Professional Documents

Culture Documents

000-ZA-E-09413 Construction Progress Meas Proc

Uploaded by

alinor_tnCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

000-ZA-E-09413 Construction Progress Meas Proc

Uploaded by

alinor_tnCopyright:

Available Formats

CLIENT JOB UNIT

274219 000

PLANT LOCATION MEXICO

EL ENCINO - TOPOLOBAMPO NATURAL GAS SPC. 000-ZA-E-09413

TRANSPORTATION SYSTEM

PROJECT / UNIT Rev.

CONSTRUCTION PROGRESS MEASUREMENT Sh. 1 of 12 0

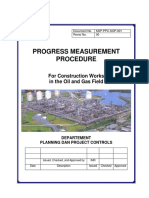

CONSTRUCTION PROGRESS MEASUREMENT PROCEDURE

_____

0 Issue

Rev. Description Prepared Checked Approved Date

000-za-e-09413 construction progress

measurement procedure.doc

This document is the property of Saipem who will safeguard its rights according to the civil and penal provisions of the law.

CLIENT JOB UNIT

274219 00

PLANT LOCATION MEXICO

EL ENCINO - TOPOLOBAMPO NATURAL GAS SPC. 0000-ZA-E-09413

saimexicana, TRANSPORTATION SYSTEM

PROJECT / UNIT Rev.

CONSTRUCTION PROGRESS MEASUREMENT Sh. 2 of 12 0

INDEX

1. INTRODUCTION 3

1.1. Scope of work 3

1.2. Definitions 3

1.3. Abbreviations 4

1.4. Reference documents 5

_____

2. CONSTRUCTION CONTROL STRATEGY 5

2.1. Goals 5

2.2. Planning 5

2.3. Progress 5

3. CONSTRUCTION SCHEDULE AND PROGRESS CRITERIA 6

3.1. Work Breakdown Structures 6

3.2. Construction Activities 6

3.3. Standard Man Hours 7

3.4. CPM Analysis 7

4. CONSTRUCTION SCHEDULE 7

4.1. Level III (First phase development) 8

4.2. Working Level III 8

5. PROGRESS 9

5.1. Progress Monitoring – Level IV 9

5.2. Productivity Analysis (K Factor) 10

6. RESPONSABILITIES AND ACTIONS 11

7. CONSTRUCTION PBS 12

000-za-e-09413 construction progress

measurement procedure.doc

This document is the property of Saipem SpA who will safeguard its rights according to the civil and penal provisions of the law.

CLIENT JOB UNIT

274219 00

PLANT LOCATION MEXICO

EL ENCINO - TOPOLOBAMPO NATURAL GAS SPC. 0000-ZA-E-09413

saimexicana, TRANSPORTATION SYSTEM

PROJECT / UNIT Rev.

CONSTRUCTION PROGRESS MEASUREMENT Sh. 3 of 12 0

1. INTRODUCTION

1.1. Scope of work

The scope of the Construction Scheduling Control Procedure is to describe the basic method of construction

planning and progress control on site.

1.2. Definitions

Client/COMPANY Transportadora de Gas Natural del Noroeste, TGNN

Contractor Saimexicana S.A. da C.V.

_____ Commissioning All activities performed after achievement of Ready for Commissioning

certificate for each Unit/System.

Contract Contract that governs the relations between Contractor and the Client

COPE COPE is used to record Subcontractor attendance, spent man hours and

mobilised equipment. It is related with COPR to measure the actual

productivity factor (K2).

COPR COPR is used to schedule the work loads in terms of standard man hours,

quantities, percentages of each SCMC and to produce the “s” curve. The

programme compares the actual progress vs. the schedule “s” curve for each

project level. COPR has structured standard reports that aid field

management with summary levels analysis.

Construction Management

Class Main activity to be carried out within a WP (for example piping steel

structures, equipment, etc.)

Home Office Saimexicana office (Mexico City)

Pre-commissioning The phase in which all the required cleaning, checks and tests (electrical,

instrumental, mechanical), are implemented without introduction of

hydrocarbons into the process.

PROM PROM is used to evaluate the progress of the SCMC on site at the level of

small elements easily measurable named items. Each item will have the same

PBS as the COPR programme.

A set of basic operations that cannot be broken down any further and that

form a typical work are assigned to each item present into the database and

then conveyed to the proper SCMC.

Punch List List of items or activities that are: not completed, outstanding or, in some way,

deficient and fails to meet the requirements of the project specifications,

drawings, procedures, etc. and are required to be provided or corrected.

Sub Construction

Management Class Sub activity of CMC (for example carbon steel pipe, heavy structures, light

structures, pumps, exchangers, etc.). Each SCMC is provided with relevant

standard efficiency.

000-za-e-09413 construction progress

measurement procedure.doc

This document is the property of Saipem SpA who will safeguard its rights according to the civil and penal provisions of the law.

CLIENT JOB UNIT

274219 00

PLANT LOCATION MEXICO

EL ENCINO - TOPOLOBAMPO NATURAL GAS SPC. 0000-ZA-E-09413

saimexicana, TRANSPORTATION SYSTEM

PROJECT / UNIT Rev.

CONSTRUCTION PROGRESS MEASUREMENT Sh. 4 of 12 0

COSMO® Software suite that consists of a series of modules, each one designed to

manage and control specific activities or aspects of construction and its

completion.

Subcontractor Entity (and its legal successors in title) named as Subcontractor in the

Contractor purchase order and/or the contract awarded to the Subcontractor

to perform specific services and/or works.

Vendor Supplier of items or equipment.

Work Package: Discipline (Mechanical, Civil, etc.) or Subcontractor’s scope of work that is

carried out in the area or in the target function.

_____ 1.2.1. Operational Levels of Construction

Operational levels of Construction mean evaluation of work in term of SMH according to the following PBS:

Lev. 0 total SMH of project and sub-projects

Lev. 1 SMH of work areas (civil, mechanical, electrical, etc.) and target

function (on-site, offsite, utilities)

Lev. 2 SMH of CMC of work areas e WP

Lev. 3 SMH of sub-CMC of work activities and WP

Lev. 4 SMH of item and/or price list item for work area and WP (i.e. one foundation and work

activities for its execution like excavation, formwork, steel bars, concrete pouring, back

filling, etc.)

1.3. Abbreviations

1.3.1. Project Organisation

CM Construction Manager

COM Commissioning Manager

DS Discipline Superintendent

FEM Field Engineering Manager

FCC Field Control Coordinator

PCL Project Construction Leader

PM Project Manager

SM Site Manager

1.3.2. Other

AMH Actual Man Hour

CMC Construction Management Class

CPM Critical Path Method

HSE Health, Safety and Environment

EMC Engineering Management Class

EMH Expected Man Hour

EPC Engineering, Procurement and Construction

NDE Non Destructive Examination

PBS Project Breakdown Structure

PMI Positive Material Identification

PMS Project Management Schedule

QA Quality Assessment

000-za-e-09413 construction progress

measurement procedure.doc

This document is the property of Saipem SpA who will safeguard its rights according to the civil and penal provisions of the law.

CLIENT JOB UNIT

274219 00

PLANT LOCATION MEXICO

EL ENCINO - TOPOLOBAMPO NATURAL GAS SPC. 0000-ZA-E-09413

saimexicana, TRANSPORTATION SYSTEM

PROJECT / UNIT Rev.

CONSTRUCTION PROGRESS MEASUREMENT Sh. 5 of 12 0

QC Quality Control

SCMC Sub Construction Management Class

SMH Standard Man Hour

PBS Project Breakdown Structure

WP Work Package

1.4. Reference documents

000-ZA-E-09400 Site Coordination procedure

000-ZA-E-09402 Project Control for Piping

_____

2. CONSTRUCTION CONTROL STRATEGY

2.1. Goals

Operative communication within construction team;

Efficient “modus operandi” in terms of:

- methods;

- control;

- construction oriented” integration with engineering and procurement;

- organization;

- construction management for other disciplines (quality, safety).

Ensuring an effective data tracking and forecasting analysis;

Rewarding contractual terms and conditions.

2.2. Planning

Level 3 EPC schedules shall be integrated; details of the construction program (schedule) shall be included.

Integration of the Schedules will be obtained by implementing:

- shared PBS;

- shared path of construction;

- set-up of engineering and material deliverables dates, so called Required on Site (ROS), to support

construction activities, logically linked to scheduled tasks.

PBSs and path of construction shall ensure an effective progress achievement and manageable control;

Progressive development of Level 3 working schedule jointly achieved by Contractor and Subcontractors;

In force and regular issuing of look ahead reports.

2.3. Progress

Ensure an objective and straightforward physical progress measurement together with an effective data

tracking based on tested and reliable standard methodology.

Collection of information organized by an agreed and organised coding system.

000-za-e-09413 construction progress

measurement procedure.doc

This document is the property of Saipem SpA who will safeguard its rights according to the civil and penal provisions of the law.

CLIENT JOB UNIT

274219 00

PLANT LOCATION MEXICO

EL ENCINO - TOPOLOBAMPO NATURAL GAS SPC. 0000-ZA-E-09413

saimexicana, TRANSPORTATION SYSTEM

PROJECT / UNIT Rev.

CONSTRUCTION PROGRESS MEASUREMENT Sh. 6 of 12 0

3. CONSTRUCTION SCHEDULE AND PROGRESS CRITERIA

3.1. Work Breakdown Structures

A PBS has been developed to ensure the fulfilment of tender requirements.

The PBS is in fact a project planning and control technique which describes project tasks using a framework to

define the contractual scope of work related to the implementation of the integrated phase of the project.

The PBS is a level by level breakdown continued beyond the contract phase levels, through the project units, to

identify and codify manageable tasks and activities.

As a general definition the “project unit” (or work package) activity consists of manageable work units assigned

_____ to the responsibility of a functional manager, which can be planned, estimated, scheduled and controlled.

Level of the PBS are as follows:

Level 0 Level 1 Level 2

Project Train 1 UNIT 32

Train 2 UNIT 33

Train 3 UNIT 34

Train 4 UNIT 35

Inlet/Outlet Facilities UNIT 37

UNIT 45

UNIT 46

UNIT 47

Common Area and Offsite UNIT 39

Where:

Level 0: Overall Project

Level 1: Areas

Level 0: Plants

3.2. Construction Activities

Construction activities are classified according to the following levels:

000-za-e-09413 construction progress

measurement procedure.doc

This document is the property of Saipem SpA who will safeguard its rights according to the civil and penal provisions of the law.

CLIENT JOB UNIT

274219 00

PLANT LOCATION MEXICO

EL ENCINO - TOPOLOBAMPO NATURAL GAS SPC. 0000-ZA-E-09413

saimexicana, TRANSPORTATION SYSTEM

PROJECT / UNIT Rev.

CONSTRUCTION PROGRESS MEASUREMENT Sh. 7 of 12 0

Level 1 - Discipline : i.e. civil works, mechanical works, etc.

Level 2 - CMC : i.e. concrete, piping, elect. cables, etc.

Level 3 - SCMC X PBS Area : i.e. lean concrete, small bore piping, etc

Level 4 - Object/Item and elementary operation : i.e. pump foundations, piping sketch, etc.

associated with SCMC

SCMC are used for scheduling and progress monitoring purposes. Physical quantities for each scheduled SCMC

are provided by the engineering during the design phase.

The PBS will be respected at all time during the preparation or updating of the data.

_____

3.3. Standard Man Hours

SMHs are obtained by dividing work quantities by the standard efficiency of construction Bill items.

SMHs are translated at each level into SMHs of construction.

The total SMHs comprises the overall construction workload.

The overall construction workload is subdivided in accordance with the PBS and by disciplines as described

above.

SMH are used as the basis for calculating the EMH for site, hence the workforce requirements.

Duration of each construction activity is established by taking into account the estimated quantities which have

been converted into SMHs, the expected availability of man power and the statistical data from previous project

achievements.

3.4. CPM Analysis

A network is prepared on the basis of the logical relationship between the various project activities.

The CPM analysis is developed in order to determine the critical path(s) and to compare actual progress versus

the planned progress in order to highlight any progress deficiencies that may impact the contract milestones or

the overall project completion date.

4. CONSTRUCTION SCHEDULE

The construction schedule is established as a part of the integrated overall PMS. As soon as commissioning and

start-up sequences are better defined, the Construction Working Level 3 is progressively revised switching the

general completion based on geographical strategy to the functional system completion.

The switching of the scheduling approach is statistically known to happen when construction progress reaches

60% of completion.

The workload of each PBS subdivision, following the logic of the construction network, is analysed. Logic links

with engineering/procurement activities are clearly identified.

000-za-e-09413 construction progress

measurement procedure.doc

This document is the property of Saipem SpA who will safeguard its rights according to the civil and penal provisions of the law.

CLIENT JOB UNIT

274219 00

PLANT LOCATION MEXICO

EL ENCINO - TOPOLOBAMPO NATURAL GAS SPC. 0000-ZA-E-09413

saimexicana, TRANSPORTATION SYSTEM

PROJECT / UNIT Rev.

CONSTRUCTION PROGRESS MEASUREMENT Sh. 8 of 12 0

This results in a commissioning/start-up oriented project logic network, where the construction programme is

driven by the commissioning/start-up targets and defines the requirements for the engineering, procurement and

logistic activities.

4.1. Level III (First phase development)

The major steps to be performed to develop Level III schedule are:

- Definition of the major activities for each major area.

- An estimation of the quantities of work to be carried out on site.

- An estimation of the SMH for construction activities.

- A plan of the construction activities workload.

- An assessment of the free floats.

_____ - An assessment of the critical path using CPM.

The documentation issued at this level is:

- Construction work load charts or graphs.

- Programs, using network analysis for each discipline and SCMC.

- S curves for the total SMHs estimated for construction.

- S curves for SMHs estimated for each discipline.

The above reported operation shall be carried out with COPR and Primavera software.

4.2. Working Level III

Once analysis, logic network and requirements are defined the detailed construction schedule is developed

considering:

- Detailed activities.

- Logic networks by areas, with free float(s) and of critical path(s).

- Workload definition, analysis and assessment by areas, and Subcontractors.

- Material arrival analysis at SCMC level.

- Drawing availability analysis at SCMC level.

- An estimation of the quantities to be erected in each construction area.

- An estimation of SMHs for each construction area.

- An estimation of the EMH and direct workforce requirements

The documentation issued at this level is:

- Logic networks, with free floats and critical path by areas.

- Workloads distribution and programmes by Subprojects areas, discipline and Subcontractors.

- Expected manpower distribution by Subprojects area, discipline and Subcontractors.

- “S” curves and manpower histograms by Sub-project area, discipline and Subcontractors.

- Weight of each activity in the framework of the overall and of each Subcontractor.

- A list of construction areas.

- A list work packages.

Consistency analysis, workload distribution and feasibility/constructability analysis are then performed to confirm

the adequacy of the construction programme.

These procedures will be carried out with the aid of the COPR programme and Primavera software.

000-za-e-09413 construction progress

measurement procedure.doc

This document is the property of Saipem SpA who will safeguard its rights according to the civil and penal provisions of the law.

CLIENT JOB UNIT

274219 00

PLANT LOCATION MEXICO

EL ENCINO - TOPOLOBAMPO NATURAL GAS SPC. 0000-ZA-E-09413

saimexicana, TRANSPORTATION SYSTEM

PROJECT / UNIT Rev.

CONSTRUCTION PROGRESS MEASUREMENT Sh. 9 of 12 0

The agreed schedule shall become the baseline on which all recorded and reported actual progress will be

measured.

The working Level III schedule shall be continually monitored and updated with actual progress and formally

issued to Company on a monthly basis.

5. PROGRESS

5.1. Progress Monitoring – Level IV

_____ The progress associated with each basic operation will be recorded on a weekly basis with PROM and this shall

automatically give a summary of progress values from basic operations to SCMC at each level of the PBS. The

method used is based on the breakdown of the SCMC into basic operations, which permits a more detailed

objective progress evaluation.

The progress of each of these basic operations will be evaluated on weekly basis as specified in SPC.00-ZA-

E02102

Construction progress is monitored with the same PBS used in scheduling to permit effective analysis of the

achieved progress against the planned. Construction progress is also defined by Subproject, by areas, by

disciplines and by Subcontractors. The consistency between schedule and progress control methodology is

maintained in order to guarantee the efficiency of the analysis and corrective actions, if required.

In order to evaluate the construction progress, the status of single basic physical activities is monitored. The

basic physical activity is the most detailed and so at the lowest level. This promotes accuracy and a clear audit

trail and ultimately an objective progress assessment.

Progress calculation

Construction quantities are transformed into construction SMHs. Once an activity is performed totally or partially,

the relevant SMHs are achieved, totally or partially, and are recorded as earned SMHs of progress.

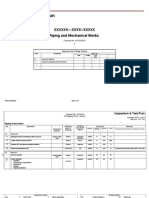

Example

As example, the erection of a single isometric line has a certain amount of SMHs. The flow of the activity and the

relevant breakdown of that in SMH are:

- Handling from fabrication yard to job site 5 %

- Spool assembly and erection 30 %

- Welding and bolting 25 %

- NDE Execution 10 %

- Post weld heat treatment 25 %

- QC Certificate 5 %

100 %

If the isometric line, at the moment of progress measurement, is erected but not yet welded, the earned man-

hours would be 35% of the SMH allocated for work. The ratio of the earned SMHs and the SMHs is the progress

achieved for the activity:

Earned SMH

= % progress

SMH

000-za-e-09413 construction progress

measurement procedure.doc

This document is the property of Saipem SpA who will safeguard its rights according to the civil and penal provisions of the law.

CLIENT JOB UNIT

274219 00

PLANT LOCATION MEXICO

EL ENCINO - TOPOLOBAMPO NATURAL GAS SPC. 0000-ZA-E-09413

saimexicana, TRANSPORTATION SYSTEM

PROJECT / UNIT Rev.

CONSTRUCTION PROGRESS MEASUREMENT Sh. 10 of 12 0

The ratio of total earned SMHs to total SMHs, is the overall progress achieved. The progress is evaluated and

reported weekly.

The progress is evaluated utilising PROM programme.

All production steps of the breakdown to measure the progress with relevant weights are to be formally approved

by Company.

The SMH and weighting by SCMC against which progress is calculated are shown in COPR reports.

Progress Reporting

_____

A weekly progress meeting shall be held between the Contractor and each Subcontractor responsible for each

Subcontract. The purpose of this meeting is:

- To evaluate and agree the status of construction in percentage progress terms.

- To analyse trends.

- To forecast manpower requirements.

- To evaluate the work plan for the coming four weeks with specific emphasis to the next week.

- To identify corrective actions if necessary.

A narrative and analytical report is issued for each target function, area, discipline and Subcontractor utilising the

findings of the above meeting. This report shall constitute the basis of the Monthly Construction and Progress

Report.

5.2. Productivity Analysis (K Factor)

At planning phase the calculated SMH for each Subcontractor are converted into EMH by multiplying an

expected productivity factor K1.

SMH x K1 = EMH

The Subcontractors EMH are utilised to plan the resources (manpower and equipment) that are required to

achieve the construction targets and end dates.

The expected productivity factor (K1) is defined by the experience gained in similar activities, circumstances and

environment.

AMHs for each work package are reported on a daily basis by the Subcontractor by means of the daily and

consolidated personnel reports. These reported man-hours are entered into COPE and utilised as detailed

below.

A productivity analysis of each Subcontractor is to be performed together with the progress evaluation. The

Subcontractor’s achieved productivity (K2) is defined as the ratio between the AMHs expended and the earned

SMHs achieved as measured from the installed quantities:

000-za-e-09413 construction progress

measurement procedure.doc

This document is the property of Saipem SpA who will safeguard its rights according to the civil and penal provisions of the law.

CLIENT JOB UNIT

274219 00

PLANT LOCATION MEXICO

EL ENCINO - TOPOLOBAMPO NATURAL GAS SPC. 0000-ZA-E-09413

saimexicana, TRANSPORTATION SYSTEM

PROJECT / UNIT Rev.

CONSTRUCTION PROGRESS MEASUREMENT Sh. 11 of 12 0

AMH Subcontractor’s Productivity Factor

Earned SMH = (K2)

Example

If the actual man-hours expended = 150

If the earned SMHs = 100

150 = 1.5

100

The Subcontractor’s achieved productivity is expressed as a K2 factor of 1.5.

_____

At the end of every reporting period the Subcontractor’s achieved productivity factor (K2) is compared with the

expected productivity factor (K1) and the necessary planning readjustments made.

6. RESPONSABILITIES AND ACTIONS

It is responsibility of the Subcontractor to provide all actual information to update the established control system

and schedules described in this procedure on a weekly basis and with agreed formats.

Contractor’s Project control team will run all analyses in terms of (but not limited to):

- Changes in quantities.

- Differences between estimated K1 and actual K2 attributable to internal and external causes of the

Subcontractor.

- Deviation from planned sequences of work depicted from applicable schedules.

- Accrued delays against scheduled progress curves.

Progress analysis shall be run on weekly basis and results as well as impacts and proposed corrective actions

shall be passed to construction management to evaluate and eventually implement the most appropriate action

to correct the recorded situation.

If the situation is such that a revision of the schedule is required, then the revision shall incorporate the

followings:

- Updated status of E&P deliverables.

- Actual progress of construction activities.

- Changes in sequencing if necessary based on site situation.

- Available resources in terms of quality and quantity.

- Latest recorded productivity factors (K2).

- Other factors if any.

- Recovering of delays with the time defined by the PMS.

000-za-e-09413 construction progress

measurement procedure.doc

This document is the property of Saipem SpA who will safeguard its rights according to the civil and penal provisions of the law.

CLIENT JOB UNIT

274219 00

PLANT LOCATION MEXICO

EL ENCINO - TOPOLOBAMPO NATURAL GAS SPC. 0000-ZA-E-09413

saimexicana, TRANSPORTATION SYSTEM

PROJECT / UNIT Rev.

CONSTRUCTION PROGRESS MEASUREMENT Sh. 12 of 12 0

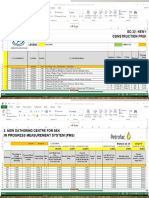

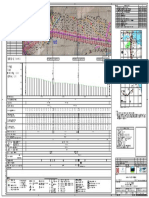

7. CONSTRUCTION PBS (EXAMPLE)

_____

000-za-e-09413 construction progress

measurement procedure.doc

This document is the property of Saipem SpA who will safeguard its rights according to the civil and penal provisions of the law.

You might also like

- S-990-5132-301 - B Work Breakdown System ProcedureDocument16 pagesS-990-5132-301 - B Work Breakdown System ProcedureMahadevan MahalingamNo ratings yet

- 000 ZA E 09411 Punch List ProcedureDocument17 pages000 ZA E 09411 Punch List Procedurealinor_tn100% (1)

- Cost Control Budget DOP3000-PRC-007!0!03Document6 pagesCost Control Budget DOP3000-PRC-007!0!03kamlNo ratings yet

- Project Progress Measurement and Management SystemDocument6 pagesProject Progress Measurement and Management SystemSubhojit AdhikaryNo ratings yet

- SP12 2y3 PC PP 993 007Document21 pagesSP12 2y3 PC PP 993 007Alex Ciupitu100% (1)

- S-990-5131-312 - 1 Progress Measurement ProcedureDocument17 pagesS-990-5131-312 - 1 Progress Measurement ProcedureMahadevan Mahalingam100% (4)

- 84501-9200-9L-007 Rev-2 Contractor Progress Measurement RequirementsDocument24 pages84501-9200-9L-007 Rev-2 Contractor Progress Measurement RequirementsPeni M. Saptoargo86% (7)

- Progress Measurement ProcedureDocument15 pagesProgress Measurement ProcedureSendhil_Kumar_2023100% (2)

- Oman Refinery Project Planning and ControlsDocument15 pagesOman Refinery Project Planning and ControlsMahadevan Mahalingam100% (1)

- WNS00 PP PC 0001Document11 pagesWNS00 PP PC 0001Subramanian Saravanan100% (1)

- A3.8 Planning Scheduling - 20090812 - 115626 PDFDocument60 pagesA3.8 Planning Scheduling - 20090812 - 115626 PDFSuhaidi Alias100% (1)

- Measure Project Progress with Weight FactorsDocument19 pagesMeasure Project Progress with Weight FactorsFalah Miftahul92% (12)

- PIPING ENGINEERING MAN-HOUR ESTIMATEDocument14 pagesPIPING ENGINEERING MAN-HOUR ESTIMATEShabeer KiblaalamNo ratings yet

- Workflow EngineeringDocument12 pagesWorkflow EngineeringbayuNo ratings yet

- Physical Progress Measurement Procedure for Banggai Ammonia Plant ProjectDocument37 pagesPhysical Progress Measurement Procedure for Banggai Ammonia Plant ProjectJan Richardo Gultom100% (1)

- 1.1-1.3 - epc - project-Rev Project Proceess Owner's Procedure 节能项目 业主前期开发Document11 pages1.1-1.3 - epc - project-Rev Project Proceess Owner's Procedure 节能项目 业主前期开发zhangj5No ratings yet

- 2.20 - Appendix G - Project Coordination Procedure 170611dfDocument65 pages2.20 - Appendix G - Project Coordination Procedure 170611dfAlex Ciupitu83% (12)

- Mechanical Completion and Commissioning Handover ProcessDocument2 pagesMechanical Completion and Commissioning Handover Processcryovikas1975No ratings yet

- Gbaran PKG 1 Schedule FinalDocument2 pagesGbaran PKG 1 Schedule FinalOkeymanNo ratings yet

- Guide 05c - C and P Tactics DevelopmentDocument25 pagesGuide 05c - C and P Tactics Developmentodunze1No ratings yet

- JPEP01231B0003 Control Procedure For Project DocumentDocument7 pagesJPEP01231B0003 Control Procedure For Project DocumentAmeya RevOsNo ratings yet

- Constructability AnalysisDocument94 pagesConstructability AnalysisDilip KumarNo ratings yet

- Planning SchedulingDocument60 pagesPlanning SchedulingHarish GundaNo ratings yet

- Construction Progress Measurement System (PMS)Document2 pagesConstruction Progress Measurement System (PMS)AMMAR MAWNo ratings yet

- Planning Package For ProjectDocument272 pagesPlanning Package For Projectyasser_abdalshafey75% (8)

- Uzu-Sedo-Gen - Cw348814-00003 - r01 - Progress Measurement and Reporting ProcedureDocument11 pagesUzu-Sedo-Gen - Cw348814-00003 - r01 - Progress Measurement and Reporting ProcedureOkeyman0% (1)

- Planning Norm Common WorkDocument6 pagesPlanning Norm Common WorkRidhwan Mad AliNo ratings yet

- S-990-5131-313 - A Schedule Control ProcedureDocument13 pagesS-990-5131-313 - A Schedule Control ProcedureMahadevan MahalingamNo ratings yet

- MLE System SubSystem SheduleDocument29 pagesMLE System SubSystem Shedulealinor_tnNo ratings yet

- Piping Pre - Fabrication Erection & Non Destructive TestingDocument39 pagesPiping Pre - Fabrication Erection & Non Destructive TestingStanley Alex100% (1)

- Uzu Sedo Gen Cw348814 00002 - r01 - Planning ProcedureDocument10 pagesUzu Sedo Gen Cw348814 00002 - r01 - Planning ProcedureOkeymanNo ratings yet

- Measuring Construction Progress in Oil and GasDocument2 pagesMeasuring Construction Progress in Oil and Gashichemokok50% (2)

- KE01!00!000 AK A PR 0001 000 AGIP Document NumberingDocument30 pagesKE01!00!000 AK A PR 0001 000 AGIP Document NumberingmasahinNo ratings yet

- Progress Measurement Procedure PDFDocument19 pagesProgress Measurement Procedure PDFKHMHN50% (2)

- Piping Progress Measurement (In Dia and in Meter)Document6 pagesPiping Progress Measurement (In Dia and in Meter)bumkj100% (1)

- CEM510 Planning & Scheduling SaipemDocument15 pagesCEM510 Planning & Scheduling SaipemKeonho LeeNo ratings yet

- Project Control ManualDocument76 pagesProject Control ManualTeoman Çağlar100% (1)

- Planning, Scheduling and Progress ManualDocument97 pagesPlanning, Scheduling and Progress Manualsenrr100% (1)

- Project Controls Handbook Vol 2Document251 pagesProject Controls Handbook Vol 2GEMIN ASSOCIATES100% (1)

- Projects Controls PlanDocument19 pagesProjects Controls PlanBGI Energy Services100% (3)

- Path of Construction Flow Diagram DRAFTDocument2 pagesPath of Construction Flow Diagram DRAFTjsmargateNo ratings yet

- ONS EPC HHI PRO 0004 Project Control Procedure Rev.FDocument50 pagesONS EPC HHI PRO 0004 Project Control Procedure Rev.FMathias Onosemuode100% (2)

- Progress Measurement Schedule..khf-00-101983-Fa-5804-00001-0000 - 02Document72 pagesProgress Measurement Schedule..khf-00-101983-Fa-5804-00001-0000 - 02GURUMOORTHY PNo ratings yet

- Progress Measurement System PMS PDFDocument7 pagesProgress Measurement System PMS PDFMohamed AtefNo ratings yet

- Standard Planning ProcedureDocument16 pagesStandard Planning ProcedureNicholas PorterNo ratings yet

- Managing a Pipe Spool Fabrication Project from Start to FinishDocument5 pagesManaging a Pipe Spool Fabrication Project from Start to FinishManyNo ratings yet

- Planning, Progress and ReportingDocument22 pagesPlanning, Progress and ReportingGURUMOORTHY P100% (1)

- Audit Reports - Register: Nigerian Westminster Dredging and Marine LimitedDocument4 pagesAudit Reports - Register: Nigerian Westminster Dredging and Marine LimitedOkeyman100% (1)

- Oil and gas engineering firm provides project management servicesDocument22 pagesOil and gas engineering firm provides project management serviceszhangj5100% (1)

- Dynamic Scheduling: E.J. (Ted) ListerDocument26 pagesDynamic Scheduling: E.J. (Ted) Listermichal_slawinskiNo ratings yet

- Planning Scheduling and Reporting ProcedureDocument18 pagesPlanning Scheduling and Reporting Procedureendika alfan100% (2)

- Uzu With CPF Upgrade - Interface Management PlanDocument20 pagesUzu With CPF Upgrade - Interface Management PlanOkeymanNo ratings yet

- PROJECT STANDARD and SPECIFICATIONS Project Coordination Procedure Rev01 WebDocument6 pagesPROJECT STANDARD and SPECIFICATIONS Project Coordination Procedure Rev01 WebPham Manh Hieu67% (3)

- Site Nonconformity Management ProcedureDocument11 pagesSite Nonconformity Management Procedurealinor_tn100% (1)

- Mechanical Completion Procedure PDFDocument69 pagesMechanical Completion Procedure PDFDoctorOberman100% (3)

- ABB-GEN-CNS-MOS-GPS-16015-00002-U-00 - Earth Work For Off Loading FaciliDocument10 pagesABB-GEN-CNS-MOS-GPS-16015-00002-U-00 - Earth Work For Off Loading Facilisaravana.bNo ratings yet

- 016calibration ProcedurDocument21 pages016calibration ProcedurYudha Andrie Sasi ZenNo ratings yet

- Method Statement For Civil Foundations & GroutingDocument18 pagesMethod Statement For Civil Foundations & GroutingAbdullah Abdullah100% (1)

- Hazop Sil Study Report For 6 Buy Back Gas PipelineDocument32 pagesHazop Sil Study Report For 6 Buy Back Gas Pipelinealinor_tn100% (1)

- Pipeline Welding Visual Inspection ReportDocument8 pagesPipeline Welding Visual Inspection Reportalinor_tn0% (1)

- IDS For Fiber Optic CableDocument5 pagesIDS For Fiber Optic Cablealinor_tnNo ratings yet

- Pipeline Hydrotest ProcedureDocument78 pagesPipeline Hydrotest Procedurealinor_tn100% (1)

- Technical Data Sheet For Control ValveDocument5 pagesTechnical Data Sheet For Control Valvealinor_tnNo ratings yet

- Technical Data Sheet For Temperature TransmitterDocument38 pagesTechnical Data Sheet For Temperature Transmitteralinor_tnNo ratings yet

- Work Method Statement For De-Watering Drying and Purging After HydrotestDocument12 pagesWork Method Statement For De-Watering Drying and Purging After Hydrotestalinor_tnNo ratings yet

- Calculation of Steel Piping SupportsDocument21 pagesCalculation of Steel Piping Supportsalinor_tnNo ratings yet

- Walkways Steel Structure and R.C. Foundations DrawingsDocument3 pagesWalkways Steel Structure and R.C. Foundations Drawingsalinor_tnNo ratings yet

- Site Nonconformity Management ProcedureDocument11 pagesSite Nonconformity Management Procedurealinor_tn100% (1)

- 000-Za-E-09303 - 0 Packing and Marking ProcedureDocument251 pages000-Za-E-09303 - 0 Packing and Marking Procedurealinor_tnNo ratings yet

- Welders MatrixDocument1 pageWelders Matrixalinor_tn100% (1)

- Flowlines NDT RequestDocument4 pagesFlowlines NDT Requestalinor_tnNo ratings yet

- Sample Test Pack - Piping HydrotestDocument96 pagesSample Test Pack - Piping Hydrotestalinor_tn75% (4)

- ITP-000 Piping Fabrication (Exemple)Document5 pagesITP-000 Piping Fabrication (Exemple)alinor_tn100% (1)

- Reports Approval Status - 11.12.2017Document4 pagesReports Approval Status - 11.12.2017alinor_tnNo ratings yet

- MLE System SubSystem SheduleDocument29 pagesMLE System SubSystem Shedulealinor_tnNo ratings yet

- Mechanical Test Specimens PlanDocument3 pagesMechanical Test Specimens Planalinor_tn100% (1)

- Tie-In StatusDocument22 pagesTie-In Statusalinor_tnNo ratings yet

- Piezometer Marker Installation GuideDocument1 pagePiezometer Marker Installation Guidealinor_tn100% (1)

- WPS MS 01C Rev. 0Document1 pageWPS MS 01C Rev. 0alinor_tnNo ratings yet

- RT Permit To WorkDocument1 pageRT Permit To Workalinor_tnNo ratings yet

- ESAB - PipelinesDocument65 pagesESAB - PipelinesLigia114100% (2)

- Comparison of API 1104 Appendix A and BS 7910 Procedures For The Assessment of Girth Weld FlawsDocument10 pagesComparison of API 1104 Appendix A and BS 7910 Procedures For The Assessment of Girth Weld Flawsalinor_tnNo ratings yet

- Omniscan Techniques For Crack SizingDocument31 pagesOmniscan Techniques For Crack Sizingalinor_tnNo ratings yet

- General Procedure For AUTDocument19 pagesGeneral Procedure For AUTalinor_tn100% (2)

- Recommandation TodfDocument14 pagesRecommandation Todfalinor_tnNo ratings yet

- Ch16 Fss CodeDocument7 pagesCh16 Fss Codeerudite_0206No ratings yet

- Propeller Shaft RequirementsDocument25 pagesPropeller Shaft RequirementsGustavo Ferreira100% (1)

- My Classes - SkillshareDocument1 pageMy Classes - SkillsharekolakNo ratings yet

- Academic Task 3 Simulation QuestionsDocument9 pagesAcademic Task 3 Simulation QuestionsAnshulNo ratings yet

- Packer Shoes Casing Manual Section 7Document22 pagesPacker Shoes Casing Manual Section 7Tong Chaipanyakul100% (1)

- Eurocell Building Plastics: Specification GuideDocument68 pagesEurocell Building Plastics: Specification GuideWilton Antony QcNo ratings yet

- P.Arivalagan: Mobile: +91 9360429742Document3 pagesP.Arivalagan: Mobile: +91 9360429742Arivalagan AnNo ratings yet

- A High Performace HMIDocument50 pagesA High Performace HMIAnonymous FFMmIJy100% (1)

- Resume Ben Ott (05-11-10)Document1 pageResume Ben Ott (05-11-10)aialosangelesNo ratings yet

- Jules Pace 2023 Updated ResumeDocument3 pagesJules Pace 2023 Updated Resumeapi-651678757No ratings yet

- Unit 1 - Introduction - V5Document45 pagesUnit 1 - Introduction - V5Aleix Cánovas EstebanNo ratings yet

- Industrial Profile of Bhavnagar DistrictDocument19 pagesIndustrial Profile of Bhavnagar Districtsiddharth singhNo ratings yet

- JSA Unstuffing Air Charge Intake...Document5 pagesJSA Unstuffing Air Charge Intake...warryNo ratings yet

- Hub and Spoke System PresentationDocument13 pagesHub and Spoke System PresentationShreyasNo ratings yet

- 08 Monoglyceride eDocument14 pages08 Monoglyceride eAlf FloNo ratings yet

- 1 Maritime TransportDocument413 pages1 Maritime TransportWondwosen Tiruneh100% (1)

- Eicher Motors Initiating CoverageDocument15 pagesEicher Motors Initiating CoverageNikhil SinghalNo ratings yet

- E - Noetix Generator For OBI EE PlusDocument2 pagesE - Noetix Generator For OBI EE PlusNarayana AnkireddypalliNo ratings yet

- Project On Powder Dispensing System of Sand 3d PrintingDocument101 pagesProject On Powder Dispensing System of Sand 3d PrintingSameer MandaogadeNo ratings yet

- Structure damage assessment using Repair ManagerDocument10 pagesStructure damage assessment using Repair ManagerJokenny WilliamNo ratings yet

- Post Graduate StudentDocument5 pagesPost Graduate StudentHatem HusseinNo ratings yet

- C182 Training Manual SAMPLE 1jul2011Document36 pagesC182 Training Manual SAMPLE 1jul2011Efrain Valcarcel100% (3)

- Black&Decker 3" X 21" Dragster Belt SanderDocument6 pagesBlack&Decker 3" X 21" Dragster Belt SanderwdowiuueNo ratings yet

- Considerations For Estimating The Costs of Pilot-Scale FacilitiesDocument9 pagesConsiderations For Estimating The Costs of Pilot-Scale FacilitiesAlexNo ratings yet

- BookDocument170 pagesBookPriscyla RoqueNo ratings yet

- PROJECT HSE PLAN REVIEWDocument21 pagesPROJECT HSE PLAN REVIEWFaldiNo ratings yet

- BSNL Project Organization BehaviourDocument32 pagesBSNL Project Organization BehaviourPrashantqmarNo ratings yet

- Tekcon - Spun Piles PropertiesDocument10 pagesTekcon - Spun Piles PropertiesChung Yiung YungNo ratings yet

- RC SCM310 ProductionOrdersDocument327 pagesRC SCM310 ProductionOrdersRRROMANCANo ratings yet

- SQL Narayana ReddyDocument124 pagesSQL Narayana ReddyTarikh Khan100% (1)

- SR EN ISO 3452-1 (2021e PDFDocument34 pagesSR EN ISO 3452-1 (2021e PDFAdrian100% (6)