Professional Documents

Culture Documents

Design

Uploaded by

Don OmarOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design

Uploaded by

Don OmarCopyright:

Available Formats

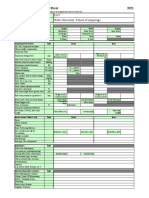

FSA Design Spec Sheet 2016

Car No. 13

School UAS MUNICH

Dimensions Units

Overall Dimensions mm Length: 2860 Width: 1427 Height: 1190

Wheelbase & Track mm Wheelbase: 1540 Front Track: 1182 Rear Track: 1163

Center of Gravity Design Height mm CG Height: 265 Confirmed Via: tilt test

Mass without driver kg Front: 79 Rear: 119 Total: 198

Weight Distribution with 68kg driver % Front: 46 % Left: 50

Suspension Parameters Units Front Rear

Tire Size, Compound and Make 18x7.5-10, R25B, Hoosier 18x7.5-10, R25B, Hoosier

Wheels (width, construction) 7.5x10, -10mm offset, 2pc Al/Cfrp Rim 7.5x10, -10mm offset, 2pc Al/Cfrp Rim

Double unequal length A-Arm. Pull rod actuated Double unequal length A-Arm. Pull rod actuated

Suspension Type

horizontally oriented spring and damper horizontally oriented spring and damper

Jounce (col D): Jounce (col G):

Suspension design travel mm 37mm 15mm 37mm 15mm

Rebound (col E): Rebound (col H):

Wheel rate (chassis to wheel center) N/mm 50.1 44.7

Roll rate (chassis to wheel center) Nm/deg 584 451

Sprung mass natural frequency Hz 45 3.05

Jounce Damping % critical 0.8 at __ mm/sec: 25 at __ mm/sec: 25

Rebound Damping % critical 0.8 at __ mm/sec: 25 at __ mm/sec: 25

Motion ratio _.__:1 0.9 Type: linear 0.95 Type: linear

Ride Camber (Rate of Camber Change) deg/m 22 40

Roll Camber deg/deg 0.75 0.5

Static Toe (- out, + in) deg 0.05 -0.3

Static camber deg -1 -0.5

Static camber adjustment method serrated plate on upright serrated plate on upright

Anti dive / Anti Squat % 12.6/18 20/64

Roll center height above ground, static mm -17 19.4

Height (col D): Height (col G):

Roll center position at 1g lateral acc mm -15.8 73 18.9 -116

Lateral (col E): Lateral (col H):

Front Caster, Trail, and Scrub Radius Caster (deg): 5.1 Kin Trail (mm): 10.5 Scrub Rad (mm) 12.6

Front Kingpin Axis Inclination (deg): 8.4 Offset (mm): 9.1

Static Ackermann % 95 Adjustable? Yes

Suspension Adjustment Methods different pickup ponts at the upright

Steer Ratio, C-Factor, Steer Arm Length Steer Ratio (x:1) 2.5 c-factor (mm) 144.5 Steer Arm Length 50

Brake System / Hub & Axle Units Front Rear

Rotors Floating, Steel, hub mounted, 190mm outer diam., Floating, Steel, hub mounted, 180mm outer diam.,

Master Cylinder 15mm bore front 15.9mm bore rear with driver adjustable bias bar

Calipers 4x 25.4mm dia., Opposing piston, fixed mtg 2x 25.4mm dia., Opposing piston, fixed mtg

Brake Pad/Lining Material AP Racing CP 4226-D27-RX / SBS organic AP Racing CP 4226-D27-RX / SBS organic

Force and Pressures @ 1g Deceleration Front Pres. (bar): 14.5 Rear Pres. (bar): 13.5 Pedal Force (kN) 0.186

Upright Assembly CNC 7075-T651-Al CNC 7075-T651-Al

Hub Bearings angular contact ball bearings, Seperate nilos rings angular contact ball bearings, Seperate nilos rings

CNC 7075-T651-Al Hub with glued tripoden insert, CFRP

Axle type, size, and material CNC 7075-T651-Al Hub

Axle with steel tripod

Ergonomics Units

Driver Size Adjustments fixed steering wheel and headrestrain position, pedals adjustment 225mm

Seat (materials, padding/damping) Individual foam seat, 80mm foam head support

Steering Wheel (dia, construction) Diamter (mm) 240 Construction selfmade in two halve from CFRP

Shift Actuator (type, location) pneumatic actuated shifting by paddels on steering wheel

Clutch Actuator (type, location) Servo actuated, lever potentiometer on steering wheel

Instrumentation Gear & Speed Indicator, shift light, multifunctional sensor gauge

Optional: Driver Safety Systems?

2016 FSA Design Spec Sheet - UAS MUNICH V1 1 27.05.2016

Electrical Units

Power Management / Control EMS (Energie Managment System) designed by team, Safety Power Off , Master Switch, Motec M800 purchased

Wiring / Loom / ECM mounting Awg 8/20/24 for supply and Signal, shielded cable for CAN,

Battery / Charging System LiFePo4 (3,3V 2,5A per Cell), 4s3p charching with Alternator,

Grounding 12V DC neg. ground System, grounded at frame and engine, seperate grounding wires for big consumer loads.

Driver Assist Systems launch control, traction control, automatic upshift, Dashboard

Logging / Telemetry Logger: 2D LG-μCAN11_Eng-000 (97 channels), 2D LG-CANMEMxC-yyy/2000TCP-000 (256 channel)

Special Sensing Technology correvit sensor, ride height sensor, three axis acceleration sensor.

Frame Units

Frame Construction Front Monocoque, rear tubular space frame

Material Monocoque:CFRP, Rohacell core; TSF: 15CrMoV6.9 steel tubing 16 to 25mm dia

Joining method and material connection of upper and lower half at the end of the lamination/TIG welding

Bare frame mass with brackets & paint kg Target: 29 Physical Test: 33

Torsional stiffness N-m/deg Target: 4300 Simulated: 4800 Physical Test:

Torsional stiffness validation method own build test bench

Impact Attenuator configuration 5 Layers of 170g/m2 Aramid Fiber (Kevlar Gewebe Style 284), AIP made of 4mm aluminum

Impact Attenuator dimensions mm Width: 263mm Height: 356mm Depth: 271mm

Impact Attenuator energy capacity kJ Energy: 7.513 kJ Method: crash test

Powertrain Units

Manufacturer / Model Honda CBR600RR PC40

Cylinders & Fuel Cylinders: 4 Fuel Type: E85

Displacement & Compression Displacement (cc): 599.4 Compression (_:1): 13.5:1

Bore & Stroke mm Bore: 57 Stroke: 42.5

Engine Output Peak Power (kW) 64 PeakTorque (Nm) 71

Design Speeds rpm Max Power: 9500 Max Torque: 8500 80% Torque: 6000

Induction (natural or forced, intercooled) naturally aspired

Throttle Body / Mechanism 28mm, butterfly throttle

Fuel Injection System (manf'r, and type) student designed and built, cylinder selective fuel injection

Fuel System Sensors (for fuel mapping) fuel pressure, fuel temperature

Fuel Pressure bar 5.00 relative

Injector location 150 mm before intake valve and directed towards intake valve

Intake Plenum Volume (cc): 2670 Runner length (mm): 235

Exhaust Header Configuration 4-2-1 Effective Runner Length (mm): 750 Variation (mm): -

Exhaust Header Diameters Primary (mm): 28 Collector (mm): 35

Ignition System student designed, single coil ignition and ignitionmodul

Ignition Timing 3-D Mapping, RPM and airbox pressure based; timing between 35 - 70 deg BTDC

Oiling System (wet/dry sump, mods) crankshaft driven dry sump, 2 scavenge/1 pressure pump

Engine Lubricants / Friction Treatment Castrol Power 1 4T 10W-50

Coolant System and Radiator location in sidebox mounted 1 core water radiator, 802 cfm fan mounted to radiator; in sidebox mounted 1 core oil radiator,

Fuel Tank Location, Type floor CFRP mounted between firewall and monocoque, student designed Capacity (L): 6.8

Muffler glass packed dissipative muffler

Other significant engine modifications CFRP valvecover

Drivetrain Units

Drive Type chaindrive 428# chain

Differential System Drexler, clutch pack limited slip, 30-35Nm preload, adjustable bias ratio

Final Drive Ratio _:1 3.08

Vehicle Speed @ max power (design) rpm kph 1st gear: 65 2nd gear: 89.38 3rd gear: 107.25

Vehicle Speed @ max power (design) rpm kph 4th gear: 123.79 5th gear: - 6th gear: -

Half shaft size and material 52mm OD 43mm ID filament windet carbon fibre driveshafts with glued steel inserts

Axle Joint type and grease used self designed tripod housings integrated steel inserts

Aerodynamics (if applicable) Units

Type / Configuration Frontwing, Sidewing, Sidebox, Undertray, Rearwing,

Forces (at 80 kph, ρ= 1.162 kg/m^3) Downforce (N): 1083 % Front: 60 Drag (N): 430

Coefficients & Reference Area Cl: -3,4 Ref. Area (m^2): 1,11 Cd: 1,35

Noteable Features (active, etc)

Other Information Units

Body Work (material, process)

Optional Information

2016 FSA Design Spec Sheet - UAS MUNICH V1 2 27.05.2016

You might also like

- TOYOTA 1CD-FTV D4D Engine FuelDocument27 pagesTOYOTA 1CD-FTV D4D Engine FuelLuis Daniel Cortes100% (16)

- 2008 Mercruiser Service Manual IndexDocument6 pages2008 Mercruiser Service Manual Indextwshelly100% (1)

- 10 K&CDocument95 pages10 K&COscar Mendoza Quintana100% (1)

- 2015 Composites Lab2Document28 pages2015 Composites Lab2Lê Ngọc-HàNo ratings yet

- AC Worksheet v016Document82 pagesAC Worksheet v016Игорь БелецкийNo ratings yet

- Formulalincolnprogram PDFDocument62 pagesFormulalincolnprogram PDFdebendra128nitrNo ratings yet

- 2021 FSAE Design Spec Sheet - EVDocument3 pages2021 FSAE Design Spec Sheet - EVDursun Can PolatNo ratings yet

- Hyundai Edc16c39 Immo Off: DownloadDocument5 pagesHyundai Edc16c39 Immo Off: DownloadRaul ViafaraNo ratings yet

- TJ LX 173 PC2317 - 19 - 30oct08Document302 pagesTJ LX 173 PC2317 - 19 - 30oct08viniciusNo ratings yet

- 4jj1 Maintain ScheduleDocument1 page4jj1 Maintain ScheduleDinukaDeshanNo ratings yet

- Cb125 Shine SPDocument87 pagesCb125 Shine SPNarasimma0% (1)

- Hyundai 35-40-45D 50da-9 PDFDocument1,343 pagesHyundai 35-40-45D 50da-9 PDFMichał LicznerskiNo ratings yet

- F350 - Diagrama Luzes PDFDocument6 pagesF350 - Diagrama Luzes PDFGabrielNo ratings yet

- Fsae DesignspecsDocument2 pagesFsae DesignspecsSureshMcNo ratings yet

- Design and Analysis of Disc Brake and Caliper of Four WheelerDocument5 pagesDesign and Analysis of Disc Brake and Caliper of Four WheelerIJSTENo ratings yet

- 29 Ritsumeikanuniversity SpecsDocument2 pages29 Ritsumeikanuniversity SpecsMari MuthuNo ratings yet

- Sae Baja India 2011 (FDR)Document22 pagesSae Baja India 2011 (FDR)Rahul ReddyNo ratings yet

- 2011 FSAE Design Spec Sheet: Car No. SchoolDocument5 pages2011 FSAE Design Spec Sheet: Car No. SchoolMohammad Parvez RazaNo ratings yet

- Modeling and Simulation Study of BAJA SAEINDIA All Terrain Vehicle (ATV) Using Integrated MBD-FEA ApproachDocument15 pagesModeling and Simulation Study of BAJA SAEINDIA All Terrain Vehicle (ATV) Using Integrated MBD-FEA ApproachRohit RajNo ratings yet

- 09 Suspension ConceptsDocument33 pages09 Suspension Conceptskaka1211402No ratings yet

- Drag Reduction SystemDocument5 pagesDrag Reduction SystemNemanja SlijepčevićNo ratings yet

- Dynamic Analysis of Double Wishbone PDFDocument76 pagesDynamic Analysis of Double Wishbone PDFMohammed Atif Uddin100% (1)

- Automotive Systems: Vehicle Performances Parameters PFI Gasoline EnginesDocument36 pagesAutomotive Systems: Vehicle Performances Parameters PFI Gasoline EnginesAmanda MoraraNo ratings yet

- Drivetrain ReportDocument12 pagesDrivetrain Reportkushagra pandeyNo ratings yet

- Optimal Valve TimingDocument19 pagesOptimal Valve TimingjehadyamNo ratings yet

- 2010 FSAE Design Spec Sheet: Car No. SchoolDocument3 pages2010 FSAE Design Spec Sheet: Car No. SchoolOswaldo BorjasNo ratings yet

- Sae Baja Final ReportDocument41 pagesSae Baja Final ReportAjay Yadav100% (2)

- Rack and Pinion Steering DesigningDocument19 pagesRack and Pinion Steering DesigningAudrian Louven Realubit Sabado0% (2)

- Brake Report 2015Document38 pagesBrake Report 2015Pratyush NagareNo ratings yet

- 07 1 Suspension ConceptsDocument26 pages07 1 Suspension ConceptspankajNo ratings yet

- 2021-2.0 Vehicle Dynamics - UploadDocument74 pages2021-2.0 Vehicle Dynamics - UploadMudit Maheshwari100% (1)

- ( (Manufacturing) ) : Example 21.1 Orthogonal CuttingDocument8 pages( (Manufacturing) ) : Example 21.1 Orthogonal CuttingNavish KotwalNo ratings yet

- ADAMS/Car Templates: About This Guide 3 Using Communicators 5 Template Descriptions 15Document103 pagesADAMS/Car Templates: About This Guide 3 Using Communicators 5 Template Descriptions 15Entropay UserNo ratings yet

- 2.2 Suspension Functionality PDFDocument70 pages2.2 Suspension Functionality PDFDrBalaramakrishna NizampatnamNo ratings yet

- RequestDocument22 pagesRequestOmar MuñozNo ratings yet

- Vehicle Dynamics University QuestionDocument2 pagesVehicle Dynamics University Questionsivakkumar14100% (1)

- VD Temario PDFDocument2 pagesVD Temario PDFJordi_fgNo ratings yet

- Economic Solution For Data Acquisition in A Formula SAE Race CarDocument6 pagesEconomic Solution For Data Acquisition in A Formula SAE Race CarmclarenrulzNo ratings yet

- Car Chassis Dimensions - Dimensions GuideDocument4 pagesCar Chassis Dimensions - Dimensions GuideKarthikeyan NavaneethakrishnanNo ratings yet

- Klein Technical GuidelineDocument21 pagesKlein Technical GuidelinePeter100% (2)

- Design of Electric Go KartDocument20 pagesDesign of Electric Go KartChakradhar YadavNo ratings yet

- 2015 FSAE - Design IC Spec Sheet - 2015 - Template - 2015!03!10 VerDocument10 pages2015 FSAE - Design IC Spec Sheet - 2015 - Template - 2015!03!10 VerAnirudh25895No ratings yet

- Chapter Four - Kinematic Steering - 2015 - Essentials of Vehicle DynamicsDocument11 pagesChapter Four - Kinematic Steering - 2015 - Essentials of Vehicle DynamicsJulián AvellaNo ratings yet

- 253 Suspension Calc ExplainedDocument1 page253 Suspension Calc ExplainedholaqNo ratings yet

- Powertrain IntegrationDocument4 pagesPowertrain IntegrationmenonmoonNo ratings yet

- Damper DynoDocument3 pagesDamper DynoEoin MurrayNo ratings yet

- Cam Experimental Lab: ObjectiveDocument8 pagesCam Experimental Lab: ObjectiveMuhammad Changez Khan100% (2)

- Design and Analysis of 9 Speed GearboxDocument7 pagesDesign and Analysis of 9 Speed GearboxHenok Ghiday0% (1)

- Driveline Dynamics NotesDocument19 pagesDriveline Dynamics NotesprabhjotbhangalNo ratings yet

- Steering Geometry and Caster Measurement PDFDocument18 pagesSteering Geometry and Caster Measurement PDFVinayChikNo ratings yet

- A18 008 Parameterized FMU Using Adams CarDocument22 pagesA18 008 Parameterized FMU Using Adams Carmikael bezerra cotias dos santos100% (1)

- Vehicle Suspension Modeling NotesDocument25 pagesVehicle Suspension Modeling Notesahmetlutfu100% (2)

- Double WishboneDocument6 pagesDouble WishboneRian SteveNo ratings yet

- FSAE PowerTrain Phase 4 NNDocument80 pagesFSAE PowerTrain Phase 4 NNAnonymous NK2QBE9oNo ratings yet

- Automotive Differentials, ReleaseDocument30 pagesAutomotive Differentials, Releasestefanovicana1No ratings yet

- Me6503 Dme Unit 5 Study Notes 2015Document25 pagesMe6503 Dme Unit 5 Study Notes 2015Bala MuruganNo ratings yet

- Brake CalculationDocument10 pagesBrake CalculationKarthick DavoothNo ratings yet

- 01ev0103 Vehicle DynamicsDocument3 pages01ev0103 Vehicle DynamicsSidharth Sabyasachi100% (1)

- Friction Brake TheoryDocument12 pagesFriction Brake TheoryamolkoushikNo ratings yet

- Sae Technical Paper Series: T. Amato, F. Frendo and M. GuiggianiDocument10 pagesSae Technical Paper Series: T. Amato, F. Frendo and M. GuiggianiAramis SchultzNo ratings yet

- Final Suspension DesignDocument60 pagesFinal Suspension DesignSNEHASIS MOHANTY100% (1)

- Brake Efficiency CalculationDocument11 pagesBrake Efficiency Calculationdevi saravananNo ratings yet

- Car PhysicsDocument27 pagesCar PhysicsHarikrishnan Rajendran0% (1)

- Development and Analysis of A Multi Link SuspensionDocument100 pagesDevelopment and Analysis of A Multi Link SuspensionGianLucaNo ratings yet

- Chassis Design Validation of A Baja CarDocument6 pagesChassis Design Validation of A Baja CarConrad54No ratings yet

- Adams Car Suspension AnalysisDocument12 pagesAdams Car Suspension Analysispeaty785No ratings yet

- FSN Design Spec Sheet 2019: 181 Ecole Centrale de LyonDocument5 pagesFSN Design Spec Sheet 2019: 181 Ecole Centrale de LyonMateus FlausinoNo ratings yet

- 19sl05111 Pros Final - RedactedDocument28 pages19sl05111 Pros Final - RedactedAlyssa Roberts100% (1)

- Prophet SL Suspension Set Up : XC FRDocument3 pagesProphet SL Suspension Set Up : XC FRGibo JaNo ratings yet

- 2021 Honda PCX 160 (Facts)Document2 pages2021 Honda PCX 160 (Facts)Robin ArsitioNo ratings yet

- Concrete Solutions. Always: Engine 4TNV98CT Engine Power 53,7 KW - 73,0 HP Operating Weight 5.470 - 5.720 KGDocument2 pagesConcrete Solutions. Always: Engine 4TNV98CT Engine Power 53,7 KW - 73,0 HP Operating Weight 5.470 - 5.720 KGjAVIER GARCIA MORIANANo ratings yet

- Honda S2000 V2Document2 pagesHonda S2000 V2Ikhtizar AbyanNo ratings yet

- Liste Des Engages / Entry ListDocument2 pagesListe Des Engages / Entry Listapi-267715685No ratings yet

- Piper 761-538 Warrior PC v2009Document422 pagesPiper 761-538 Warrior PC v2009df100% (1)

- The Physics of Cycling PDFDocument79 pagesThe Physics of Cycling PDFDiego PolliniNo ratings yet

- ENGINEd 16 CDocument12 pagesENGINEd 16 CMurniansyah AnsyahNo ratings yet

- Delphi Katalog Duesen PDFDocument373 pagesDelphi Katalog Duesen PDFDavid Lincoln83% (6)

- Area: Count 0 1 Area: Count 0 1 AreaDocument6 pagesArea: Count 0 1 Area: Count 0 1 Areachong xiao tongNo ratings yet

- Remf-132 Efficient Control of Active Steering System in CarsDocument3 pagesRemf-132 Efficient Control of Active Steering System in CarsretechNo ratings yet

- 12 Ud2000 PDFDocument4 pages12 Ud2000 PDFIGNACIONo ratings yet

- 2010 Nissan Versa S Fluid CapacitiesDocument2 pages2010 Nissan Versa S Fluid CapacitiesRubenNo ratings yet

- FJS-727 SeriesChecklistandProceduresManualDocument67 pagesFJS-727 SeriesChecklistandProceduresManualDave91No ratings yet

- Catalogue Edition 6.8 301012Document208 pagesCatalogue Edition 6.8 301012Ningmin TunNo ratings yet

- Komatsu, 830eDocument2 pagesKomatsu, 830eRalf MaurerNo ratings yet

- Kwik Wire InstructionsDocument72 pagesKwik Wire InstructionsCoco RocoNo ratings yet

- McLaren 720S Spider Order SummaryDocument4 pagesMcLaren 720S Spider Order SummaryLorenzo BertolinoNo ratings yet

- Pruject 2Document90 pagesPruject 2vipin554100% (1)

- SM 33 PDFDocument4 pagesSM 33 PDFCesar Maüricio TorresNo ratings yet

- 785C - Apx LineasDocument43 pages785C - Apx LineasChema VenegasNo ratings yet