Professional Documents

Culture Documents

TEST LV CABLES SAFELY

Uploaded by

YJoe18Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TEST LV CABLES SAFELY

Uploaded by

YJoe18Copyright:

Available Formats

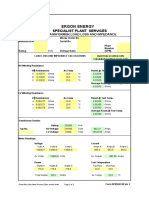

FIELD TEST LV UNDERGROUND CABLE INSTALLATIONS SWP

1. PURPOSE AND SCOPE 3. DOCUMENTATION

CS000501F115. Daily/Task Risk Management Plan

The purpose of this Standard Work Practice (SWP) is to standardise

and prescribe the method for the commissioning of low voltage ES000901R102. Health and Safety Risk Control Guide

underground cable installations. SP0405R01. Field Test LV Underground Cable Installations Job

Safety Analysis

2. STAFFING RESOURCES

SP0405R02. Commissioning LV Underground Cable Installations

Technical Service Person (Electrical Fitter Mechanic or Cable SWP SP0405 - Field instruction

Jointer) and a Competent Assistant. SP0405C01. LV Cable Commissioning Test Report

Safety Observer where required. SP0405C03. LV Cable Inspection and Test Plan

Required Training and Certificates P53. Operate the Network Enterprise Process

Regulatory Training P53K55. Manage Low Voltage Switching for De-Energised Access

on the Network Procedure

Course Code Course Description

SP0203R04. Working at Heights – Elevated Work Platform Safe

2120 Cardio-Pulmonary Resuscitation Work Method Statement

2130 Low Voltage/ Switchboard Rescue Code of Practice Electrical Work Electrical Safety Act 2002

2140 Pole Top Rescue Code of Practice Working Near Exposed Live Parts Electrical Safety

3131 Pole Testing for Safe Access Act 2002

4491 Safe Approach to Structures Work Health and Safety Regulations 2011 (QLD) Division 3

Excavations

Additional Training

Underground Construction Manual

Course Code Course Description

Electrical Safety Regulation 2002 Section 12, 14(2)

4365 Joint and Terminate LV Polymeric Cables

3071 Confirmed Space Awareness

4. KEY TOOLS AND EQUIPMENT

3070 Safe Work in Confined Spaces, if required Insulating gloves applicable to task, work gloves, safety headwear

where gravitational hazards exist, safety eyewear and footwear, high

UETTDRRF07A Perform Cable Pit/Trench/Excav visibility clothing, protective clothing, hearing protection, and sun

T0405

Rescue, if required

protection.

4480 Low Voltage Switching & Access Pole top rescue kit LV Rescue Kit (where required).

Check this is the latest Process Zone version before use. Page 1 of 4 Standard Work Practice SP0405 Ver 8

Ergon Energy Corporation Limited ABN 50 087 646 062

Ergon Energy Queensland Pty Ltd ABN 11 121 177 802

FIELD TEST LV UNDERGROUND CABLE INSTALLATIONS SWP

Confined space monitoring and rescue equipment (where required). Assign adequate staffing resources with required competencies to

Roadway warning signs. safely complete task.

Barricading. Ensure all persons required to use test equipment are competent in

its operation.

Work site communication equipment (e.g. 2 way radio, etc).

Assign adequate staffing resources with required competencies to

Test equipment shall comply with Code of Practice for Electrical safely complete tests.

Work Section 6 and be fitted with fused leads (where applicable).

Reinforce requirement to wear all required PPE including applicable

DC insulation resistance tester.

class of gloves. Ensure class 00 gloves, and insulated mats are

Dry chemical fire extinguisher. used while working on or near exposed live parts.

Class 00 Low Voltage Gloves. Live work on LV including testing is only to be performed where a

documented safe system of work is implemented.

5. TASK STEPS

Persons performing electrical testing must ensure electrical

5.1. Carry out an on site risk assessment equipment is tested to confirm electrical work performed is

electrically safe and all persons not necessary for testing are

Prior to performing this activity any hazards associated with

electrically safe.

prerequisite tasks at the worksite shall be identified and assessed

with appropriate control measures implemented and documented in Use roadway warning signs/ barricading to control vehicle and

accordance with Daily/Task Risk Management Plan CS000501F115 pedestrian traffic around work zone and relevant exclusion zones

and using reference document Health and Safety Risk Control Guide around live parts.

ES000901R102. Ground conditions and potential slip/fall hazards in travel path

If any risks cannot be managed or reduced to an acceptable level, considered in CS000501F115 Daily/Task Risk Management Plan.

do not proceed with the task and seek assistance from your

Identify locations defined as confined spaces and ensure compliance

Supervisor.

with confined space entry requirements.

5.2. Preliminary steps

Ensure ready on site access to dry chemical fire extinguisher where

As per constructed drawing supplied to work crew with construction a gas torch is used.

folder. 5.3. Confirm isolation prior to test

Ensure test equipment is suitable for task. Confirm all test

Check phase rotation where required.

equipment is within current test date, calibrated and operational.

Confirm LV fuse carriers open & fuse cartridges removed (where

Select all required test equipment for performing earthing resistance,

applicable).

continuity and insulation resistance, voltage, phase rotation and

polarity tests.

Check this is the latest Process Zone version before use. Page 2 of 4 Standard Work Practice SP0405 Ver 8

Ergon Energy Corporation Limited ABN 50 087 646 062

Ergon Energy Queensland Pty Ltd ABN 11 121 177 802

FIELD TEST LV UNDERGROUND CABLE INSTALLATIONS SWP

Confirm LV cables to be tested are isolated from all sources of value is achieved (minimum allowable resistance on new cables is

supply and tagged, and locked where provision is made, in 100M, minimum allowable resistance prior to energisation of aged

accordance with LV isolation requirements. Ensure all members of cables is 1M) and record readings.

working party sign on and understand requirements of LV Isolation

Section of Daily/Task WH&S Plan. For cables metallic sheaths, disconnect all earth leads/MEN links

and test the Sheath Integrity by applying 1.0kV between the

Ensure class 00 gloves, and insulated mats are used while working Metallic Sheathing (Msh) and Earth. Record values as measured.

on or near exposed live parts. Ensure insulated tools are used while Measured value of 10MΩ or greater is acceptable.

working on or near exposed live parts.

Conduct earth resistance tests at MEN points and record results.

Comply with Working at Heights – Elevated Work Platform

SP0203R04 Safe Work Method Statement when working aloft. Energise Cable And Confirm Polarity.

Ensure ground based persons are clear of drop zone while work is Remove DNOB from LV cable isolation points.

performed aloft. Replace fuse cartridges and close.

5.4. Prove mechanical and electrical integrity of LV cable At the last pillar of each circuit and at sample locations (at intervals

installations no greater than 6 pillars apart):

Confirm by sample (at intervals no greater than 6 pillars apart) that

cable terminations at pillars and poles are tight and phase colours

Check polarity and record (Phase to phase, phase to neutral,

phase to independent earth).

correct.

Disconnect all Multiple Earth Neutral connections of cable section Check phase rotation.

under test.

Phase out to other supply across existing LV open point (where

Remove street light fuses and disconnect associated neutrals at applicable).

street light poles.

Reconnect all Multiple Earth Neutral connections of cable section

Remove any other loads that may be connected to the cable section. under test.

Perform continuity test between each phase and neutral conductor Conduct polarity tests at street lights and reconnect streetlight

combinations with a bridge connected between applicable neutrals.

conductors at cable end and confirm similar resistance values

Confirm all neutral and MEN conductors are reinstated after polarity

between tests (i.e. A-B, B-C, A-C, -N) – a maximum variation of

tests.

10% between readings. Ensure all Tee off sections off the feeder

also have a continuity test performed. 5.5. Final checks

Perform the Insulation Resistance test by applying 1.0kV between Ensure all final tests have been carried out and completed works

phase to phase and phase to neutral (e.g. A-B+C+N+E, B- have been built to the design plan / construction standards.

A+C+N+E, C-A+B+N+E, N-A+B+C+E) for LV cables until a steady

Check this is the latest Process Zone version before use. Page 3 of 4 Standard Work Practice SP0405 Ver 8

Ergon Energy Corporation Limited ABN 50 087 646 062

Ergon Energy Queensland Pty Ltd ABN 11 121 177 802

FIELD TEST LV UNDERGROUND CABLE INSTALLATIONS SWP

Check that the cabinet / padmount is locked, or the pillar lid is

replaced and securely bolted down, where work has been carried in

these areas.

Make the site electrically and mechanically safe and tidy the area

before leaving.

Update all records relevant to the work undertaken.

Check this is the latest Process Zone version before use. Page 4 of 4 Standard Work Practice SP0405 Ver 8

Ergon Energy Corporation Limited ABN 50 087 646 062

Ergon Energy Queensland Pty Ltd ABN 11 121 177 802

You might also like

- Capacitor Bank TestingDocument8 pagesCapacitor Bank TestingIranthaMuthuNo ratings yet

- Safe Useof TelehandlersDocument86 pagesSafe Useof TelehandlersNicolae Burca100% (2)

- Employee Handbook Policies and Procedures SampleDocument5 pagesEmployee Handbook Policies and Procedures SampleAbid IqbalNo ratings yet

- Commission HV Underground CablesDocument12 pagesCommission HV Underground CablesisukuruNo ratings yet

- IBEF Metals-and-Mining-Feb-2023Document44 pagesIBEF Metals-and-Mining-Feb-2023Gurnam SinghNo ratings yet

- User Requirement Specification (URS) of EquipmentsDocument2 pagesUser Requirement Specification (URS) of EquipmentsAshish Mittal0% (1)

- Ee2036 - Flexible Ac Transmission System: 2 Marks and 16 Marks-Question BankDocument27 pagesEe2036 - Flexible Ac Transmission System: 2 Marks and 16 Marks-Question Bankgunasekaran RajendranNo ratings yet

- Failures in Excavator ArmsDocument8 pagesFailures in Excavator ArmsSonyAcerNo ratings yet

- Extrusion Technology (Compatibility Mode)Document64 pagesExtrusion Technology (Compatibility Mode)Nachiappan CNNo ratings yet

- Unit-1 Facts (Part-A & Part-B)Document5 pagesUnit-1 Facts (Part-A & Part-B)Udaya KumarNo ratings yet

- What Is The Difference Between Power and Distribution TransformerDocument8 pagesWhat Is The Difference Between Power and Distribution Transformermaniking1No ratings yet

- T&DDocument5 pagesT&DMATHANKUMAR.SNo ratings yet

- Electromagnetic Fields Temperature: BurdenDocument2 pagesElectromagnetic Fields Temperature: BurdenBashaNo ratings yet

- PR-1159 - Commissioning and Start-UpDocument117 pagesPR-1159 - Commissioning and Start-Upalokc100% (1)

- NI000401R122ver2 Subs Construction ManualDocument57 pagesNI000401R122ver2 Subs Construction ManualmjoratenaxNo ratings yet

- R o Y o B oDocument6 pagesR o Y o B oloffycrazeNo ratings yet

- Wire and CableDocument5 pagesWire and CablejosemartinpenatorresNo ratings yet

- Ts Based All StandardsDocument12 pagesTs Based All Standardsanjes1No ratings yet

- Power Quality Issues, Standards, Monitoring and MitigationDocument2 pagesPower Quality Issues, Standards, Monitoring and MitigationLakshmi Priya SubburajanNo ratings yet

- Site Test Report Date: Contractor's Name: Customer: Sec-Eoa Name of Substation: Acdb-Mccb Trip TestDocument1 pageSite Test Report Date: Contractor's Name: Customer: Sec-Eoa Name of Substation: Acdb-Mccb Trip TestmaheshknmNo ratings yet

- Static VAR Compensation (SVC)Document2 pagesStatic VAR Compensation (SVC)Vedant KulkarniNo ratings yet

- Commissioning Tests For HV Cables PDFDocument12 pagesCommissioning Tests For HV Cables PDFkrcdewanew100% (3)

- EE 466 Power System Protection: University of HailDocument22 pagesEE 466 Power System Protection: University of Hailselvithimmarajan@gmail.comNo ratings yet

- Tinh Dong Ngan Mach Va Ton That Co TaiDocument3 pagesTinh Dong Ngan Mach Va Ton That Co TaiNga VũNo ratings yet

- Substation Commissioning Test Report - SAMPLEDocument1 pageSubstation Commissioning Test Report - SAMPLEArun MuthuramanNo ratings yet

- Psps Unit 1 QBDocument9 pagesPsps Unit 1 QBNaveen RajNo ratings yet

- Psps Ut 2 QBDocument6 pagesPsps Ut 2 QBNaveen RajNo ratings yet

- Mitsubishi Electric Automation Book 2013 enDocument200 pagesMitsubishi Electric Automation Book 2013 enlunatiko21No ratings yet

- QCP 22 HVAC Cab LayingDocument2 pagesQCP 22 HVAC Cab LayingNEERAJ DAHIYANo ratings yet

- EE2036 2 MarksDocument19 pagesEE2036 2 MarksSaravanan RameshNo ratings yet

- Voltage Compensation: Reyes, Sabaña, Sombrado, Valenzuela and VivoDocument17 pagesVoltage Compensation: Reyes, Sabaña, Sombrado, Valenzuela and VivoFreddie MendezNo ratings yet

- Senior Lead Engineer - Electrical: This Job Is Saved SuccessfullyDocument3 pagesSenior Lead Engineer - Electrical: This Job Is Saved SuccessfullySanjay PatelNo ratings yet

- SP0518Document15 pagesSP0518NgigiDanielNo ratings yet

- Power System Pro Switchgear QBDocument9 pagesPower System Pro Switchgear QBKumaranNo ratings yet

- Schematic Wiring Diagram GuideDocument6 pagesSchematic Wiring Diagram GuideramyapothurNo ratings yet

- PE LessonPlanDocument4 pagesPE LessonPlanNarasimman DonNo ratings yet

- SP0407 Commissioning Tests For HV UG CablesDocument13 pagesSP0407 Commissioning Tests For HV UG Cablesyavuz772100% (4)

- 2nd Mid Assingnment QuestionsDocument3 pages2nd Mid Assingnment QuestionsSatya TejaNo ratings yet

- Transformer injection connection scheduleDocument5 pagesTransformer injection connection scheduleNiall BegleyNo ratings yet

- EE 1351 Power System Analysis Per-Unit Impedance DiagramDocument31 pagesEE 1351 Power System Analysis Per-Unit Impedance DiagramStephen Kenth La GuerreNo ratings yet

- Mlp-Ee 51Document11 pagesMlp-Ee 51prasad357No ratings yet

- PS7203-Advanced Power System ProtectionDocument6 pagesPS7203-Advanced Power System ProtectionntrimurthuluNo ratings yet

- Buku Management Science PDFDocument248 pagesBuku Management Science PDFMuutiyara muti100% (1)

- Job Description Oacett Experience Requirements - Revised November 2021Document6 pagesJob Description Oacett Experience Requirements - Revised November 2021Deepak MasaunNo ratings yet

- WWW Universityquestions inDocument8 pagesWWW Universityquestions inagreykatoNo ratings yet

- Commissioning Tests For HV Underground Cables (Up To 33Kv) SWPDocument13 pagesCommissioning Tests For HV Underground Cables (Up To 33Kv) SWPCharles Robiansyah100% (1)

- Subject Code: Ee 1005 Subject Name: Power Quality: What Are The Causes Due To Short Circuit in TheDocument22 pagesSubject Code: Ee 1005 Subject Name: Power Quality: What Are The Causes Due To Short Circuit in TheChetan KotwalNo ratings yet

- Interview Questions on Power System ComponentsDocument27 pagesInterview Questions on Power System ComponentsashishNo ratings yet

- Prist University: Question BankDocument7 pagesPrist University: Question BankJhon LouisNo ratings yet

- HV Cable Commissioning ReportDocument10 pagesHV Cable Commissioning Reportvo100% (1)

- EE2036 Flexible AC Transmission Systems Two Mark Question and AnswersDocument15 pagesEE2036 Flexible AC Transmission Systems Two Mark Question and Answersanshuman nayakNo ratings yet

- Anna University Affiliated Colleges Be Eee Semester Vi Ee2353 - High Voltage Engineering Unit - Iover Voltages in Electrical Power SystemsDocument6 pagesAnna University Affiliated Colleges Be Eee Semester Vi Ee2353 - High Voltage Engineering Unit - Iover Voltages in Electrical Power Systemspvanitha143No ratings yet

- New QBhve3yearDocument29 pagesNew QBhve3yearArun SelvarajNo ratings yet

- Unified Power Flow ControlDocument9 pagesUnified Power Flow ControlpavanNo ratings yet

- Power Quality-Model QPDocument3 pagesPower Quality-Model QPKarthick GuberanNo ratings yet

- Introduction To FACTS: Alternating Current Transmission System (FACTS) Devices in Power Grids. FACTS AllowDocument4 pagesIntroduction To FACTS: Alternating Current Transmission System (FACTS) Devices in Power Grids. FACTS AllowsameekshaNo ratings yet

- UL Calibration RequirementsDocument7 pagesUL Calibration RequirementsMehdi MehdiNo ratings yet

- Test Procedure TXDocument4 pagesTest Procedure TXVasu100% (1)

- Testing and Commissioning of MV CablesDocument8 pagesTesting and Commissioning of MV CablesYJoe18No ratings yet

- EFQM Model CriterionDocument18 pagesEFQM Model CriterionibnmosawiNo ratings yet

- Addc Procedures For 22kv Permananet Power SupplyDocument8 pagesAddc Procedures For 22kv Permananet Power Supplybasem_eng77No ratings yet

- Streetlight ManualDocument75 pagesStreetlight ManualisukuruNo ratings yet

- Manage construction projects with Microsoft Project: Track progress and control plansDocument125 pagesManage construction projects with Microsoft Project: Track progress and control plansForbes Kamba100% (1)

- Electrical Acceptance TestingDocument12 pagesElectrical Acceptance Testingcizer_azNo ratings yet

- IUBAT-International University of Business Agriculture and TechnologyDocument8 pagesIUBAT-International University of Business Agriculture and TechnologyMd Hasibur RahmanNo ratings yet

- QUESTIONBANK EcadDocument19 pagesQUESTIONBANK EcadVarsha WaingankarNo ratings yet

- Commissioning Service Department Commissioning Standard Test Formats Description: Function Test - AccsDocument11 pagesCommissioning Service Department Commissioning Standard Test Formats Description: Function Test - AccsDinesh PitchaivelNo ratings yet

- Unit-6 Circuit Breakers (Switchgear and Protection)Document84 pagesUnit-6 Circuit Breakers (Switchgear and Protection)sujithNo ratings yet

- 86 Lockout Auxiliary Relay Site Test Report: Mechanical Checks & Visual InspectionDocument2 pages86 Lockout Auxiliary Relay Site Test Report: Mechanical Checks & Visual InspectionJaikaran DanNo ratings yet

- Commissioning Ground Mounted Distribution SubstationsDocument6 pagesCommissioning Ground Mounted Distribution SubstationsSergio Henrique F. CArniettoNo ratings yet

- KDON-350Y - 1200 Technical Solution of Air Separation EquipmentDocument18 pagesKDON-350Y - 1200 Technical Solution of Air Separation EquipmentYJoe18No ratings yet

- Yika Electric FZSW33-8 Line Post InsulatorDocument1 pageYika Electric FZSW33-8 Line Post InsulatorYJoe18No ratings yet

- NSP/004/011 Guidance On Overhead Line Clearances: 1.0 PurposeDocument25 pagesNSP/004/011 Guidance On Overhead Line Clearances: 1.0 PurposeYJoe18No ratings yet

- Elastimold CableDocument2 pagesElastimold CableYJoe18No ratings yet

- Elastimold CableDocument40 pagesElastimold CableArmin Fernández GerardoNo ratings yet

- Safety Detection Solutions Preventa LowDocument10 pagesSafety Detection Solutions Preventa LowYJoe18No ratings yet

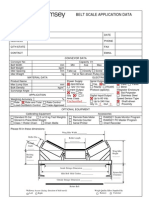

- Belt scale application data formDocument1 pageBelt scale application data formYJoe18No ratings yet

- SMJBossAgent Conf EnuDocument117 pagesSMJBossAgent Conf EnuSuma LathaNo ratings yet

- EPC Model RFQ & RFP Document for Highway ProjectsDocument74 pagesEPC Model RFQ & RFP Document for Highway Projectsइंजि कौस्तुभ पवारNo ratings yet

- How the World Bank Built an Enterprise TaxonomyDocument28 pagesHow the World Bank Built an Enterprise TaxonomyChiKita Tinitana100% (1)

- Dbmoto 8Document2 pagesDbmoto 8Philip CalmerinNo ratings yet

- Time Table of GDR (German Democratic Republic) Interchangeable Lenses For 35 MM Cameras ©Document3 pagesTime Table of GDR (German Democratic Republic) Interchangeable Lenses For 35 MM Cameras ©sgalaxys5660No ratings yet

- T3PM User ManualDocument247 pagesT3PM User Manualsilenman72No ratings yet

- Strategic Management Internal Project (TATA Motors)Document17 pagesStrategic Management Internal Project (TATA Motors)soumya20044No ratings yet

- Warehouse Management System and Business Performance:: Case Study of A Regional Distribution CentreDocument6 pagesWarehouse Management System and Business Performance:: Case Study of A Regional Distribution CentreVizay Vicky PratamaNo ratings yet

- Android Online Local Train ReservationDocument57 pagesAndroid Online Local Train ReservationHarsha ReddyNo ratings yet

- Esd.70J / 1.145J Engineering Economy Module: Mit OpencoursewareDocument14 pagesEsd.70J / 1.145J Engineering Economy Module: Mit OpencoursewarePanagiotis StamatisNo ratings yet

- JayapuraDocument4 pagesJayapuraAriadi DwiputraNo ratings yet

- COMPIT 13 ProceedingsDocument499 pagesCOMPIT 13 ProceedingsMaciej ReichelNo ratings yet

- Account GeneratorDocument6 pagesAccount Generatorshashi_ksgNo ratings yet

- Innovation Catalogue: Trench DiggerDocument2 pagesInnovation Catalogue: Trench DiggerSukh SagarNo ratings yet

- OH100 Series TemplateDocument2 pagesOH100 Series TemplateRahul KumarNo ratings yet

- Sop For Package Integrity - Leak TestDocument4 pagesSop For Package Integrity - Leak TestMusyoka UrbanusNo ratings yet

- Hicom 102 Technical Specs and Installation GuideDocument4 pagesHicom 102 Technical Specs and Installation Guidejunnior23No ratings yet

- SWOT Analysis Connectivity and Digitization in German Automobile IndustryDocument12 pagesSWOT Analysis Connectivity and Digitization in German Automobile IndustryOzair ShaukatNo ratings yet

- Examen 1 Diseño de Procesos Químicos IDocument29 pagesExamen 1 Diseño de Procesos Químicos IDavid Tovar HernándezNo ratings yet

- Wall Tile Romane BookletDocument55 pagesWall Tile Romane Bookletmuhamad bastianNo ratings yet