Professional Documents

Culture Documents

ARM313R Data Sheet

Uploaded by

cakebuildOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ARM313R Data Sheet

Uploaded by

cakebuildCopyright:

Available Formats

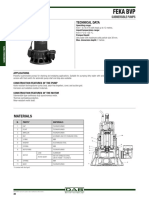

DIMENSIONS (mm/in.

3 Series

Models

309, 312 and 313

CUTAWAY

1 High strength, lightweight

11

die cast crankcase 13

2 Oversized crankshaft

bearings for long life and

1 8

quiet operation

12 FEATURES MODEL SPECIFICATIONS

3 Forged crankshaft is

3 10 • Triplex pumps provide smooth liquid flow Model 309 US METRIC

machined for low friction,

4 5 7 • Liquid cooled, low drag seals provide long life, improved Flow 3.7 gpm 14 lpm

quiet operation and

suction, higher efficiency and longer dry running Pressure 1500 psi 105 bar

high efficiency without damage

4 High strength connecting 2 RPM 1725 1725

• Balanced flow crankcase design and precision machining

rods are tolerance matched for ensure uniform lubrication and quiet operation Shaft .945” 24mm

extended life • Manifold is designed and machined to guarantee Inlet Pressure Flooded to 70 psi 0 to 5 bar

and low friction operation superior fluid flow

6 9 Model 312

5 High polish stainless steel • Interchangeable valves for maintenance ease

• Zero-clearance exclusionary seals protect crankcase Flow 5 gpm 19 lpm

plunger rods for smooth

operation and even wear

Pressure 1500 psi 105 bar

RPM 1725 1725

6 Zero clearance, polymer exclusionary seal protects pump crankcase from fluid entry and will not corrode

QUALITY Shaft .945” 24mm

7 Proprietary blend, solid ceramic plungers for long wear and increased thermal shock resistance

8 Forged brass manifolds for strength and corrosion resistance, machined to optimize fluid flow and performance while • Stainless steel valves with polished valve seats and Inlet Pressure Flooded to 70 psi 0-5 bar

hardened seating surfaces for efficient operation

extending useful life Model 313

• Precision ground ceramic plungers utilize a proprietary

9 Liquid-cooled, low drag seals provide long life, extended run-dry ability and increased suction lift

material blend for long life and increased thermal Flow 4 gpm 15 lpm

10 Stainless steel valves with polished valve seats and hardened seating surfaces for efficient operation shock resistance Pressure 1500 psi 105 bar

11 Mechanically-loaded seals require no adjustment and self-compensate for wear • Forged brass manifolds offer strength and corrosion resistance RPM 1050 1050

12 Balanced flow crankcase ensures lubrication and quiet operation • Proprietary, proven seal blend maximizes life and

Shaft .709” 18mm

13 Slide-in seal cases mean no special tools are required, making seal replacement easy lengthens maintenance intervals

• Oversized crankshaft bearings for long life and quiet operation

Inlet Pressure -5 to 70 psi 0-5 bar

Common Specifications

Arimitsu of North America, Inc.

MAINTENANCE Inlet 1/2” 1/2”

Outlet 3/8” 3/8”

700 McKinley St. NW • No special tools required for repair or maintenance

Oil Requirement 17 oz .5 liter

Anoka, MN 55303 • Fluid end is easily serviced without entering crankcase

Max Liquid Temp. 175˚F 80˚C

ph: 763.433.0303 • Easy access seal case and valve assemblies

• Seals self-compensate for wear

Shaft Location L or R L or R

fax: 763.433.0404 Manufactured by Arimitsu Industry Co, Ltd., of Osaka, Japan, a leading supplier of Industrial Rev.2, 3 Series, (2-06)

www.arimitsupumps.com plunger pumps and systems used by Industrial leaders throughout the World. Part #. 102 Weight 17 lbs 7.5 kg

Parts List Exploded View

REF. # PART NUMBER PART NAME MATERIAL QTY Models 309, 312, 313

F01 0121001010 MANIFOLD FORGED BRASS 1

F05 0122211200 SEAL RETAINER BRASS 3

F06 01222014000A SEAL ASSEMBLY 3

F08 (included in F06) V-PACKING NBR/TEXTILE 3

F09 (included in F06) VACUUM SEAL NBR 3

F22 0122711430 SPREADER BRASS 3

F23 0122201450 WAVE WASHER STAINLESS 3

F25 9203B15026 O-RING, RETAINER NBR 3

F30 0121001130 BOLT, 6MM PLATED STEEL 4

F40 0121003300 VALVE ASSEMBLY 6

F41 (included in F40) SEAT STAINLESS 6

F42 0362003340 O-RING NBR 6

F43 (included in F40) POPPET STAINLESS 6

F44 (included in F40) SPRING STAINLESS 6

F45 (included in F40) CAGE STAINLESS 6

F48 9201F20020 O-RING, VALVE CAP NBR 6

F49 0120003230 VALVE CAP FORGED BRASS 6

P05 0122052010 CRANKCASE ALUMINUM 1

P07 01220020401 BACK COVER PLATED STEEL 1

P08 0120002050 GASKET BONDED PAPER 1

P09 9138A05015 SCREW, PHILLIPS PLATED STEEL 8 09/05

P25 0090002320 DRAIN PLUG FP 1

P26 0090002340 GASKET, DRAIN PLUG NBR 1

P29 01300026000A OIL DIPSTICK ASSEMBLY FP 1 REF. # PART NUMBER PART NAME MATERIAL QTY

P31 9201B20016 O-RING, DIPSTICK NBR 1 30114 SEAL KIT, (F06, F25) NBR 1

P37 0122051730 WATER SLINGER NBR 3 30108 VALVE KIT, (F40) STAINLESS/FP 2

P40 01200024001A OIL SEAL ASSEMBLY NBR 3 30102 RAIL, STANDARD PLATED STEEL 2

P50 0122844010 CRANKSHAFT (309) STEEL 1 30113 RAIL, 310/5CP REPLACEMENT (SET) PLATED STEEL 1

0122454010 CRANKSHAFT (312) STEEL 1 30103 OIL, BOTTLE (32 OZ) ISO 100 1

0122140101 CRANKSHAFT (313) STEEL 1

Recommended Accessories (309 & 312 only)

P51 9180630500 BEARING, BALL STEEL 2

P53 0256004030 OIL SEAL, SHAFT SIDE NBR 1 70201 CLUTCH KIT, 7” SINGLE GROOVE, 24mm STEEL 1

P54 0256104430 OIL SEAL, COVER NBR 1

P56 0122004600 CON-ROD ASSEMBLY ALUMINUM 3 Horsepower Requirements Pressure (psi) Formulas

P60 01220547S0 PLUNGER ASSEMBLY 3

P61 (included in F60) ROD STAINLESS 3 RPM GPM LPM 800 1000 1200 1400 1500

Determining Rated GPM

P62 (included in F60) PLUNGER CERAMIC 3

600 1.3 5.1 0.7 0.9 1.1 1.2 1.3 = “Desired” GPM

P63 (included in F60) SPACER BRASS 3 Pump RPM Rated RPM “Desired” RPM

P66 (included in F60) BOLT STAINLESS 3 309 1400 3.0 11.9 1.6 2.0 2.5 2.9 3.1

P64 0121114852 GASKET COPPER 3 1725 3.7 14.6 2.0 2.5 3.0 3.5 3.8

P65 0030004900 PIN, PLUNGER STEEL 3 1000 3.0 11.8 1.6 2.0 2.4 2.8 3.0 Determining GPM x PSI

=

Electric Brake

P70 02560044201 COVER, BEARING PLATED STEEL 2 Required HP 1460 H.P. Required

P80 0150008050A SHAFT KEY, STEPPED STEEL 1

312 1350 4.0 15.9 2.2 2.7 3.3 3.8 4.1

1725 5.1 20.3 2.8 3.5 4.2

* Material listed may be a proprietary version. Parts names without part numbers are only available 950 3.6 14.3 2.0 2.5 3.0 3.5 3.7 Determining Motor Pulley OD Pump Pulley OD

Motor Pulley

=

within complete assemblies. Pump RPM Motor RPM

* Material codes: FP=Flouropolymer, NBR=Medium Nitrile (Buna-N), 313 1050 4.0 15.8 2.2 2.7 3.3 3.8 4.1

Size

STAINLESS=Stainless Steel (300 Series) 1450 5.5 21.9 3.0 3.8 4.5

You might also like

- Bearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsFrom EverandBearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsRating: 4 out of 5 stars4/5 (1)

- 7 Series: Model 709Document4 pages7 Series: Model 709Dark CenobiteNo ratings yet

- Chainsaw Carving for Beginners: Patterns and 250 Step-by-Step PhotosFrom EverandChainsaw Carving for Beginners: Patterns and 250 Step-by-Step PhotosNo ratings yet

- 35 Frame Plunger Pumps: Specifications FeaturesDocument4 pages35 Frame Plunger Pumps: Specifications FeaturesAnonymous alQXB11EgQNo ratings yet

- Models 3180/3185Document40 pagesModels 3180/3185Israel ColinaNo ratings yet

- 3520 Cat PDFDocument4 pages3520 Cat PDFluis mirandaNo ratings yet

- Data Sheets Pneumatic Actuators KTM en en 5196736Document6 pagesData Sheets Pneumatic Actuators KTM en en 5196736VarshaNo ratings yet

- Ak Series (For Small and Middle Sized Valves) : KTM Pneumatic ActuatorsDocument6 pagesAk Series (For Small and Middle Sized Valves) : KTM Pneumatic ActuatorsVarshaNo ratings yet

- RMT 1240 Product Flyer (RMT)Document1 pageRMT 1240 Product Flyer (RMT)Hector OscarNo ratings yet

- Z22 DoubleSuctionAxiallysplitSingleStageCentrifugalPump60HzUS E10118 USDocument2 pagesZ22 DoubleSuctionAxiallysplitSingleStageCentrifugalPump60HzUS E10118 USediNo ratings yet

- Jonsered Chain Guide 72LGX - F&BDocument2 pagesJonsered Chain Guide 72LGX - F&BMycastNo ratings yet

- Manual de Partes Cat 3507Document4 pagesManual de Partes Cat 3507Julito Santa CruzNo ratings yet

- A Series Air Cooled and Vacuum PumpDocument12 pagesA Series Air Cooled and Vacuum Pumpahmad_394661978No ratings yet

- GARO Liquid Ring CompressorsDocument6 pagesGARO Liquid Ring Compressorsmember1000100% (1)

- CAT 2531 Pump Manual.Document4 pagesCAT 2531 Pump Manual.Armando VelardeNo ratings yet

- A Series Air Cooled and Vacuum Pump BrochureDocument12 pagesA Series Air Cooled and Vacuum Pump BrochureEber.CVNo ratings yet

- Goulds - ICO I-Frame SeriesDocument16 pagesGoulds - ICO I-Frame SeriesAlexNo ratings yet

- Alfa Laval 3s Pumps Emd00458enDocument6 pagesAlfa Laval 3s Pumps Emd00458enMuhd Khir RazaniNo ratings yet

- 5 Frame Plunger Pump: Model Gearbox ModelDocument4 pages5 Frame Plunger Pump: Model Gearbox ModeljulioramcaNo ratings yet

- Section MillingDocument2 pagesSection MillingCharles DesmazuresNo ratings yet

- ZPP Z22 DoubleSuctionAxiallySplitPumps E00502 PDFDocument5 pagesZPP Z22 DoubleSuctionAxiallySplitPumps E00502 PDFAdelmo FilhoNo ratings yet

- Magnum: Rock BitsDocument1 pageMagnum: Rock Bitsmohammad teimuriNo ratings yet

- Quincy Compresor QR25Document8 pagesQuincy Compresor QR25Gabriel Llerena100% (1)

- Product Catalog 2015Document35 pagesProduct Catalog 2015António PedrosaNo ratings yet

- Atlas Copco - Hydraulic Nut SplitterDocument3 pagesAtlas Copco - Hydraulic Nut Splitterlildevil277No ratings yet

- Pellet Mill 7700 Series WebDocument4 pagesPellet Mill 7700 Series WebJavier Moises CastroNo ratings yet

- Pompe LibertyDocument2 pagesPompe LibertytnuscokxlhxzefqkpbNo ratings yet

- 005056B6021E1ED4AEFF0B99E4B424D3Document8 pages005056B6021E1ED4AEFF0B99E4B424D3Cristhian Niño MartinezNo ratings yet

- Sentinel 250 Fire Hydrant: Product FeaturesDocument2 pagesSentinel 250 Fire Hydrant: Product FeaturesBalaji NaikNo ratings yet

- Magnum: Rock BitsDocument1 pageMagnum: Rock Bitsmohammad teimuriNo ratings yet

- PD DF Fam - 4th - 3 17Document16 pagesPD DF Fam - 4th - 3 17sergiomarbellogNo ratings yet

- Lipe Setco BrochureDocument33 pagesLipe Setco BrochurePRASUN NATHNo ratings yet

- Feka BVP Submersible PumpsDocument3 pagesFeka BVP Submersible PumpsMatheus BetoniNo ratings yet

- Shaffer Type SL 13 5:8 Data SheetDocument7 pagesShaffer Type SL 13 5:8 Data Sheetlucas ronaldo coronel mendozaNo ratings yet

- Cabezotes Gardner DenverDocument8 pagesCabezotes Gardner DenverChristian CardenasNo ratings yet

- KombatDocument8 pagesKombatjesus_manrique2753No ratings yet

- V4 SUBMERSIBLE PUMPSET - cUuTUtdDocument8 pagesV4 SUBMERSIBLE PUMPSET - cUuTUtdtayadeyadhneshNo ratings yet

- Mack Maxitorque Es 10 Speed Transmission t310Document3 pagesMack Maxitorque Es 10 Speed Transmission t310Octavio Bellido100% (1)

- Tecreel BrochureDocument4 pagesTecreel Brochureswapnil0211No ratings yet

- CR UiDocument20 pagesCR UiLEKH021No ratings yet

- HHE-VL-Recip-Compressor-Flyer-June-2021-pdf - Original FileDocument2 pagesHHE-VL-Recip-Compressor-Flyer-June-2021-pdf - Original Fileaatishsehgal94No ratings yet

- OPW NozzlesDocument3 pagesOPW NozzlesjayendrapatilNo ratings yet

- Pressure Operated Valves 2 - 2 Air Operated 290 CAT 00047GBDocument8 pagesPressure Operated Valves 2 - 2 Air Operated 290 CAT 00047GBNelson AlvarezNo ratings yet

- 1050 Pump Data SheetDocument4 pages1050 Pump Data SheetRery Dwi SNo ratings yet

- High Torque, Low Inertia, Compact Design: Combination Clutch/BrakeDocument8 pagesHigh Torque, Low Inertia, Compact Design: Combination Clutch/Brakegrupa2904No ratings yet

- Electrovalvulas de Control Filtro MangasDocument2 pagesElectrovalvulas de Control Filtro MangasJosé Emilio Vásquez CarrascoNo ratings yet

- Crompton Greaves Agro Centrifugal Submersible Pumps Catalogues PDFDocument40 pagesCrompton Greaves Agro Centrifugal Submersible Pumps Catalogues PDFbijubijayNo ratings yet

- ProBell Rotary ApplicatorDocument12 pagesProBell Rotary Applicatorgenmar.workNo ratings yet

- R-Series Reciprocating Air Compressor BrochureDocument12 pagesR-Series Reciprocating Air Compressor BrochureAlisha Lynn LacoursiereNo ratings yet

- 3.thick CC122 172 222 322 PDFDocument3 pages3.thick CC122 172 222 322 PDFAlex DreyerNo ratings yet

- Tubing Cutter Replacement WheelsDocument1 pageTubing Cutter Replacement WheelsKTNo ratings yet

- Sump Pumps: Single Channel Soft Solids Handling Sewage PumpDocument2 pagesSump Pumps: Single Channel Soft Solids Handling Sewage PumpMohammad ZeeshanNo ratings yet

- J VLVDocument11 pagesJ VLVjesus_manrique2753No ratings yet

- AirStarDSL - Milk HarvestDocument2 pagesAirStarDSL - Milk HarvestYasir6732No ratings yet

- VMT 330Document6 pagesVMT 330Ansh Mishra100% (1)

- CompresorDocument8 pagesCompresorEliazer Sarca CoaguilaNo ratings yet

- CCFM BrochureDocument3 pagesCCFM BrochureJulian GaleanoNo ratings yet

- EMW Tech Book 1.2Document15 pagesEMW Tech Book 1.2samuel humphreysNo ratings yet

- Spicer 10 Series Driveshafts: Proven Reliability For Light Vehicle ApplicationsDocument2 pagesSpicer 10 Series Driveshafts: Proven Reliability For Light Vehicle ApplicationsPrasadNo ratings yet

- Fairbanks End SuctionDocument16 pagesFairbanks End SuctionKitikhun VichanarksornsitNo ratings yet

- Sensit II Operation and Service Manual PDFDocument62 pagesSensit II Operation and Service Manual PDFcakebuildNo ratings yet

- Dx1000 InstrDocument6 pagesDx1000 InstrcakebuildNo ratings yet

- Ams 39 VRM Operators ManualDocument50 pagesAms 39 VRM Operators ManualcakebuildNo ratings yet

- Shurvend: Big Eagle EnterprisesDocument2 pagesShurvend: Big Eagle EnterprisescakebuildNo ratings yet

- DX300 X4Document3 pagesDX300 X4cakebuildNo ratings yet

- Dx200B Installation and Programming: WiringDocument1 pageDx200B Installation and Programming: WiringcakebuildNo ratings yet

- Dx200D Installation and Programming: WiringDocument1 pageDx200D Installation and Programming: WiringcakebuildNo ratings yet

- Dixmor Dx300 Digital Bay TimerDocument1 pageDixmor Dx300 Digital Bay TimercakebuildNo ratings yet

- DX200 DX200 Flyer FlyerDocument1 pageDX200 DX200 Flyer FlyercakebuildNo ratings yet

- Ad QuadraDocument1 pageAd QuadracakebuildNo ratings yet

- 2012 PriceGuideDocument2 pages2012 PriceGuidecakebuildNo ratings yet

- Ad BigIncomeDocument1 pageAd BigIncomecakebuildNo ratings yet

- TM9-2815-200-35 AVDS-1790-2A M60 EngineDocument780 pagesTM9-2815-200-35 AVDS-1790-2A M60 EngineTom TechoueyresNo ratings yet

- Yamaha Motor CatalogDocument59 pagesYamaha Motor CatalogMagnus Cycles PHNo ratings yet

- Catalogo Typhoon Piaggio 125 4T 2V 2010-2011Document62 pagesCatalogo Typhoon Piaggio 125 4T 2V 2010-2011elysbrNo ratings yet

- 575 & 595 Parts Catalogue PDFDocument93 pages575 & 595 Parts Catalogue PDFRoshan100% (13)

- Sperre HL2:77 Manual and PartsDocument23 pagesSperre HL2:77 Manual and PartsDaniil100% (1)

- Mi 1722Document16 pagesMi 1722amir barekati100% (1)

- Ekm Motor Class 2Document84 pagesEkm Motor Class 2Anonymous 4ylE57C6100% (1)

- TR280i Service ManualENDocument61 pagesTR280i Service ManualENRicardo VargasNo ratings yet

- Yamaha Virago 2007Document61 pagesYamaha Virago 2007YuriLV100% (1)

- OB5 Transmission InfoDocument98 pagesOB5 Transmission InfoRobert Moreau95% (21)

- Perkins 1106D Electrical Inst. GuideDocument60 pagesPerkins 1106D Electrical Inst. GuideAbdul KhaliqNo ratings yet

- 503installationmanual PDFDocument68 pages503installationmanual PDFAndone AnutuNo ratings yet

- BSA Bantam D14-4 Workshop ManualDocument120 pagesBSA Bantam D14-4 Workshop ManualPeter Theodosiussen100% (1)

- Operating Inst - Mikasa Rammer MT76DDocument16 pagesOperating Inst - Mikasa Rammer MT76DVíctor ManuelNo ratings yet

- Chapter 1-1Document19 pagesChapter 1-1محمد عبدالكريم عابدNo ratings yet

- Engine Yuchai YC6MJDocument59 pagesEngine Yuchai YC6MJArfaUjianto100% (1)

- Mar Power Week 1Document15 pagesMar Power Week 1DarkxeiDNo ratings yet

- 3616 5875 kVA 50Hz Continuous LowbsfcDocument6 pages3616 5875 kVA 50Hz Continuous LowbsfcjokanovNo ratings yet

- Engine: Aftermarket Parts ForDocument353 pagesEngine: Aftermarket Parts ForJohn Maisonnett100% (2)

- ENGINE 6.4L - Service Information - Ram Pickup PDFDocument294 pagesENGINE 6.4L - Service Information - Ram Pickup PDFcharlesNo ratings yet

- MC Stradale enDocument58 pagesMC Stradale enaiigee100% (2)

- An Introduction To Internal Combustion EnginesDocument20 pagesAn Introduction To Internal Combustion Enginesmech118No ratings yet

- L23-30H GenSet TierII PDFDocument856 pagesL23-30H GenSet TierII PDFvesper100% (1)

- SM-Bobcat 630, 631, 632 Skid Steer Loader Service Repair Manual PDFDocument284 pagesSM-Bobcat 630, 631, 632 Skid Steer Loader Service Repair Manual PDFbager83% (12)

- SpeedAire ManualDocument56 pagesSpeedAire ManualLizcarroll100% (1)

- Fungsi 1 Operate Main and Auxiliary MachineryDocument3 pagesFungsi 1 Operate Main and Auxiliary MachineryJamaluddinNo ratings yet

- CPI Cheetah XS Service Manual 2tDocument46 pagesCPI Cheetah XS Service Manual 2tKlara PataiNo ratings yet

- CMP40 - 50sD (Lot No - 9684)Document288 pagesCMP40 - 50sD (Lot No - 9684)Eldelson Baggeto100% (1)

- Hatlapa L220, L270, L350Document2 pagesHatlapa L220, L270, L350hao0% (1)