Professional Documents

Culture Documents

Lecture 1 - Magnetic Circuit PDF

Uploaded by

Afeef Abu BakarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lecture 1 - Magnetic Circuit PDF

Uploaded by

Afeef Abu BakarCopyright:

Available Formats

Power Engineering EPO460

Chapter 1 – Magnetic Circuit

Magnets

Objects which produce their own magnetic field are called magnets.

Magnetism is a force of attraction or repulsion that produced by magnets to the other

materials.

The orientation of electrons is the reason behind the production of magnetic field and

magnetism.

o In a natural state of an object, the electrons are scattered.

o If the orientation of electrons is aligned in one direction, it becomes a magnet.

Magnets have 2 poles: North and South.

There are 3 major groups of magnets:

Permanent magnets Temporary magnets Electromagnets

o Objects that o Become o Magnets made by wire loops around a

retain their magnetized when core material when electricity pass

magnetism once they come within through a wire, it produces magnetic

magnetized range of magnet field

o The magnetic o The magnetism o Magnetic property become strong if:

properties last lasts for a short

i. The core is made of ferromagnetic

for a long period period

material

o Example: fridge, o Example: nail,

ii. A coil is used instead of straight wire

cabinet door, etc. needle, paper

clips, etc. iii. Current is high

o Example: transformers, motors,

generators, floating bullet train, etc.

Ferromagnetic materials exhibit a strong attraction to magnetic fields and retain their magnetic

properties after the external field has been removed.

Iron, nickel, manganese and cobalt are the example of ferromagnetic materials.

It is used as a core of transformers and stator of motors.

Electromagnets

Magnetic field (or flux) is the region around a magnet where magnetic effects can be

experienced. (magnetic flux symbol: Φ, unit: Weber (Wb))

A magnetic line of force (or flux line) is a continuous line whose direction at any point is the

direction of the magnetic field at that point.

D. Johari, FKE UiTM-modified by NZA 1

Power Engineering EPO460

Fig. 1: Magnetic field

The magnetic flux through a region is a measure of the number of magnetic field lines passing

through the region.

The strength of magnetic flux is measured using magnetic field intensity. (magnetic flux

intensity symbol: H, unit: ampere turn per meter, At/m)

The direction of magnetic field intensity can be determined by the right-hand grip rule.

Figure 2: Right hand grip rule

Magnetic flux intensity produces magnetic flux density everywhere it exists. (magnetic flux

density symbol: B, unit: Tesla (T). 1Wb/m2 = 1T)

Magnetic flux density indicates the magnitude and direction of a magnetic field of an area. (how

to increase the magnetic flux density?)

The ease with which a material will conduct magnetic lines force is called permeability.

The concept of electromagnetism and electromagnetic induction are applied in many electrical

appliances such as motors, transformers and generators.

o Electromagnetism is a process of making magnetism using electrical current. A

current carrying wire produces a magnetic field in the area around it.

o Electromagnetic induction is a process of creating an electrical current using

magnetism.

D. Johari, FKE UiTM-modified by NZA 2

Power Engineering EPO460

Laws related to electromagnetic induction (*refer to video at I-learn)

Faraday’s law:

o First law: Whenever the magnetic flux linked with a circuit changes, an electromotive-

force (EMF) is always induced in it OR whenever a conductor cuts magnetic flux, an

EMF is induced in that conductor (*when EMF is induced, the current is also induced)

o Second law: The magnitude of the induced EMF is equal to the rate of change of flux

linkages

The direction of motion or direction of induced current can be determined using Fleming’s right

and left hand rules

o Right hand rule: applicable for generator

o Left hand rule: applicable for motor

Fore finger: direction of magnetic field

Middle finger: direction of current

Thumb: direction of force

Fig. 3: Fleming’s right hand rule

Lenz’s law states that when EMF is induced as in Faraday's law, the polarity (direction) of

that induced EMF is such that it opposes the cause of its production.

Three basic principles that describe how magnetic fields are used in transformers, motors and

generators are as follows:

1. A time-changing magnetic field induces EMF/voltage in a coil of wire if it passes through

that coil. (This is the basis of transformer)

2. A current-carrying wire in the presence of a magnetic field has a force induced on it (This is

the basis of motor action)

3. A moving wire in the presence of a magnetic field has a voltage induced in it (This is the

basis of generator action)

In most electrical machines (except permanent magnet machines), magnetic flux is produced

by passing an electrical current through coils looped on ferromagnetic materials.

D. Johari, FKE UiTM-modified by NZA 3

Power Engineering EPO460

Magnetic Field

The relation between current, i and magnetic flux intensity, H (i-H relation) can be obtained

using Ampere’s law. This law stated that the line integral of the magnetic flux intensity, H,

around a closed path is equal to the total current linked by the contour.

It is given by:

Hlc Ni

Where H – the magnetic field intensity produced by total current Ni

lc – the mean path length of the core (in meter)

Cross-sectional area, A

Mean path length lc

Fig. 4: Simple magnetic core

The magnitude of the magnetic field intensity, H in the core due to the applied current is

Ni

H

lc

The relationship between the magnetic field intensity H and the resulting magnetic flux density

B produced within a material is given by

B H or B 0 r H

Where H – magnetic field intensity (ampere-turn per meter)

µ – magnetic permeability of material (henrys per meter)

B – resulting magnetic flux density produced (Weber per square meter or Tesla)

µr – relative permeability

µo – permeability of free space (4 x 10-7H/m)

The permeability of any material compared to the permeability of free space is called relative

permeability given by:

r

o

D. Johari, FKE UiTM-modified by NZA 4

Power Engineering EPO460

The magnetic flux density for magnetic core in Fig. 2 is, therefore, given by:

Ni

B H

lc

Now the total flux in a given area is given by

BA

Where A is the cross-sectional area of the core (in meter square-m2)

Thus, the total flux in the core in Fig. 2 due to the current i, in the winding is

NiA

BA

lc

The core shapes can be of rectangular, toroid, solenoid and shell type (**how to determine the

length and area of each core shapes?)

Relationship between B and H

The relationship between B and H of any magnetic materials is generally shown by Fig. 4. This

curve is also known as magnetization curve

In the core, magnetic intensity, H is increased proportionally by the increasing current

The flux density, B in the core changes in the way shown below:

Fig. 4: General magnetization curve

From Fig. 4, the flux density, B increases almost linearly with the increase of flux intensity, H, at

initial condition

However, at higher value of H, the change of B is nonlinear and shows the effect of saturation

D. Johari, FKE UiTM-modified by NZA 5

Power Engineering EPO460

Fig. 5: Sample of magnetization curve of a few magnetic materials

From magnetization curve, information of B and/or H of magnetic core can be obtained.

Magnetic Circuits

Magnetic flux circulated in a closed area or path of ferromagnetic materials is called as

magnetic circuit.

If the flux is divided into 2 or more path of magnetic flux, it is called as parallel magnetic circuit.

Otherwise, it has series magnetic circuit.

A circulating force called Magneto Motive Force (MMF) or magnetic potential is responsible for

establishing magnetic flux in a magnetic circuit. Unit of MMF is Ampere-turn (At)

The magnetic circuit can be drawn analogous to an electric circuit as shown below:

Fig. 6 a) A simple electric circuit (b) The magnetic circuit

D. Johari, FKE UiTM-modified by NZA 6

Power Engineering EPO460

The electrical terms used in electric and magnetic circuits

Electric circuit Magnetic circuit

The voltage or electromotive force The magnetomotive force (mmf) causes

(emf) causes current I, to flow. flux to be produced.

V IR F

V = voltage or electromotive force F = magnetomotive force (mmf) of circuit

I = current = Flux of circuit

R = resistance = Reluctance of circuit

1 1

G (conductance) = (permeance) =

R

Core Reluctance

Each core (ferromagnetic material) has its own reluctance. Reluctance is the opposite of

permeability.

Magnetic property of the core can be improved by using material that has very low reluctance.

The resulting flux in a core (as shown in Fig. 4) is given by:

NiA A A

Ni F

lc lc lc

We can see that the reluctance of the core is

lc

A

Reluctance in a magnetic circuit obeys the same rules as resistance in an electric circuit.

The equivalent reluctance of several reluctances in series is just the sum of the individual

reluctances:

eq 1 2 3 .......

Similarly, reluctances in parallel combine according to the equation

1 1 1 1

.........

eq 1 2 3

D. Johari, FKE UiTM-modified by NZA 7

Power Engineering EPO460

Magnetic circuit with air gap

In electric machines, the rotor is isolated from the stator by the air gap to reduce the saturation

effect at the core (or poles)

A magnetic circuit having 2 or more medium (magnetic core and air gap) is known as a

composite structure. Magnetic equivalent circuit for magnetic core with air gap is shown below:

Figure 7: Composite structure. (a) Magnetic core with air gap (b) magnetic equivalent circuit

In Fig. 7(a)

lc lg

c g

c A and

0 A

Thus, the resulting flux for magnetic circuit with air gap is:

F Ni

c g

Ni H c lc H g l g

The flux densities are:

c g

Bc and Bg

Ac Ag

At the air gap, magnetic fluxes flowing in a magnetic core spreads out (or fringes out) into the

surrounding medium. This is called fringing of the flux as shown below:

Figure 7: Fringing effect at the air gap

D. Johari, FKE UiTM-modified by NZA 8

Power Engineering EPO460

Fringing is directly proportional to the length of the air gap. If the length increases, the fringing

effect will increase and vice versa

Leakage flux is defined as the magnetic flux which does not follow the intended path in a

magnetic circuit

Useful flux is the flux that passes through the core and is utilized in the magnetic circuit

Ferromagnetic Materials

All substances are affected by magnetic fields.

They are classified into 3 according to the way they are affected:

o Diamagnetic materials

Show very weak magnetic effects

μr is very slightly less than one (typically 0.99999)

o Paramagnetic materials

Show very weak magnetic effects

μr is very slightly greater than one (typically 1.001)

o Ferromagnetic materials

Exhibit very strong magnetic effects

Have very large values of μr (typically 104)

Examples are iron, nickel and cobalt

D. Johari, FKE UiTM-modified by NZA 9

Power Engineering EPO460

Losses in Ferromagnetic Core

There are 2 types of losses occur in the magnetic core; one is Eddy Current Loss (ECL) and

the other is hysteresis loss.

ECL takes place when a coil is wrapped around a core and alternating ac supply is applied to it

As the supply to the coil is alternating, the flux produced in the coil is also alternating

By Faradays law of electromagnetic induction, the change in flux through the core causes EMF

induction inside the core

Due to induction of EMF, eddy current starts to flow in the core and exist as loss in the form of

heat energy

Eddy current losses can be reduced by laminations in the core

Thin sheet steels must be used which are insulated from each other

Due to insulated sheets the amount of current which flows get reduced and hence the eddy

current losses

Lamination of core to reduce ECL

Hysteresis loss occurs when the amount of energy absorbed by magnetic material does not

returned to its original path (refer to hysteresis curve)

Hysteresis curve

D. Johari, FKE UiTM-modified by NZA 10

Power Engineering EPO460

When the magnetic field strength or the current is increased the flux density increase

proportionally until it (flux) gets saturated

When we reduce the current from saturation to zero side the flux density starts to decrease

But when the current value reaches zero the flux density should also be zero but it is not

For zero current there is still some flux density present in the material, this is known as residual

magnetic flux

Hence the amount of power is never recovered

The power which gets trapped in the core of the material is lost in the form of heat

The area of the B-H curve determines the amount of hysteresis loss

The larger the area greater is the loss and vice versa

Since hysteresis loss depends on the material of the core, then to reduce such loss, it is

recommended to use high permeability material for the core

Since both losses (hysteresis and ECL) occur within the metal of the core, they are usually

lumped together and called as core losses.

Example 1

A ferromagnetic core is shown in Fig. 8. Three sides of this core are of uniform width, while the

fourth side is somewhat thinner. The depth of the core (in to page) is 10cm, and the other

dimensions are shown in the figure. There is a 200-turn coil wrapped around the left side of the

core. Assuming relative permeability µr of 2500, how much flux will be produced by a 1A input

current?

D. Johari, FKE UiTM-modified by NZA 11

Power Engineering EPO460

Fig. 8: The Ferromagnetic Core

Example 2

Fig. 9 shows a ferromagnetic core whose mean path length is 40cm. There is a small gap of

0.05cm in the structure of the otherwise whole core. The cross-sectional area of the core is 12cm2,

the relative permeability of the core is 4000, and the coil of wire on the core has 400 turns. Assume

that fringing (border) in the air gap increases the effective cross-sectional area of the air gap by 5

percent. Given this information, find:

a) the total reluctance of the flux path (iron plus air gap) and

b) the current required to produce a flux density of 0.5T in the air gap

Fig. 9: The Ferromagnetic Core

D. Johari, FKE UiTM-modified by NZA 12

Power Engineering EPO460

Example 3

Fig. 10 shows a simplified rotor and stator for a DC motor. The mean path length of the stator is

50cm, and its cross-sectional area is 12 cm2. The mean path length of the rotor is 5cm, and its

cross-sectional area also may be assumed to be 12cm2. Each air gap between the rotor and the

stator is 0.05cm wide, and the cross-sectional area of each air gap (including fringing) is 14 cm2.

The iron of the core has a relative permeability of 2000, and there are 200 turns of wire in the core.

If the current in the wire is adjusted to be 1 A, what will the resulting flux density in the air gaps be?

Fig. 10: A simplified diagram of a rotor and stator for a dc motor.

D. Johari, FKE UiTM-modified by NZA 13

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- A Sample of Second Quiz For Computer OrganizationDocument1 pageA Sample of Second Quiz For Computer OrganizationAfeef Abu BakarNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Chapter 2 Ece351Document19 pagesChapter 2 Ece351Afeef Abu BakarNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- A Sample of Second Quiz For Computer OrganizationDocument1 pageA Sample of Second Quiz For Computer OrganizationAfeef Abu BakarNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Multi-core zEnterprise EC12 PU chip componentsDocument1 pageMulti-core zEnterprise EC12 PU chip componentsAfeef Abu BakarNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Lecture 1 - Magnetic CircuitDocument13 pagesLecture 1 - Magnetic CircuitAfeef Abu BakarNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Multi-core zEnterprise EC12 PU chip componentsDocument1 pageMulti-core zEnterprise EC12 PU chip componentsAfeef Abu BakarNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Chapter 1 Ece351 Digital SystemsDocument49 pagesChapter 1 Ece351 Digital SystemsAfeef Abu BakarNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

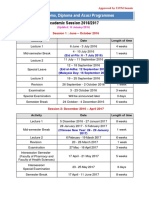

- Academic Sessions 2016-2017 PDFDocument2 pagesAcademic Sessions 2016-2017 PDFMat HuzainiNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Academic Sessions 2016-2017 PDFDocument2 pagesAcademic Sessions 2016-2017 PDFMat HuzainiNo ratings yet

- Ee 303 Pti Version 34 Power Flow Project Fall 2018Document2 pagesEe 303 Pti Version 34 Power Flow Project Fall 2018api-458050099No ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- M A I N T e N A N C e M A N U A L F o R La B o R at o R y e Q U I P M e N TDocument77 pagesM A I N T e N A N C e M A N U A L F o R La B o R at o R y e Q U I P M e N TBMTNo ratings yet

- Biaxial Bending of SFRC Slabs Is Conventional Reinforcement NecessaryDocument15 pagesBiaxial Bending of SFRC Slabs Is Conventional Reinforcement NecessaryDan MaceNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- 6m RTP Design ReportDocument25 pages6m RTP Design Reportmanohargud100% (1)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Plate Tectonic UnitDocument95 pagesPlate Tectonic Unitapi-227272561No ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- 1711710238363Document93 pages1711710238363srashmiiiscNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Principles of Rotary Flight HelicopterDocument2 pagesPrinciples of Rotary Flight Helicopterrex-strikerNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Lm331 AppnoteDocument8 pagesLm331 AppnoteEward KenNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- EE593Document4 pagesEE593hassanNo ratings yet

- The Philosophy of David Hume According to HumeDocument7 pagesThe Philosophy of David Hume According to HumePaul Kallan100% (1)

- Scribd Download Com A Das Gupta 39 S Problems Plus in Iit Mathematics PDFDocument24 pagesScribd Download Com A Das Gupta 39 S Problems Plus in Iit Mathematics PDFsinghmk10% (1)

- ABB Digital Substation - Presentation - Apr 2017 - ANIMP PDFDocument29 pagesABB Digital Substation - Presentation - Apr 2017 - ANIMP PDFMohsin ElgondiNo ratings yet

- Boundary Wall DesignDocument26 pagesBoundary Wall DesignAtanu Bhattacharya50% (2)

- Wave OpticsDocument1 pageWave OpticsBhupeshNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 2A The Structure of The Atom-AnswerDocument6 pages2A The Structure of The Atom-AnswerSiti Nursahidah0% (1)

- 111年下A卷題庫Document10 pages111年下A卷題庫陳奕安No ratings yet

- Soundness TestDocument4 pagesSoundness TestC-one Goncalves100% (2)

- Liquid Nitrogen Safety TrainingDocument21 pagesLiquid Nitrogen Safety TrainingSteven James CapuanoNo ratings yet

- 4 - 002 Qafco Urea3 Plant High PressureDocument13 pages4 - 002 Qafco Urea3 Plant High PressureJUNAID RAFEYNo ratings yet

- FMDocument4 pagesFMvishalNo ratings yet

- 4 D8722 DEd 01Document28 pages4 D8722 DEd 01Dhani AmeliaNo ratings yet

- Karthika Dass - From Somewhere Out ThereDocument154 pagesKarthika Dass - From Somewhere Out ThereAdina Elena Aruștei100% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- PTC Slides 1Document36 pagesPTC Slides 1Argo LuusNo ratings yet

- Weather CardDocument2 pagesWeather Cardmekstone100% (1)

- Boiler Performance Guarantee R0Document3 pagesBoiler Performance Guarantee R0Prafitri KurniawanNo ratings yet

- Extraction in Chemical Technology PrincipleDocument24 pagesExtraction in Chemical Technology PrincipleFatima ZaharaNo ratings yet

- Remote Turbine Vibration Diagnostics Service (Technical Data)Document22 pagesRemote Turbine Vibration Diagnostics Service (Technical Data)Candra Yanuar SalehNo ratings yet

- NB,.NB LHGJK JLHKDocument1 pageNB,.NB LHGJK JLHKPatrícia MouraNo ratings yet

- Practice FinalDocument26 pagesPractice Finalchaseutd123No ratings yet

- Aits 2223 FT Vi Jeem OfflineDocument15 pagesAits 2223 FT Vi Jeem OfflineSuvrajyoti TaraphdarNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)