Professional Documents

Culture Documents

2011 Catalog PIC Parte29

Uploaded by

Paolo RossiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2011 Catalog PIC Parte29

Uploaded by

Paolo RossiCopyright:

Available Formats

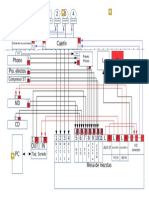

+ 0 V

L

U 0 V

P

–

L

OD

D

TH P LP L

P P

OD OD

D TH W OD TH W

TH P P

ID P

ID

OD

L

ID P

L

L TH L TH

P P

TH P W W

Disks with special electrodes (wrap-around contacts)

Design OD in mm TH in mm Electrodes:

Soldering instructions

for users

10 / 16 / 20 / 20 / 25 / 40 0.5 / 1.0 / 2.0 Fired silver

L

All our metallizations

P

(thick film) can be soldered in

TH W or PVD (thin film) conformance with

L

P RoHS. We recom-

TH W mend the use of a

Rings solder with the com-

position Sn 95.5. Ag

Design OD in mm ID in mm TH in mm Electrodes: 3.8. Cu 0.7. If the

L TH piezoceramic element

10 2.7 0.5 / 1.0 / 2.0 Fired silver

P is heated throughout

10* W 4.3* L 0.5 / 1.0 / 2.0 (thick film)

L TH L above the Curie

OD

OD

TH TH P TH 10* 5* P 0.5 / 1.0 / 2.0 or CuNi temperature, the

W P

12.7 5.2* 0.5 / 1.0 / 2.0 (thin film)

material is depolari-

zed, and there is thus

25 16* 0.5 / 1.0 / 2.0 a loss of, or reduction

*Tolerances as fired, 38 13* 5.0 / 6.0 in, the piezoelectric

s. table p. 27 50 19.7* 5.0 / 6.0 / 9.5 parameters.

OD OD

P This can be prevented

TH TH P

Tubes ID ID by adhering to the

following conditions

Design OD in mm ID in mm L in mm Electrodes: under all circumstan-

ces when soldering:

76 60 50 Inside:

40 38 40 Fired silver ꔴ All soldered

L

20 18 30 (thick film) contacts must be

TH

P point contacts.

10 9 L 30 Outside:

TH 10 8 P 30 Fired silver ꔴ The soldering times

6.35 5.35 30 (thick film)

must be as short

as possible (≤ 3 sec).

3.2 2.2 30 or CuNi or Au

OD 2.2 1.0 20 (thin film) ꔴ The specific

P soldering

TH

ID

OD

temperature must

Tubes with special electrodes

P

not be exceeded.

TH

ID

Design OD in mm ID in mm L in mm Electrodes:

20 18 30 Inside:

10 9 30 Fired silver

Quartered outer 10 8 30 (thick film)

electrodes

6.35 5.53 30 Outside:

3.2 2.2 30 Fired silver

2.2 1.0 30 (thick film)

Wrap-around

contacts or CuNi or Au

(thin film)

29

PIEZOTECHNOLOGY

You might also like

- Mork Borg - Tenebrous - ReliquaryDocument7 pagesMork Borg - Tenebrous - ReliquaryMat100% (5)

- Uncut September 2017 PDFDocument125 pagesUncut September 2017 PDFDee EffNo ratings yet

- Alcohol, Phenol and Ethers Digital Notes by Bharat PanchalDocument24 pagesAlcohol, Phenol and Ethers Digital Notes by Bharat Panchalzaid ansari86% (7)

- SEAL SELECTION GUIDEDocument2 pagesSEAL SELECTION GUIDEZAMFERLENONo ratings yet

- Bit RecordDocument1 pageBit RecordstevebeardsleyNo ratings yet

- Learn About Rocks and MineralsDocument6 pagesLearn About Rocks and MineralsDarwin SawalNo ratings yet

- Sans 1200 LeDocument9 pagesSans 1200 Lefilipe100% (1)

- Nickel and Nickel-Base Alloy-Clad Steel Plate: Standard Specification ForDocument6 pagesNickel and Nickel-Base Alloy-Clad Steel Plate: Standard Specification Forsharon blushteinNo ratings yet

- Peri Tillbehör PDFDocument20 pagesPeri Tillbehör PDFAchmadRiduwanNo ratings yet

- Welding CrackingDocument8 pagesWelding CrackingjensdcvNo ratings yet

- 2011 Catalog PIC Parte27Document1 page2011 Catalog PIC Parte27Paolo RossiNo ratings yet

- Chaín AgriculturalDocument3 pagesChaín AgriculturalWilheam Mamani CasillaNo ratings yet

- Esquema Eixea Corr PDFDocument1 pageEsquema Eixea Corr PDFpuçaNo ratings yet

- Samsung Chassis S66ADocument18 pagesSamsung Chassis S66AНиколай ПолNo ratings yet

- Chain Descriptions and Dimensions: Standard Attachment Roller ChainDocument4 pagesChain Descriptions and Dimensions: Standard Attachment Roller ChainmakanakiliNo ratings yet

- Ai FLEX Interior LED Strip FixtureDocument5 pagesAi FLEX Interior LED Strip FixtureRobert CNo ratings yet

- 12mm diameter sag rod connectionDocument1 page12mm diameter sag rod connectionNathaniel Llido HamotNo ratings yet

- NTC Thermistor:TTC05 Series: Ф5 mm Lead Type for Temperature Sensing/CompensationDocument8 pagesNTC Thermistor:TTC05 Series: Ф5 mm Lead Type for Temperature Sensing/Compensationümit ilyas balNo ratings yet

- SANDOWN22 TrackMapDocument1 pageSANDOWN22 TrackMapjmcnally648No ratings yet

- Change of Dimensions Stress Strain TheoryDocument1 pageChange of Dimensions Stress Strain TheoryHILMAN NAZRINo ratings yet

- Dokumen - Tips - PNP Patrol Plan 2030 Guidebook 17Document1 pageDokumen - Tips - PNP Patrol Plan 2030 Guidebook 17mogijo11asaffdffdfgdfgNo ratings yet

- Fowzia N Zainab CCTV DWG, P-2091Document3 pagesFowzia N Zainab CCTV DWG, P-2091Great impressionsNo ratings yet

- Perfection: The Entire Foam Core)Document3 pagesPerfection: The Entire Foam Core)2222222No ratings yet

- Notam DecodeDocument16 pagesNotam DecodeEduardo LuqueNo ratings yet

- ComeineDocument1 pageComeineJules LaverdiereNo ratings yet

- ANSI ROLLER CHAIN SPECSDocument1 pageANSI ROLLER CHAIN SPECSKR123No ratings yet

- Hobby Electronics 1978 12Document76 pagesHobby Electronics 1978 12Annamária ApátiNo ratings yet

- JeffDocument1 pageJeffJules LaverdiereNo ratings yet

- Guard Rail On-System Bridge (MASH) Set (4-13-23)Document11 pagesGuard Rail On-System Bridge (MASH) Set (4-13-23)Mike2322No ratings yet

- Financial Statement Analysis: Admin Group 11Document51 pagesFinancial Statement Analysis: Admin Group 11Aakruti Dilip PatodiaNo ratings yet

- Rotary Spoa7-9 Spo9 400 Series Install PDFDocument16 pagesRotary Spoa7-9 Spo9 400 Series Install PDFFranck RoyerNo ratings yet

- Safe N Silent Pro330 - RW-RAY - PSB - EN13501-1 - FIRE CLASSIFICATIONDocument5 pagesSafe N Silent Pro330 - RW-RAY - PSB - EN13501-1 - FIRE CLASSIFICATIONQuyen NgoNo ratings yet

- 92-95 Taillight and Illumination PDFDocument4 pages92-95 Taillight and Illumination PDFRia TriaNo ratings yet

- Satyam ElectronicsDocument12 pagesSatyam ElectronicsDeleter DoraNo ratings yet

- Time Zone MapDocument1 pageTime Zone MapdinkoNo ratings yet

- Catalogo Toshiba Transistores IgbtDocument16 pagesCatalogo Toshiba Transistores Igbtluis daniel suarez narvaezNo ratings yet

- Skymap Enero NorteDocument2 pagesSkymap Enero NorteRobdaniel KoloNo ratings yet

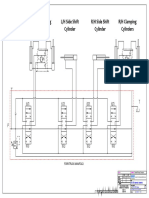

- 5TD STD Hydraulic SchematicDocument1 page5TD STD Hydraulic SchematicYazad DoctorrNo ratings yet

- Main Kart Complete 11 Steering Track RodsDocument1 pageMain Kart Complete 11 Steering Track RodsdannnnuNo ratings yet

- Discrete Igbts: Product GuideDocument16 pagesDiscrete Igbts: Product GuideJuan CarlosNo ratings yet

- CD 2x100 BMSTDocument1 pageCD 2x100 BMSTAhmad SabraNo ratings yet

- 28220 industry driveDocument10 pages28220 industry driveEric ParkerNo ratings yet

- Discrete IGBT Product Guide 2010Document16 pagesDiscrete IGBT Product Guide 2010Edmilson Mendes PimentelNo ratings yet

- Igbt 30F125Document15 pagesIgbt 30F125Efren CisnerosNo ratings yet

- Discrete Igbts: SemiconductorDocument16 pagesDiscrete Igbts: Semiconductormoacir carlos guandaliniNo ratings yet

- Door CloserDocument3 pagesDoor Closermarquin84No ratings yet

- The next step for your businessDocument8 pagesThe next step for your business970186csNo ratings yet

- Soviet StrengthDocument26 pagesSoviet StrengthGanga DahalNo ratings yet

- 01 Direct Optd - Pressure Relief Valves DRV 122115Document4 pages01 Direct Optd - Pressure Relief Valves DRV 122115Bullet DassNo ratings yet

- GT45F122 PDFDocument16 pagesGT45F122 PDFSinkdna AmdNo ratings yet

- 5B5-02 3PU 2pot Part 1Document12 pages5B5-02 3PU 2pot Part 1Witit WattanaNo ratings yet

- Overnight Cloth PadDocument1 pageOvernight Cloth PadAnonymous tIhcNRlpSnNo ratings yet

- T Series PartsListDocument4 pagesT Series PartsListmohammad alhajNo ratings yet

- Pages From FDM (Ducted Split R22)Document1 pagePages From FDM (Ducted Split R22)ZiyadawaliNo ratings yet

- Trails-Overview A1 v1Document1 pageTrails-Overview A1 v1Adrian JessNo ratings yet

- Cielo Nocturno - Febrero 2023Document2 pagesCielo Nocturno - Febrero 2023Yahashua ParedesNo ratings yet

- On-Trade Range Brochure English VersionDocument8 pagesOn-Trade Range Brochure English VersionHidden GardenNo ratings yet

- 5B5-02 3PU 3pot Part 1Document12 pages5B5-02 3PU 3pot Part 1Carsons TLHNo ratings yet

- ModelsDocument11 pagesModelsPranjal AgarwalNo ratings yet

- Knit Tops, Tees, Tunics & MoreDocument11 pagesKnit Tops, Tees, Tunics & MoreLucId NguyễnNo ratings yet

- T-1 (3Mm) Low Current Led LampsDocument5 pagesT-1 (3Mm) Low Current Led Lampsioan jeanNo ratings yet

- BruhhhDocument1 pageBruhhhJules LaverdiereNo ratings yet

- Registro Auxiliar de Religion Primaria 2023 LetrasDocument4 pagesRegistro Auxiliar de Religion Primaria 2023 LetrasSebastian HuamanNo ratings yet

- Registro Auxiliar de Redaccion Primaria 2023 LetrasDocument3 pagesRegistro Auxiliar de Redaccion Primaria 2023 LetrasSebastian HuamanNo ratings yet

- Hi-Cap Wedge Stock QD SheavesDocument18 pagesHi-Cap Wedge Stock QD SheavesAlex LopezNo ratings yet

- 2011 Catalog PIC Parte36Document1 page2011 Catalog PIC Parte36Paolo RossiNo ratings yet

- 2011 Catalog PIC Parte37Document1 page2011 Catalog PIC Parte37Paolo RossiNo ratings yet

- 2011 Catalog PIC Parte35Document1 page2011 Catalog PIC Parte35Paolo RossiNo ratings yet

- 2011 Catalog PIC Parte38Document1 page2011 Catalog PIC Parte38Paolo RossiNo ratings yet

- 2011 Catalog PIC Parte33Document1 page2011 Catalog PIC Parte33Paolo RossiNo ratings yet

- 2011 Catalog PIC Parte31Document1 page2011 Catalog PIC Parte31Paolo RossiNo ratings yet

- 2011 Catalog PIC Parte32Document1 page2011 Catalog PIC Parte32Paolo RossiNo ratings yet

- 2011 Catalog PIC Parte34Document1 page2011 Catalog PIC Parte34Paolo RossiNo ratings yet

- 2011 Catalog PIC Parte28Document1 page2011 Catalog PIC Parte28Paolo RossiNo ratings yet

- 2011 Catalog PIC Parte30Document1 page2011 Catalog PIC Parte30Paolo RossiNo ratings yet

- 2011 Catalog PIC Parte26Document1 page2011 Catalog PIC Parte26Paolo RossiNo ratings yet

- 2011 Catalog PIC Parte24Document1 page2011 Catalog PIC Parte24Paolo RossiNo ratings yet

- 2011 Catalog PIC Parte25Document1 page2011 Catalog PIC Parte25Paolo RossiNo ratings yet

- 2011 Catalog PIC Parte23Document1 page2011 Catalog PIC Parte23Paolo RossiNo ratings yet

- 2011 Catalog PIC Parte13Document1 page2011 Catalog PIC Parte13Paolo RossiNo ratings yet

- 2011 Catalog PIC Parte25Document1 page2011 Catalog PIC Parte25Paolo RossiNo ratings yet

- 2011 Catalog PIC Parte19Document1 page2011 Catalog PIC Parte19Paolo RossiNo ratings yet

- 2011 Catalog PIC Parte21Document1 page2011 Catalog PIC Parte21Paolo RossiNo ratings yet

- 2011 Catalog PIC Parte22Document1 page2011 Catalog PIC Parte22Paolo RossiNo ratings yet

- 2011 Catalog PIC Parte14Document1 page2011 Catalog PIC Parte14Paolo RossiNo ratings yet

- 2011 Catalog PIC Parte12Document1 page2011 Catalog PIC Parte12Paolo RossiNo ratings yet

- 2011 Catalog PIC Parte20Document1 page2011 Catalog PIC Parte20Paolo RossiNo ratings yet

- 2011 Catalog PIC Parte17Document1 page2011 Catalog PIC Parte17Paolo RossiNo ratings yet

- 2011 Catalog PIC Parte15Document1 page2011 Catalog PIC Parte15Paolo RossiNo ratings yet

- 2011 Catalog PIC Parte16Document1 page2011 Catalog PIC Parte16Paolo RossiNo ratings yet

- 2011 Catalog PIC Parte11Document1 page2011 Catalog PIC Parte11Paolo RossiNo ratings yet

- 2011 Catalog PIC - Parte10 PDFDocument1 page2011 Catalog PIC - Parte10 PDFPaolo RossiNo ratings yet

- (Doi 10.1016/B978-0-08-055294-1.00270-1) Efron, N. - Comprehensive Biomaterials - Development of Contact Lenses From A Biomaterial Point of View - Materials, Manufacture, and Cli - Compressed PDFDocument25 pages(Doi 10.1016/B978-0-08-055294-1.00270-1) Efron, N. - Comprehensive Biomaterials - Development of Contact Lenses From A Biomaterial Point of View - Materials, Manufacture, and Cli - Compressed PDFAstrit KiranaNo ratings yet

- STEEL DESIGN (PDF - Io)Document24 pagesSTEEL DESIGN (PDF - Io)Maher AbdullahNo ratings yet

- Standard Test Methods For Conducting Creep, Creep-Rupture, and Stress-Rupture Tests of Metallic MaterialsDocument14 pagesStandard Test Methods For Conducting Creep, Creep-Rupture, and Stress-Rupture Tests of Metallic MaterialsviverefeliceNo ratings yet

- Introduction To Composite Materials (Laminated Composite Materials)Document60 pagesIntroduction To Composite Materials (Laminated Composite Materials)soma_durga6606No ratings yet

- Fibre Rope - Terminology and Good PracticesDocument19 pagesFibre Rope - Terminology and Good PracticesLe Quyen NguyenNo ratings yet

- Green Synthesis of Zinc Oxide Nanoparticles Using Citrus Sinensis ExtractDocument7 pagesGreen Synthesis of Zinc Oxide Nanoparticles Using Citrus Sinensis ExtractClaudia UngureanuNo ratings yet

- 12.3 PPTDocument22 pages12.3 PPTKingProNo ratings yet

- Synthetic Oils: E-Books Download Weblog: Water Engineering WeblogDocument11 pagesSynthetic Oils: E-Books Download Weblog: Water Engineering WeblogalbertofgvNo ratings yet

- Thermodynamically Stabilized B-Cspbi - Based Perovskite Solar Cells With Efficiencies 18%Document6 pagesThermodynamically Stabilized B-Cspbi - Based Perovskite Solar Cells With Efficiencies 18%HalfAton BaiNo ratings yet

- A Course in General ChemistryDocument590 pagesA Course in General Chemistryd010060002No ratings yet

- Astm C-330-04 PDFDocument4 pagesAstm C-330-04 PDFJAlberto LópezNo ratings yet

- Namma Kalvi 12th Chemistry Volume 1 One Mark Study Material 215342Document25 pagesNamma Kalvi 12th Chemistry Volume 1 One Mark Study Material 215342Aakaash C.K.No ratings yet

- The Effect of Strain Rate On Mechanical PropertiesDocument11 pagesThe Effect of Strain Rate On Mechanical Propertiesmechanicaltestinglab.acmsNo ratings yet

- Thisspecificati N: SupersedingDocument33 pagesThisspecificati N: Supersedingshahramm_gh6062No ratings yet

- Hook-Up Solutions Hanley Controls Compressed AirDocument16 pagesHook-Up Solutions Hanley Controls Compressed AirAriel HughesNo ratings yet

- To Hold Tight & Right Anywhere ... EverywhereDocument8 pagesTo Hold Tight & Right Anywhere ... EverywhereRohit JoshiNo ratings yet

- Lesson Plan ME-220 Engineering MaterialsDocument2 pagesLesson Plan ME-220 Engineering MaterialsHajiasifAliNo ratings yet

- Structural steel elements classification and buckling analysisDocument1 pageStructural steel elements classification and buckling analysisNeeraj DubeyNo ratings yet

- Ash Fusion MANUAL-IF2000201209Document118 pagesAsh Fusion MANUAL-IF2000201209Ch Rajeswara RaoNo ratings yet

- Plastics AssignmentDocument2 pagesPlastics AssignmentKatharine MorrisonNo ratings yet

- Batch Asphalt Mixing Plants Brochure Ppb-1591-04-En 221009Document17 pagesBatch Asphalt Mixing Plants Brochure Ppb-1591-04-En 221009Mohammad Rabnawaz imamNo ratings yet

- Awareness of Domestic Solid Waste ManagementDocument6 pagesAwareness of Domestic Solid Waste ManagementJenemarNo ratings yet

- Dektite Diverter and Retrofit Dektite Diverter: Pipe FlashingsDocument2 pagesDektite Diverter and Retrofit Dektite Diverter: Pipe FlashingscherandinhoNo ratings yet

- Kinetic Particle TheoryDocument6 pagesKinetic Particle TheoryHassan AlviNo ratings yet