Professional Documents

Culture Documents

Discover The World's Research: 14+ Million Members 100+ Million Publications 700k+ Research Projects

Uploaded by

Hilmy MuhammadOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Discover The World's Research: 14+ Million Members 100+ Million Publications 700k+ Research Projects

Uploaded by

Hilmy MuhammadCopyright:

Available Formats

Abstract

The national guidelines for design of silage bunker silo walls are not available today. The present calculation and

design is based on previously issued guidelines. These were elaborated to be used in designing silo wall heights of

maximum 3 m. There are reasons to believe that these guidelines overestimate the forces and pressures, mainly

from silage juice, that are occurring especially for silo walls > 3 m. This could result in over-sizing, material waste and

increased investment costs. The aim of the project is to determine silage physical properties of importance for the

horizontal wall pressure and evaluate maximum silage juice level of silos with a wall height of 3 m or more. The data

will form a basis for new national design guidelines and a revised Swedish Standard. The ultimate goal is to lower the

investment costs for silage bunker silos. A pressure profile was acquired by means of transducers mounted on a

"ladder rack" placed vertically along the inside silo wall. The pressure on the transducers was recorded by a data

acquisition system displaying static and total load (pressures imposed by silage matter and compacting tractor). The

silage juice levels were measured by slotted 16 mm steel pipes placed vertically along the silo walls. The level inside

the pipe was determined by a measuring stick. Additionally the juice level could be registered in one of the legs of the

"ladder rack". Silage juice level measurement were carried out during two seasons, all together in 24 silos, while

pressure profiles were measured during 10 grass and maize harvests in one season, with approximately 400

pressure profiles at each harvest. The static loads were recorded with no tractor present and total loads as a tractor

was passing in front of the transducer racks. The difference between the static and the total load was defined as the

dynamic load. Preliminary results show that the silage juice level can vary considerably between harvests within the

farm due to weather conditions and geographic location in Sweden. Mean of peak levels was approximately 40% of

the silage height. A direct relation was found between grass silage juice level and silage total solid content. The

silage juice level tends to remain stable during the storage but can be radically redistributed between layers within the

silo. Tentative pressure profile results show that the dynamic pressure created by the compacting tractor is largely

concentrated to the first half metre below the vehicle when driving 0.1-0.5 m from the silo wall. Pressure

measurements after filling the silo show an increase in wall pressure. The pressure profile results are presently under

evaluation.

Discover the world's research

14+ million members

100+ million publications

700k+ research projects

Join for free

Figures

You might also like

- Cocchiere 2020Document12 pagesCocchiere 2020Nasim KazemiNo ratings yet

- Design Criteria For Structural Design of Silage Silo Walls: July 2012Document7 pagesDesign Criteria For Structural Design of Silage Silo Walls: July 2012Bayari ArNo ratings yet

- Lippold Harder Silowalls Worldcement 11 2004Document5 pagesLippold Harder Silowalls Worldcement 11 2004Uttam Kumar GhoshNo ratings yet

- Paper 9 Registro de PozosDocument9 pagesPaper 9 Registro de PozosWaldinho Gaucho da SilvaNo ratings yet

- Geothermal Well Completion Tests - Hagen HoleDocument5 pagesGeothermal Well Completion Tests - Hagen HoleAdil AytekinNo ratings yet

- Evaluation of A Depth Proportional Intake Device For Automatic Pumping SamplersDocument4 pagesEvaluation of A Depth Proportional Intake Device For Automatic Pumping SamplersHizbar ArsjadNo ratings yet

- ChuteDesignFormulas Paper43Document11 pagesChuteDesignFormulas Paper43Martin LarochelleNo ratings yet

- IADC/SPE-178881-MS Swab and Surge Pressures With Reservoir Fluid Influx Condition During MPDDocument13 pagesIADC/SPE-178881-MS Swab and Surge Pressures With Reservoir Fluid Influx Condition During MPDqjbsexNo ratings yet

- Estiramiento CasingDocument13 pagesEstiramiento CasingFrancisco RoccaNo ratings yet

- Spe 126Document13 pagesSpe 126advantage025No ratings yet

- Announcing The Release of F.A.S.T. CBM™ Version 2.6: Fall 2006Document4 pagesAnnouncing The Release of F.A.S.T. CBM™ Version 2.6: Fall 2006Pedraza Velandia JhonNo ratings yet

- Raft FoundationDocument7 pagesRaft FoundationSouliman AlkhoderNo ratings yet

- 11evaluation of Oxygen Transfer Efficiency Via Off-Gas Testing at FullDocument8 pages11evaluation of Oxygen Transfer Efficiency Via Off-Gas Testing at FullIrving VazquezNo ratings yet

- Spe PetrobrasDocument12 pagesSpe PetrobrasLawrence MbahNo ratings yet

- Impact of New Codes in Silos DesignDocument8 pagesImpact of New Codes in Silos DesignRohit GadekarNo ratings yet

- Pressure Drop and Closure Forces in Velocity Type SSSV API-77-B001 PDFDocument64 pagesPressure Drop and Closure Forces in Velocity Type SSSV API-77-B001 PDFQaiser Hafeez100% (1)

- Autriche, Juillet 2018: Assessment of Water Flow Measurement in A Zoned Dam Using Artificial Neural Network ModelsDocument10 pagesAutriche, Juillet 2018: Assessment of Water Flow Measurement in A Zoned Dam Using Artificial Neural Network ModelsRicardo SantosNo ratings yet

- Relave ThickenerDocument9 pagesRelave Thickenersonia gutierezNo ratings yet

- Comparison of Intake Pressures in Physical and Numerical Models of The Cabinet Gorge Dam Tunnel 29 07Document15 pagesComparison of Intake Pressures in Physical and Numerical Models of The Cabinet Gorge Dam Tunnel 29 07Bhaskar ReddyNo ratings yet

- Impact of New Codes in Silos DesignDocument7 pagesImpact of New Codes in Silos DesignKhaled EidNo ratings yet

- Underground Storage of Natural GasDocument13 pagesUnderground Storage of Natural GaszirimiaNo ratings yet

- Study On Fluid Flow Assurance Through Subsea Pipelines SystemsDocument2 pagesStudy On Fluid Flow Assurance Through Subsea Pipelines SystemsVirforeanu RazvanNo ratings yet

- Gas Production Gathering NetworkDocument9 pagesGas Production Gathering NetworkVhaieNo ratings yet

- Technology: Gravitude File://192.168.82.211Document2 pagesTechnology: Gravitude File://192.168.82.211rnoordinNo ratings yet

- Well Test CompleteDocument342 pagesWell Test CompleteTarek100% (3)

- 12 Automation DraworksDocument12 pages12 Automation DraworksKhaledFekairNo ratings yet

- Production Eng 2Document106 pagesProduction Eng 2himanshu_petroengg100% (1)

- Silo PDFDocument6 pagesSilo PDFCalNo ratings yet

- Formation Evaluation Using Wireline Formation Tester Pressure Data - JPT 1978Document8 pagesFormation Evaluation Using Wireline Formation Tester Pressure Data - JPT 1978Roni Hepson TambunNo ratings yet

- Pressure Chamber Testing of Model Caisson Foundations in SandDocument11 pagesPressure Chamber Testing of Model Caisson Foundations in SandLTE002No ratings yet

- SPE-178298-MS Gas Well Test Interpretation: Niger Delta Field ExperienceDocument14 pagesSPE-178298-MS Gas Well Test Interpretation: Niger Delta Field ExperienceAnis BoukezoulaNo ratings yet

- B.R. Pedersen, Baker Hughes INTEQ, J. Zajaczkowski, Statoil: Service DescriptionDocument3 pagesB.R. Pedersen, Baker Hughes INTEQ, J. Zajaczkowski, Statoil: Service DescriptionJohnSmithNo ratings yet

- Is 6966 1 1989 PDFDocument19 pagesIs 6966 1 1989 PDFPrachita RautNo ratings yet

- Considerations in Designing Multiphase Flow LinesDocument8 pagesConsiderations in Designing Multiphase Flow LinesCuando la dictadura es un hecho, la Revolución es un derechoNo ratings yet

- Well Testing Fundamentals: Senior EditorDocument2 pagesWell Testing Fundamentals: Senior EditorRoyGustavoOlivaCruzNo ratings yet

- Bulk Materials Handling in The Mining IndustryDocument12 pagesBulk Materials Handling in The Mining IndustrypabulumzengNo ratings yet

- Influence of Diffuser Angle On A Bluff Body in Ground EffectDocument7 pagesInfluence of Diffuser Angle On A Bluff Body in Ground EffectVyssion100% (2)

- SPE 59464 Full Field Model Study of A Dense Highly Fractured Carbonate ReservoirDocument5 pagesSPE 59464 Full Field Model Study of A Dense Highly Fractured Carbonate ReservoircmkohNo ratings yet

- Samuel 2020Document18 pagesSamuel 2020aidaNo ratings yet

- Analisa Pressure Build Up TestDocument49 pagesAnalisa Pressure Build Up TestLuc ThirNo ratings yet

- Analisa Pressure Build Up TestDocument28 pagesAnalisa Pressure Build Up TestDerips PussungNo ratings yet

- MudSummary - DERRICK2019 - MUD MAN - Davin DjustinDocument18 pagesMudSummary - DERRICK2019 - MUD MAN - Davin DjustinHerro GamaNo ratings yet

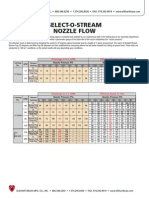

- Select O Stream Nozzle FlowDocument1 pageSelect O Stream Nozzle FlowJohnny JosephNo ratings yet

- Hydrodynamic Performance of A Surfboard FinDocument4 pagesHydrodynamic Performance of A Surfboard FinWesley FernandesNo ratings yet

- PA Determining Multiphase Pressure Drops and Flow CapaDocument8 pagesPA Determining Multiphase Pressure Drops and Flow CapaRodrigo RosasNo ratings yet

- Core Flooding Manual-1Document6 pagesCore Flooding Manual-1Boniphace JohnNo ratings yet

- Orifice Coefficient Data from Pipe Flow TestsDocument56 pagesOrifice Coefficient Data from Pipe Flow TestsDan GarayNo ratings yet

- Mystery nozzle flow and reachDocument1 pageMystery nozzle flow and reachevaneliasibNo ratings yet

- Spe 96587 MS PDFDocument6 pagesSpe 96587 MS PDFamahaminerNo ratings yet

- Planning and Design of ReservoirsDocument79 pagesPlanning and Design of ReservoirsSrinivasaRaoPeddintiNo ratings yet

- Ep Petrochina MangroveDocument3 pagesEp Petrochina MangroveStiveGrajalesNo ratings yet

- Results of Laboratory Experiments To Simulate The Downhole Environment of Formation Testing While DrillingDocument8 pagesResults of Laboratory Experiments To Simulate The Downhole Environment of Formation Testing While DrillingjameeloNo ratings yet

- Portland Cement Association: Aggregate Interlock AT Joints IN Concrete PavementsDocument23 pagesPortland Cement Association: Aggregate Interlock AT Joints IN Concrete PavementsFelipe FernándezNo ratings yet

- 120 Icpmg 2002 89 94Document6 pages120 Icpmg 2002 89 94Nu NguyenNo ratings yet

- Pipeline InspectionDocument19 pagesPipeline InspectionsaeedalemveNo ratings yet

- Jet-Flow Gate Model Study Discharge Coefficients and Pressure ConditionsDocument32 pagesJet-Flow Gate Model Study Discharge Coefficients and Pressure Conditionsaliekberkilinc87No ratings yet

- Setiyo Pamungkas, Maire Flavien, and Salley Baptiste, ADNOC OnshoreDocument15 pagesSetiyo Pamungkas, Maire Flavien, and Salley Baptiste, ADNOC OnshoreBarham Sabir MahmoodNo ratings yet

- Oil and Gas Artificial Fluid Lifting TechniquesFrom EverandOil and Gas Artificial Fluid Lifting TechniquesRating: 5 out of 5 stars5/5 (1)

- Notation: Objective/ScopeDocument3 pagesNotation: Objective/ScopeHilmy MuhammadNo ratings yet

- 15 PDFDocument16 pages15 PDFHilmy MuhammadNo ratings yet

- Cement Properties and CharacteristicsDocument1 pageCement Properties and Characteristicsarylananyla100% (1)

- Diagnostic Study For Cement Mill OptimizationDocument9 pagesDiagnostic Study For Cement Mill OptimizationHilmy MuhammadNo ratings yet

- HB Stepper Motor EDocument22 pagesHB Stepper Motor EEthan ColeNo ratings yet

- 2 Phase Stepper Motor PDFDocument2 pages2 Phase Stepper Motor PDFArif FaturohmanNo ratings yet

- Pu PDFDocument1 pagePu PDFHilmy MuhammadNo ratings yet

- Esp 8266 at Commands SetDocument1 pageEsp 8266 at Commands Setthanhvnpt100% (1)

- Price ListDocument6 pagesPrice ListMistḗr AjikNo ratings yet

- Lab Chi ML EngDocument7 pagesLab Chi ML EngHilmy MuhammadNo ratings yet

- New Method To Measure The Fill Level of The Ball Mill I - Theoretical Analysis and DEM SimulationDocument8 pagesNew Method To Measure The Fill Level of The Ball Mill I - Theoretical Analysis and DEM SimulationJoshua JordanNo ratings yet

- Cement Properties and CharacteristicsDocument1 pageCement Properties and Characteristicsarylananyla100% (1)

- WT 085 270 003 Ua PS 1209Document2 pagesWT 085 270 003 Ua PS 1209Hilmy MuhammadNo ratings yet

- Lab Chi ML EngDocument7 pagesLab Chi ML EngHilmy MuhammadNo ratings yet

- New Method To Measure The Fill Level of The Ball Mill I - Theoretical Analysis and DEM SimulationDocument8 pagesNew Method To Measure The Fill Level of The Ball Mill I - Theoretical Analysis and DEM SimulationJoshua JordanNo ratings yet

- Cement Mill Calculation DesaignDocument1 pageCement Mill Calculation DesaignHilmy MuhammadNo ratings yet

- Asset Upload File422 3529Document94 pagesAsset Upload File422 3529Hilmy MuhammadNo ratings yet

- Coastal Aquaculture and Mariculture Course OutlineDocument39 pagesCoastal Aquaculture and Mariculture Course OutlineHaha HahaNo ratings yet

- Bfdj94 Profitable Beekeeping With Apis CeranaDocument4 pagesBfdj94 Profitable Beekeeping With Apis CeranaMario Echipare Jr.No ratings yet

- Fewkes, Neolithic SitesDocument85 pagesFewkes, Neolithic SitesivansuvNo ratings yet

- 1846 PDFDocument86 pages1846 PDFJosephine ChirwaNo ratings yet

- Sample 2 - Poetry AnalysisDocument3 pagesSample 2 - Poetry Analysisalnajdawisewar2No ratings yet

- Ielts Peter May Reading (12-7)Document6 pagesIelts Peter May Reading (12-7)Ngọc MinhNo ratings yet

- Rome City Guide /TITLEDocument129 pagesRome City Guide /TITLEDevi AswandiniNo ratings yet

- Agri Crops Module 2Document77 pagesAgri Crops Module 2Danica HerealwaysNo ratings yet

- SorptivityDocument7 pagesSorptivityMujiono MujionoNo ratings yet

- PVC Pipes SpecificationsDocument3 pagesPVC Pipes SpecificationsNima AhvaziNo ratings yet

- Water Ecology Unit 1Document30 pagesWater Ecology Unit 1सुनिल बाबु खत्रीNo ratings yet

- Popular Mechanics PDFDocument116 pagesPopular Mechanics PDFdhani_is100% (2)

- Precast Concrete Wall Panel With Banana Fiber and Coconut Coir As AdmixturesDocument77 pagesPrecast Concrete Wall Panel With Banana Fiber and Coconut Coir As Admixturesic80% (5)

- A Project Feasibility Study FinalDocument10 pagesA Project Feasibility Study FinalMark Jovin RomNo ratings yet

- UNIT 2 - Produce Organic VegetablesDocument80 pagesUNIT 2 - Produce Organic VegetablesBest School100% (1)

- Saving The RainforestDocument7 pagesSaving The Rainforestkate100% (1)

- OsirisDocument5 pagesOsirischrisNo ratings yet

- African CivilizationsDocument2 pagesAfrican CivilizationsRomelyn AngadolNo ratings yet

- Use of Appropriate Technologies For Conservation of Environmental ResourcesDocument14 pagesUse of Appropriate Technologies For Conservation of Environmental ResourcesEthan RamdeenNo ratings yet

- Introduction To Dairy Science and TechnologyDocument120 pagesIntroduction To Dairy Science and TechnologyShagun GuptaNo ratings yet

- Science 1 Quarter 2Document3 pagesScience 1 Quarter 2Venickson Bituin TumaleNo ratings yet

- Cellular Control Questions F215Document101 pagesCellular Control Questions F215Miles StacksNo ratings yet

- A Traceability System For Outgrower Schemes PDFDocument157 pagesA Traceability System For Outgrower Schemes PDFsebichondoNo ratings yet

- Mtap ReviewerDocument4 pagesMtap Reviewerjessica vargasNo ratings yet

- UntitledDocument31 pagesUntitledMarcelo Baeza TalentoNo ratings yet

- Problems and Solutions for Poultry Farming in a Tropical ClimateDocument4 pagesProblems and Solutions for Poultry Farming in a Tropical ClimateNeverSad Ej Nadabar100% (2)

- Design Manual South Sudan PDFDocument569 pagesDesign Manual South Sudan PDFYohannes GirmaNo ratings yet

- New Varieties of Crops Released and Identified - Indian Council of Agricultural ResearchDocument4 pagesNew Varieties of Crops Released and Identified - Indian Council of Agricultural ResearchSonuNo ratings yet

- 1DA20ME435 Pramodraj D G. Agricultural Multi SprayerDocument27 pages1DA20ME435 Pramodraj D G. Agricultural Multi SprayerPramod RajNo ratings yet