Professional Documents

Culture Documents

Us6841712 PDF

Uploaded by

Antonela PortaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Us6841712 PDF

Uploaded by

Antonela PortaCopyright:

Available Formats

US006841712B1

12 United States Patent 10 Patent N0.: US 6 9 841 9 712 B1

Iezzi et al. (45) Date of Patent: Jan. 11, 2005

(54) PROCESS FOR THE DEHYDROGENATION (52) US. Cl. ..................... .. 585/444; 585/445; 585/440;

OF ETHYLBENZENE TO STYRENE 585/660; 585/661

_ _ _ (58) Field of Search ............................... .. 585/444, 445,

(75) Inventors: Rodolfo Iezz1, Milan (IT); Domenico 585/440, 660, 661

San?lippo, Milan (IT)

(73) Assignee: Snamprogetti S.p.A., San Donato (56) References Clted

Milanese (IT) U.S. PATENT DOCUMENTS

(*) Notice: Subject to any disclaimer, the term of this 3,472,794 A 10/1969 Carter et 211.

patent is extended or adjusted under 35 672427660 B1 6/2001 Buonomo et 91

U'S'C' 154(b) by 313 days‘ FOREIGN PATENT DOCUMENTS

(21) Appl. No.: 10/070,440 AU 499 659 4/1997

(22) PCT Filed: Sep. 19, 2000 EP 0 794 004 9/1997

EP 0 905 112 3/1999

(86) PCT No.: PCT/EP00/09196

Primary Examiner—Thuan D Dang

§ 371 (6)0)’ (74) Attorney, Agent, or Firm—Oblon, Spivak, McClelland,

(2)’ (4) Date: Mar‘ 19’ 2002 Maier & Neustadt, P.C.

PCT Pub’ Date: Apr‘ 5’ 2001 Aprocess is described for the dehydrogenation of ethylben

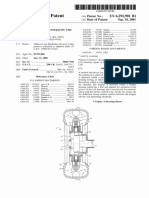

(30) Foreign Application Priority Data Zene to styrene in a ?uid-bed reactor-regenerator system,

Which uses a catalyst based on iron oxide supported on a

Sep. 30, 1999 (IT) ....................................... .. MI99A2031 modi?ed alumina and promoted With further metal oxides'

(51) Int. Cl.7 ....................... .. C07C 5/327; C07C 5/333;

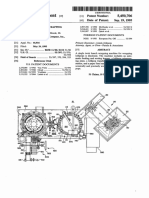

C07C 5/32 18 Claims, 1 Drawing Sheet

7 27

1f 22

6 23

F 26 2S 21'

2 _

21

3 _

33 32 31

3B 37 " 29 H 2°

5 0 l —£—v

a 3 \

28

34

as _

L 13 1l.\ ' 117

35 r [18

I A [19

U.S. Patent Jan. 11,2005 US 6,841,712 B1

US 6,841,712 B1

1 2

PROCESS FOR THE DEHYDROGENATION supplying the heat necessary for the dehydrogenation of

OF ETHYLBENZENE TO STYRENE the ethylbenZene;

sloWing doWn the aging of the catalyst.

The present invention relates to a process for the dehy Operating With these technologies, conversions ranging

drogenation of ethylbenZene to styrene in a ?uid-bed 5 from 60 to 65% are obtained, With a selectivity to styrene

reactor/regenerator system, in the presence of a catalyst higher than 90% by Weight.

based on an iron oxide and further promoters, selected, e.g., These processes hoWever have the folloWing disadvan

from metal oxides such as alkaline oxides, earth-alkaline

metal oxides and/or oxides of the metals of the group of tages:

lanthanides, supported on a modi?ed alumina. use of large quantities of vapor (H2O/EB=9.0—10 molar)

10 superheated With temperatures higher than 700° C.; this

Styrene is an important intermediate Which can be used

in the preparation of plastic materials and rubbers. impels the use of superheating ovens and therefore high

More speci?cally, styrene is used for the production of investment costs;

polystyrenes (GPPS crystals, high impact HIPS and expand aging of the catalyst and consequently the necessity of

able EPS), acrylonitrile-styrene-butadiene (ABS) and substituting it after 18—36 months of operation; this

styrene-acrylonitrile (SAN) copolymers and styrene 15

involves stopping the unit and consequently interrupt

butadiene rubbers (SBR). ing the production for the period necessary for substi

The dehydrogenation reaction of ethylbenZene to styrene tuting the catalyst;

has a feW particular characteristics Which should be taken in

account for the technological design. non-optimiZed energy recovery; present technologies, in

The ?rst lies in the fact that the reaction is controlled by 20

fact, only comprise the recovery of the sensitive vapor

thermodynamic equilibrium and consequently the conver heat and not that of the latent heat;

sion per passage is not total. The dehydrogenation degree carrying out the reaction under vacuum (average absolute

increases With a rise in the temperature and With a decrease pressure of 40.52 KPa (abs Pa) (0.4 ata)) and therefore

in the total pressure, the reaction taking place at a constant in extremely diluted phase in EB; the partial EB

pressure, With an increase in the volume. In order to obtain 25 pressure is on an average equal to 4.052 KPa (abs Pa)

economically acceptable conversions, it is therefore neces (0.04 ata).

sary to carry out the reaction at temperatures generally It has noW been found that it is possible to overcome these

ranging from 540 to 630° C. draWbacks by means of a process Which uses a ?uid-bed

The use of high temperatures hoWever stimulates side reactor/regenerator system and a catalyst based on iron

reactions characteriZed by a greater activation energy With oxide supported on a microspheroidal alumina modi?ed

30

respect to the dehydrogenation value. As a result of this, With silica and further metal oxides as promoters.

more or less signi?cant quantities of by-products mainly The process of the present invention has considerable

consisting of toluene, benZene, coke and light products are economic advantages, in particular:

formed together With the main product.

It is therefore necessary to use a catalyst capable of thermal pro?le of the reactor favorable for the reaction

directing the reaction toWards the desired product. 35 thermodynamics;

The last important aspect consists in the fact that the the heat is directly transferred to the reaction by the

reaction is extremely endothermic, With a reaction heat equal regenerated catalyst, superheating ovens are therefore

to 28 Kcal/moles of styrene corresponding to 270 Kcal/kg of not required for the thermal exchange and the strong

styrene produced. remixing of the ?uidiZed bed prevents the formation of

The high heat required and the high thermal levels at 40 hot spots Which Would loWer the selectivity;

Which it must be exchanged greatly in?uence the techno the possibility of recycling the hydrogen;

logical design. the plant can be run With great ?exibility in terms of actual

The technologies at present commercialiZed (Fina/

Badger and Lummus/U OP Classic SM processes) satisfy the productive capacity With respect to that projected;

demands imposed by the thermodynamics of the reaction by the dehydrogenation reaction and the regeneration take

45

means of processes Which use a bulk catalyst prevalently place in physically separated Zones; this avoids the

based on iron, oxide and promoted With alkalis, and Which mixing of hydrocarbon streams With oxygen streams;

comprise the use of: the process is carried out at a pressure Which is atmo

several adiabatic reactors in series, With intermediate spheric or slightly higher; as a result, there are no air

heating steps at a temperature ranging from 540° C. to 50

in?ltrations from the outside in the reaction Zone;

630° C. and With contact times in the order of tenths of the molar concentration of the inert gas/ethylbenZene in

a second; the feeding is much loWer With respect to commercial

radial ?oW reactor Which operate under vacuum at a technologies;

pressure ranging from 30.39 to 50.65 Kpa (absolute it is not necessary to effect any speci?c treatment for

Pascal) (0.3 to 0.5 ata) (absolute atmospheres); and 55 reducing the emissions of gas pollutants; and

Water vapor Which is fed With the charge to be dehydro the possibility of operating Without Water vapor Without

genated. there being any chemical deterioration in the catalyst.

Water is the main component in the charge fed to the Japanese patent application 7-328,439 discloses a process

reactor. The typical molar concentration is 90%, even if for the dehydrogenation of ethylbenZene in the presence of

higher concentrations are often adopted to lengthen the 60 a catalyst Which consists of alumina, carrying a complex of

chemical life of the catalyst. potassium ferrate and possibly rare earth metal oxides,

The vapor has the function of: modi?ed by basic metallic oxide addition. Said catalyst

reducing the partial pressure of the products and therefore shoWs activity When operated in the presence of Water but no

favorably shifting the thermodynamic equilibrium; data are given in said patent application about the perfor

contributing to the removal of the coke Which is deposited 65 mances of the catalyst in the absence of Water, as co-feed of

on the surface of the catalyst, there being no regenera ethylbenZene, nor the effect of ageing is detailed.

tion of the catalyst With air; Surprisingly, it Was found that through a partial modi?cation

US 6,841,712 B1

3 4

of the alumina carrier by silica it Was possible to improve According to a preferred embodiment, the catalyst is

signi?cantly the catalytic performances in dehydrogenation prepared by:

yield, With evident advantages. In the same time, the (a) addition of an aliquot of the promoters to the carrier;

mechanical resistance of the catalyst itself is improved by (b) drying at 100—150° C. and, optionally, calcination of the

silica modi?cation making it more suited to ?uid bed dried solid at a temperature not exceeding 900° C.;

operations. Furthermore, the catalyst is also able to operate (c) dispersion of the iron oxide and remaining aliquot of the

With nitrogen other than With Water. promoters on the modi?ed carrier (a);

In accordance With this, the present invention relates to a (d) drying at 100—150° C. and calcination of the dried solid

process for dehydrogenating ethylbenZene to styrene Which at a temperature ranging from 500 to 900° C.

essentially consists in: 10

Steps c) and d) can be repeated several times.

(a) reacting ethylbenZene mixed With an inert product, in a Nitrogen, methane, hydrogen or Water vapor can be used

?uid-bed reactor, in the presence of a catalytic system as the gaseous inert product, in a volumetric ratio inert

consisting of iron oxide and promoters supported on gas/ethylbenZene ranging from 1 to 6, preferably from 2 to

alumina modi?ed With 0.01—10% by Weight of silica and 4. Methane and nitrogen are preferably used.

operating at a temperature ranging from 400 to 700° C., 15

According to a further embodiment of the process of the

at a total pressure of 10.13 to 303.9 KPa (abs Pa) (0.1 to present invention, the ethylbenZene can be co-fed to the

3 ata) and With a GHSV space velocity ranging from 50 reactor With a paraffin selected from ethane, propane,

to 10,000 b“1 (normal liters of the mixture ethylbenZene isobutane, in order to obtain the contemporaneous dehydro

and inert gas/h><liter of catalyst); and genation of the co-fed products to give styrene and the

(b) regenerating the catalyst in a regenerator by burning the 20

corresponding ole?ns respectively.

coke deposited on its surface at a temperature exceeding In particular When the ethylbenZene is fed With ethane, the

4000 C. process can be carried out as described in Us. Pat. No.

The catalytic system used in the process of the present 6,031,143.

invention consists of: According to a further embodiment of the process of the

(1) 1—60% by Weight, preferably 1—20%, of iron oxide; 25

present invention, ethylene can be recycled to an alkylation

(2) 0.1—20% by Weight, preferably 0.5—10%, of at least one unit together With a stream of benZene to give ehtylbenZene.

alkaline or alkaline earth metal oxide; In the reactor-regenerator system, the catalyst circulates

(3) 0—15% by Weight, preferably 0,1—7% of a second continuously, in ?uidiZed state, betWeen the reactor and

promoter consisting of at least one rare earth oxide; regenerator, thus alloWing the process to be carried out in

(4) the complement to 100 being a carrier consisting of a 30

continuous.

microspheroidal alumina With a diameter selected from The heat necessary for the reaction is provided by the

those in delta, theta phase or their mixtures, in theta+alpha regenerated catalyst Which reaches the reactor at a tempera

phase or delta+theta+alpha phase, modi?ed preferably ture higher than the average reaction temperature.

With 0.08—5% by Weight of silica. The catalyst is maintained in a ?uidiZed state in the

The carrier has an average particle diameter and particle 35

reactor by the reagent mixture (inert gas/ethylbenZene),

density such that the ?nal product can be classi?ed as Which enters the catalytic bed from beloW, by means of an

Group-A according to Geldart (Gas FluidiZation appropriate distribution system.

Technology, D. Geldart, John Wiley & Sons) and a surface The reacted gas, after passing through a system of

area of less than 150 m2/g (BET). cyclones or another poWder separation system, leaves the

Alkaline metal preferably used as ?rst promoter in the 40

reactor from above. The gas can then be sent to a heat

present invention is potassium. Preferred second promoters exchanger for the preheating of the feeding and subse

belonging to the rare earth metals are cerium, lantanium and quently to the separation section Where the styrene produced

praseodymium. is recovered, Whereas the non-reacted charge is recycled to

An example of catalyst according to the present invention the dehydrogenation reactor and the reaction by-products

consists of: 45

(light hydrocarbons and hydrogen) are recovered and used in

(1) 5—50% by Weight of iron oxide; the regenerator as fuel gas.

(2) 0,5—10% by Weight of a promoter expressed as oxide; The catalyst moves in ?uidiZed state in the reactor, in

(3) the complement to 100 being a carrier consisting of a countercurrent With respect to the gas phase. It enters the

microspheroidal alumina With a diameter ranging from 50 catalytic bed from above, through a distributor Which dis

to 70 microns selected from those in delta, theta phase or 50

perses it equally on the surface of the bed, and it leaves the

their mixtures, in theta+alpha phase or delta+theta+alpha reactor from beloW, passing by gravity into a desorption

phase, modi?ed preferably With 0.08—3% by Weight of Zone Where the moving and desorption of the intraparticle

silica. The process for preparing the catalytic system gas take place, nitrogen or methane being introduced from

described above can be essentially carried out by means beloW, so that the moved or desorbed gas re-enters the

of the folloWing steps: 55

reactor, thus avoiding losses in reagents or products.

preparation of solutions based on derivatives of the com It is preferable to operate in the ?uid-bed reactor as

ponents of the catalytic system; folloWs:

dispersion of the solutions on carriers as de?ned above; at a temperature ranging from 450 to 650° C. in relation

drying of the solids obtained; to the desired reaction; the temperature is maintained

calcination of the dried solids at a temperature ranging 60 Within the pre-selected values by regulating the ?oW

from 500 to 900° C. rate of the regenerated catalyst;

The dispersion of the catalyst components on the carrier at a pressure Which is atmospheric or slight higher;

can be carried out using conventional techniques such as at a GHSV space velocity ranging from 100 and 1000 h_1,

impregnation, ion exchange, vapor deposition or surface preferably from 150 to 300 h_1; and

adsorption. 65 With a residence time of the catalyst in the ?uid bed

The “incipient Wetness” impregnation technique is pref ranging from 5 to 30 minutes, and in the desorption

erably used. Zone from 0.2 to 10 minutes.

US 6,841,712 B1

5 6

According to an embodiment of the process of the present the process can be carried out in continuous Without

invention, grids can be horizontally arranged inside the having to modify the operating parameters during the

reactor, at a distance of 20 to 200 cm from each other, and life of the plant;

With a free area ranging from 10 to 90%, preferably from 20 the reaction and regeneration take place in physically

to 40%. The purpose of the grids is to prevent the gas and 5 separated zones so that the hydrocarbon streams do not

catalyst from re-mixing, so that the gas ?oW inside the mix With streams containing oxygen;

reactor resembles a plug-?oW. The use of these grids alloWs the molar concentration inert product/ethylbenzene in the

maximization of the conversion of ethylbenzene and selec feeding is much loWer With respect to the commercial

tivity to styrene. technologies.

The selectivity of the reaction can be further improved by 10 With reference to FIG. 1, a possible application of the

the longitudinal thermal pro?le Which is established along reactor-regenerator scheme is provided, Which uses the

the catalytic bed, With the maximum temperature in the catalyst based on supported iron oxide.

upper part Where the regenerated catalyst arrives and the The liquid stream of ethylbenzene (1), consisting of fresh

minimum temperature in the loWer part. The temperature and recycled feeding, at room temperature and a pressure of

difference along the bed preferably ranges from 15 to 65° C.

15

263.38 KPa (abs Pa) (2.6 ata) is vaporized in the evaporator

In order to optimize the longitudinal thermal pro?le, the (2), preheated to about 420° C. in the gas-gas exchanger (3),

regenerated catalyst can be distributed at various heights of mixed in a suitable mixer (4) With a stream (5) prevalently

the catalytic bed. consisting of nitrogen and Whose origin is described

The ?uidized catalyst is subsequently sent to the regen hereunder, and fed to the reactor (6) by means of an

erator through a pneumatic transport system consisting of: 20

appropriate distributor situated in the loWer part. The stream

a transport line With at least one zone in Which the catalyst (7), effluent from the reactor at a temperature of 600° C., at

moves doWnWards by the introduction of suitable quan a pressure of 135.76 KPa (abs Pa) (1.34 ata), essentially

tities of gas at appropriate heights, and consisting of nitrogen, styrene, hydrogen and non-reacted

a zone in Which the catalyst moves upWards until it ethylbenzene, undergoes a ?rst cooling in the gas-gas

reaches the upper part of the catalytic bed, by the 25

exchanger (3) and a second cooling in the gas-gas exchanger

introduction of gas at the base of the raiser. (8), from Which it ?oWs at a temperature of 320° C. This

The regenerator preferably has similar dimensions to stream then passes through the ?lter system (9) to eliminate

those of the reactor to maintain the catalyst for a period the ?ne particles entrained and is subsequently cooled With

sufficient for its regeneration. Water to a temperature of 40° C. in the exchanger (10). The

The regeneration of the catalyst is carried out by the mixture becomes biphasic at this temperature as a result of

30

combustion of coke With air and oxygen, Whereas its heating the partial condensation of the hydrocarbon.

is effected With the use of methane, a fuel gas, or The condensed stream (12) is recovered from the bottom

by-products of the dehydrogenation reaction, at a tempera in the phase separator (11), and is sent, like the gas stream

ture higher than the average reaction temperature. (13), to the subsequent recovery and puri?cation zone of the

The movement of the gas and solid takes place in coun 35

products (14), not shoWn in detail, Where the folloWing

tercurrent also in the regenerator: air enters the bottom of the streams are recovered, using techniques knoWn to experts in

catalytic bed, Whereas the fuel gas is introduced at suitable the ?eld:

heights along the bed. stream (15) consisting of pure styrene (product);

The gas leaving the regenerator, substantially consisting stream (16) consisting of ethylbenzene, Which is recycled

of nitrogen and combustion products, is passed through a 40 to the dehydrogenation;

system of cyclones, or other system, situated in the upper stream (17) essentially consisting of nitrogen and

part of the apparatus, to separate the entrained poWders and hydrogen, containing light hydrocarbons;

is then sent to a heat exchanger to preheat the combustion stream (18) essentially consisting of benzene and toluene;

air. stream (19) consisting of heavy hydrocarbon by-products.

Before being discharged into the atmosphere, these gases 45 The stream (17), after ?ushing stream (20), is heated in

can be treated With a ?lter system or other devices for the gas-gas exchanger (21) up to a temperature of 550° C.

reducing the poWder content to a feW tenths of mg per Nm3 and fed to the regenerator (22) by means of the distributor

of gas. (23) situated above the air inlet. The stream of air (24) is

In the regenerator, it is preferable to operate at atmo compressed in the compressor (25) and preheated to a

spheric pressure or slightly higher, at a space velocity 50 temperature of 560° C. in the gas-gas exchanger (26), before

ranging from 100 to 1,000 h_1and With a residence time of being fed to the regenerator (22). The stream (27) effluent

the catalyst ranging from 5 to 60 minutes, preferably from from the regenerator, prevalently consisting of nitrogen and

20 to 40 minutes. Water vapor is subsequently cooled in the exchangers (21)

The regenerated and reheated catalyst is sent to the reactor and (26), passes through the ?lters (28) to eliminate the ?ne

by means of a pneumatic system having the characteristics 55 poWders entrained and is cooled in the exchanger (29) at 40°

described above. C.

The use of the reactor-regenerator system has the folloW The stream of condensed Water (30) is separated in the

ing advantages: vessel (31), Whereas the remaining gas stream (32), still

the possibility of keeping the operating parameters and containing signi?cant quantities of Water vapor, is com

catalytic performances constant for the Whole technical 60 pressed in the compressor (33) at a pressure of 263.38 KPa

life of the plant; (abs Pa) (2.6 ata) and is subsequently cooled in the

the heat is transferred to the reaction directly by the exchanger (34) at such a temperature as to alloW the almost

regenerated catalyst; there is therefore no need for complete condensation of the Water present. The condensed

super-heating ovens for the thermal exchange and the stream (35) is removed from the bottom of the vessel (36),

strong re-mixing of the ?uid bed prevents the formation 65 Whereas the gas stream (37), after a part of it has been

of hot spots Which Would loWer the selectivity; ?ushed (38), is heated in the gas-gas exchanger The

the hydrogen can be recycled; resulting stream (5) is then treated as described above.

US 6,841,712 B1

7 8

All the catalytic tests are carried out using a quartz 150 g of microspheroidal alumina are impregnated, using

micro-reactor in Which 50—100 ml of catalyst are charged. the “incipient Wetness” procedure, With 33 ml of an aqueous

The reactor is heated by an electric oven in order to keep the solution containing 7.8 g of KNO3 (titer 99.5%) in deioniZed

catalytic bed at the desired temperature. Water, maintained at a temperature of 25° C.

The ethylbenZene is fed to an evaporator by means of a The impregnated product is dried at 80° C. for 1 night and

dosing pump and is then mixed With the inert gas Whose then calcined, in a stream of dry air, at 650° C. for 4 hours

?oW-rate is measured by means of a rotameter. in a stream of dry air. The concentration of potassium,

The reaction mixture is preheated to 200° C. and fed to the expressed as oxide, With respect to the calcined product, is

reactor from beloW through a calibrated septum Which acts equal to 2.4% by Weight.

as gas distributor, thus ?uidiZing the catalyst. 10

An impregnating solution is then prepared by dissolving

A quartZ expansion vase is assembled on the head of the

in 23 ml of deioniZed Water: 56.2 g of Fe(NO3)3.9H2O (titer

reactor, Which has the function of decelerating the effluent 99% by Weight) and 6.7 g of KNO3 (titer 99.5% by Weight).

gas and making the ?ne catalyst particles fall back into the The solution, heated to 50° C. to complete the dissolution of

reactor. The expander and sampling lines are maintained at the salts, is maintained at this temperature for the Whole

200° C. to avoid the condensation of styrene, non-reacted 15

duration of the impregnation.

ethylbenZene and any possible heavy by-products.

The catalytic cycle consists of: The alumina modi?ed With potassium oxide (153.6 g) is

impregnated With an aliquot (48 g) of impregnating solution,

a reaction phase, in Which the ethylbenZene mixed With dried at 120° C. for 4 hours and impregnated again With the

the inert product or With the paraf?n, is fed to the remaining aliquot of impregnating solution.

reactor over a period of 10 minutes; 20

The impregnated product is dried at 120° C. for a night

a stripping phase, into Which nitrogen is passed for about and ?nally calcined at 700° C. for 4 hours.

15 minutes to removed the products adsorbed on the

catalyst; The Weight composition of the formulate is the folloWing:

6.6% Fe2O3, 4% K20 and carrier the complement to 100.

a regeneration phase, into Which air is fed for about 45 25 The formulate Was tested in the dehydrogenation reaction

minutes; and

of ethylbenZene to styrene and the average results, after a

a Washing phase With nitrogen for about 20 minutes. test run of 100 hours, are indicated in table 1.

The catalytic cycle Was carried out continuously for 100

hours Without having any loss of activity of the catalyst. EXAMPLE 2

The dehydrogenation reaction is carried out at 560—650° 30

C., Whereas the regeneration is carried out at 660° C. 150 g of microspheroidal alumina obtained as described

The overall space velocity, expressed as normal liters of in example 1, are impregnated With a solution containing:

ethylbenZene plus normal liters of inert product, is main 56.3 g of Fe(NO3)3.9H2O (titer 99% by Weight) and 14.2 g

tained at 30015 Nl/h/lt of catalytic bed. of KNO3 (titer 99.5% by Weight).

During the reaction and stripping phase, the effluent is 35 The impregnation, drying and calcination are carried out

cooled in a trap immersed in liquid nitrogen in Which the With the same procedure described in example 1.

non-reacted ethylbenZene, styrene and condensable The Weight composition of the formulate is the folloWing:

by-products are condensed. The effluent from the trap is sent 6.6% Fe2O3, 4% K20 and carrier the complement to 100.

to a sack from Which hydrogen, inert products and C1—C3, The dehydrogenation average results of ethylbenZene,

light hydrocarbons from cracking reactions, are recovered. 40 after a test run of 100 hours, are indicated in table 1.

The liquid fraction is Weighed and analyZed by gas

chromatography using an HP 5890 gas chromatograph EXAMPLE 3

equipped With a CP WAX 10 capillary column. The dosing The same procedure is adopted as in example 2, but using

of the components is effected using an internal standard.

an impregnating solution containing: 55.2 g of

The gas recovered from the sack is analyZed by gas 45

chromatography using the external standard procedure for Fe(NO3)3.9H2O (titer 99% by Weight) and 6.7 g of KNO3

the dosing of the components. The contents of the sack are

(titer 99.5% by Weight).

measured With a counter for the material balancing. The Weight composition of the formulate is the folloWing:

The coke deposited on the surface of the catalyst is 6.6% Fe2O3, 1.9% K20 and carrier the complement to 100.

combusted With air and the effluent collected in a sack. The 50

The dehydrogenation average results of ethylbenZene,

gas is then analyZed by gas chromatography to dose the after a test run of 100 hours, are indicated in table 1.

concentration of CO2, Whereas the volume is measured to EXAMPLE 4

establish the quantity of coke formed during the reaction.

The folloWing examples, Whose sole purpose is to The same procedure is adopted as in example 2, but using

describe this invention in greater detail, should in no Way be 55

an impregnating solution containing: 53.9 g of

considered as limiting the scope of the invention. Fe(NO3)3.9H2O (titer 99% by Weight) and 2.8 g of KNO3

(titer 99.5% by Weight).

EXAMPLE 1 The Weight composition of the formulate is the folloWing:

A microspheroidal pseudobohemite to Which silica (1.2% 6.5% Fe2O3, 0.8% K20 and carrier the complement to 100.

by Weight) has been added, is prepared, With a particle 60 The dehydrogenation average results of ethylbenZene,

diameter ranging from 5 to 300p, by the spray drying of a sol after a test run of 100 hours, are indicated in table 1.

of hydrated alumina and Ludox silica.

Asample of pseudobohemite is calcined at 450° C. for 1 EXAMPLE 5

hour and then at 1190° C. for 4 hours in a stream of dry air. The same procedure is adopted as in example 2, but using

The product obtained, consisting of 6, 0 and 0t transition 65 an impregnating solution containing: 93.1 g of

alumina, has a speci?c surface of 34 m2/g and a porosity of Fe(NO3)3.9H2O (titer 99% by Weight) and 14. B g of KNO3

0.22 cc/g. (titer

US 6,841,712 B1

9 10

99.5% by Weight) and at a temperature of 60° C. The The dehydrogenation results of ethylbenZene, during a

impregnation is carried out in three subsequent steps using test run of 150 hours, are shoWn in table 2.

45 g of the mother impregnating solution in each step.

The ?rst aliquot is added on alumina alone Which is then

. o . . .

dried at ‘120 C.‘ for 4 hours after impregnation. The dried 5 EXAMPLE 7 (COMPARATIVE)

product is then impregnated With a further 45 g of mother

solution and dried at 120° C. This treatment is repeated

twigs‘ _ h _ _ f h f 1 _ h f H _ _ In order to demonstrate the promoting effect of silica in

eWelg tcomposmono t 6. Ormu ate 1st 6 O OWlng' the carrier, a sample has been prepared according to the

10.3% Fe2O3, 4% K20 and carrier the complement to 100. 10 .

. same procedure of eXample 6 but based on a carrier, free of

The dehydrogenation average results of ethylbenZene, Silica havin a Surface area of 104 m2/

after a test run of 100 hours, are indicated in table 1. ’ g g‘

EXAMPLE 6 .

A _ h _ f f 100 2 h b The dehydrogenation average results of ethylbenZene,

Gamer avlng a Sur ace area 0 m. /g as . éen 15 during a test run of 188 hours, are indicated in Table 2.

prepared by calcining the same pseudobohem1te containing

silica of eXample 1 at 1060° C.

200 g of such a carrier are impregnated With a solution

containing 57.05 g of Fe(NO3)3.9H2O (titer 99% b.W.) and EXAMPLE 8

17.23 g of KNO3 (titer 99.5% b.W.), 2.97 g of

Ce NO .6H O and 2.93 of La NO .6H O at a tem- 2O .

( 3)3 2o - g 3-)3 2- - The contemporaneous dehydrogenation of ethylbenZene

perature of 60 C. The impregnation is carried out in a _ _ _ _ _

- and ethane is carried out in the micro-reactor described

umque Step' b t t t f 600° C ' th t 1 t f

The impregnated material is dried at 120° C. for 4 hours, a ove’la 1a empera ure 0 " usmg 6 Ca a ys 0

then calcined at 750° C. for 4 hours. examp e '

The Weight composition of the formulate is the folloWing: 25

5.0% Fe2O3, 3.68% K20, 0.5% Ce2O3, 0.5% La2O3 and Table 3 enclosed indicates the operating parameters and

carrier the complement to 100. results obtained.

TABLE 1

Feeding KPa Conversion Selectivity Styrene yield

EX. Fe2O3 % K20 % T O C. EB % vol H2O % vol N2 % vol P (ata) pEB Ethylbenzene % Styrene mol. % mol. %

1 6.6 4 540 20 0 80 (1.1)* 0.22 50 93 47

1 bis 6.6 4 540 20 60 20 (1.1)* 0.22 42 96 40

1 ter 6.6 4 572 20 60 20 (1.1)* 0.22 53 87 46

2 6.6 4 545 20 0 80 (1.1)* 0.22 50 89 45

2 bis 6.6 4 570 20 60 20 (1.1)* 0.22 52 85 44

3 6.6 1.9 550 20 0 80 (1.1)* 0.22 50 87 44

3 bis 6.6 1.9 580 20 60 20 (1.1)* 0.22 50 84 42

4 6.5 0.8 580 20 0 80 (1.1)* 0.22 50 82 41

4 bis 6.5 0.8 580 20 17 63 (1.1)* 0.22 31 79 24

5 10.4 4 550 20 0 80 (1.1)* 0.22 50 87 44

5 bis 10.4 4 572 20 60 20 (1.1)* 0.22 51 84 43

Examples 1 bis-5 bis are comparative examples carried out in the presence of Water

*111.63 KPa (abs Pa)

TABLE 2

Select. Yield

Catalyst composition % Feed %V Conv. Styrene Styrene

EX. Fe2O3 K20 Ce2O3 La2O3 T O C. HOS EB H2O N2 P (ata) EB % % mol % mol

6 5.0 3.6 0.5 0.5 560 30 20 0 80 (1.1)* 56.2 82.7 46.5

6 560 150 20 0 80 (1.1)* 57.3 86.9 49.8

7 5.0 3.6 0.5 0.5 560 34 20 0 80 (1.1)* 57.9 73.5 42.6

7 580 59 20 0 80 (1.1)* 64.8 56.1 36.4

7 560 188 20 0 80 (1.1)* 56.9 77.9 44.3

*111.63 KPa (abs Pa)

US 6,841,712 B1

TABLE 3

Feeding Conversion Selectivity

EB % Ethane % Pressure EB Ethane Styrene Ethylene

vol. vol. H2O (ata) PEB pEthane % % rnol. % rnol. %

10 90 0 (1.1)* 0.11 0.99 59 13 90 90

20 80 0 (1.1)* 0.22 0.88 53 10 92 93

30 70 0 (1.1)* 0.33 0.77 45 8 94 93

*111.63 KPa (abs Pa)

What is claimed is: (d) drying at 100—150° C. and calcination of the dried

1. A process for the dehydrogenation of ethylbenZene to support at a temperature ranging from 500 to 900° C.;

styrene Which comprises: 15

and Wherein steps c) and d) can be repeated several times.

(a) reacting the ethylbenZene mixed With an inert gas in a 7. The process according to claim 1, Wherein the inert gas

?uid-bed reactor, in the presence of a catalytic system is selected from nitrogen, methane, hydrogen and Water

consisting of iron oxide and promoters supported on vapor.

alumina modi?ed With 0.01—10% by Weight of silica 8. The process according to claim 7, Wherein the inert gas

20

and operating at a temperature ranging from 400 to is selected from nitrogen and methane.

700° C., at a total pressure of 10.13 to 303.9 Kpa 9. The process according to claim 1, Wherein the volu

(absolute) (0.1 to 3 ata) and With a GHSV space metric ratio inert gas/ethylbenZene ranges from 1 to 6.

velocity ranging from 50 to 10,000 b‘1 (normal liters of 10. The process according to claim 9, Wherein the volu

a mixture of ethylbenZene and inert gas/hxliter of

25 metric ratio ranges from 2 to 4.

catalyst); and

11. The process according to claim 1, Wherein the dehy

(b) regenerating and heating the catalyst in a regenerator drogenation reaction in step (a) is carried out at a tempera

at a temperature exceeding 400° C. Wherein, the pro

ture ranging from 450 to 650° C., at atmospheric pressure or

moter is at least one selected from the group consisting

slightly higher, at a GHSV space velocity ranging from 100

of alkali, alkaline-earth, and lanthanide metal. 30

2. The process according to claim 1, Wherein the catalyst to 1,000 h“1 and With a residence time of the catalyst ranging

consists of: from 5 to 30 minutes.

12. The process according to claim 11, Wherein the space

(1) 1—60% by Weight of iron oxide; velocity ranges from 150 to 300 h“1 and the residence time

(2) 0.1—20% by Weight of at least one alkaline or alkaline of the catalyst ranges from 10 to 15 minutes.

earth metal oxide; 35

13. The process according to claim 1, Wherein in step (b)

(3) 0—15% by Weight of a second promoter consisting of the regeneration of the catalyst is carried out With air or

at least one rare earth oxide; oxygen Whereas its heating is effected using methane, a fuel

(4) the complement to 100 being a carrier consisting of a gas or by-products of the dehydrogenation reaction, operat

microspheroidal alumina selected from those in delta, ing at a higher temperature With respect to the average

40

theta phase or their mixtures, in 10.13 to 303.9 KPa dehydrogenation temperature, at atmospheric pressure or

(abs Pa). slightly higher, at a space velocity ranging from 100 to 1,000

3. The process according to claim 1, Wherein the catalyst h“1 and With a residence time of the catalyst from 5 to 60

consist of: minutes.

(1) 5—50% by Weight of iron oxide; 45 14. The process according to claim 1, Wherein in step a)

(2) 0.5—10% by Weight of a metal promoter, expressed as the inert gas is a gaseous stream essentially consisting of

oxide nitrogen recovered from the combustion products of a

(3) the complement to 100 being a carrier consisting of a regenerator.

microspheroidal alumina With a diameter ranging from 15. The process according to claim 1, Wherein in step a)

50 to 70 microns selected from those in delta, theta the ethylbenZene is fed into the reactor mixed With a paraf?n

phase or their mixtures, in theta+alpha phase or delta+ selected from ethane, propane or isobutane obtaining the

theta+alpha phase modi?ed preferably With 0.08—3% contemporaneous dehydrogenation of the components of the

by Weight of silica. mixture to give styrene and the corresponding ole?ns,

4. The process according to claim 1, Wherein the promoter respectively.

is potassium oxide. 55

16. The process according to claim 15, Wherein the

5. The process according to claim 1, Wherein the promot ethylbenZene is fed to the reactor mixed With ethane obtain

ers are potassium oxide, cerium oxide, lantanium oxide and

praseodymium oxide. ing the contemporaneous dehydrogenation of the compo

6. The process according to claim 1, Wherein the catalyst nents of the mixture to give styrene and ethylene respec

is obtained by: 60 tively.

17. The process according to claim 16, Wherein the

(a) addition of an aliquot of the promoter to the support; ethylene is recycled to an alkylation unit together With a

(b) drying at 100—150° C. and, optionally, calcination of stream of benzene to give ethylbenZene.

the dried support at a temperature not exceeding 900° 18. The process according to claim 3, Wherein the alumina

C.; 65 is modi?ed With 0.08—3% by Weight if silica.

(c) dispersion of the iron oxide and remaining aliquot of

promoter onto the support obtained in (a); and * * * * *

You might also like

- US7963479Document10 pagesUS7963479雷黎明No ratings yet

- United States Patent (10) Patent No.: US 6,367,365 B1: Weickert Et Al. (45) Date of Patent: Apr. 9, 2002Document10 pagesUnited States Patent (10) Patent No.: US 6,367,365 B1: Weickert Et Al. (45) Date of Patent: Apr. 9, 2002back1949No ratings yet

- United States Patent (10) Patent No.: US 6,519,855 B1: Marando (45) Date of Patent: Feb. 18, 2003Document8 pagesUnited States Patent (10) Patent No.: US 6,519,855 B1: Marando (45) Date of Patent: Feb. 18, 20034728Vishakha KambleNo ratings yet

- United States Patent (10) Patent No.: US 7,520,989 B2: Ostergaard (45) Date of Patent: Apr. 21, 2009Document35 pagesUnited States Patent (10) Patent No.: US 7,520,989 B2: Ostergaard (45) Date of Patent: Apr. 21, 2009Cristian GomezNo ratings yet

- United States Patent (19) 11 Patent Number: 6,111,492: Fink (45) Date of Patent: Aug. 29, 2000Document8 pagesUnited States Patent (19) 11 Patent Number: 6,111,492: Fink (45) Date of Patent: Aug. 29, 2000ahmadNo ratings yet

- United States Patent (10) Patent No.: US 8.066,046 B2Document6 pagesUnited States Patent (10) Patent No.: US 8.066,046 B2Erin GokNo ratings yet

- US7156267Document7 pagesUS7156267Efabind OtNo ratings yet

- C D 12 C D: United States Patent (19) 11 Patent Number: 5,122,235Document7 pagesC D 12 C D: United States Patent (19) 11 Patent Number: 5,122,235sundharNo ratings yet

- US7109268Document8 pagesUS7109268Kamilo ArciniegazNo ratings yet

- Ulllted States Patent (10) Patent N0.: US 8,362,749 B2Document12 pagesUlllted States Patent (10) Patent N0.: US 8,362,749 B2kristin madelinNo ratings yet

- N, N 3 Gé28 G 3 Z2%at: (12) United States Patent (10) Patent No.: US 6,877,682 B2Document14 pagesN, N 3 Gé28 G 3 Z2%at: (12) United States Patent (10) Patent No.: US 6,877,682 B2tmNo ratings yet

- United States Patent (10) Patent No.: US 6,702,561 B2Document11 pagesUnited States Patent (10) Patent No.: US 6,702,561 B2Vansala GanesanNo ratings yet

- United States Patent (10) Patent No.: US 6,234,058 B1: Morgado (45) Date of Patent: May 22, 2001Document18 pagesUnited States Patent (10) Patent No.: US 6,234,058 B1: Morgado (45) Date of Patent: May 22, 2001Teo ListNo ratings yet

- Us 6964501Document12 pagesUs 6964501alchjunkmailNo ratings yet

- United States Patent: (10) Patent No.: (45) Date of PatentDocument21 pagesUnited States Patent: (10) Patent No.: (45) Date of PatentRicardo Jimenez SNo ratings yet

- United States Patent: (10) Patent No.: (45) Date of PatentDocument23 pagesUnited States Patent: (10) Patent No.: (45) Date of PatentGiancarloRichardRivadeneyraMirandaNo ratings yet

- United States Patent: (10) Patent No.: (45) Date of PatentDocument34 pagesUnited States Patent: (10) Patent No.: (45) Date of PatentDaniela ScobarNo ratings yet

- United States Patent (19) 11 Patent Number: 5,852,331: Giorgini (45) Date of Patent: Dec. 22, 1998Document6 pagesUnited States Patent (19) 11 Patent Number: 5,852,331: Giorgini (45) Date of Patent: Dec. 22, 1998Fawad AhmadNo ratings yet

- United States Patent: Cheung Et A) - (45) Date of Patent: Oct. 30, 2007Document19 pagesUnited States Patent: Cheung Et A) - (45) Date of Patent: Oct. 30, 2007Shahzada IrshadNo ratings yet

- United States Patent: Fiigel US 6,840,540 B2Document12 pagesUnited States Patent: Fiigel US 6,840,540 B2jemanuelvNo ratings yet

- Ess Hitachi 2001 Us6183210 PDFDocument21 pagesEss Hitachi 2001 Us6183210 PDFnguyenteoNo ratings yet

- Us5955039 PDFDocument8 pagesUs5955039 PDFMayur B NeveNo ratings yet

- Importante Fator Q 322lecture6Document7 pagesImportante Fator Q 322lecture6AndersonNo ratings yet

- US8299606Document10 pagesUS8299606Pardeep SharmaNo ratings yet

- EMFC Scale DescriptionDocument6 pagesEMFC Scale Descriptionisi miyakeNo ratings yet

- United States Patent: (10) Patent N0.: (45) Date of PatentDocument23 pagesUnited States Patent: (10) Patent N0.: (45) Date of Patentmaulik_20_8No ratings yet

- Quick Connector and CheckerDocument41 pagesQuick Connector and CheckerTUNCAY GUMUSNo ratings yet

- United States Patent (10) Patent No.: US 7,718,919 B2Document8 pagesUnited States Patent (10) Patent No.: US 7,718,919 B2kartikkeyyanNo ratings yet

- Us7718919 PDFDocument8 pagesUs7718919 PDFkartikkeyyanNo ratings yet

- United States Patent (10) Patent No.: US 6,382,646 B1: Shaw (45) Date of Patent: May 7, 2002Document10 pagesUnited States Patent (10) Patent No.: US 6,382,646 B1: Shaw (45) Date of Patent: May 7, 2002Eric Manuel Mercedes AbreuNo ratings yet

- Us6944575Document49 pagesUs6944575Anonymous KiraNo ratings yet

- Pressureless Multi-Lane Dividing ApparatusDocument11 pagesPressureless Multi-Lane Dividing Apparatusalguna54No ratings yet

- United States Patent: Riittger Et A)Document6 pagesUnited States Patent: Riittger Et A)Taufiq AhmadNo ratings yet

- US7605285 Patente Confirmada Produccion de Dimetil de CarbonatoDocument13 pagesUS7605285 Patente Confirmada Produccion de Dimetil de CarbonatoBRENDA MARYSABEL ESTEBAN HUARINo ratings yet

- United States Patent: (10) Patent No.: (45) Date of PatentDocument35 pagesUnited States Patent: (10) Patent No.: (45) Date of PatentLazlo JoószNo ratings yet

- Ceramic Notes (2.10.17)Document10 pagesCeramic Notes (2.10.17)Thinesh ShankarNo ratings yet

- United States Patent (10) Patent No.: US 7,928,345 B2Document8 pagesUnited States Patent (10) Patent No.: US 7,928,345 B2alfarisyi27No ratings yet

- United States: (12) Patent Application Publication (10) Pub. No.: US 2013/0085307 A1Document11 pagesUnited States: (12) Patent Application Publication (10) Pub. No.: US 2013/0085307 A1SyahriRomadhoniNo ratings yet

- US6189197Document11 pagesUS6189197Simon VotteroNo ratings yet

- Bridgestone Brands v. Balkrishna Indus. - ComplaintDocument55 pagesBridgestone Brands v. Balkrishna Indus. - ComplaintSarah BursteinNo ratings yet

- Ulllted States Patent (19) (11) Patent Number: 6,118,097: Kaga Et Al. (45) Date of Patent: Sep. 12, 2000Document27 pagesUlllted States Patent (19) (11) Patent Number: 6,118,097: Kaga Et Al. (45) Date of Patent: Sep. 12, 2000xinfeng HENo ratings yet

- United States Patent: Reworked-S161Document9 pagesUnited States Patent: Reworked-S161alimajnoonNo ratings yet

- Cfox) : United States Patent (19) 11 Patent Number: 6,143,644Document8 pagesCfox) : United States Patent (19) 11 Patent Number: 6,143,644RIZA MELİH KÖKSALLINo ratings yet

- United States Patent: Pasquier Et Al. Nov. 18, 2003Document7 pagesUnited States Patent: Pasquier Et Al. Nov. 18, 2003marcela walterosNo ratings yet

- Patent Application Publication (10) Pub. No.: US 2008/0028883 A1Document49 pagesPatent Application Publication (10) Pub. No.: US 2008/0028883 A1Daniel Sarmiento VanegasNo ratings yet

- United States Patent (10) Patent No.: US 6,382,943 B1: Metz Et Al. (45) Date of Patent: May 7, 2002Document8 pagesUnited States Patent (10) Patent No.: US 6,382,943 B1: Metz Et Al. (45) Date of Patent: May 7, 2002DaikinllcNo ratings yet

- US8426779Document10 pagesUS8426779Alex de Lima e SilvaNo ratings yet

- Biological Treatment Process 2006 CATABOL US 6984323 PatentDocument16 pagesBiological Treatment Process 2006 CATABOL US 6984323 Patentmiguel_vera6592No ratings yet

- Effés: United States PatentDocument4 pagesEffés: United States PatentsivakumarNo ratings yet

- Us 7370885Document9 pagesUs 7370885Abrizal HaryadiNo ratings yet

- Wheel PWR GenerationDocument8 pagesWheel PWR GenerationAsad Ahmed KhanNo ratings yet

- United States Patent (10) Patent No.: US 7,395,626 B2: Zedrosser (45) Date of Patent: Jul. 8, 2008Document14 pagesUnited States Patent (10) Patent No.: US 7,395,626 B2: Zedrosser (45) Date of Patent: Jul. 8, 2008Слэйтер Строительная компанияNo ratings yet

- US7992581Document17 pagesUS7992581Ragil YogaNo ratings yet

- United States PatentDocument29 pagesUnited States Patentعلی ربانیNo ratings yet

- United States Patent (10) Patent No.: US 8,745,833 B2Document23 pagesUnited States Patent (10) Patent No.: US 8,745,833 B2Jagadish RajapuNo ratings yet

- US7586071Document13 pagesUS7586071Darkos333No ratings yet

- Process For The Production of Phenol and Acetone From CumeneDocument17 pagesProcess For The Production of Phenol and Acetone From CumeneFabi OneNo ratings yet

- US4392295Document14 pagesUS4392295chahineNo ratings yet

- United States Patent: Yorifuji Et AlDocument16 pagesUnited States Patent: Yorifuji Et AlErin GokNo ratings yet

- How to Find Out About Patents: The Commonwealth and International Library: Libraries and Technical Information DivisionFrom EverandHow to Find Out About Patents: The Commonwealth and International Library: Libraries and Technical Information DivisionNo ratings yet

- Plant Design EthylbenzeneDocument43 pagesPlant Design EthylbenzeneDex JH100% (2)

- Project 1 StyreneDocument11 pagesProject 1 StyreneAbigail MCabezasNo ratings yet

- Design of Vacuum Systems For Crude Oil Vacuum Tower DistillationDocument5 pagesDesign of Vacuum Systems For Crude Oil Vacuum Tower DistillationnasirmuzaffarNo ratings yet

- Production of StyreneDocument7 pagesProduction of StyreneNeil Tesaluna75% (4)

- HEI Standards For Steam Jet Vacuum Systems 5thDocument132 pagesHEI Standards For Steam Jet Vacuum Systems 5thCh Fai100% (12)

- Ethylbenzene Dehydrogenation Into Styrene: Kinetic Modeling and Reactor SimulationDocument249 pagesEthylbenzene Dehydrogenation Into Styrene: Kinetic Modeling and Reactor Simulationrobinhood1010198883% (6)

- Catalytic Rates & Pressure Drop in PFR Reactors: HYSYS 3.0 by Robert P. Hesketh Spring 2003Document30 pagesCatalytic Rates & Pressure Drop in PFR Reactors: HYSYS 3.0 by Robert P. Hesketh Spring 2003Michael NgNo ratings yet

- Thermostable β-GalactosidaseDocument8 pagesThermostable β-GalactosidaseAntonela PortaNo ratings yet

- The Quality of Low Lactose Milk Is Affected by The Side Proteolytic Activity of The Lactase Used in The Production ProcessDocument12 pagesThe Quality of Low Lactose Milk Is Affected by The Side Proteolytic Activity of The Lactase Used in The Production ProcessAntonela PortaNo ratings yet

- Hydrogen Peroxide Brochure EvonikDocument28 pagesHydrogen Peroxide Brochure EvonikAntonela PortaNo ratings yet

- The Quality of Low Lactose Milk Is Affected by The Side Proteolytic Activity of The Lactase Used in The Production ProcessDocument12 pagesThe Quality of Low Lactose Milk Is Affected by The Side Proteolytic Activity of The Lactase Used in The Production ProcessAntonela PortaNo ratings yet

- From By-Product To Valuable Components: Efficient Enzymatic Conversion of Lactose in Whey Using Galactosidase From Streptococcus ThermophilusDocument9 pagesFrom By-Product To Valuable Components: Efficient Enzymatic Conversion of Lactose in Whey Using Galactosidase From Streptococcus ThermophilusAntonela PortaNo ratings yet

- Bio-Production of Lactobionic Acid: Current Status, Applications and Future ProspectsDocument17 pagesBio-Production of Lactobionic Acid: Current Status, Applications and Future ProspectsAntonela PortaNo ratings yet

- cssc201600895 PDFDocument10 pagescssc201600895 PDFAntonela PortaNo ratings yet

- SMART Styrene 12 PDFDocument2 pagesSMART Styrene 12 PDFAntonela PortaNo ratings yet

- Transient Kinetic Studies On The Dehydrogenation PDFDocument160 pagesTransient Kinetic Studies On The Dehydrogenation PDFAntonela PortaNo ratings yet

- Review of Measuring Methods and Results in Nonviscous Gas-Liquid Mass Transfer in Stirred VesselsDocument8 pagesReview of Measuring Methods and Results in Nonviscous Gas-Liquid Mass Transfer in Stirred VesselsAntonela PortaNo ratings yet

- US8641992 - Recuperacion de LitioDocument29 pagesUS8641992 - Recuperacion de LitioAntonela PortaNo ratings yet

- Role of K in EB Deshidrogenation PDFDocument15 pagesRole of K in EB Deshidrogenation PDFAntonela PortaNo ratings yet

- AdsorptionDocument22 pagesAdsorptionaleena'No ratings yet

- Instruction Manual: DS-2000 Series Reflecting and Refracting TelescopesDocument44 pagesInstruction Manual: DS-2000 Series Reflecting and Refracting TelescopesBrandon BohannonNo ratings yet

- 15 CH 4 Columns and StructsDocument22 pages15 CH 4 Columns and StructsgNo ratings yet

- Common Ion Effect and Buffer SolutionDocument23 pagesCommon Ion Effect and Buffer Solutionribots2002100% (1)

- Decarburization Kinetics During Annealingil.44.618Document5 pagesDecarburization Kinetics During Annealingil.44.618Suvro ChakrabortyNo ratings yet

- HOW TO DESIGN AMMONIA REFRIGERATION PLANT USING AAR STANDARD 1 2016 by Ramesh ParanjpeyDocument7 pagesHOW TO DESIGN AMMONIA REFRIGERATION PLANT USING AAR STANDARD 1 2016 by Ramesh ParanjpeyMark Anthony CentenoNo ratings yet

- 11-Heat and Thermodynamics-Done (9 Files Merged) PDFDocument307 pages11-Heat and Thermodynamics-Done (9 Files Merged) PDFBobby100% (1)

- RE 401 - Residence Time DistributionDocument6 pagesRE 401 - Residence Time DistributionAakash R RajwaniNo ratings yet

- Anchor Scan ParametersDocument3 pagesAnchor Scan ParametersMagician PeruNo ratings yet

- Is 456 2000 Most Expected Questions (Avnish Sir) 30-03-22Document35 pagesIs 456 2000 Most Expected Questions (Avnish Sir) 30-03-22Satypal NishadNo ratings yet

- 2015 Nasa Technology Roadmaps Ta 14 Thermal Management FinalDocument97 pages2015 Nasa Technology Roadmaps Ta 14 Thermal Management FinaloxotosNo ratings yet

- DS1 2023 Vapour Power Cycle Part 2Document29 pagesDS1 2023 Vapour Power Cycle Part 2Tommba Tommy100% (1)

- 1.1 Fluid Power Defined: 1.2 Hydraulics Versus PneumaticsDocument2 pages1.1 Fluid Power Defined: 1.2 Hydraulics Versus Pneumaticsswami061009No ratings yet

- Your Reliable Welding Business Partner Worldwide"Document70 pagesYour Reliable Welding Business Partner Worldwide"Anonymous SLI4aGNo ratings yet

- Study of Steel Hardness Effect On The Abrasive Wear ResistanceDocument7 pagesStudy of Steel Hardness Effect On The Abrasive Wear ResistanceArslan Zulfiqar AhmedNo ratings yet

- Surface Preparation White PaperDocument7 pagesSurface Preparation White Paperrondulf goNo ratings yet

- Green Bipropellant Optimisation AOkninskiDocument11 pagesGreen Bipropellant Optimisation AOkninskiMariano SerranoNo ratings yet

- CH 1 Solid State SsnotesDocument29 pagesCH 1 Solid State SsnotesAnonymous 8VJhV1eI2yNo ratings yet

- Endress-Hauser Proline Prowirl F 200 7f2c en Vortex Flowmeter BiogasDocument13 pagesEndress-Hauser Proline Prowirl F 200 7f2c en Vortex Flowmeter Biogashk168No ratings yet

- Minor LossesDocument8 pagesMinor LossesshieferNo ratings yet

- TPFT IG1 Jan 2020 PDFDocument6 pagesTPFT IG1 Jan 2020 PDFrehanNo ratings yet

- EM Paper 1Document1,156 pagesEM Paper 1sCience 123No ratings yet

- Seminar ON Non-Destructive Testing: Department of Automobile EngineeringDocument23 pagesSeminar ON Non-Destructive Testing: Department of Automobile EngineeringAjith K100% (1)

- CLS Aipmt 16 17 XII Che Study Package 5 SET 1 Chapter 2Document8 pagesCLS Aipmt 16 17 XII Che Study Package 5 SET 1 Chapter 2Kareena Gupta100% (3)

- The X-Ray BeamDocument26 pagesThe X-Ray Beamdanlen faye flojoNo ratings yet

- AA02Phys132 Course Guide Midyear Term 2020-2021Document4 pagesAA02Phys132 Course Guide Midyear Term 2020-2021Music LastNo ratings yet

- Emm Question Bank Unit3Document3 pagesEmm Question Bank Unit3MANOJ MNo ratings yet

- (W Ni Fe) Re CoDocument9 pages(W Ni Fe) Re CoSiddharthNo ratings yet

- Data Sheet Control Valve FisherDocument9 pagesData Sheet Control Valve FisherFIRMANSYAHNo ratings yet

- Reaction Rates Worksheet-1452167356Document6 pagesReaction Rates Worksheet-1452167356feta cumaniNo ratings yet