404 is available in many product forms and dimensions, • pharmaceutical industry

commonly also from many stainless steel stockholders. It can be • chemical industry

supplied with a wide range of functional and aesthetic surface • textile finishing

finishes. • roofs & façade cladding

• street ware & outdoor furniture

• art & monuments

Products & dimensions

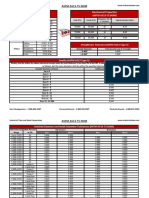

Cold rolled products available dimensions in mm

Coil / Strip Plate / Sheet

Surface finish Thickness Width Thickness Width

2H Work hardened 0,05

0,05--6,00 3-1530 0,25

0,25--6,00 18

18--1530

1 - Outokumpu 4404 Printed: 26 maj 2015

Chemical composition

The chemical composition of specific steel grades may vary slightly between different national standards. The required standard will be

fully met as specified on the order.

The typical chemical composition for this grade is given in the table below, together with composition limits given for this grade according

to different standards. The required standard will be fully met as specified on the order.

The chemical composition is given as % by weight.

C Mn Cr Ni Mo N Other

Typical 0.020 17.2 10.1 2.1

ASME II A SA

SA--240 0.030

≤0.030 2.00

≤2.00 16.0

16.0--18.0 10.0

10.0--14.0 2.00

2.00--3.00 0.10

≤0.10

ASTM A240 0.030

≤0.030 2.00

≤2.00 16.0

16.0--18.0 10.0

10.0--14.0 2.00

2.00--3.00 0.10

≤0.10

ASTM A666 0.030

≤0.030 2.00

≤2.00 16.0

16.0--18.0 10.0

10.0--14.0 2.00

2.00--3.00 0.10

≤0.10

EN 10028

10028--7 0.030

≤0.030 2.00

≤2.00 16.5

16.5--18.5 10.0

10.0--13.0 2.00

2.00--2.50 0.10

≤0.10

EN 10088

10088--2 0.030

≤0.030 2.0

≤2.0 16.5

16.5--18.5 10.0

10.0--13.0 2.0

2.0--2.5 0.11

≤0.11

EN 10088

10088--4 0.030

≤0.030 2.0

≤2.0 16.5

16.5--18.5 10.0

10.0--13.0 2.0

2.0--2.5 0.11

≤0.11

Corrosion resistance

Outokumpu grade 4404 has excellent corrosion resistance in solutions of many halogenhalogen--free organic and inorganic compounds over a

wide temperature and concentration range. It can withstand many organic and diluted mineral acids depending on the temperature and

concentration of the solution. Grade 4404 may suffer from uniform corrosion in strong mineral acids and hot strong alkaline solutions.

More detailed information on corrosion properties of grade 4404 can be found in Outokumpu

Outokumpu’’s Corrosion Tables published in the

Outokumpu Corrosion Handbook and on www.outokumpu.com

www.outokumpu.com..

Due to its low carbon content, the risk of sensitisation for intergranular corrosion after welding of up to 6 mm thick sheets is strongly

reduced when compared to austenitic CrNiMo grade 4401 with normal carbon content.

In aqueous solutions containing halogenides like e.g. chlorides or bromides, pitting and crevice corrosion may occur depending on

halogenide concentration, temperature, pH pH--value, concentration of oxidizing compounds and crevice geometry, if applicable. The

presence of corrosion inhibiting or accelerating compounds like e.g. transition metal ions or organic compounds may influence the

corrosion behaviour of grade 4404.

Grade 4404 is prone to chloride

chloride--induced stress corrosion cracking at temperatures over about 50°C depending on the applied stress and

the chloride concentration in the environment. Prior cold deformation of the structure under load increases the risk for stress corrosion

cracking.

Grade 4404 can be used for indoor and outdoor applications in rural, urban and moderately corrosive industrial environments. When

chloride contamination may be high like for instance in coastal areas, pitting and staining is possible. The best material performance is

reached usually with the help of adequate design, correct post

post--weld treatment and regular cleaning during use (if applicable).

For more information on corrosion resistance refer to the Outokumpu Corrosion Handbook or contact the Outokumpu corrosion experts.

Pitting corrosion resistance Crevice corrosion resistance

PRE CPT CCT

24 20

20±±2 <0

PRE Pitting Resistant Equivalent calculated using the formula: PRE = %Cr + 3.3 x %Mo + 16 x %N

CPT Corrosion Pitting Temperature as measured in the Avesta Cell (ASTM G 150), in a 1M NaCl solution (35,000 ppm or mg/l chloride

ions).

CCT Critical Crevice Corrosion Temperature is the critical crevice corrosion temperature which is obtained by laboratory tests according

to ASTM G 48 Method F

2 - Outokumpu 4404 Printed: 26 maj 2015

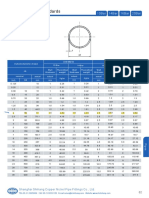

Mechanical properties

The mechanical properties of the available products are given in the table below.

The mechanical properties of the available products in soft annealed condition at room temperature are given in the table below.

Moderate strengths can be reached at elevated temperatures (~550°C / 1022 °F). Temperatures for excessive scaling are close to 850°

C/1562°F. This grade among other austenitic corrosion resistant steels exhibits very high ductility and high elongation to fracture. It is

not susceptible to brittle fracture in the solution annealed condition.

Rp0.2 Rp1.0 Rm Impact

Cold rolled coil and sheet MPa MPa MPa strength J Rockwell HB HV

Typical (Thickness 1mm) 300 325 625

ASME II A SA

SA--240 ≥ 170 ≥ 485 ≤ 217

ASTM A240 ≥ 170 ≥ 485 ≤ 217

EN 10028

10028--7 ≥ 240 ≥ 270 530 - 680

EN 10088

10088--2 ≥ 240 ≥ 270 530 - 680

EN 10088

10088--4 ≥ 240 ≥ 270 530 - 680

Rp0.2 Rp1.0 Rm Impact

Hot rolled coil and sheet MPa MPa MPa strength J Rockwell HB HV

Typical (Thickness 4mm) 300 350 600 170

ASME II A SA

SA--240 ≥ 170 ≥ 485 ≤ 217

ASTM A240 ≥ 170 ≥ 485 ≤ 217

EN 10028

10028--7 ≥ 240 ≥ 270 530 - 680

EN 10088

10088--2 ≥ 240 ≥ 270 530 - 680

EN 10088

10088--4 ≥ 240 ≥ 270 530 - 680

Rp0.2 Rp1.0 Rm Impact

Hot rolled quarto plate MPa MPa MPa strength J Rockwell HB HV

Typical (Thickness 15mm) 260 300 570

ASME II A SA

SA--240 ≥ 170 ≥ 485 ≤ 95HRB ≤ 217

ASTM A240 ≥ 170 ≥ 485 ≤ 95HRB ≤ 217

ASTM A666 ≥ 170 ≥ 485 ≤ 217

EN 10028

10028--7 ≥ 220 ≥ 260 520 - 670

EN 10088

10088--2 ≥ 220 ≥ 260 520 - 670

EN 10088

10088--4 ≥ 220 ≥ 260 520 - 670

Rp0.2 Rp1.0 Rm Impact

Wire rod MPa MPa MPa strength J Rockwell HB HV

Typical 220 260 530

1)Elongation according to EN standard:

A80 for thickness below 3 mm.

A for thickness = 3 mm.

Elongation according to ASTM standard A2” or A50.

3 - Outokumpu 4404 Printed: 26 maj 2015

Physical properties

Physical properties according to EN 10088 are shown below.

Modulus of Thermal exp. at Thermal Thermal Electrical

Density elasticity 100°C conductivity capacity resistance Magnetizable

kg/dm3 GPa 10-6/°C W/m°C J/kg°C µΩm

8.0 200 16,0 15 500 0.75 No

Fabrication

Cold forming

These grades can be readily formed and fabricated by a full range of cold working operations. They can be used in heading, drawing and

bending. Any cold working operations will increase the strength and hardness of the material.

Hardening

These grades cannot be hardened by heat treatment. However, they can be hardened by cold working.

Hot forming

Hot working can be carried out in the 850 – 1150°C range. For maximum corrosion resistance, forgings should be annealed at 1070°C

and rapidly cooled in air or water after hot working operations.

Heat treatment

Annealing

Quench annealing should be performed at 1030 – 1110°C and followed by rapid cooling in water or air.

In applications where high residual stresses cannot be accepted, stress relief treatment may be necessary.

This can be performed by annealing as outlined above, but may also be performed at lower temperatures.

Please contact Outokumpu Stainless for further information.

Machining

These austenitic grades are more difficult to machine than ordinary carbon steels but are still comparatively easy to machine compared

to more highly alloyed stainless grades. Unless modified for improved machinability, they require higher cutting forces than carbon steels,

show resistance to chip breaking and a high tendency to built

built--up edge formation. The best machining results are obtained by using

highpower equipment, sharp tooling and a rigid setset--up. Better machinability performance is given by PRODEC versions, which have been

modified for improved machinability. PRODEC is available as hot rolled plate and bar in 4401, 4404, 4436 and 4432.

Welding

Austenitic stainless steel Outokumpu 4404 grade has excellent weldability and is suited to a full range of conventional welding methods

(like MMA, MIG, MAG, TIG, SAW, LBW or RSW), except gas welding. Austenitic 4404 have about 50% higher thermal expansion and lower

heat conductivity compared to carbon steels. This means that larger deformation and higher shrinkage stresses may result from welding.

In thin sections, autogenous welding may be used. To ensure that the weld metal properties (e.g. strength, corrosion resistance) are

equivalent to those of the parent metal, matching or slightly over

over--alloyed fillers should preferably be used. Recommended filler metal is

19 12 3L.

Generally post weld heat treatment is not required. In special cases with high risks of stress corrosion cracking or fatigue, stress relief

treatment may be considered.

In order to fully restore the corrosion resistance of the weld seam, the weld discoloration should be removed by pickling and passivation.

More detailed information concerning welding procedures can be obtained from the Outokumpu Welding Handbook, available from our

sales offices.

Standards & approvals

The most commonly used international product standards are given in the table below.

Standard Designation

ASME SA

SA--240M Code Sect. II. Part A TYPE 316L / UNS S31603

ASTM A 666

666--03 Anneal&cold

Anneal&cold--work TYPE 316L / UNS S31603

ASTM A240/A240M TYPE 316L / UNS S31603

EN 10028

10028--7, PED 97/23/EC 1.4404

4 - Outokumpu 4404 Printed: 26 maj 2015

EN 10088

10088--2 1.4404

EN 10088

10088--4 1.4404

Contacts & Enquiries

Contact your nearest sales office

www.outokumpu.com/contacts

5 - Outokumpu 4404 Printed: 26 maj 2015

Working towards forever.

We work with our customers and

partners to create long lasting solutions

for the tools of modern life and the

world

world’’s most critical problems: Clean

energy, clean water and efficient

infrastructure. Because we believe in a

world that lasts forever.

Information given in this brochure may be subject to alterations without notice. Care has been taken to ensure that the contents of this

publication are accurate but Outokumpu and its affiliated companies do not accept responsibility for errors or for information which is

found to be misleading. Suggestions for or descriptions of the end use or application of products or methods of working are for information

only and Outokumpu and its affiliated companies accept no liability in respect thereof. Before using products supplied or manufactured by

the company the customer should satisfy himself of their suitability

outokumpu.com

steelfinder.outokumpu.com

6 - Outokumpu 4404 Printed: 26 maj 2015

7 - Outokumpu 4404 Printed: 26 maj 2015

You might also like

- 001 AggregateDocument4 pages001 Aggregatevanessa ImlerNo ratings yet

- Ferritic Stainless Steel Core 441/4509 GuideDocument5 pagesFerritic Stainless Steel Core 441/4509 GuideEnrique Ruiz HonoratoNo ratings yet

- Ovako 20NiCrMoS2-2 4548, MoCN 206 M Steel, +ADocument2 pagesOvako 20NiCrMoS2-2 4548, MoCN 206 M Steel, +Aayoube mecaNo ratings yet

- PT. Tekenomiks Indonesia: 05357110 PT - Kalimantan Prima Persada - SangattaDocument2 pagesPT. Tekenomiks Indonesia: 05357110 PT - Kalimantan Prima Persada - SangattaReksiNo ratings yet

- Astm-A519 - 06Document13 pagesAstm-A519 - 06claudiaNo ratings yet

- Micro Alloyed Steels Voestalpine EN 30102020Document4 pagesMicro Alloyed Steels Voestalpine EN 30102020pierocarnelociNo ratings yet

- Lincoln (Data Sheet) Murex E7024Document2 pagesLincoln (Data Sheet) Murex E7024PubcrawlNo ratings yet

- 3F38E25D 64A8 410F 9C801CD965DE26AD Uniram RC Technical InformationDocument12 pages3F38E25D 64A8 410F 9C801CD965DE26AD Uniram RC Technical InformationRADHAMES ASTACIONo ratings yet

- All Single Values Except EN8D Show Maximum Limit: Elements SR No Grade Carbon Manganese Phosphorus Sulfur SiliconDocument3 pagesAll Single Values Except EN8D Show Maximum Limit: Elements SR No Grade Carbon Manganese Phosphorus Sulfur SiliconkartikNo ratings yet

- Micro-Alloyed Steels: High-Strength Steels With Yield Strengths Up To 550 MpaDocument4 pagesMicro-Alloyed Steels: High-Strength Steels With Yield Strengths Up To 550 MpacurtisvaleroNo ratings yet

- P460 N Europe Standard P460 N Europe Standard P460 N P460 NDocument2 pagesP460 N Europe Standard P460 N Europe Standard P460 N P460 NLuis AvilaNo ratings yet

- Seamless Carbon and Alloy Steel Mechanical Tubing: Standard Specification ForDocument13 pagesSeamless Carbon and Alloy Steel Mechanical Tubing: Standard Specification ForTamil funNo ratings yet

- Generalized Soil Profile: Cone Resistance (kg/cm2)Document3 pagesGeneralized Soil Profile: Cone Resistance (kg/cm2)Md Zamzuri Md YunusNo ratings yet

- BS3100 CastingDocument1 pageBS3100 Castingrakesh100% (1)

- 16 Bs en 10025 2 2004 Hot Rolled Products of Structural Steel PDFDocument5 pages16 Bs en 10025 2 2004 Hot Rolled Products of Structural Steel PDFmaga2000No ratings yet

- BEMAnnex4 (CaractéristiquesdesMatériaux)Document3 pagesBEMAnnex4 (CaractéristiquesdesMatériaux)HTR WAS HERENo ratings yet

- Hot-Rolled Wire Rod GuideDocument2 pagesHot-Rolled Wire Rod GuideEltjon PumiNo ratings yet

- Laser Cutting Process Parameters - O2&N2: Material Thickness Speed M/min Speed M/min Speed M/minDocument2 pagesLaser Cutting Process Parameters - O2&N2: Material Thickness Speed M/min Speed M/min Speed M/minbeemasundarNo ratings yet

- Cutting Speed and Feed Recommendations TableDocument1 pageCutting Speed and Feed Recommendations Tablegame downloadNo ratings yet

- Material delivery specificationsDocument2 pagesMaterial delivery specificationsviyfNo ratings yet

- Ductile Iron Grade 60-40-18, Low Temperature ServiceDocument2 pagesDuctile Iron Grade 60-40-18, Low Temperature Servicevamsi patnalaNo ratings yet

- Ferrous Weld Metal Classification ChartDocument1 pageFerrous Weld Metal Classification ChartBruno SantosNo ratings yet

- LFBCW510L TN enDocument4 pagesLFBCW510L TN endrgilleNo ratings yet

- ASTM A234 2010 (No Oficial)Document10 pagesASTM A234 2010 (No Oficial)Santiago Loría NavaNo ratings yet

- ASTM A513-T5 DOM Mechanical Properties and SpecificationsDocument3 pagesASTM A513-T5 DOM Mechanical Properties and SpecificationsOscar JuárezNo ratings yet

- Din 6346Document2 pagesDin 6346Dule JovanovicNo ratings yet

- Oven Calibration Report for NH ProjectDocument2 pagesOven Calibration Report for NH ProjectDeepakNo ratings yet

- Copper Nickel Pipe Din86089 Eemua145Document1 pageCopper Nickel Pipe Din86089 Eemua145Araby GamalNo ratings yet

- Cat 2Document1 pageCat 2Sheva Intania Meilan PutriNo ratings yet

- Chemical Compositions of Stainless SteelsDocument2 pagesChemical Compositions of Stainless Steelsmohamed faragNo ratings yet

- Din 17175 PDFDocument22 pagesDin 17175 PDFMilica Antic0% (1)

- Astm A493 16Document2 pagesAstm A493 16wongNo ratings yet

- HINGED 42MM SERIES PROFILESDocument120 pagesHINGED 42MM SERIES PROFILESViswanathan Kannoor67% (3)

- 100Cr6 & SAE 8620 & 16MnCr5Document3 pages100Cr6 & SAE 8620 & 16MnCr5amh.fpdNo ratings yet

- Oil Tempered Steel WireDocument11 pagesOil Tempered Steel WireHans GoetheNo ratings yet

- C Staehle Kalt Datenblatt EN 1511Document7 pagesC Staehle Kalt Datenblatt EN 1511pierocarnelociNo ratings yet

- BS 3059-2Document11 pagesBS 3059-2abhiNo ratings yet

- Tính Toán Diện Tích Cốt Thép DầmDocument1 pageTính Toán Diện Tích Cốt Thép DầmPhạm HưngNo ratings yet

- Montana Thermal Break 120 MM Sliding SeriesDocument74 pagesMontana Thermal Break 120 MM Sliding SeriesHisham AtraNo ratings yet

- Montana 120Document84 pagesMontana 120Abdul BasithNo ratings yet

- Square Rectangular Hollow SectionDocument76 pagesSquare Rectangular Hollow Sectionbusiness.developmentNo ratings yet

- Justificacion - Planilla de Metrados - Concreto Pre MezcladoDocument5 pagesJustificacion - Planilla de Metrados - Concreto Pre MezcladoRonald Crisostomo LlallicoNo ratings yet

- Vortex 70Document92 pagesVortex 70MajazNo ratings yet

- (4)Document1 page(4)Алексей ЗавгороднийNo ratings yet

- Tính Toán Diện Tích Cốt Thép DầmDocument1 pageTính Toán Diện Tích Cốt Thép DầmPhạm HưngNo ratings yet

- Brush and Brush-Holder Tolerances On "T" and "A" Dimensions: Technical Note Sta Be 16-4 GBDocument2 pagesBrush and Brush-Holder Tolerances On "T" and "A" Dimensions: Technical Note Sta Be 16-4 GBloulou_beNo ratings yet

- Chemical Composition: Si Fe Cu MN MG Ni ZN SN Ti PB CRDocument2 pagesChemical Composition: Si Fe Cu MN MG Ni ZN SN Ti PB CRQuality teamNo ratings yet

- RMA Extruded Tolerance Table International Standard For Rubber ProductsDocument6 pagesRMA Extruded Tolerance Table International Standard For Rubber ProductsSreesanth SaruvilNo ratings yet

- BRUSH and BRUSH-HOLDER TOLERANCES On T and A DIMENSIONS - Carbone Lorraine - INGDocument2 pagesBRUSH and BRUSH-HOLDER TOLERANCES On T and A DIMENSIONS - Carbone Lorraine - INGClaylson Figueiredo JúlioNo ratings yet

- A 53 - A 53m - 00 QtuzltawDocument7 pagesA 53 - A 53m - 00 QtuzltawPablo CzNo ratings yet

- Thermanit Weldingfillermetalsforpowerplantengineering1Document18 pagesThermanit Weldingfillermetalsforpowerplantengineering1DarioNo ratings yet

- Table 1 Chemical RequirementsDocument2 pagesTable 1 Chemical RequirementsmoodydoodyNo ratings yet

- Worksheet in RC Retaining WallDocument1 pageWorksheet in RC Retaining WallteweldeNo ratings yet

- REV - No: 01 DATE OF ISSUE:20.10.2015: Store Control Loading ControlDocument8 pagesREV - No: 01 DATE OF ISSUE:20.10.2015: Store Control Loading ControlMOHAMEDNo ratings yet

- QuadriDocument76 pagesQuadrisvenNo ratings yet

- Plate A36 (2016)Document4 pagesPlate A36 (2016)eko kusumoNo ratings yet

- TB 600 v1Document106 pagesTB 600 v1Saud Affan100% (1)

- 78W 10ni 5Nb 5mo 1Zr 1TiO2Document23 pages78W 10ni 5Nb 5mo 1Zr 1TiO2devi SaravaniNo ratings yet

- Fabrication CostDocument6 pagesFabrication CostChong Cong100% (1)

- 18.625 CSG & CMT PlanDocument2 pages18.625 CSG & CMT PlanMohamed AbozeimaNo ratings yet

- Mezzanine Floor Sanitation ChecklistDocument1 pageMezzanine Floor Sanitation ChecklistSafdar JangNo ratings yet

- Forging Process: Types, Advantages & ApplicationsDocument10 pagesForging Process: Types, Advantages & ApplicationsVipin TitariyaNo ratings yet

- GSE - RODE-1 - 8.5in - Fishing OperationDocument10 pagesGSE - RODE-1 - 8.5in - Fishing OperationMansour MohamedTNo ratings yet

- 3 Marks - MT 2Document2 pages3 Marks - MT 2Shobin BalakrishnanNo ratings yet

- Materials For Shims and Laminated Shim Stock Peel-Plate GMBHDocument4 pagesMaterials For Shims and Laminated Shim Stock Peel-Plate GMBHAVINASH ANAND RAONo ratings yet

- SwissBlue - APKT INSERTSDocument12 pagesSwissBlue - APKT INSERTSgkhnNo ratings yet

- A Basic Guide To Field Paint TestingDocument6 pagesA Basic Guide To Field Paint TestingVinod NairNo ratings yet

- Webinar ChemistryDocument50 pagesWebinar Chemistryilham ditamaNo ratings yet

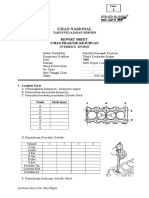

- Report Sheet Overhaul EngineDocument5 pagesReport Sheet Overhaul EngineRoe De HardtoknowNo ratings yet

- Palm Oil Mill ProcessDocument20 pagesPalm Oil Mill Processmuhdjusri50% (2)

- Ishu Kumar PPT UsmDocument16 pagesIshu Kumar PPT UsmIshu BassanNo ratings yet

- Mo Production Processes and ResourcesDocument19 pagesMo Production Processes and ResourcesJo An MeMeNo ratings yet

- Pharmaceutical DryersDocument2 pagesPharmaceutical Dryersf_azarNo ratings yet

- Manufacturing and Metal Working Process ClassificationDocument5 pagesManufacturing and Metal Working Process ClassificationPeeka Prabhakara RaoNo ratings yet

- Xuper Nucleotec 2222Document2 pagesXuper Nucleotec 2222jose amad nolazcoNo ratings yet

- Durmat PTA Laser Thermal SprayDocument32 pagesDurmat PTA Laser Thermal SpraySergeyNo ratings yet

- 05 - Milling Operations in The Lathe - TextDocument64 pages05 - Milling Operations in The Lathe - Textslade_fanNo ratings yet

- Uj2 48 52Document5 pagesUj2 48 52AS BaizidiNo ratings yet

- Comparing Vertical and Horizontal Subsea Christmas TreesDocument22 pagesComparing Vertical and Horizontal Subsea Christmas TreesRuben Waldir Segarra MoralesNo ratings yet

- Edm Wire Cut ReportDocument15 pagesEdm Wire Cut ReportBawen MuralitharanNo ratings yet

- MP Lab ReportDocument4 pagesMP Lab ReportAbdul RehmanNo ratings yet

- Conducting Machining Tests of Wood and Wood-Base Panel MaterialsDocument17 pagesConducting Machining Tests of Wood and Wood-Base Panel Materialsalejo-peña100% (1)

- Catalyst 1Document23 pagesCatalyst 1Julie CabusaoNo ratings yet

- Basic Punching Theory: ©2008 Mate Precision ToolingDocument79 pagesBasic Punching Theory: ©2008 Mate Precision ToolingBong ThoNo ratings yet

- DSM NeoResins+ Film Coatings Provide Functionality and AestheticsDocument69 pagesDSM NeoResins+ Film Coatings Provide Functionality and Aestheticskhalidkhanani100% (2)

- Metallurgical Test Report: NAS Mexico SA de CV Privada Andres Guajardo No. 360 Apodaca, N.L., C.P. 66600 MexicoDocument1 pageMetallurgical Test Report: NAS Mexico SA de CV Privada Andres Guajardo No. 360 Apodaca, N.L., C.P. 66600 MexicoEmigdio MartinezNo ratings yet

- Is 4431yDocument12 pagesIs 4431yEzhil ArasanNo ratings yet

- Carbon Steel s45cDocument4 pagesCarbon Steel s45ctam200No ratings yet