Professional Documents

Culture Documents

Article HarmonicResonance 083

Uploaded by

rencydCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Article HarmonicResonance 083

Uploaded by

rencydCopyright:

Available Formats

Wind-Induced Harmonic Resonance:

Considerations for Light Pole Design

Design Factors Reduce Probability of Weld Damage or Failure

By Peter Manis, PE, and Wes Jones, PE for replacement light poles by saying that its

On nearly every building project there are standard one-year warranty does not cover

non-building structures that require some naturally occurring harmonic vibration light

design and/or engineering. These structures pole failures. Additional calls to various light

range from trash enclosures and culverts to pole manufacturers revealed that none of them

flagpoles and light poles. In the case of light warrant failure due to harmonic vibration.

poles, a common design approach is to either

specify a light pole or have the contractor or Selection Procedures

light pole supplier submit one for approval. It is important to note that the failed light pole

In many instances, specifying a light pole is a met all manufacturer requirements and had

straightforward process; however, under certain been properly selected and installed based

circumstances, additional effort and attention on its criteria. Many light pole manufacturers

is required to avoid wind-induced resonance. publish wind speed maps and light pole

selection criteria for their products. A common

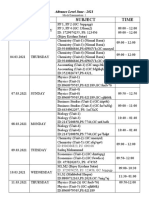

On a recent project, most of the installed light pole selection procedure:

light poles were swaying under recorded wind

velocities of 17 to 28 mph with gusts up to 46 1. Select the light fixture, and obtain its

mph. The estimated top-of-pole movement was effective projected area (EPA) and weight.

approximately 8 to 12 inches from horizontal The EPA is the area that is loaded by

repetitive motion, or vibration (see Figure 1). wind. This information is located on the

fixture cut sheet.

The next day, one of the light poles was found 2. Determine the number of light fixtures and

on the ground with what appeared to be fatigue any special mounting methods (arm or

cracking at the weld between the base plate and bracket) to be installed on the pole. Obtain

the pole. The project was under construction, the EPA and weight for any arms or brackets Figure 1: Wind velocities of

so subcontractors took down the remaining from the corresponding cut sheets. 17 to 28 mph caused side-to-

poles to prevent further failures. Fortunately, 3. Total the EPA and the weights of all fixtures, side swaying of 8 to 12 inches.

there were no injuries since the failure occurred arms and brackets. (Graphic courtesy of Structure

during the night. 4. Select the design wind speed for the project magazine.)

location from the light pole manufacturer’s

Review of the light pole submittal revealed that wind map. Typically, this is a fastest mile

the subcontractor had proposed a different size wind speed, which is different from the

and type of pole than what had been originally current building code values for a 3-second

specified — a 30-foot-tall, 6-inch square gust. Conversion tables exist.

aluminum pole. Instead, the subcontractor 5. Select a pole and compare the EPA and

proposed a 30-foot-tall, 4-inch square steel pole, fixture weights with the allowable EPA and

which was approved because the 4-inch pole weights for that pole. If the actual EPA and

more than met the performance specification fixture weights are less than the allowable

according to the manufacturer’s literature. EPA and maximum weight listed on the cut

sheet, the pole meets the requirements.

Consultations with the light pole supplier

and manufacturer indicated that the failure In this project, both the specified and

of the light pole was most likely due to wind- subcontractor-proposed light poles met

induced harmonic resonance of the light pole these criteria, yet still failed under the

and subsequent fatigue cracking of the weld destructive effects of vibration under modest

between the base plate and the pole. The light wind speeds. The design wind speed was 80

pole manufacturer responded to a request mph ( fastest mile). Generally, when the wind

TECHBriefs 2008 No. 3 10 Burns & McDonnell

speed matches the natural frequency of

the light pole, resonance will result. In many Reducing Wind-Induced Resonance

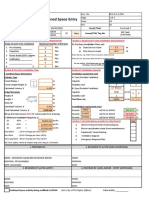

cases, the resonance is destructive, leading to Criteria that should be considered to reduce

fatigue cracking of the weld at the base plate to the probability of wind-induced resonance:

pole interface. • Use round, tapered light poles less than 25

feet tall, with a minimum 6-inch diameter.

Only in certain circumstances are light • Use a minimum of two fixtures per pole to

poles designed to resist fatigue, according to provide weight at the top for dampening.

Standard Specifications for Structural Supports

• Include in the pole specifications a

for Highway Signs, Luminaires and Traffic

Peter Manis, PE, is a senior requirement for factory- or field-installed

Signals from the American Association of

structural engineer in the vibration dampers to be provided by the

State Highway and Transportation Officials

Burns & McDonnell Aviation light pole manufacturer.

(AASHTO). These include specific high-level

& Facilities Group. He has

lighting structures, along with overhead • Contact the light pole manufacturer when

bachelor’s and master’s degrees there are site-specific concerns that should

in civil engineering from the

cantilevered traffic signal and sign structures.

AASHTO indicates that light poles do not be considered during light pole design.

Missouri University of Science

& Technology and 10 years normally exhibit fatigue problems, but as this • Provide specific wind loading information

of experience as a structural case study indicates, such failures can occur. in the documents, and indicate whether

engineer on military and wind loading is based on a 3-second gust

industrial projects. Preventive Design or fastest mile wind speed.

Rather than investing time and energy into

fatigue analysis and mitigation in common light Table 1: Study of manufacturer literature yields these

poles, a cost-effective approach is to minimize recommendations to reduce the likelihood of wind-induced

the probability of resonance. Two contributing resonance.

factors to light pole resonance are height and

fixture arrangement. One pole manufacturer Consequently, the use of shorter light poles

indicates that light poles with a fixture EPA of with multiple fixtures will generally reduce

less than 2 square feet (very little fixture area) at the chances of resonance. The shorter length

a height of 25 feet or greater have an increased provides a more rigid structure, and having

probability of resonance. While such a slender more fixtures at the top equates to greater

light pole can withstand the maximum design wind loading. The wind loading and the fixture

wind speeds, which generally are above 70 mph, weight at the top act as dampers to reduce

it is susceptible to wind-induced vibration, resonant pole movement.

which typically occurs around 20-40 mph.

Wes Jones, PE, is a senior Additionally, although no shape is exempt from

electrical engineer in the As an example, consider the vibration of a wind-induced resonance, it has been noted that

Aviation & Facilities Group. He flagpole exposed to wind. When there is no flag round (or octagonal) tapered light poles are

has eight years of electrical on the pole, it is quite common to hear cables less susceptible than square ones. The natural

systems design experience and banging against the pole. This is caused by frequency of a tapered light pole varies along

expertise in medium-voltage movement or vibration of the pole. However, its length, which makes it less likely to develop

power distribution, building when there is a flag at the top of the pole, the overall resonance from a constant wind.

electrical systems, central wind loading applied to the flag acts to dampen

plants and military projects. He the resonant movement of the pole, eliminating Further, the geographic location of a light pole

received his bachelor’s degree the banging sound. Incidentally, flagpoles have may also contribute to the steady-state, low

in computer and electrical

a different foundation anchoring system that wind speeds that result in light pole resonance.

engineering from the Georgia

typically does not include a base plate or welds. Features such as unobstructed flat land or low-

Institute of Technology.

See Guide Specifications for Design of Metal level mountains, where wind can be channeled

Flagpoles from the National Association of through an area, may contribute to resonance.

For more information, please e-mail:

pmanis@burnsmcd.com or Architectural Metal Manufacturers (NAAMM) Turbulence created by aircraft or vehicular

wjones@burnsmcd.com for more information on flagpole design. traffic may also be a contributor.

Burns & McDonnell 11 TECHBriefs 2008 No. 3

TECHBriefs

Burns & McDonnell • 9400 Ward Parkway • Kansas City, MO 64114

ADDRESS SERVICE REQUESTED

2008 No. 3

• Defining Smart Grid

• Aeration Blowers

for Wastewater

• Building

Information

Modeling

• Wind-Induced

Harmonic

Resonance

For more information, e-mail

techbriefs@burnsmcd.com

To subscribe, go to

www.burnsmcd.com/techbriefs

For address changes,

contact Darla Amstein at

damstein@burnsmcd.com

© 2008 Burns & McDonnell

Marketing, Communications

Printed on recycled paper

References

Many light pole manufacturers have attempted The client should be notified of the potential 1. AASHTO, Standard

to minimize light pole resonance by offering problem — possibly as part of a specifications- Specification for Structural

factory- or field-installed dampers. A damper required operations and maintenance Supports for Highway Signs,

increases the damping coefficient of the light manual — and a maintenance plan should Luminaires and Traffic Signals

pole, resulting in reduced movement of the be implemented. If there is concern during 2. NAAMM, Guide Specifications

for Design of Metal Flagpoles

light pole. In many cases, these dampers are periodic maintenance, the light pole

3. Lithonia Lighting, Light

hanging weights installed either on the surface manufacturer and a structural engineer should Standards Effects of Vibration

of the light pole or inside the pole near the assist in determining whether wind-induced Technical Bulletin

top. Dampers are not a cure-all for resonance, vibration is the cause. 4. Valmont Structures, “Pole

because they only change the range of wind Owner’s Manual,” Warranty

speeds that can cause wind-induced resonance. One Question Remains and Maintenance

If harmonic resonance is prevalent during or

Best Practices after construction, who picks up the repair bill? This article has been reprinted

Based on this information, best practices can In this case, the light pole supplier replaced from the March 2008 issue of

be gleaned from manufacturer literature. (See all 16 poles on the project (with dampers Structure magazine, published by

Table 1.) Periodic maintenance and inspection installed), since it was discovered that the light the National Council of Structural

Engineers Associations (NCSEA).

of a light pole can help determine if wind- pole manufacturer warranty would not cover

induced vibration is a concern. Items to be this type of failure. The project continued with

inspected include the weld between the base minimal disruption thanks to that supplier.

plate and the light pole shaft and loosening It is in the best interest of all parties to work

or damage of the light fixture. Frequent lamp together to minimize the probability of wind-

replacement is also a sign of pole movement. induced resonance and to establish measures

to monitor future concerns.

E n g i n e e r i n g , A r c h i t e c t u r e , C o n s t r u c t i o n , E n v i r o n m e n t a l a n d C o n s u l t i n g S o l u t i o n s

Atlanta • Chicago • Denver • Houston • Kansas City, Mo. • Miami • Phoenix • San Diego • St. Louis

Chattanooga, Tenn. • Cincinnati • Dallas-Fort Worth • Minneapolis-St. Paul • New York • O’Fallon, Ill. • San Francisco • Wallingford, Conn. • Washington, D.C. • Wichita, Kan.

You might also like

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Guide Specifications For Design of Metal Flagpoles - FP - 1001-07 PDFDocument27 pagesGuide Specifications For Design of Metal Flagpoles - FP - 1001-07 PDFmtNo ratings yet

- Design Manual 7.2 - Foundations and Earth StructuresDocument266 pagesDesign Manual 7.2 - Foundations and Earth StructuresBenny Lin100% (2)

- Foundation Ch.8Document42 pagesFoundation Ch.8Ilham HusseinNo ratings yet

- Overhead Line DesignDocument6 pagesOverhead Line DesignNazeeh MohammedNo ratings yet

- Introspective Hypnosis Class - 052017 - Antonio Sangio (2745)Document62 pagesIntrospective Hypnosis Class - 052017 - Antonio Sangio (2745)sandra100% (4)

- Earthing SystemdesignDocument32 pagesEarthing Systemdesignlrpatra100% (1)

- Small Wind: Planning and Building Successful InstallationsFrom EverandSmall Wind: Planning and Building Successful InstallationsRating: 5 out of 5 stars5/5 (2)

- High Mast Lighting PolesDocument7 pagesHigh Mast Lighting PolesRaheem JunaidiNo ratings yet

- Guidelines For Overhead Line DesignDocument20 pagesGuidelines For Overhead Line Designmrasdan100% (1)

- Bimetallic CorrosionDocument20 pagesBimetallic CorrosionchristophedepaepeNo ratings yet

- 1.1 Design of Pipe Racks Writeup PDFDocument5 pages1.1 Design of Pipe Racks Writeup PDFCarlosAlbertoGrimaldoBarajasNo ratings yet

- The Stress Relief PrescriptionDocument8 pagesThe Stress Relief PrescriptionRajesh KumarNo ratings yet

- The Design of Active Crossovers by Douglas Self - Appointedd PDFDocument33 pagesThe Design of Active Crossovers by Douglas Self - Appointedd PDFBrandy ThomasNo ratings yet

- Copper Busbar Design GuideDocument136 pagesCopper Busbar Design GuideOscar SchmüthNo ratings yet

- CFSEI Tech Note X Bracing L001-09Document8 pagesCFSEI Tech Note X Bracing L001-09Jane EyreNo ratings yet

- Hand Book of Concrete Mixes SP23 PDFDocument160 pagesHand Book of Concrete Mixes SP23 PDFSravan Kumar100% (1)

- SI UnitsDocument90 pagesSI UnitsManas KarnureNo ratings yet

- 01 - BUSBAR Copper Info (Design Considerations)Document5 pages01 - BUSBAR Copper Info (Design Considerations)Zen Azhar Bin ShuibNo ratings yet

- Solar Parking Canopies Design Offsets Energy UseDocument17 pagesSolar Parking Canopies Design Offsets Energy UsegullipalliNo ratings yet

- F2787 PDFDocument26 pagesF2787 PDFHernando Andrés Ramírez Gil100% (1)

- FE 2200 Spark Resistant Fan ConstructionDocument2 pagesFE 2200 Spark Resistant Fan ConstructionAvery OppegardNo ratings yet

- PW-3 Part Design For Ultrasonic Welding (Single PGS) HRDocument8 pagesPW-3 Part Design For Ultrasonic Welding (Single PGS) HRAlba R.No ratings yet

- Air Blue E-TicketDocument1 pageAir Blue E-TicketMuneeb Ahmed100% (3)

- The Wood Pole Tech BulletinDocument14 pagesThe Wood Pole Tech BulletinBenjamin EdwardNo ratings yet

- Practical Design Guide For GRCDocument98 pagesPractical Design Guide For GRCrencydNo ratings yet

- FEMA MasonryDocument362 pagesFEMA MasonryJohan Ramirez100% (1)

- The Danieli Danarc Plus M Furnace at Abs Meltshop: Aldo A. Fior Danieli C M - Process Engineer Buttrio, ItalyDocument6 pagesThe Danieli Danarc Plus M Furnace at Abs Meltshop: Aldo A. Fior Danieli C M - Process Engineer Buttrio, ItalyBrandon CoxNo ratings yet

- HydrodynamicsDocument122 pagesHydrodynamicsIustin Cristian100% (2)

- Advantages and Disadvantages of Social MediaDocument2 pagesAdvantages and Disadvantages of Social MediaCeleste GalvanNo ratings yet

- Ventilation Plan For Confined Space EntryDocument9 pagesVentilation Plan For Confined Space EntryMohamad Nazmi Mohamad Rafian100% (1)

- Astm d4923-01Document10 pagesAstm d4923-01Lucas Maximiliano Perez100% (1)

- Pub-22 Copper For BusbarsDocument101 pagesPub-22 Copper For BusbarssteevemrNo ratings yet

- Small Turbine BladesDocument18 pagesSmall Turbine BladesMathias HölzerNo ratings yet

- Rigid Bus StructuresDocument54 pagesRigid Bus Structuresroger rojasNo ratings yet

- Structures, Towers and PolesDocument4 pagesStructures, Towers and PolesHeidi ELmesiryNo ratings yet

- Steel Construction - Fire Protection (Tata Steel) PDFDocument40 pagesSteel Construction - Fire Protection (Tata Steel) PDFmdavies20No ratings yet

- CUEE DhakalandMacRae CeilinglessonsDocument10 pagesCUEE DhakalandMacRae Ceilinglessonsumar khalifa shehuNo ratings yet

- Norma D 4923-01Document10 pagesNorma D 4923-01RicardoNo ratings yet

- Steel Chimney Oscillations: A Comparative Study of Their Reported Performance Versus Predictions Using Existing Design TechniquesDocument9 pagesSteel Chimney Oscillations: A Comparative Study of Their Reported Performance Versus Predictions Using Existing Design TechniqueshikoNo ratings yet

- 38 PDFDocument2 pages38 PDFjuanmata26No ratings yet

- GROUND 2023-TLstandardDocument4 pagesGROUND 2023-TLstandardIng. Daniel Pereira PierceNo ratings yet

- 40a1 ReadingDocument7 pages40a1 ReadingSumanta BhayaNo ratings yet

- The Hong Kong Polytechnic University Department of Civil and Environmental Engineering Master of Science in Civil and Structural EngineeringDocument42 pagesThe Hong Kong Polytechnic University Department of Civil and Environmental Engineering Master of Science in Civil and Structural EngineeringTik HonNo ratings yet

- Antenna Design and RF Layout Guidelines You Must KnowDocument26 pagesAntenna Design and RF Layout Guidelines You Must KnowjackNo ratings yet

- Air Core Versus Iron Core ReactorsDocument4 pagesAir Core Versus Iron Core ReactorsBISLA ANONo ratings yet

- AIAA 2012 2291foldedcavitylinersforturbofanengineintakesDocument14 pagesAIAA 2012 2291foldedcavitylinersforturbofanengineintakesLIM SHANYOUNo ratings yet

- Selection of Suitable Bracing System for Communication TowersDocument10 pagesSelection of Suitable Bracing System for Communication TowersNazish AhmedNo ratings yet

- Gas Turbine Exhaust Systems Design ConsiderationsDocument8 pagesGas Turbine Exhaust Systems Design ConsiderationsArne AndersenNo ratings yet

- Is 6533 - 2Document23 pagesIs 6533 - 2AMRENDRANo ratings yet

- Aqua Silencere Final ReportDocument62 pagesAqua Silencere Final ReportHemeshPatil67% (3)

- Iron Core Vs Air CoreDocument5 pagesIron Core Vs Air CorebansalrNo ratings yet

- Wp513001en Light Poles White Paper BroDocument10 pagesWp513001en Light Poles White Paper BrokokoNo ratings yet

- RwdiDocument4 pagesRwdiJonathan WardropNo ratings yet

- PW-3 Part Design For Ultrasonic Welding (Single PGS) HRDocument8 pagesPW-3 Part Design For Ultrasonic Welding (Single PGS) HRhjgajjarNo ratings yet

- Branson - Part Design For Ultrasonic Welding PDFDocument6 pagesBranson - Part Design For Ultrasonic Welding PDFOsama MohammedNo ratings yet

- C1479 Hlja5316Document9 pagesC1479 Hlja5316Brisa YulietNo ratings yet

- Lightning MastsDocument67 pagesLightning MastsTafadzwa MurwiraNo ratings yet

- Reinforced Thermosetting Plastic Poles: Standard Specification ForDocument10 pagesReinforced Thermosetting Plastic Poles: Standard Specification ForDANIEL GUERRERO SANCHEZNo ratings yet

- BRBF Vs MRFDocument13 pagesBRBF Vs MRFrondana1No ratings yet

- Steel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Document2 pagesSteel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Andres CasadoNo ratings yet

- 3-AC428-Acceptance Criteria For ModularDocument24 pages3-AC428-Acceptance Criteria For ModularEric ChienNo ratings yet

- Airfoil Optimization For Noise Emission Problem and Aerodynamic Performance Criterion On Small Scale Wind TurbinesDocument10 pagesAirfoil Optimization For Noise Emission Problem and Aerodynamic Performance Criterion On Small Scale Wind TurbinesKrishnadeva Pentayah100% (1)

- Key Apps UtilitiesDocument12 pagesKey Apps UtilitiesDamodharan Chandran100% (1)

- Compact Integrated AntennasDocument26 pagesCompact Integrated AntennasEdy JjNo ratings yet

- Vibration Based Wind Turbine Tower Foundation Design Utilizing Soil-Foundation-Structure InteractionDocument8 pagesVibration Based Wind Turbine Tower Foundation Design Utilizing Soil-Foundation-Structure InteractionCristi BrebanNo ratings yet

- Ashrae 2019Document50 pagesAshrae 2019Poovelan ViswanathanNo ratings yet

- SA4018Document33 pagesSA4018tlidiaNo ratings yet

- Full Introduction About Antenna Types and PCB MaterialsDocument40 pagesFull Introduction About Antenna Types and PCB MaterialsjackNo ratings yet

- Part Design For Ultrasonic Welding: Three Major Joint Design CharacteristicsDocument6 pagesPart Design For Ultrasonic Welding: Three Major Joint Design CharacteristicsMiguel ArriecheNo ratings yet

- This Is A Case Study of Multiple: May/June 2009Document6 pagesThis Is A Case Study of Multiple: May/June 2009Anonymous mcHqIfbnV1No ratings yet

- Design and Modeling of High Mast Solar Light PDFDocument5 pagesDesign and Modeling of High Mast Solar Light PDFGeEs AnggaNo ratings yet

- TIA 222 Codes and Dielectric Antenna Design March 2021 Final 3Document6 pagesTIA 222 Codes and Dielectric Antenna Design March 2021 Final 3kheang mengNo ratings yet

- Steel Fiber Reinforced ConcreteDocument2 pagesSteel Fiber Reinforced ConcreteGangqin ZhangNo ratings yet

- Lines and PatternsDocument21 pagesLines and PatternsrencydNo ratings yet

- Corbels and NibsDocument4 pagesCorbels and NibsrencydNo ratings yet

- Facts 25-Diaphragm DesignDocument3 pagesFacts 25-Diaphragm DesignrencydNo ratings yet

- Coloring Pages For ChildrenDocument1 pageColoring Pages For ChildrenrencydNo ratings yet

- StoriesDocument12 pagesStoriesSathyamoorthy VenkateshNo ratings yet

- Why Is Nita Upside Down - FKB - Pratham PDFDocument19 pagesWhy Is Nita Upside Down - FKB - Pratham PDFSridhar BandiNo ratings yet

- Strength Vs Serviceability Beam Section PDFDocument1 pageStrength Vs Serviceability Beam Section PDFrencydNo ratings yet

- Technical Article July - WebSC Crack ReinforcementDocument1 pageTechnical Article July - WebSC Crack ReinforcementMohamed SaaDNo ratings yet

- Why Is Nita Upside Down - FKB - Pratham PDFDocument19 pagesWhy Is Nita Upside Down - FKB - Pratham PDFSridhar BandiNo ratings yet

- KeralapadavaliMal 1 PDFDocument96 pagesKeralapadavaliMal 1 PDFrencydNo ratings yet

- NPTEL Course: Ground ImprovementDocument35 pagesNPTEL Course: Ground ImprovementmmNo ratings yet

- Indian Currency SeriesDocument5 pagesIndian Currency SeriesrencydNo ratings yet

- Effect of Concrete Strength on Building Frame BehaviorDocument10 pagesEffect of Concrete Strength on Building Frame BehaviorPrapa KaranNo ratings yet

- Clay Product-Faced Precast Concrete PanelsDocument18 pagesClay Product-Faced Precast Concrete PanelsrencydNo ratings yet

- Efficient HSS Truss Connection Design - ..Document3 pagesEfficient HSS Truss Connection Design - ..rencydNo ratings yet

- Diapositivas PTE en Cerchas PDFDocument56 pagesDiapositivas PTE en Cerchas PDFFabián Martínez MuñozNo ratings yet

- GRCA Specification PDFDocument15 pagesGRCA Specification PDFrencydNo ratings yet

- Creek Bridge - A Review PDFDocument14 pagesCreek Bridge - A Review PDFrencydNo ratings yet

- Testing 7 Wire Strand Prestressed ConcreteDocument24 pagesTesting 7 Wire Strand Prestressed ConcreterencydNo ratings yet

- GRCA Specification PDFDocument15 pagesGRCA Specification PDFrencydNo ratings yet

- Anthony Robbins With Harvard Business SchoolDocument3 pagesAnthony Robbins With Harvard Business SchoolluffylovemangaNo ratings yet

- Operator Interface SERIES 300 Device Platform EAGLE OS ET-316-TXDocument6 pagesOperator Interface SERIES 300 Device Platform EAGLE OS ET-316-TXDecoNo ratings yet

- This Study Resource Was: Practice Questions and Answers Inventory Management: EOQ ModelDocument7 pagesThis Study Resource Was: Practice Questions and Answers Inventory Management: EOQ Modelwasif ahmedNo ratings yet

- E-Governance in KeralaDocument10 pagesE-Governance in KeralaRahmath SafeenaNo ratings yet

- MECHANICAL ENGINEERING DEPARTMENT - Copy (Repaired)Document10 pagesMECHANICAL ENGINEERING DEPARTMENT - Copy (Repaired)Wan Mohd AfnanNo ratings yet

- Features Description: LT3598 6-String 30ma LED Driver With 1.5% Current MatchingDocument24 pagesFeatures Description: LT3598 6-String 30ma LED Driver With 1.5% Current MatchingMick Thomson RcNo ratings yet

- 03 - Gherkin An OverviewDocument19 pages03 - Gherkin An OverviewArunkumar KrishnamoorthyNo ratings yet

- Legal Opinion WritingDocument53 pagesLegal Opinion WritingBenedict AnicetNo ratings yet

- Course Material For Module 3Document11 pagesCourse Material For Module 3Noble VargheseNo ratings yet

- Hegemonic Masculinity As A Historical Problem: Ben GriffinDocument24 pagesHegemonic Masculinity As A Historical Problem: Ben GriffinBolso GatoNo ratings yet

- Gr07 S DanceDocument17 pagesGr07 S DanceMaliNo ratings yet

- Materials Selection For Engineering DesignDocument31 pagesMaterials Selection For Engineering Designsyamsudin2006No ratings yet

- Chlorine (Free or Total) Manual For Test Kits CN-70, CN-70F, CN-70TDocument6 pagesChlorine (Free or Total) Manual For Test Kits CN-70, CN-70F, CN-70TDemétrius Ivo FernandesNo ratings yet

- Bio-Climatic Tower/Eco-Tower: Bachelor of ArchitectureDocument12 pagesBio-Climatic Tower/Eco-Tower: Bachelor of ArchitectureZorawar Singh Basur67% (3)

- Spatial Personality For Human Space InteractionDocument10 pagesSpatial Personality For Human Space Interactionavijitsaha bornoNo ratings yet

- Vision and Mission Analysis ChapterDocument15 pagesVision and Mission Analysis Chapterzaza bazazaNo ratings yet

- Borrero Nuevo Delaunay Mendez - 2019 - Ethnographical and Historical Accounts For Understanding The Exploration of New Lands The Case PDFDocument16 pagesBorrero Nuevo Delaunay Mendez - 2019 - Ethnographical and Historical Accounts For Understanding The Exploration of New Lands The Case PDFBárbara Olguín MuñozNo ratings yet

- MrsDocument8 pagesMrsalien888No ratings yet

- Mock Examination Routine A 2021 NewDocument2 pagesMock Examination Routine A 2021 Newmufrad muhtasibNo ratings yet

- General Chemistry 2 - LAS 2 LEARNING CAPSULEDocument5 pagesGeneral Chemistry 2 - LAS 2 LEARNING CAPSULEMark RazNo ratings yet

- Annexure - Subject Wise IBDP Grade BoundariesDocument4 pagesAnnexure - Subject Wise IBDP Grade BoundariesazeemNo ratings yet

- Ternary Phase Diagram Guided Question 1 PDFDocument1 pageTernary Phase Diagram Guided Question 1 PDFLuci FernNo ratings yet

- Cahyadi J Malia Tugas MID TPODocument9 pagesCahyadi J Malia Tugas MID TPOCahyadi J MaliaNo ratings yet