Professional Documents

Culture Documents

Plasma Display Panels PDP With Oscilloscope - Guide

Uploaded by

sttecnicoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Plasma Display Panels PDP With Oscilloscope - Guide

Uploaded by

sttecnicoCopyright:

Available Formats

Troubleshooting

Troubleshooting Plasma Display Panels

with the Oscilloscope

Plasma Display Panel Troubleshooting with the Oscilloscope - 2008

Troubleshooting

Troubleshooting Plasma Display Technology using the Oscilloscope

Introduction

The most versatile diagnostic tool we have available to us as Technicians is the Oscilloscope

but it is probably the least used piece of equipment in the Service Center. This presentation is

an attempt at explaining and illustrating the use of the Scope to decrease the diagnostic time

and increase the production and the revenue for the Service Centers. As prices fall on the

Consumer Electronics Products we need to more accurately and quickly determine which

circuits are working and which have failed, changing multiple circuit boards at one time will

become cost prohibitive as the prices of product continue to fall. The Oscilloscope when used in

conjunction with the Volt Meter will greatly improve the chances of a first time repair without

costly repeat service calls which inconvenience the Customer and drain revenues from the

Service Centers.

Plasma Display Panel Troubleshooting with the Oscilloscope - 2008

Troubleshooting

This Section will cover Amplitude, Time and Frequency, Duty Cycle, and Phasing

The Oscilloscope gives us more information about what is happening in a circuit then any

other piece of test equipment we have. In this Section we will look at some of the things the

Scope is telling us and see how we can utilize this information to quickly isolate a circuit

failure.

First we will look at the basic operation and adjustments and how to set them to obtain a

useful display.

We will use some examples and some simple calculations to give us more insight to the

operation of the circuit we are testing for figuring Frequency once we have determined Time.

The difference between Duty Cycle and Frequency will be explored, as will the relationship

between Drive Signals on separate circuit boards, by checking the Phasing of the those Signals.

When we finish this Section the technician should understand what Amplitude, Frequency,

Duty Cycle, and Phasing mean when used for Troubleshooting.

CAUTION: When using the Oscilloscope we must be cautious of where we put our ground. If

working on the Primary Side of the Power Supply, we must use an Isolation Transformer.

Never connect the Oscilloscope Ground to a Floating Ground as damage can occur. When

Troubleshooting an LG Plasma Display use the metal Frame of the Chassis for Ground.

Plasma Display Panel Troubleshooting with the Oscilloscope - 2008

Voltage and Time Adjustment Troubleshooting

This Section will cover the Basic Operation and Adjustments for using the Oscilloscope

The function of an Oscilloscope is to draw a Graph of Voltage against Time with

Voltage on the Vertical or Y-Axis and Time on the Horizontal or X-Axis.

Voltage

Time

The Oscilloscope Screen has 8 squares Y-Axis and

10 squares on the X-Axis. The Grid is made of 1 CM squares.

Plasma Display Panel Troubleshooting with the Oscilloscope - 2008

Voltage and Time Adjustment Troubleshooting

Typical Control Panel for Dual Trace Oscilloscope consisting of both

Y-Axis Voltage adjustment and X-Axis Time adjustment.

Vertical Position Control Horizontal Position Control

adjusts the display position on adjusts the display position on the

Vertical Plane Horizontal Plane

Volts/Div Control adjusts the

Horizontal or X-Axis Time

Amplitude of the waveform being

measurement measured in

displayed in the Vertical Plane .

Seconds, Milli-Seconds or

Micro-Seconds/cm

Voltage is measured in either

volts/cm or milli-volts/cm

ms

v mv s μs

Frequency can be obtained by taking the reciprocal of time F = 1/T

Plasma Display Panel Troubleshooting with the Oscilloscope - 2008

Troubleshooting

Oscilloscope Triggering

The Triggering determines when the oscilloscope starts to acquire data and

Display a waveform. When the Trigger is set correctly the Oscilloscope converts

unstable displays or blank screens into useful waveforms.

HF gives Triggering to high frequency signals and LF gives Triggering to low frequency signals.

Delay introduces a delay relative to the Trigger Point so a different part of the signal can be seen.

Plasma Display Panel Troubleshooting with the Oscilloscope - 2008

Probe Compensation Troubleshooting

Under compensated

Normal

Overcompensated

Before getting started, remember to check the Probe Compensation Adjustment.

Connect the Oscilloscope Probe to the test jack and adjust the screw adjustment on

the Probe to square the waveform as seen in the upper right figure.

Test Jack

Plasma Display Panel Troubleshooting with the Oscilloscope - 2008

Frequency / Duty Cycle Troubleshooting

The Oscilloscope provides the Technician with Amplitude, Timing, Duty Cycle, DC level as

well as Phasing when compared to another known signal. The example in Fig. 1 illustrates a

waveform with a Duty Cycle of 50% the Amplitude is 40VPP (4 squares vertical @ 10v/ Div.)

the Time for 1 Cycle is 60μs (6 squares @ 10μs/division horizontal) a simple calculation

Freq. = 1/T reveals the Frequency of Approx 16KHz.

Fig 1 Fig 2

VOLTS/DIV = 10V

SEC/DIV = 10µs

Plasma Display Panel Troubleshooting with the Oscilloscope - 2008

Duty Cycle Troubleshooting

The change in the waveform in Fig 3 indicates a change in Duty Cycle with the Timing of the

Positive and Negative half cycles being different but the Frequency staying the same. Failure

of circuits that require a 50% Duty Cycle (matched Power Output Circuit) requiring “ on / off ”

times of equal duration can be located by checking for proper Duty Cycle. When “ on / off “

times are not Identical circuit failures will occur, this can be found using the Oscilloscope!

FIG 3

VOLTS/DIV = 10V

SEC/DIV = 10µs

Plasma Display Panel Troubleshooting with the Oscilloscope - 2008

Frequency Troubleshooting

The Waveform in Fig 4 has the same Voltage and Time settings as previously used but we have

twice as many cycles. This indicates a change in Frequency, the Duty Cycle is at 50% but

Frequency has increased because the Time Duration of each cycle has decreased. As Time

decreases Frequency increases, each cycle is now 30μs in duration and by calculating the

Frequency F = 1/T we can determine the increase in Frequency to Approx 33KHz

FIG 4

VOLTS/DIV = 10V

SEC/DIV = 10µs

Plasma Display Panel Troubleshooting with the Oscilloscope - 2008

Troubleshooting

Phasing

Phasing allows us to see the Time Relationship at which two different Signals occur

and be able to determine that they are occurring at the proper times. This function can be very

helpful when troubleshooting loss of color in TV because the color burst signal will occur during

the Horizontal Retrace Time a quick check of the signals will often reveal the problem.

The usefulness of this Test in Plasma Troubleshooting is also helpful when comparing

Y SUS and Z SUS Drive Waveforms, below is an example of both a Normal and Abnormal

Waveform, note the differences in each.

Y SUS Z SUS Y SUS Z SUS

Comparison of the Illustrations

show the Amplitude of the

waveforms displayed to be equal.

The Oscilloscope reveals the

problem to be a failure of the Z

Board. The voltmeter would not

have diagnosed the failure!

Waveforms shown on the right

result in no raster condition

Normal Phase Relationship Abnormal Phase Relationship

Between Y and Z SUS Waveforms Between the Y and Z SUS Waveforms

Plasma Display Panel Troubleshooting with the Oscilloscope - 2008

Phasing Troubleshooting

Phasing can also be plotted on a Graph of Voltage to Voltage in what is called Vector or

XY Mode the input to each channel drives the beam Vertically on one channel and

Horizontally on the other channel. The waveform shown below represents what should occur

if the Micro-Processor Circuit Resets. Vcc should occur first driving the Beam Vertically and

when Reset occurs the rise in voltage drives the beam Horizontally.

Stereo Sound since each

Audio channel is different

results in a circle pattern

on the screen. A Mono

Audio Pattern would look

like a 45° line on the Screen

since both channels are in

Phase.

In this Example, channel 1 is connected to VCC and channel 2 in connected to Reset. Reset being an active low occurs

after the VCC Supply is present, in this manner Reset can be confirmed! Failure to Reset would result in both lines going

high at the same time resulting in a line displayed on the screen at a 45° angle.

Plasma Display Panel Troubleshooting with the Oscilloscope - 2008

Troubleshooting

Checking DC Voltage

DC Voltage can be checked by first grounding the scope probe and setting the

Vertical Position Control at a reference point, setting the volts p/cm at the level expected

to be measured and connecting to the circuit under test. The DC level can then be

determined by counting the offset deflection of the pattern in the Y-Axis or Vertical Plane.

The advantage of the Scope is you can also see any noise that may be present as a

result of a circuit failure.

At a setting of 1v/cm the Oscilloscope Display in indicating a 5v DC Level

any noise present would be located at the 5v level. Once again a Meter would not confirm this failure.

Plasma Display Panel Troubleshooting with the Oscilloscope - 2008

Normal Waveforms Troubleshooting

In this Section, we will look at the waveforms for a working Display Panel as compared to

a Display Panel with a circuit failure. We will analyze the problem waveform to determine

which board is at fault. When we finish this Section the Technician should be able to

quickly recognize which circuit has failed by observing the Scope waveform.

Scope Setting as follows:

Y SUS 100v/cm x100 probe Z SUS 50v/cm x10 probe

50μs 50µs

Y SUS 450vpp Z SUS 200vpp Y SUS and Z SUS

The above waveforms are from a working 60” Plasma Display the Y SUS and Z SUS

Waveforms are illustrated separately and together as they actually occur. These two

Waveforms are independent of each other meaning one could be present with out the other.

Plasma Display Panel Troubleshooting with the Oscilloscope - 2008

Troubleshooting

Y SUS Failure

This Screen shows a failure has occurred on the Y SUS Board, with this check there is no Picture

the unit has Sound and there was no “Reset” of the Panel visible at turn on. The Z SUS

waveform looks normal so there is no need to replace the Z Board for this failure. Be sure to

check the Y Drive Boards before replacing the Y SUS for possibility of a failure.

Plasma Display Panel Troubleshooting with the Oscilloscope - 2008

Troubleshooting

Z SUS Failure

The Waveforms on this screen suggest a failure has occurred on the Z SUS Board. The Y SUS

signal is normal the Z SUS signal is tracking the Y SUS. This symptom would result in a no

Picture, no Raster, or “Reset” Symptom. The Y SUS waveform is normal so there would be no

need to replace the Y SUS Board for this problem. IPM Failure, Loss of 5v or Logic Input from

the Control Board results in this waveform.

Protection Diodes in the Output Stage of the Z Board if shorted would result in a Flat

Line waveform, indicating a short to Ground or the VS voltage

Plasma Display Panel Troubleshooting with the Oscilloscope - 2008

Troubleshooting

VS Power Supply Failure

This screen is indicating that both the Y SUS and Z SUS waveforms are incorrect. This failure

is affecting the operation of both circuits, a check of the Supply Voltages indicates we lost

the VS Voltage (open VS Fuse on the Y SUS Board). In this case, we had no raster and no

“RESET” because the amplitude of the waveforms was not sufficient to drive the Panel.

Time setting is 50μs

YSUS

100v/cm

350vpp

Z SUS

50v/cm

75vpp

Plasma Display Panel Troubleshooting with the Oscilloscope - 2008

Troubleshooting

Control Board

This screen Shows a complete loss of any waveforms from either the Y SUS

or the Z SUS this results in no Picture no “Reset” and is the result of a possible failure on

the Control Board. Loss of 5v to the Control Board or a loss of Signal from the Crystal

will result with this lack of a waveform, look for the operation of Temperature LED’s.

Plasma Display Panel Troubleshooting with the Oscilloscope - 2008

Troubleshooting

NO RASTER

The presence of these two Waveforms as viewed here is an indication that both the Y SUS

and the Z SUS Boards are working properly. A no Raster complaint with both waveforms

correct is either a loss of Video from the Main Board to the Control Board ( Short Pins 1 and 2

on P1 unused connector on the Control Board look for Test Patterns ) or a loss of VA voltage.

Check for the presence of the LVDS Signal.

Plasma Display Panel Troubleshooting with the Oscilloscope - 2008

Troubleshooting

LVDS

Video Signals from the Main Board to the Control Board are referred to as

Low Voltage Differential Signals or LVDS and their presence can be confirmed

with the Oscilloscope by monitoring the signal with no input while pressing the

Menu Button on and off with the Remote Control. Loss of these Signals would

confirm the failure is on the Main Board!

Menu OFF Menu ON

Example of Normal Signals measured at 200mv/cm at 5µs/cm.

Plasma Display Panel Troubleshooting with the Oscilloscope - 2008

Troubleshooting

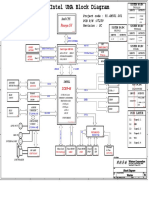

Y SUS and Z SUS

Waveform Analysis

Ramp up sets the pitch of the Top Ramp

VSET UP changes the amplitude at the The Amplitude of this portion of the waveform

top of the waveform below is adjusted by Z Bias on the Z Board

VSC sets the V Scan

DC level

Loss of Z Bias lowers the Amplitude

Vset Down adjusts the pitch of the Bottom Ramp

-VY sets the amplitude of the negative excursion

Plasma Display Panel Troubleshooting with the Oscilloscope - 2008

THE END

THANK YOU!

Plasma Display Panel Troubleshooting with the Oscilloscope - 2008

You might also like

- HK.T.RT2851P839 (Power Board)Document7 pagesHK.T.RT2851P839 (Power Board)sttecnicoNo ratings yet

- Dimensiones 1Document1 pageDimensiones 1sttecnicoNo ratings yet

- Acer Aspire 4741Z 4741ZG 5741 5741G 5741Z 5741ZG - COMPAL LA-5891P - REV 1.0Document59 pagesAcer Aspire 4741Z 4741ZG 5741 5741G 5741Z 5741ZG - COMPAL LA-5891P - REV 1.0Agus Agus AgusNo ratings yet

- Brother DCP 1612wDocument200 pagesBrother DCP 1612wsttecnicoNo ratings yet

- RN TurboHD DVR v3.4.88 031918NADocument1 pageRN TurboHD DVR v3.4.88 031918NAsttecnicoNo ratings yet

- Samsung d6000 Series Ue32d6000 Ue37d6000 Ue40d6000 Ue46d6000tw Ua32d6000 Ua46d6000 Ua55d6000 Led TrainingDocument31 pagesSamsung d6000 Series Ue32d6000 Ue37d6000 Ue40d6000 Ue46d6000tw Ua32d6000 Ua46d6000 Ua55d6000 Led TrainingMd BahraouiNo ratings yet

- Curve 3Document1 pageCurve 3sttecnicoNo ratings yet

- Curve 4Document1 pageCurve 4sttecnicoNo ratings yet

- Mosfet 1Document1 pageMosfet 1sttecnicoNo ratings yet

- RN TurboHD DVR v3.4.88 031918NADocument1 pageRN TurboHD DVR v3.4.88 031918NAsttecnicoNo ratings yet

- Resistor EnglishDocument9 pagesResistor EnglishsttecnicoNo ratings yet

- LCD Modification 1Document159 pagesLCD Modification 1Jeank Rivadeneyra89% (19)

- Recycle ElectronicDocument3 pagesRecycle ElectronicsttecnicoNo ratings yet

- Power Supply TroubleshootingDocument1 pagePower Supply TroubleshootingsttecnicoNo ratings yet

- Diagrama Electrico Opel AstraDocument1 pageDiagrama Electrico Opel AstrasttecnicoNo ratings yet

- CapsuleDocument1 pageCapsulesttecnicoNo ratings yet

- Waveforms Board Sony Chasis FE1Document1 pageWaveforms Board Sony Chasis FE1sttecnicoNo ratings yet

- Diagrama Electrico Opel AstraDocument1 pageDiagrama Electrico Opel Astrasttecnico100% (1)

- Diagrama Electrico Opel Astra PDFDocument1 pageDiagrama Electrico Opel Astra PDFsttecnico0% (3)

- Cool Invoice A4Document1 pageCool Invoice A4sttecnicoNo ratings yet

- Conector USBDocument1 pageConector USBsttecnicoNo ratings yet

- ScartDocument1 pageScartsttecnicoNo ratings yet

- Repair Neovo E17daDocument10 pagesRepair Neovo E17dasttecnicoNo ratings yet

- Siva Institute of Electronics Guntur AP India 1Document7 pagesSiva Institute of Electronics Guntur AP India 1ZoranNo ratings yet

- Lvds LG PlasmaDocument1 pageLvds LG PlasmasttecnicoNo ratings yet

- Op To Electronic ADocument20 pagesOp To Electronic AsttecnicoNo ratings yet

- Badblocks LinuxDocument1 pageBadblocks LinuxsttecnicoNo ratings yet

- Gigabytes Training MotherboardDocument16 pagesGigabytes Training MotherboardsttecnicoNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Load Testing, Inspection of Cranes, Lifting Gears and AppliancesDocument5 pagesLoad Testing, Inspection of Cranes, Lifting Gears and Applianceseddie2166100% (1)

- Needle Valves: Flow ControlsDocument2 pagesNeedle Valves: Flow ControlsyorisfmNo ratings yet

- Centro de Procesado de Barras de Cobre Cu-Flex eDocument19 pagesCentro de Procesado de Barras de Cobre Cu-Flex eBoschert MéxicoNo ratings yet

- Sharp 21MFG1L Chasis GA6Document60 pagesSharp 21MFG1L Chasis GA6Xavier Lg100% (1)

- Vk3ye Dot Com - Compact L-Match For Portable UseDocument7 pagesVk3ye Dot Com - Compact L-Match For Portable Usetito351No ratings yet

- Atlas Copco - Air MotorDocument80 pagesAtlas Copco - Air MotorNo HopeNo ratings yet

- S LV SWG Vip - 00Document35 pagesS LV SWG Vip - 00afsar.erNo ratings yet

- CRI Pump & ControllerDocument5 pagesCRI Pump & ControllerJoko WahonoNo ratings yet

- 100 STATOR EF P345 With 20HZ INJECTION Apr 09Document6 pages100 STATOR EF P345 With 20HZ INJECTION Apr 09Amaresh NayakNo ratings yet

- Esquema-HP COMPAQ PRESARIO CQ60 CQ70 WISTRON WARRIORDocument42 pagesEsquema-HP COMPAQ PRESARIO CQ60 CQ70 WISTRON WARRIORErmirio MarquesNo ratings yet

- ANSI A9220 Machine Design InfographicDocument1 pageANSI A9220 Machine Design InfographicMohammadhossein SahlabadiNo ratings yet

- Dp1600i t3 Maintenance Planner Combo EnglishDocument2 pagesDp1600i t3 Maintenance Planner Combo Englishsoledad alvis arotaipeNo ratings yet

- SMA Connector SeriesDocument26 pagesSMA Connector SeriesCmpterRFNo ratings yet

- York Pres IPLVDocument40 pagesYork Pres IPLVArclasseNo ratings yet

- E-1 Deluge ValveDocument10 pagesE-1 Deluge ValveTracy SankarNo ratings yet

- 13 IndexDocument9 pages13 IndexVilius BukysNo ratings yet

- Interruptores CQD Manual PDFDocument8 pagesInterruptores CQD Manual PDFAfredo DiazNo ratings yet

- Sequential Logic BasicsDocument20 pagesSequential Logic Basicskhairalla mohamedNo ratings yet

- Brush Wear GuideDocument3 pagesBrush Wear GuideSomkene MbakweNo ratings yet

- RS232 InterfacingDocument41 pagesRS232 InterfacingPuspala ManojkumarNo ratings yet

- Plansa Motopompa Caprari MEC-MG 80-4-3ADocument2 pagesPlansa Motopompa Caprari MEC-MG 80-4-3AAlex BancilaNo ratings yet

- 45KW 4P DatasheetDocument5 pages45KW 4P Datasheetvitthal01No ratings yet

- User'S Manual: Model 29840Document18 pagesUser'S Manual: Model 29840Escandon Vicario LinoNo ratings yet

- Gos-6Xxg Family Dual Trace Oscilloscope: Members of The FamilyDocument36 pagesGos-6Xxg Family Dual Trace Oscilloscope: Members of The FamilyNguyen VansuNo ratings yet

- Océ 5120 User's ManualDocument172 pagesOcé 5120 User's ManualdrchapmanNo ratings yet

- Fuel Pump Pressure & Volume Testing: Y ARL EyfertDocument1 pageFuel Pump Pressure & Volume Testing: Y ARL Eyfertford62bNo ratings yet

- Internship Project Report 1Document17 pagesInternship Project Report 1Aniruddha verulkar50% (2)

- Zener DiodeDocument15 pagesZener DiodeEEE M.AASTHIKANo ratings yet

- X1 SystemDocument21 pagesX1 SystemMos CraciunNo ratings yet

- Gua Conduit Outlet BoxesDocument4 pagesGua Conduit Outlet BoxesPipitlyNo ratings yet