Professional Documents

Culture Documents

Astm D 543-06

Uploaded by

varniktpOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Astm D 543-06

Uploaded by

varniktpCopyright:

Available Formats

Designation: D 543 – 06

Standard Practices for

Evaluating the Resistance of Plastics to Chemical

Reagents1

This standard is issued under the fixed designation D 543; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* D 396 Specification for Fuel Oils

1.1 These practices cover the evaluation of all plastic D 618 Practice for Conditioning Plastics for Testing

materials including cast, hot-molded, cold-molded, laminated D 883 Terminology Relating to Plastics

resinous products, and sheet materials for resistance to chemi- D 1040 Specification for Uninhibited Mineral Insulating Oil

cal reagents. These practices include provisions for reporting for Use in Transformers and in Oil Circuit Breakers3

changes in weight, dimensions, appearance, and strength prop- D 1898 Practice for Sampling of Plastics3

erties. Standard reagents are specified to establish results on a D 5947 Test Methods for Physical Dimensions of Solid

comparable basis. Provisions are made for various exposure Plastics Specimens

times, stress conditions, and exposure to reagents at elevated 2.2 Military Specifications:4

--`,,```,,,,````-`-`,,`,,`,`,,`---

temperatures. The type of conditioning (immersion or wet MIL-A-11755 Antifreeze, Arctic-Type

patch) depends upon the end-use of the material. If used as a MIL-A-46153 Antifreeze, Ethylene Glycol, Inhibited,

container or transfer line, specimens should be immersed. If the Heavy Duty, Single Package

material will only see short exposures or will be used in close MIL-C-372 Cleaning Compound, Solvent (For Bore of

proximity and reagent may splash or spill on the material, the Small Arms and Automatic Aircraft Weapons)

wet patch method of applying reagent should be used. MIL-D-12468 Decontaminating Agent, STB

1.2 The effect of chemical reagents on other properties shall MIL-D-50030 Decontaminating Agent, DS2

be determined by making measurements on standard speci- MIL-F-46162 Fuel, Diesel, Referee Grade

mens for such tests before and after immersion or stress, or MIL-G-5572 Gasoline, Aviation, Grades 80/87, 100/130,

both, if so tested. 115/145

1.3 The values stated in SI units are to be regarded as MIL-H-5606 Hydraulic Fluid, Petroleum Base, Aircraft,

standard. The values given in brackets are for information only. Missiles, and Ordinance

1.4 This standard does not purport to address all of the MIL-H-6083 Hydraulic Fluid, Petroleum Base, for Preser-

safety concerns, if any, associated with its use. It is the vation and Operation

responsibility of the user of this standard to establish appro- MIL-H-83283 Hydraulic Fluid, Fire Resistant, Synthetic

priate safety and health practices and determine the applica- Hydrocarbon Base, Aircraft

bility of regulatory limitations prior to use. Specific hazards MIL-L-7808 Lubricating Oil, Aircraft Turbine Engine, Syn-

statements are given in Section 7. thetic Base, NATO Code Number 0–148

MIL-L-14107 Lubricating Oil, Weapons, Low Temperature

NOTE 1—This standard and ISO 22088 Part 3 address the same subject MIL-L-23699 Lubricating Oil, Aircraft Turbine Engines,

matter, but differ in technical content (and the results cannot be directly

Synthetic Base

compared between the two test methods).

MIL-L-46000 Lubricant, Semi-Fluid (Automatic Weapons)

2. Referenced Documents MIL-T-5624 Turbine Fuel, Aviation, Grades JP-4 and JP-5

2.1 ASTM Standards: 2 MIL-T-83133 Turbine Fuel, Aviation, Kerosene Type,

D 13 Specification for Spirits of Turpentine Grade JP-8

2.3 U.S. Army Regulation:4

AR 70-71 Nuclear, Biological, and Chemical Contamina-

1

These practices are under the jurisdiction of ASTM Committee D20 on Plastics tion Survivability of Army Material

and are the direct responsibility of Subcommittee D20.50 on Permanence Properties.

Current edition approved April 1, 2006. Published June 2006. Originally

approved in 1939. Last previous edition approved in 2001 as D 543 - 95 (2001).

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Withdrawn.

4

Standards volume information, refer to the standard’s Document Summary page on Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

the ASTM website. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

Copyright ASTM International 1

Provided by IHS under license with ASTM

No reproduction or networking permitted without license from IHS Not for Resale

D 543 – 06

2.4 ISO Standards:5 5.4 Containers—Suitable containers for submerging speci-

ISO 175 Plastics—Determination of Resistance to Liquid mens in chemical reagents. They must be resistant to the

Chemicals corrosive effects of the reagents being used. Venting should be

ISO 22088 Part 3 Plastics—Determination of Resistance to provided, especially when using volatile reagents at elevated

Environmental Stress Cracking (ESC)—Bent Strip temperatures. Tightly sealed containers are preferred for room

Method temperature testing to minimize loss.

5.5 Strain Jigs—Jigs are to be capable of supplying known

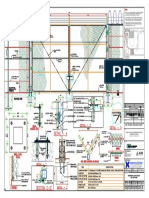

3. Terminology amounts of strain to test specimens. Fig. 1 is a side view

3.1 Definitions—Definitions of terms applying to these drawing of a typical strain jig used to obtain 1.0 % strain in a

practices appear in Terminology D 883. 3.2 mm [0.125 in.] thick test specimen. Shown in Fig. 1 is an

equation that can be used to calculate strain from known

4. Significance and Use

dimensions or back-calculate jig dimensions for a desired

4.1 The limitations of the results obtained from these specimen strain.

practices should be recognized. The choice of types and 5.6 Oven or Constant Temperature Bath, capable of main-

concentrations of reagents, duration of immersion or stress, or taining temperatures within 62°C of the specified test tem-

both, temperature of the test, and properties to be reported is peratures.

necessarily arbitrary. The specification of these conditions 5.7 Testing Devices—Testing devices for determining spe-

provides a basis for standardization and serves as a guide to cific strength properties of specimens before and after submer-

investigators wishing to compare the relative resistance of sion or strain, or both, conforming to the requirements pre-

various plastics to typical chemical reagents. scribed in the ASTM test methods for the specific properties

4.2 Correlation of test results with the actual performance or being determined.

serviceability of plastics is necessarily dependent upon the 5.8 Laboratory Hood, or other system adequate for vapor

similarity between the testing and the end-use conditions. For ventilation.

applications involving continuous immersion, the data ob-

tained in short-time tests are of interest only in eliminating the

most unsuitable materials or indicating a probable relative

order of resistance to chemical reagents.

4.3 Evaluation of plastics for special applications involving

corrosive conditions should be based upon the particular

reagents and concentrations to be encountered. The selection of

test conditions should take into account the manner and

duration of contact with reagents, the temperature of the

system, applied stress, and other performance factors involved

in the particular application.

5. Apparatus

5.1 Balance—A balance capable of weighing accurately to

0.05 % for a test specimen weighing 100 g or less, and to 0.1 %

for a test specimen weighing over 100 g. Assurance that the

balance meets the performance requirements should be pro-

vided by frequent checks on adjustments of zero points and

sensitivity and by periodic calibration for absolute accuracy,

using standard masses.

5.2 Micrometers—Use a suitable micrometer for measuring

the dimensions of test specimens similar to that described in

Test Method D 5947. The micrometer should have an incre-

mental discrimination of at least 0.025 mm [0.001 in.]. For

specimens 0.100 in. thick or less, the micrometer used shall

have an incremental discrimination of at least 0.0025 mm

--`,,```,,,,````-`-`,,`,,`,`,,`---

[0.0001 in.]. The micrometer must be verified using gage

blocks traceable to National Institute of Standards and Tech-

nology (NIST) every 30 days minimum.

5.3 Room, or enclosed space capable of being maintained at

the standard laboratory atmosphere of 23 6 2°C [73.4 6

3.6°F] and 50 6 5 % relative humidity in accordance with

Practice D 618.

5

Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

4th Floor, New York, NY 10036. FIG. 1 Determination of Strain Level of ESCR Fixtures

Copyright ASTM International 2

Provided by IHS under license with ASTM

No reproduction or networking permitted without license from IHS Not for Resale

D 543 – 06

6. Reagents and Materials 6.3.26 Hydrogen Peroxide Solution (3 % or USP 10

6.1 The following list of standard reagents is intended to be volume)—Add 98 mL (108 g) of commercial grade (100

representative of the main categories of pure chemical com- volume or 28 %) hydrogen peroxide (H2O2) to 901 mL of

pounds, solutions, and common industrial products. Chemicals water.

used in these practices shall be of technical grade or greater 6.3.27 Isooctane, 2,2,4-trimethyl pentane.

purity. All solutions shall be made with freshly prepared 6.3.28 Kerosine—No. 2 fuel oil, Specification D 396.

distilled water. Specific concentrations are on a weight percent 6.3.29 Methyl Alcohol.

or specific gravity basis. Mixing instructions are based on 6.3.30 Mineral Oil, White, USP, sp gr 0.830 to 0.860;

amounts of ingredients calculated to produce 1000 mL of Saybolt at 100°F: 125 to 135 s.

solution of the specified concentration. 6.3.31 Nitric Acid (sp gr 1.42)—Concentrated nitric acid

6.2 The following list of standard reagents is not intended to (HNO3).

preclude the use of other reagents pertinent to particular 6.3.32 Nitric Acid (40 %)—Add 500 mL (710 g) of

chemical resistance requirements. It is intended to standardize HNO3(sp gr 1.42) to 535 mL of water.

typical reagents, solution concentrations, and industrial prod-

6.3.33 Nitric Acid (10 %)—Add 108 mL (153 g) of

ucts for general testing of the resistance of plastics to chemical

HNO3(sp gr 1.42) to 901 mL of water.

reagents. Material specifications in which chemical resistance

is indicated shall be based upon reagents and conditions 6.3.34 Oleic Acid, cP.

selected from those listed herein except by mutual agreement 6.3.35 Olive Oil, edible grade.

between the seller and the purchaser. 6.3.36 Phenol Solution (5 %)—Dissolve 47 g of carbonic

6.3 Standard Reagents: acid crystals, USP, in 950 mL of water.

6.3.1 Acetic Acid (sp gr 1.05)—Glacial acetic acid. 6.3.37 Soap Solution (1 %)—Dissolve dehydrated pure

6.3.2 Acetic Acid (5 %)—Add 48 mL (50.5 g) of glacial white soap flakes (dried 1 h at 105°C) in water.

acetic acid (sp gr 1.05) to 955 mL of water. 6.3.38 Sodium Carbonate Solution (20 %)—Add 660 g of

6.3.3 Acetone. sodium carbonate (Na2·CO3·10H2O) to 555 mL of water.

6.3.4 Ammonium Hydroxide (sp gr 0.90)—Concentrated 6.3.39 Sodium Carbonate Solution (2 %)—Add 55 g of

ammonium hydroxide (NH4OH). Na2·CO3·10H2O to 964 mL of water.

6.3.5 Ammonium Hydroxide (10 %)—Add 375 mL (336 g) 6.3.40 Sodium Chloride Solution (10 %)—Add 107 g of

of (NH4OH) (sp gr 0.90) to 622 mL of water. sodium chloride (NaCl) to 964 mL of water.

6.3.6 Aniline. 6.3.41 Sodium Hydroxide Solution (60 %)—Slowly dis-

6.3.7 Benzene. solve 971 g of sodium hydroxide (NaOH) in 649 mL of water.

6.3.8 Carbon Tetrachloride. 6.3.42 Sodium Hydroxide Solution (10 %)—Dissolve 111 g

6.3.9 Chromic Acid (40 %)—Dissolve 549 g of chromic of NaOH in 988 mL of water.

anhydride (CrO2) in 822 mL of water.

6.3.43 Sodium Hydroxide Solution (1 %)—Dissolve 10.1 g

6.3.10 Citric Acid (1 %)—Dissolve 104 g of citric acid of NaOH in 999 mL of water.

crystals in 935 mL of water.

6.3.44 Sodium Hypochlorite Solution, National Formulary,

6.3.11 Cottonseed Oil, edible grade.

(4 to 6 %)—The concentration of this solution can be deter-

6.3.12 Detergent Solution, Heavy Duty (0.025 %)—

mined as follows: Weigh accurately in a glass-stoppered flask

Dissolve 0.05 g of alkyl aryl sulfonate and 0.20 g of trisodium

about 3 mL of the solution and dilute with 50 mL of water. Add

phosphate in 1000 mL of water.

2 g of potassium iodide (KI) and 10 mL of acetic acid, and

6.3.13 Diethyl Ether.

titrate the liberated iodine with 0.1 N sodium thiosulfate

6.3.14 Dimethyl Formamide.

(Na2S2O3), adding starch solution as the indicator. Each

6.3.15 Distilled Water, freshly prepared.

millilitre of 0.1 N Na2S2O3 solution is equivalent to 3.7222 mg

6.3.16 Ethyl Acetate. of sodium hypochlorite.

6.3.17 Ethyl Alcohol (95 %)—Undenatured ethyl alcohol.

6.3.45 Sulfuric Acid (sp gr 1.84)—Concentrated sulfuric

6.3.18 Ethyl Alcohol (50 %)—Add 598 mL (482 g) of 95 %

acid (H2SO4).

undenatured ethyl alcohol to 435 mL of water.

6.3.46 Sulfuric Acid (30 %)—Slowly add 199 mL (366 g) of

6.3.19 Ethylene Dichloride.

H2SO4(sp gr 1.84) to 853 mL of water.

6.3.20 2-Ethylhexyl Sebacate.

6.3.21 Heptane, commercial grade, boiling range from 90 to 6.3.47 Sulfuric Acid (3 %)—Slowly add 16.6 mL (30.6 g) of

100°C. H2SO4 (sp gr 1.84) to 988 mL of water.

6.3.22 Hydrochloric Acid (sp gr 1.19)—Concentrated hy- 6.3.48 Toluene.

drochloric acid (HCl). 6.3.49 Transformer Oil, in accordance with the require-

6.3.23 Hydrochloric Acid (10 %)—Add 239 mL (283 g) of ments of Specification D 1040.

HCl (sp gr 1.19) to 764 mL of water. 6.3.50 Turpentine—Gum spirits or steam distilled wood

6.3.24 Hydrofluoric Acid (40 %)—Slowly add 748 mL (866 turpentine in accordance with Specification D 13.

g) of hydrofluoric acid (52 to 55 % HF) to 293 mL of water. 6.4 Table 1 contains a list of military specifications for

6.3.25 Hydrogen Peroxide Solution, 28 % or USP 100 various liquids intended to be representative of the main types

volume. of liquids that may be encountered in a military service

--`,,```,,,,````-`-`,,`,,`,`,,`---

Copyright ASTM International 3

Provided by IHS under license with ASTM

No reproduction or networking permitted without license from IHS Not for Resale

D 543 – 06

TABLE 1 Military Specifications for Liquids Encountered in or finer sandpaper or emery cloth. Molding shall conform to

Military Service Environments conditions recommended by the manufacturer of the material

Specification Title (see Note 2). The shape and dimensions of specimens shall

MIL-C-372 Cleaning Compound, Solvent (for Bore of Small Arms depend upon the test to be performed and shall conform to the

and Automatic Aircraft Weapons)

MIL-G-5572 Gasoline, Aviation, Grades 80/87, 100/130, 115/145

following:

MIL-H-5606 Hydraulic Fluid, Petroleum Base, Aircraft, Missiles, 9.1.1.1 Weight and Dimension Changes—Standard speci-

and Ordinance

MIL-T-5624 Turbine Fuel, Aviation, Grades JP-4 and JP-5

mens shall be in the form of disks 50.80 mm [2 in.] in diameter

MIL-H-6083 Hydraulic Fluid, Petroleum Base, for Preservation and and 3.175 mm [0.125 in.] in thickness molded or cut from

Operation molded slabs. The nominal surface area of this standard disk is

MIL-L-7808 Lubricating Oil, Aircraft Turbine Engine, Synthetic

Base, Nato Code Number 0–148 45.60 cm2 [7.1 in.2].

MIL-A-11755 Antifreeze, Artic-Type 9.1.1.2 Mechanical Property Changes—Standard tensile

MIL-D-12468 Decontaminating Agent, STB

MIL-L-14107 Lubricating Oil, Weapons, Low Temperature specimens shall be used in accordance with the test method

MIL-L-23699 Lubricating Oil, Aircraft Turbine Engines, Synthetic prescribed in the appropriate specification for the material

Base

MIL-L-46000 Lubricant, Semi-Fluid (Automatic Weapons)

being tested or by agreement among those concerned. Where

MIL-A-46153 Antifreeze, Ethylene Glycol, Inhibited, Heavy Duty, the determination of other mechanical properties is agreed

Single Package upon between the seller and the purchaser, standard specimens

MIL-F-46162 Fuel, Diesel, Referee Grade

MIL-D-50030 Decontaminating Agent, DS2

prescribed in the appropriate test methods shall be used.

MIL-T-83133 Turbine Fuel, Aviation, Kerosene Type, Grade JP-8 9.1.2 Sheet Materials—Specimens from sheet materials

MIL-H-83283 Hydraulic Fluid, Fire Resistant, Synthetic Hydrocarbon

Base, Aircraft

shall be cut from a representative sample of the material (see

Note 3) in a manner depending upon the tests to be performed

and the thickness of the sheet, as follows (see 9.1.1 regarding

preparation of cut edges):

environment. Plastics that are intended for use in such envi-

ronments shall be tested for chemical resistance to the liquids 9.1.2.1 Weight and Dimension Changes—Standard speci-

in Table 1 as applicable. mens shall be in the form of bars 76.20 mm [3 in.] in length by

6.4.1 Army Regulation 70-71 establishes the requirement 25.40 mm [1 in.] in width by the thickness of the material. The

for chemical contamination survivability of Army material nominal surface area of the standard bar, having a thickness of

intended to withstand the hazards of a chemical warfare (CW) 3.175 mm [0.125 in.], is 45.16 cm2[7.0 in.2]. Circular disk

environment. Decontaminating agents STB and DS2 are in- specimens 50.80 mm [2 in.] in diameter by the thickness of the

cluded in Table 1. In addition, selected CW agents (or suitable material are permissible under mutual agreement between the

simulants) are liquids against which it may be appropriate to seller and the purchaser. Permissible variations in thickness of

test the resistance of certain plastics. both types of specimens are 60.18 mm [60.007 in.] for hot

molded and 60.30 mm [60.012 in.] for cold molded or cast

7. Hazards materials.

7.1 Safety precautions should be taken to avoid personal 9.1.2.2 Mechanical Property Changes—Standard ma-

contact, to eliminate toxic vapors, and to guard against chined, sheared, or cut tensile specimens shall be used in

explosion hazards in accordance with the hazardous nature of accordance with the test methods prescribed in the appropriate

the particular reagents being used. specifications of the material to be tested, or by agreement

among those concerned (see 9.1.1.2).

8. Sampling

8.1 For Practices A and B, Procedure I, sample in accor- NOTE 2—Specimen surface area greatly affects the weight change due

to immersion in chemical reagents. Thickness influences percentage

dance with the pertinent considerations outlined in Practice

dimension change as well as percentage change in mechanical properties.

D 1898. In addition, molded specimens may not agree with specimens cut from

8.2 For Practices A and B, Procedure II, sample in accor- molded or otherwise formed sheet of a given material. Consequently,

dance with the ASTM test methods for the specific properties comparison of materials should be made only on the basis of results

to be determined. obtained from specimens of identical dimensions and like methods of

specimen preparation.

9. Test Specimens NOTE 3—Molding conditions can affect the resistance of plastics to

9.1 The type and dimensions of test specimens to be used chemical reagents. Compression moldings should be prepared in a manner

depend upon the form of the material and the tests to be that will disburse external lubricants and result in complete fusion of the

performed (see Note 2). At least three specimens shall be used particles. Injection molding should be accomplished in a manner that

results in a minimum of molecular orientation and thermal stress or a

for each material being tested, for each reagent involved, for

--`,,```,,,,````-`-`,,`,,`,`,,`---

controlled level of both, depending upon the condition being simulated.

each length of conditioning, and for each strain level. The test

NOTE 4—For certain products, such as laminates, in which edge effects

specimens shall be as follows: are pronounced, larger coupons may be exposed from which standard

9.1.1 Molding and Extrusion Materials—Specimens shall specimens can be cut after immersion for determining the effects of

be molded to shape or cut from molded slabs as required in reagents on mechanical properties. This may be allowed in provisions of

9.1.1.1 and 9.1.1.2. The cut edges of specimens shall be made material specifications by mutual agreement between the seller and the

smooth by sharp cutting, machining, or by finishing with No. 0 purchaser and should be reported as such.

Copyright ASTM International 4

Provided by IHS under license with ASTM

No reproduction or networking permitted without license from IHS Not for Resale

D 543 – 06

10. Conditioning ligroin, before wiping dry. Specimens removed from volatile

10.1 Conditioning—Condition the test specimen at 23 6 solvents such as acetone, alcohol, etc., need no rinsing before

2°C [73.4 6 3.6°F] and 50 % 6 5 % relative humidity for not wiping dry. Some specimens may become tacky due to

less than 40 h prior to the test in accordance with Procedure A dissolved material on the surface or solvent absorbed through-

of Practice D 618 for those tests where conditioning is re- out the specimen. Take care in wiping such specimens not to

quired. In case of disagreement, the tolerances shall be 1°C disturb or contaminate the surface.

[1.8°F] and 62 % relative humidity. 11.5 Observe the surface of each specimen after exposure to

10.2 Test Conditions—Conduct tests in the standard labora- the chemical reagent. Observe and report appearance on the

tory atmosphere of 23 6 2°C [73.4 6 3.6°F] and 50 6 5 % basis of examination for evidence of loss of gloss, developed

relative humidity, unless otherwise specified in these practices. texture, decomposition, discoloration, swelling, clouding,

In case of disagreement, the tolerances shall be 1°C [1.8°F] and tackiness, rubberiness, crazing, bubbling, cracking, solubility,

62 % relative humidity. etc. See Terminology D 883 for proper descriptive terminol-

ogy.

PRACTICE A—IMMERSION TEST

NOTE 5—For some materials, absorption of the reagent over the 168 h

11. Procedure I—Weight and Dimension Changes (See immersion period is nearly balanced by the removal of soluble constitu-

ents from the plastic. This type of behavior may be revealed by comparing

Note 4 and 6.2)

the initial conditioned weight of the specimen with its weight when dried

11.1 Weigh each conditioned specimen separately and mea- for 168 h at 23°C and 50 % relative humidity, after removal from the

sure thickness at the center, length, and width, or two diameters chemical reagent. A final weight lower than the initial weight may indicate

at right angles to each other, to the nearest 0.025 mm [0.001 removal of soluble constituents. However, only for particular combina-

in.]. In the case of laminates, edge swelling is not uncommon tions of reagent and test specimen can this weight difference be considered

as due strictly to the removal of soluble constituents.

under certain conditions. Consequently, it may be necessary to NOTE 6—In making tests for shorter or longer periods of time than 168

measure thickness both at the center and at the edges and report h, it is recommended that the tests be run at 24 and 72 h for times that are

the percentage change separately for each position. made up of increments of 4 weeks, respectively. The containers should be

11.2 Place the specimens in appropriate containers for the stirred once each day during the first week, and once each week thereafter.

reagents being used and allow the specimens to be totally

12. Procedure II—Mechanical Property Changes

immersed in fresh reagent for seven days in the standard

laboratory atmosphere. Suspend the specimens to avoid any 12.1 Immerse and handle the mechanical test specimens in

contact with the walls or bottom of the container. For speci- accordance with instructions given in Procedure I (Section 11).

mens of thin sheeting or those having a lower density than the 12.2 Determine the mechanical properties of identical non-

reagent, it may be necessary to attach small weights such as immersed and immersed specimens in accordance with the

nichrome to prevent floating or curling. Several specimens of a standard methods for tensile tests prescribed in the specifica-

given material may be immersed in the same container tions for the materials being tested (see Note 7). Make

provided sufficient reagent is allowed for the total surface area mechanical properties tests on nonimmersed and immersed

exposed and the specimens do not touch each other. For specimens prepared from the same sample or lot of material in

specimens of nonextractable and relatively insoluble materials, the same manner, and run under identical conditions. Test

the quantity of reagent shall be approximately 10 mL/in.2 of immersed specimens immediately after they are removed from

specimen surface area. For specimens that tend to dissolve or the chemical reagent. Where specimens are exposed to re-

which involve extraction of plasticizers, the quantity of reagent agents at elevated temperature, unless they are to be tested at

shall be approximately 40 mL/in.2 of specimen surface area. the elevated temperature, they shall be placed in another

Where there is any doubt in these matters, use the higher container of the reagent at the standard laboratory temperature

solvent ratio. For tests at other than room temperatures, it is for approximately 1 h to effect cooling prior to testing (see

recommended that the test temperature be 50°C, 70°C, or other Note 7).

temperatures recommended in Practice D 618. It is important NOTE 7—While tensile tests are generally more applicable and pre-

that the reagent be at the elevated test temperature before the ferred for assessing mechanical property changes due to the effects of

specimens are immersed. chemical reagents, other mechanical properties may be more significant in

11.3 Stir the reagents every 24 h by moderate manual special cases (for example, flexural properties of rigid materials that are

rotation of the containers or other suitable means (see Note 5). not appreciably softened by the reagents under study but may be

extremely sensitive to surface attack such as crazing). Consequently, in the

11.4 After 168 h, or other agreed upon period of time,

use of these practices for establishing chemical resistance levels in

individually remove each specimen from the reagent, immedi- material or product specifications, consideration should be given to the

ately weigh, and remeasure its dimensions. Wash with running choice of mechanical properties that properly characterize the effects of

water specimens removed from acid, alkali, or other aqueous exposure to chemical reagents.

solutions, wipe them dry with a cloth or tissue, and immedi- NOTE 8—To isolate the effects of certain chemical reagents on the

ately weigh. Hygroscopic reagents such as concentrated sulfu- mechanical properties of some plastics, it is necessary to test identical

ric acid may remain absorbed on the surface of the specimens specimens that have been immersed in water. This is especially true of

tests for determining the effects of aqueous solutions, where these may not

even after rinsing, requiring immediate special handling to differ greatly from the effects of immersion in water alone. When tests are

avoid moisture pickup before and during weighing. Rinse run with a variety of aqueous solution reagents, the effects due to water

specimens removed from nonvolatile, nonwater-soluble or- alone should be established for better comparison of results. Similar

ganic liquids with a nonaggressive but volatile solvent, such as behavior may result when tests are run at elevated temperatures, requiring

--`,,```,,,,````-`-`,,`,,`,`,,`---

Copyright ASTM International 5

Provided by IHS under license with ASTM

No reproduction or networking permitted without license from IHS Not for Resale

D 543 – 06

knowledge of the effects of temperature alone to properly assess the 19.2 Expose the strained test specimens, along with one set

effects due to the chemical reagents. of 0.0 % strain (unstrained) specimens, to the reagent being

evaluated for compatibility. The test specimens can be im-

PRACTICE B—MECHANICAL STRESS AND

mersed in liquid reagents, or alternately, a wet patch method

REAGENT EXPOSURE

can be used. The wet patch method involves applying a cotton

13. Scope patch (cheesecloth) over the test specimens and saturating the

patch with liquid. For volatile reagents, the liquid should be

13.1 This practice consists of exposing standard ASTM test

reapplied daily to provide continuous saturation. Greases can

--`,,```,,,,````-`-`,,`,,`,`,,`---

specimens to the reagents being evaluated under standardized

be wiped directly onto the specimen surface.

conditions of applied strain. After exposure, the specimens are

19.3 Exposure times for chemically exposed and unexposed

visually evaluated and mechanically tested to determine the

test specimens shall be 7 days for room temperature exposure

effects of reagents on the stressed chemically exposed plastics.

and 3 days for elevated temperature exposure unless other

14. Apparatus exposure times are agreed upon between those concerned. Test

temperatures other than room temperature shall be as recom-

14.1 Micrometers (see 5.2).

mended in Practice D 618, unless specified otherwise.

14.2 Room (see 5.3).

19.4 Maintain one set of test specimens strained identically

14.3 Containers (see 5.4).

to the specimens being exposed (including 0.0 %) but with no

14.4 Strain Fixtures—Use three point flexural strain devices

reagent, to act as a control. If exposure includes elevated

capable of applying known amounts of strain to the test

temperatures, a set of chemically unexposed controls shall be

specimen. The fixtures are to be made of stainless steel with

conditioned at the same temperature and times as the exposed

stainless steel tabs at each end capable of affixing the test

specimen. Control test specimens shall be tested for the

specimen to the fixtures in such a way that intimate contact is

specified mechanical properties at the same time as the exposed

maintained between the test specimen and the fixture along the

test specimens.

entire length of the test specimen. The clamping system should

19.5 After the specified exposure period, determine the

allow for thermal expansion of the material when exposure to

mechanical properties of the unexposed control and exposed

elevated temperature is specified. The stainless steel is to be of

specimens in accordance with the standard methods for tensile,

Type 304 with a surface finish of 64. Fig. 1 provides a drawing

flexural, or other properties as prescribed in the specifications

of a typical strain fixture along with calculations for determin-

for the materials being tested (see Note 9). Test mechanical

ing the radius of curvature required for a specified percent

properties of unexposed and exposed specimens prepared from

strain.

the same sample or lot of material in the same manner, and run

14.5 Oven or Constant Temperature Bath (see 5.6).

under identical conditions. Test specimens within 24 h after

14.6 Testing Devices (see 5.7).

removal from chemical agent and removal from strain fixtures

14.7 Laboratory Hood (see 5.8).

unless specified otherwise as agreed upon between those

15. Reagents and Materials concerned.

15.1 See Section 6. NOTE 9—In some cases deviations from standardized test methods may

occur, for example, it may not be feasible to use extensometers when

16. Hazards measuring strain during tensile testing due to the curvature of the test

specimen resulting from the applied strain. Also, after exposure to some

16.1 See Section 7. reagents, some materials may soften, in which case, contact extensometers

could induce flaws resulting in premature failure. In all cases modifica-

17. Test Specimens tions to standard test methods shall be noted on test reports.

17.1 Same as 9.1 except a minimum of five test specimens

shall be tested. 20. Report

17.1.1 Molding and Extrusion Materials—Same as 9.1.1. 20.1 Report the following information:

17.1.1.1 Same as 9.1.1.2. 20.1.1 Complete identification of the material tested includ-

17.1.2 Sheet Materials—Same as 9.1.2. ing type, source, manufacturer’s code, form, and previous

17.1.2.1 Same as 9.1.2.2. history,

20.1.2 Method of preparing test specimen,

18. Conditioning 20.1.3 Specimen type and dimensions,

18.1 Conditioning—See 10.1. 20.1.4 Method of test,

18.2 Test Conditions—See 10.2. 20.1.5 Conditioning procedure used,

20.1.6 Chemical reagents,

19. Procedure 20.1.7 Stress level used,

19.1 Mount the appropriate test specimens, as specified by 20.1.8 Chemical agent application type (for example, im-

the mechanical test being performed, onto strain fixtures that mersion or wet patch),

have the radius of curvature necessary to provide the specified 20.1.9 Exposure temperatures,

strain. Ensure that intimate contact of the specimens and 20.1.10 Duration of exposure,

fixtures is maintained along the entire length of the gage area 20.1.11 Mechanical properties of identical unexposed/

or specimen area to be tested. unstressed specimens and exposed/stressed specimens,

Copyright ASTM International 6

Provided by IHS under license with ASTM

No reproduction or networking permitted without license from IHS Not for Resale

D 543 – 06

20.1.12 Average percentage increase or decrease in me- 22. Keywords

chanical properties taking the properties of the unexposed/

22.1 chemical reagent; dimensional changes; exposure; me-

unstressed specimens as 100 %,

chanical property changes; plastics; stress

20.1.13 Mean of the changes for the mechanical property,

20.1.14 Standard deviation of the changes for the mechani-

cal property, and

20.1.15 Appearance changes.

21. Precision and Bias

21.1 Precision—It is not practical to specify precision for

these practices because of the wide differences possible in the

effects of specific reagents to different plastics.

SUMMARY OF CHANGES

--`,,```,,,,````-`-`,,`,,`,`,,`---

Committee D20 has identified the location of selected changes to this standard since the last issue, D 543 - 95

(01), that may impact the use of this standard. (April 1, 2006)

(1) Updated the ISO equivalency statement in Note 1 to reflect (4) Revised Figure 1 to correct the strain sign from a summa-

the similarity of Practice B and ISO 22088 Part 3. tion to lower case epsilon.

(2) Added D 5947 to Section 2, Referenced Documents. (5) Added a Summary of changes section.

(3) Replaced D 374 in 5.2 with D 5947.

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org).

Copyright ASTM International 7

Provided by IHS under license with ASTM

No reproduction or networking permitted without license from IHS Not for Resale

You might also like

- Concrete Mix Design: Strength (Psi) 4000 Slump (In) : 3 To 4 Max. Aggregate (In) : 0.750 Cement: Coarse AggregateDocument2 pagesConcrete Mix Design: Strength (Psi) 4000 Slump (In) : 3 To 4 Max. Aggregate (In) : 0.750 Cement: Coarse AggregateAnonymous PeFQLw19No ratings yet

- Norma Astm 2412Document7 pagesNorma Astm 2412Jluis IpnNo ratings yet

- ASTM D2240 Durometer HardnessDocument13 pagesASTM D2240 Durometer HardnessGermanPersico100% (1)

- D870 PDFDocument3 pagesD870 PDFBupesh Raja100% (1)

- Static Coefficient of Friction of Polish-Coated Flooring Surfaces As Measured by The James MachineDocument5 pagesStatic Coefficient of Friction of Polish-Coated Flooring Surfaces As Measured by The James MachineMin KhantNo ratings yet

- ISO - 11998 - Wet Scub Resistance and CleanabilityDocument6 pagesISO - 11998 - Wet Scub Resistance and Cleanabilityichsan hakim100% (1)

- Bs8666 ShapesDocument2 pagesBs8666 ShapesMahaveer Janapala50% (2)

- ASTMDocument10 pagesASTManalesiNo ratings yet

- Alchemical Psychology Uniform Edition o - HillmanDocument207 pagesAlchemical Psychology Uniform Edition o - HillmanElsy Arana95% (22)

- ASTM D 618 - 13 Practice For Conditioning Plastics For TestingDocument4 pagesASTM D 618 - 13 Practice For Conditioning Plastics For TestingCRISA3000000100% (1)

- ASTM D 792 - 08 Densidad PolímerosDocument6 pagesASTM D 792 - 08 Densidad PolímerosDunia100% (1)

- Introduction To Wireless Communication - Radio CommunicationDocument21 pagesIntroduction To Wireless Communication - Radio CommunicationYas773No ratings yet

- Baroque MusicDocument15 pagesBaroque Musicthot777100% (2)

- En Iso 2578Document19 pagesEn Iso 2578Uriel Peña100% (2)

- Astm D 746 PDFDocument9 pagesAstm D 746 PDFmanoj madurangaNo ratings yet

- Hand Out To Borbet GMBH: Coating Adhesion TestDocument8 pagesHand Out To Borbet GMBH: Coating Adhesion Testferhat aydoganNo ratings yet

- ASTM-D543 (2014) - Evaluating The Resistance of Plastics To Chemical ReagentsDocument7 pagesASTM-D543 (2014) - Evaluating The Resistance of Plastics To Chemical ReagentsAndre Castelo100% (1)

- Astm D4000, 2004Document19 pagesAstm D4000, 2004aletapia100% (1)

- ASTM-D-2247 Standard Practice Testing Coatings100Document5 pagesASTM-D-2247 Standard Practice Testing Coatings100chinocatNo ratings yet

- ASTM D5420-04 - Gardner - Impact Resistance of Flat Rigid Plastic Specimen PDFDocument8 pagesASTM D5420-04 - Gardner - Impact Resistance of Flat Rigid Plastic Specimen PDFMehdi Gouader0% (1)

- Astm C 679-2003 PDFDocument3 pagesAstm C 679-2003 PDFzeqs967% (3)

- GRP Tank BrochureDocument8 pagesGRP Tank BrochuresegunoyesNo ratings yet

- Astm D-4212Document6 pagesAstm D-4212Dan Mat100% (2)

- Iso 178 PDFDocument22 pagesIso 178 PDFThiago Torres0% (1)

- Plastics: Standard Terminology Relating ToDocument15 pagesPlastics: Standard Terminology Relating ToMuhamed RiskhanNo ratings yet

- She Walks in BeautyDocument6 pagesShe Walks in Beautyksdnc100% (1)

- D1005Document3 pagesD1005meealsoNo ratings yet

- Peel or Stripping Strength of Adhesive Bonds: Standard Test Method ForDocument3 pagesPeel or Stripping Strength of Adhesive Bonds: Standard Test Method ForCris BandaNo ratings yet

- ASTM D2228 Rubber Prop-Abrasion Resistance TestingDocument9 pagesASTM D2228 Rubber Prop-Abrasion Resistance TestingJesse KrebsNo ratings yet

- Astm D925Document6 pagesAstm D925Chloe ReyesNo ratings yet

- Testing Water Resistance of Coatings Using Controlled CondensationDocument4 pagesTesting Water Resistance of Coatings Using Controlled CondensationErin JohnsonNo ratings yet

- CvaDocument20 pagesCvanuraNo ratings yet

- ASTM-D543 (2006) - Evaluating The Resistance of Plastics To Chemical Reagents PDFDocument7 pagesASTM-D543 (2006) - Evaluating The Resistance of Plastics To Chemical Reagents PDFAndre Castelo100% (1)

- Astm D 3164 - 03Document4 pagesAstm D 3164 - 03phaindikaNo ratings yet

- Radiology Final QuestionsDocument52 pagesRadiology Final QuestionsRashed Shatnawi50% (4)

- ASTM D696 Coeficiente de Expansão TérmicaDocument5 pagesASTM D696 Coeficiente de Expansão TérmicaEva SilvaNo ratings yet

- D 2578 - 04 - Rdi1nzgDocument4 pagesD 2578 - 04 - Rdi1nzgaless2056100% (1)

- Unitized Curtain Wall SystemDocument38 pagesUnitized Curtain Wall Systems.senthil nathan100% (1)

- Linear Dimensional Changes of Nonrigid Thermoplastic Sheeting or Film at Elevated TemperatureDocument2 pagesLinear Dimensional Changes of Nonrigid Thermoplastic Sheeting or Film at Elevated TemperaturePyone Ei ZinNo ratings yet

- Astm D1735-21Document3 pagesAstm D1735-21bdr85No ratings yet

- ASTM D883 - 12e1 Standard Terminology Relating To PlasticsDocument2 pagesASTM D883 - 12e1 Standard Terminology Relating To PlasticsRenzo PONo ratings yet

- Filtered Open-Flame Carbon-Arc Exposures of Paint and Related CoatingsDocument5 pagesFiltered Open-Flame Carbon-Arc Exposures of Paint and Related CoatingsDeepak D MishraNo ratings yet

- Industrial Training (Tarun Kumar) - Final ReprtDocument46 pagesIndustrial Training (Tarun Kumar) - Final ReprtSaumya GargNo ratings yet

- Design Inducer PumpDocument2 pagesDesign Inducer PumpnicoNo ratings yet

- M0007 - 2014-1 Testing Method For Automotive PaintDocument164 pagesM0007 - 2014-1 Testing Method For Automotive PaintErick Hernández0% (1)

- EX-GM-006 - GMW 14698 - 200709 - EN - Scratch Resistance of Orangnic Coatings and Self-Adhesion Foils PDFDocument3 pagesEX-GM-006 - GMW 14698 - 200709 - EN - Scratch Resistance of Orangnic Coatings and Self-Adhesion Foils PDFEd RiNo ratings yet

- Handbook of Fire and Explosion Protection Engineering Principles: for Oil, Gas, Chemical and Related FacilitiesFrom EverandHandbook of Fire and Explosion Protection Engineering Principles: for Oil, Gas, Chemical and Related FacilitiesRating: 5 out of 5 stars5/5 (2)

- PV 3952 (2002)Document4 pagesPV 3952 (2002)Matthew Taylor100% (2)

- G151 7888Document15 pagesG151 7888Sukanya KamathNo ratings yet

- Surface Energy TestingDocument4 pagesSurface Energy TestingvalentinarichitaNo ratings yet

- D522Document5 pagesD522Jeremy TohNo ratings yet

- D4585 PDFDocument3 pagesD4585 PDFten100% (1)

- D1654Document4 pagesD1654manox007No ratings yet

- Astm D648 HDT PDFDocument13 pagesAstm D648 HDT PDFEva SilvaNo ratings yet

- Respi-Nclex QuestionsDocument160 pagesRespi-Nclex QuestionsSophia Rose Delos Santos100% (3)

- Astm D 3363-05Document3 pagesAstm D 3363-05briham100% (1)

- Rust Protection by Metal Preservatives in The Humidity CabinetDocument9 pagesRust Protection by Metal Preservatives in The Humidity CabinettoanvmpetrologxNo ratings yet

- Laminated Architectural Flat Glass: Standard Specification ForDocument6 pagesLaminated Architectural Flat Glass: Standard Specification ForDmitry_ucpNo ratings yet

- Din Iso 75-2Document14 pagesDin Iso 75-2Diego CamargoNo ratings yet

- Astm D 1002Document5 pagesAstm D 1002Aisya IbrahimNo ratings yet

- ASTM D2228 04 - Standard Test Method For Rubber Property-Relative Abrasion Resistance by Pico Abrader MethodDocument9 pagesASTM D2228 04 - Standard Test Method For Rubber Property-Relative Abrasion Resistance by Pico Abrader MethodAndre Rodriguez Spirim100% (1)

- Din 50018 Sulfur Dioxide Corrosion TestDocument3 pagesDin 50018 Sulfur Dioxide Corrosion TestJoao Pedro Rendeiro Correia de SousaNo ratings yet

- Astm b0117Document10 pagesAstm b0117Anjali AnjuNo ratings yet

- D1187 PDFDocument2 pagesD1187 PDFArnold RojasNo ratings yet

- Volkswagen SpecsDocument1 pageVolkswagen SpecsYash KanherkarNo ratings yet

- ASTM D 638 - 14 Standard Test Method For Tensile Properties of PlasticsDocument1 pageASTM D 638 - 14 Standard Test Method For Tensile Properties of PlasticsGustavoNo ratings yet

- Astm d412 Testing FixtureDocument6 pagesAstm d412 Testing FixturePallab Jyoti DasNo ratings yet

- ASTM D3163 For Determining Strength of Adhesively Bonded Rigid Plastic Lap-Shear Joints in Shear by Tension LoadingDocument3 pagesASTM D3163 For Determining Strength of Adhesively Bonded Rigid Plastic Lap-Shear Joints in Shear by Tension LoadingSaavedra Aurel MarcNo ratings yet

- 2 Astm D6943Document16 pages2 Astm D6943Boris CardenasNo ratings yet

- Astm D543Document7 pagesAstm D543Gerardo Lopez GochiNo ratings yet

- D 543 - 95 - Rdu0my05nqDocument7 pagesD 543 - 95 - Rdu0my05nqLuis RebolledoNo ratings yet

- D543 37526Document7 pagesD543 37526roshniNo ratings yet

- Evaluating The Resistance of Plastics To Chemical Reagents: Standard Practices ForDocument7 pagesEvaluating The Resistance of Plastics To Chemical Reagents: Standard Practices ForDuy NguyenNo ratings yet

- Determination of The Required Part-Turn of The Nut With Respect To The Number of Free Threads at Loaded Face of The Fully TensionedDocument9 pagesDetermination of The Required Part-Turn of The Nut With Respect To The Number of Free Threads at Loaded Face of The Fully TensionedvarniktpNo ratings yet

- Module - 6 - Slides - Part 1 PDFDocument124 pagesModule - 6 - Slides - Part 1 PDFvarniktpNo ratings yet

- Asmuss Steel Catalogue PDFDocument272 pagesAsmuss Steel Catalogue PDFvarniktpNo ratings yet

- GF Formwork Cuplock SystemDocument4 pagesGF Formwork Cuplock SystemvarniktpNo ratings yet

- IC-VBN-0618-34-18-03 - 10.5m X 5m SWING GATE-CUC4Document1 pageIC-VBN-0618-34-18-03 - 10.5m X 5m SWING GATE-CUC4varniktpNo ratings yet

- State of Desiccation in Clay Soils PDFDocument5 pagesState of Desiccation in Clay Soils PDFvarniktpNo ratings yet

- Irc - SP 21 2009Document92 pagesIrc - SP 21 2009varniktpNo ratings yet

- 2014 Itr1 PR2 02Document6 pages2014 Itr1 PR2 02varniktpNo ratings yet

- Urea CycleDocument2 pagesUrea CycleyoungdandareNo ratings yet

- Numerical Methods NotesDocument21 pagesNumerical Methods Notesdean427No ratings yet

- Useful List of Responsive Navigation and Menu Patterns - UI Patterns - GibbonDocument16 pagesUseful List of Responsive Navigation and Menu Patterns - UI Patterns - Gibbonevandrix0% (1)

- Optimize Your Portfolio With Modern TheoriesDocument65 pagesOptimize Your Portfolio With Modern Theoriesastro9jyotish9asim9mNo ratings yet

- The Biologic Width: - A Concept in Periodontics and Restorative DentistryDocument8 pagesThe Biologic Width: - A Concept in Periodontics and Restorative DentistryDrKrishna DasNo ratings yet

- The Syntactic Alignments Across Three-Ar PDFDocument441 pagesThe Syntactic Alignments Across Three-Ar PDFabiskarNo ratings yet

- Guide To Program EVK1100 With AVR32studioDocument2 pagesGuide To Program EVK1100 With AVR32studioRobert T. WursterNo ratings yet

- (Homebrew) ShamanDocument15 pages(Homebrew) ShamanVictor Wanderley CorrêaNo ratings yet

- UI Symphony Orchestra and Choirs Concert Features Mahler's ResurrectionDocument17 pagesUI Symphony Orchestra and Choirs Concert Features Mahler's ResurrectionJilly CookeNo ratings yet

- Best Practice Guidelines For Cardiac Rehabilitation and Secondary Prevention: A SynopsisDocument16 pagesBest Practice Guidelines For Cardiac Rehabilitation and Secondary Prevention: A SynopsisErdy VincentNo ratings yet

- Right to Personal Liberty and Judicial Process in IndiaDocument636 pagesRight to Personal Liberty and Judicial Process in IndiaDrDiana PremNo ratings yet

- Ozone Layer EssayDocument7 pagesOzone Layer Essayb71bpjha100% (2)

- Using The 12c Real-Time SQL Monitoring Report History For Performance AnalysisDocument39 pagesUsing The 12c Real-Time SQL Monitoring Report History For Performance AnalysisJack WangNo ratings yet

- Glycerol Mono StreateDocument6 pagesGlycerol Mono StreateJaleel AhmedNo ratings yet

- Concept Deck de BosBoerderij - Dec2023Document32 pagesConcept Deck de BosBoerderij - Dec2023Bruna San RomanNo ratings yet

- Odoo Video Conference User GuidesDocument12 pagesOdoo Video Conference User GuidesZeus TitanNo ratings yet

- CGE Quester Spec Sheet E29Document2 pagesCGE Quester Spec Sheet E29Ruveen Jeetun100% (1)

- FDocument109 pagesFssissaaNo ratings yet

- LAC and Location UpdateDocument10 pagesLAC and Location UpdateAndres RockeNo ratings yet