Professional Documents

Culture Documents

Upsi - Method Statements Piling Works

Uploaded by

Faeez Zain0 ratings0% found this document useful (0 votes)

190 views129 pagesmos

Original Title

Upsi- Method Statements Piling Works

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentmos

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

190 views129 pagesUpsi - Method Statements Piling Works

Uploaded by

Faeez Zainmos

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 129

METHOD STATEMENT

PILING WORKS

Olgalal

DALAL TECHNOLOGY SDN BHD

No 13, Jalan Astaka UBIB4A, Pare 1,

“Tmn, Perindustian Bu, Jetutong

‘Seksyen UB, BUKtJelutong,

40160 Shah Alam, Selangor, Malaysia

30Dee 2017

PEMBINAAN FAKULTI PENDIDIKAN

TEKNOLOGI & VOKASIONAL (FPTV)

UNIVERSITI PENDIDIKAN SULTAN IDRIS (UPSI)

KAMPUS TELUK INTAN, PERAK DARUL RIDZUAN.

Laue ula

PILING WORKS

pret Ta ES

Ol Code 1 APPROVED

(Work Proceed With Accordance To The Method Statement)

Cl code2 APPROVED WITH COMMENT

(Work May Proceed Subject To Incorporation of Comments Indicated)

Ocodes RESUBMIT

(Physical Work Cannot Proceed)

Rev tem ao

14 March 2038

‘Ad calibration cartcte 0

Signature

Law yitMeng

‘Law it Meng

METHOD STATEMENT

PILING WORKS

Table of Content

Introduction 2

Reference 2

Material 2

Manpower 2

Construction Procedure 3

5.1 Preliminaries or Damage Due to Piling Works 3

5.4.1 Access Road and Working Platform Preparation 3

5.1.2 Prevention of Damage Due to Piling Works 3

5.1.3 Determination of Pile Driving Method, Selection Hammer and Pile Bearing Capacity 3

6.1.3.1 Pile Driving Method 3

6.1.32 Selection of Hammer and Determination of Pile Bearing Capacity 3

5.1.4 Survey Works 4

4

4

4

5

6

8

8

5

6

8

1

2

3

4

6

5.2 Pile Delivery and Storage at Site

52.1 Material Inspection

52.2 Handling and Storage

5.3 Installation Preliminaries Test Piles and Working Piles

53.1. Preliminaries Piles

5.3.2 Working Piles,

6.3.2.1 Pile Marking

6.322 Pile Pitching

53.2.3 Pile Driving

5.32.4 Pile Jointing and Record

5.325 Colouring Penetration Detection Method 9

5.4 Common Pile Installation and Problem Solutions 2

5.8 Provision For Pile Load Testing 2

5.5.1 Dynamic Pile Testing 12

5.8.1.1 Introduction R

5.5.1.2 Dynamic Pile Testing Equipment 2B

55.1.3 Test Parameters 2B

55.14 Test Procedures 13

55.1.8 Data Assessment and CAPWAP, TNPWAVE or FEIWEAP Analysis “

85.16 Presentation of Test Results 4

55.2 Maintained Load Test 16

5.5.2.1 Introduction 18

55.22 Material 15

55.23 Equipment 16

55.24 Method 16

55.25 Standard for The Acceptance of Test Piles 16

‘Appendix 1 ~ Inspection and Test Plan

‘Appendix 2 ~ Hazard Identification, Risk Assessment and Risk Control

Appendix 3 — Hiley's Formula for Set Calculation of Prestressed Spun Pile Driven

2IPage

METHOD STATEMENT

PILING WORKS.

10

2.0

3.0

40

INTRODUCTION

This document is prepared to provide a guideline for the necessary installation of the spun

pile which cover the following scope of works:-

a, Preliminaries works prior to commence the piling activities

b. Pile delivery and storage at site

. Installation preliminaries test piles and working piles

d._ Strip ple to cut-off level and identity pile eccentricity at cut off level.

REFERRENCE

The scope of works is carried out in accordance to the following:-

a. Technical Specification

b. British Standard BS 5950

c. British Standard BS 639

4d. Approved for construction drawings

MATERIAL

‘The material proposed to use for this work, but not limited as listed below:-

a. 300mm spun pile class B x various length prestressed spun pile

b. Welding electrode

c. Dye-pen solution: Cleaner, Developer and Penetrant

MANPOWER

‘Work force that will be mobilized for the works is grouped under the following categories:-

Field Personnel

a. Site supervisor Planning, coordinating and supervision the piling

activities

b. Land surveyor/Chainman Establish temporary bench mark, setting out of works

and as built survey before and after work complete

¢. Machinery / Plant Operator Operating the plants and machineries

d. Welder Carry out welding for pile jointing

@. Surveyor and chainman Surveying the plle position before and after pling

f. Pile Recorder Recording the pile driving record

g. General Worker Carry out general works at site

Quality Assurance and Quality Control

a. Site Supervisor To implement and audit Project Quality Pian at site

Safety, Health and Environment

a. Safety Officer To implement and audit safety requirement at site

3|Page

METHOD STATEMENT

PILING WORKS.

5.0

CONSTRUCTION PROCEDURE.

5A

PRELIMINARIES WORKS PRIOR TO COMMENCE THE PILING ACTIVITIES

BAA

512

PREVENTION OF DAMAGE DUE TO PILING WORKS.

a. The position of existing utilities shall be determined and underground

utlties adjacent to the piles shall be exposed or otherwise accurately

located before piling works start.

b. Dilapidation survey will be carried out on the existing adjacent structure

and utlities if required depend on its distance to the working area to

measure the degree of damage due to the piling works.

ACCESS ROAD AND WORKING PLATFORM PREPARATION

a. The access road shall be prepared for the machinery and material able to

transportedidelivered to work site and maintained it in good condition

throughout the construction periods,

b. The working platform will be cut and/or fill above 150mm higher than the

required cut off level which the work shall be comply with the earthwork

specification.

. For the area where the pile cap level is lower than the original ground

level. The original ground level will be maintained. The working platform

shall be prepared to support the machineries load during piling activities.

Steel plate may require to place on top of the working platform to evenly

distribute the load of the machineries on the ground,

DETERMINATION OF PILE DRIVING METHOD, SELECTION OF HAMMER

AND PILE BEARING CAPACITY

5.1.3.1 PILE DRIVING METHOD

(i) Hydraulic Method is adopted for this project which with

accordance to the tender / construction drawing,

The noise level of these hydraulic hammers is below 60

phones (A) at distance of 30m from the pile driving machine

A hydraulic machine consists of a hammer pressure or

supplied by the power unit and drops it freely to hit the pile

and penetrate it

5.1.3.2 SELECTION OF HAMMER AND DETERMINATION OF PILE

BEARING CAPACITY

‘The proper selection of the hammer to drive a given pile is necessary

in order to insure the ability of the hammer to drive the pile to the

desired penetration, and to prevent over stressing of the pil.

‘The actual hammer selection shall be depending on the pile length,

bearing capacity and ground conditions. For this project, 3 tonne and

8 tonne and above weight hammer is adopted.

4|Page

METHOD STATEMENT

PILING WORKS

514

5.1.3.3 DETERMINATION OF PILE BEARING CAPACITY

When the method of driving is adopted for prestressed spun pile, the

bearing capacity can be estimated from:-

‘| Hammer condition

+ Pile penetration depth

+ Rebound

In general the length of test pile will be greater than the estimated

length of pile in order to provide variation in soil condition.

The pile bearing capacity can be determined using following

methods:-

+ Hiley’s formula

+ Wave equation formula

SURVEY WORK

‘The setting out of piles shall be carried out on site after the platform is

prepared. The data and references points of piles shall be as shown on the

Construction Drawings. Immediately before installation of the pile, the pile

position shall be marked with suitable identifiable pins, pegs or markers.

The temporary bench mark (TBM) shall be established near to the structure

and protect against disturbance and damaged

Two perpendicular offsets shall be taken from each pile point before

commencement of piling works at the point For rake pile, an offset point

calculated based on the designed cut-off level of the pile and existing ground

level at the particular pile points shall be provided.

5.2 PILE DELIVERY AND STORAGE AT SITE

5.24

5.22

MATERIAL INSPECTION

‘The piles delivered are to be inspected for physical non-conformities such as

hairline cracks and etc. The marked on the piles shall be checked against the

record in the delivery order:-

a. Pile size and class

b. Date of cast

©. Serial no and factory code

d. Pile length and type

HANDLING AND STORAGE

Prestressed spun piles shall be handied by such method and equipment,

which shall not impair its strength or cause damage to the pile head, pile shaft

and pile shoe. Mobile crane will be used to unload to it required location and

‘ease for piling machine to drag into the pile driving helmet.

Prestressed spun piles shall be carefully handled to prevent any excessive

loads. When lifting on site, sling pile by crane at two points marked on all plies,

at 2/10 of the length of ends. Lifting is by wrapping rope around the piles at

these points. Lifting of piles shall be using sling shall coincide with indicated

lifting points marked on the pile’s shaft

5\Page

METHOD STATEMENT

PILING WORKS.

The piles are only to stored or stacked above the firm ground using timber

sleeper or equivalent and strictly not allowed to rest directly against the

ground to prevent damage due to differential settlement of ground under the

self-weight of the pile. They shall stacked in such a manner as to allow easy

identification, lifting and minimize stresses on pile.

The piles shall be assured that a minimum concrete strength has been

obtained after casting before driving is allowed

5.3 INSTALLATION PRELIMINARIES TEST PILES AND WORKING PILES

5.34

5.3.2

PRELIMINARIES PILES

Preliminaries test piles shall be constructed using the material and method of

construction proposed for working piles and which had submitted to the

Resident Engineer. The location and details of the preliminary piles shall be

as instructed by the Resident Engineer.

After twenty-eight (28) day of preliminaries test piles had driven into it posit

the maintained load test will be carried out

Unless otherwise permitted by the Resident Engineer the relevant piling works

shall not commence until the construction, testing and records of the

preliminaries piles stated had satisfied the requirement.

Preliminary piles shall be left in position, cut-off, incorporated in the

Permanent work. Preliminary piles intended to be incorporated in the

Permanent work and which do not comply with the specified requirement shall

be removed and disposed of or dealt with as instructed by the Resident

Engineer

WORKING PILES

5.3.2.1 PILE MARKING

The piles prior to pitching and driving into the position shail be marked

‘at 300mm intervals along its length with indelible markings in order

that depth of penetration at any stage of driving can be easily read

5.3.2.2 PILE PITCHING

For shorter piles (< 12m) a single pick-up point may be acceptable.

‘The pick-up point location should be as specified by the manufacturer

or at the middle portion of the pile. For longer pile (> 12m) two or more

Pick-up points at designated locations or generally at quarter length

of the starter pile from both ends.

The pile is winched up and towards the piling frame top where

attached with driving helmet with the necessary packing The

‘inching is done with care until the piles head is fit into the heimet

and base of hammer. Once the pile is approximate vertical, the piling

6iPage

METHOD STATEMENT

PILING WORKS

piant will move toward the pile point and slowly lowered until

approximate few inches above the pile point peg. Fine turing may

require to obtain the exact position of the pile point. After the complete

adjustment to the exact pile location, the pile will be lowered into the

ground at its position and verticality or rake is checked and adjusted.

Then the pile driven activities will be commence.

The piles shall have no noticeable cracks when place in leads or

during installation, Spaliing of the concrete at the top or near splices

should not be evident.

PILE DRIVING

Driven piles shall be supported and restrained by means of leaders,

trestles, temporary supports or other guide arrangements in such a

manner that:-

The piles are maintained in position and alignment

+ The piles are not loosened in the ground, and

‘+ Damage resulting from oscillation, vibration or movement

of free-standing piles does not occur.

‘The supports and restraints shall be maintained at all times during

driving and until the piles are incorporated into the structure.

During pile driving, periodical checks for verticality must be made,

using plumb bobs. For starter pile, the verticality of pile shall be

checked for every meter of pile penetration,

-—

| Pile Vertical Guides

Figure 1: Pile Vertical Guides

A pile recorder will be in place for counting the number of hammer

blows per every 300mm and tabulated in the pile driving log. The

driving record form a basis for payment and for making engineering

decisions regarding the adequacy of the foundation to support the

design loads. The pile recorder has to include the information on

equipment at the site, combination of piles per point, levels of ground,

pile toe, cut-off length, and etc. as shown in the pile driving log

T|Page

METHOD STATEMENT

PILING WORKS

‘A hammer cushion of manufactured material usually lasts for many

hours of pile driving (as much as 200 hours for some manufactured

materials) so it is usually sufficient to check before the pile driving

begins and periodically thereafter. Pile cushions (usually made of

plywood) need frequent changing because of excessive compression

‘or charring and have a typical life of about 1000 to 2000 hammer

blows. Pile cushions shall preferably be replaced as soon as they

compress to one half of the original thickness, or if they begin to burn

No changes to the pile cushion thickness should be permitted near

final driving.

‘The maximum permissible deviation of the center of each finished pile

shall not exceed 75mm in any direction from the actual position of the

same pile

The vertical of each pile shall not deviate at any point below the ground

by more than 1 in 75 from the true vertical position as shown in the

figure 2. However, the maximum permitted deviation of the finished

pile from the specified rake or the rake shown on the Construction

Drawings is 1 in 25.

Vertical axis

(Ground Level

6

spun ple

Figure 2: Maximum permitted pile deviation from vertical axis

The driving sequence of the pile groups shall be from the center of the

group outward or from one side to the other side. Pile group shall not

rive from the outside to the center. If groups are driven in that order,

displaced soils becomes trapped and compacted in the center of the

pile group.

The site supervisor shall ensure that the pile set is taken with a pencil

placed horizontally and resting on firm support to record the set on a

{graph paper pasted on pile shaft as shown in the figure 3. The pile

shall be driven until the set criteria are achieved as in the set

computational

B|Pege

METHOD STATEMENT

PILING WORKS

Figure 3: Taken pile set

5.3.2.4 PILE JOINTING AND RECORD

The pile will be driven until the expected set is achieved. When the

extension pile is required, the starter pile will be stop approximate

500mm above the ground. Then, the extension pile will be positioned

into the starter pile in perfect contact and axis to ensure the extension

pile is in true straight line, using a leveling ruler before weld using

shielded metal arc welding (SMAV) method

Welder shall be qualified in accordance with the requirement of AWS.

Code D1.1. Only welders who pass the qualifying tests for the type of

weld specified shall be employed on the Works.

Pile joint is important for pile integrity. Poorly made joint are a

potential source of problems and possible pile damage during driving

In some cases damage may be detected from the blow count records.

Dynamic pile testing can be useful in questionable cases.

The bending strength of a joint between two lengths of pile shall be

equal or more than the bending strength of the concrete shaft. When

two lengths of pile are jointed, the end plates must bear over their

complete areas,

The spun piles pile joint for the end plate thickness is 12 mm thick

which less than 20mm generally is single beveled with a small groove

with 45° throat. The weld shall be carried out in accordance with the

requirement of B.S. 5135 1975 - Metal-Arc Welding of carbon and

carbon manganese steel.

‘The ampere needed to weld depends on electrode diameter the size

and thickness of the pieces to be welded and the position of the

welding. When welding horizontally, the welding shall be maintained

a short arc, moving the electrode at a uniform speed and feeding the

electrode eastward or westward at a constant speed as it melts.

Start the joint weld with a pass of 2.6mm diameter electrode for the

first bead or root run and finish with one passes of 3mm diameter

electrode. After complete a passes of weld, the joint will let it cools on

its own and its will harden after few extra minutes due to its volume

and being in open at atmosphere, Chipping hammer and wire brush

will be use to remove slag and check the weld bead before making

another weld pass

siPage

METHOD STATEMENT

PILING WORKS

25

Butt welds between the end plates of the joints shall be tested using

magnetic particle or dye penetrant test method. Where such

examination reveals defects in the welds, the joints shall either be

rejected or repaired. f repeat tests show the weld to be stil defective,

the joint shall be rejected. The defective weld shall be removed,

replaced with a fresh weld and re-examined.

The welded joint will be coated with red oxide or black oxide paint

after Coloring Penetration Detection Test before resume of criving

Until meet the expected set criteria

The piles shall be checked for damage after driving is completed. The

driving record for all piles shall be compared with adjacent piles for

unusual record or vastly different penetrations. Piles suspected of

damage can be tested to confirm integrity and/or determine extend

and location of damage using the pile driving analyzer or low stain

integrity testing methods. Alternatively, the pile can be replaced or

repaired, if possible

After all piles are driven and installed, land surveyor or Resident

Engineer shall make field survey of completed piling work. Submit

drawing to Resident Engineer showing actual pile locations with

respect to planned pile locations.

COLORING PENETRATION DETECTION METHOD

This method use to discovers invisible flaws easily by making red

penetrant liquid penetrate into surface flaw areas of inspection object,

removing residual red penetrant liquid with cleaner and developing

red penetrant in flaw areas by using white developer and capillary

phenomenon

PRE TREATMENT

Remove completely the dirt ike dust, oil content, coating materials

and rust prevents penetration of red penetrant with cleaner before

inspection.

PENETRATION

Apply red penetrant evenly 20~30 cm away from target object to

make the surface covered with the penetrant and left it penetrate for

approximate 2 - 3 minutes. Application at the interval 3~6 minutes

ensures better effects.

CLEANING

After penetration treatment is done, remove red penetrant remained

on the inspection object using dry dust cloth, tissue paper, other

absorbents or water rinsing and clean the object with dust cloth or

tissue paper containing cleaner

Use white or near-white dust cloth or tissue paper to know cleaning

degree easily. Do not apply it directly to the surface of inspection

object

10\Page

METHOD STATEMENT

PILING WORKS

DEVELOPMENT

After cleaning red penetrant remained after penetration, apply white

developer evenly to make it cover whole surface. Immediately after

the white developer applied, it will show white colour

As iit dries, red penetrant in flaw area is absorbed and appeared,

making the position and shape of flaw marked sharply on the white

powder phase

INSPECTION

The areas not show any red after development means that they have

no flaws,

5.3.3 COMMON PILE INSTALLATION AND PROBLEM SOLUTIONS.

Problem

Possible Solutions

Piles encountering

refusal driving

resistance (biow count)

above minimum pile

penetration

requirement

Piles diving

significantly deeper

than estimated pile

penetration depths

Have wave equation analysis performed and check that pile has

sufficient drivabilty and that the driving system is matched to the

pile. If the pile and driving system are suitably matched, checked

driving system operation for compliance with manufacturer's

guidelines. If no obvious problems found, dynamic measurement

should be made to determine if the problem is driving system or

soil behavior related. Driving system problems could include

greater soil strength than anticipated, temporarily increased soil

resistance with later relaxation (requires restrike to check), large

soil quakes or high soil damping,

Soil resistance at the time of driving probably 1s lower than

anticipated or driving system performance is better than

anticipated. Have wave equation analysis performed to assess

ultimate pile capacity based on the blow count at the time of

driving. Perform restrike tests after an appropriate waiting period

to evaluate soil strength changes with time. Ifthe ultimate capacity

based on restrike blow count is still low, check drive system

performance and restrike capacity with dynamic measurements,

If drive system performance is as assumed and restrike capacity

Jow, the soil conditions are weaker than anticipated. Foundation

piles will probably need to be driven deeper than originally

estimated or additional piles will be required to support the load.

Contact the Resident Engineer for recommended change.

‘Abrupi change oF

decrease in driving

resistance (blow count)

for bearing piles

If borings do not indicate weathered profile above

bedrock/bearing layer then pile toe damage is likely. Have wave

equation analysis performed and evaluate pile toe stress. If

calculated toe stress is high and blow counts are low, a reduced

hammer energy (stroke) and higher blow count could be used to

achieve capacity with a lower toe stress. If calculated toe stress is

bbigh at high blow counts, @ different hammer or pile section may

be required. For piles that allow intemal inspection reflec light to

the pile toe and tape the length inside the pile for indications of

toe damage problem.

[Peg

METHOD STATEMENT

PILING WORKS _

Problem

Driving resistance (iow |

count) significantly

lower than expected

during driving

| Vertical (heave) or

lateral movement of

Previously installed

piles when driving new

piles

Possible Solutions

| Review soit borings. IF eoils boring do nol indicate S08 layers, pie |

may be damaged below grade. Have wave equation analysis

performed and investigation both tensile stresses along pile and

compressive stresses at toe. if calculated stresses are within

allowable limits investigate possibilty of obstruction / uneven toe

contact on hard layer or other reasons for pile toe damage. If pile

| was spliced, re-evaluate splice detail and field splicing procedures

for possible splice failure.

Pile movement likely due to soil displacement from adjacent pile

driving. Contact geotechnical engineer for recommended action,

Possible solutions include re-driving of installed piles, change in

sequence of pile installation, or predriling of pile locations to

reduce ground movements. Lateral pile movements could also

result from adjacent slope failure in applicable conditions.

Piles driving out oF

alignment tolerance

Pile driving out of

location tolerance

Piles may be moving out of alignment tolerance due to hammer

pile alignment control or due to soil conditions. If due to poor

hammer-pile alignment control, a pile gate, template or fixed lead

‘system may improve the ability to maintain alignment tolerance. |

Soll conditions such as near surface obstructions (see

subsequent section) or steeply sloping bedrock having minimal

overburden material (pile point detail is important) may prevent

tolerances from being met even with good alignment control. In

these cases, survey the as built condition and contact the

structural engineer for recommendation action,

| Piles may be moving out of location tolerance due to hammer ple

alignment control or due to soll conditions. if due to poor hammer-

pile alignment control, a pile gate, template or fixed lead system

may improve the ability to maintain location tolerance. Soil

conditions such as near surface obstruction (see subsequent

section) or steeply sloping bedrock having minimal overburden

‘material (pile point detail is important) may prevent tolerances

from being met even with good condition and contact the Resident

Engineer for recommended action,

Pile encountered

shallow obstruction

Piles encountering

obstructions at depth

abstruction are within am of working grade obstruction

excavation and removal is probably feasible. If obstruction are at

deeper depth, are below the water table, or the soil is

contaminated, excavation may not be feasible. Spudding or

predriling of pile locations may provide a solution with method

selection based on the type of obstruction and soil conditions

~ TF deep abstractions are encountered That prevent reaching the

desired/ pile penetration depth, contact the Resident Engineer for

remedial design. Ultimate capacity of piles hitting obstructions

should be reduced based upon pile damage potential and soil

‘matrix support characteristics. Additional foundation piles may be

necessary

12|Page

METHOD STATEMENT

PILING WORKS

Problem

‘Conerete piles develop

complete horizontal

cracks in easy driving

Possible Solutions

stresses along pile (extrema tables) for the observed blow counts.

If the calculated tension stresses are high, add cushioning or

reduce stroke. If calculated tension stresses are low, check

hammer performance andlor perform dynamic measurements,

Concrete piles develop

‘complete horizontal

cracks in hard driving

Concrete piles develop

partial horizontal cracks

in easy driving

Have wave equation analysis performed and check tensior

stresses along pile (extrema table). If the calculated tension

stresses are high, consider a hammer with a heavier ram. Ifthe

calculated tension stresses are low, perform dynamic

measurements and evaluate soll quakes which are probably

higher than anticipated,

Gheck hammer-pile alignment since bending may be causing the |

problem. If the alignment appears to be normal, tension and

bending combined may be too high. The possible solution is as

above with complete cracks.

jave wave equation analysis performed and check tension |

Concrete pile spalling

or siabbing near pile

head

Have wave equation analysis perfonmed. Determine the pile head

stress at the cbserved blow count and compare predicted stress.

If allowable material stress. If the calculated stress is high,

increase the pile cushioning. If the calculated stress is low,

investigate pile quality, hammer performance and hammer-pile

alignment.

5.4 STRIP PILE TO CUT-OFF LEVEL AND IDENTIFY PILE ECCENTRICITY AT CUT

OFF LEVEL

\When a pile has been driven to the required set or depth, the head of the pile shall be cut off

to the level specified or shown in the drawings by using diamond, The pile will be knock down

using excavator and remove the debris / cut off section from site,

5.8 PROVISION FOR PILE LOAD TESTING

5.5.4

DYNAMIC PILE TESTING

5.5.1.1 INTRODUCTION

Dynamic pile testing on Prestressed spun piles is normally performed

using the Pile Driving Analyser (PDA) to enable field estimation of the

static geotechnical carrying capacity of the pile installed. This method

of testing is served to obtain field data for computer signal matching

using commercially established computer software such as the

CAPWAP, TNOWAVE or FEIWEAP program to assess the

geotechnical capacity

13|Page

METHOD STATEMENT

PILING WORKS:

5.5.1.2 DYNAMIC PILE TESTING EQUIPMENT

‘The dynamic pile testing equipment mainly comprises a PDA which

is a powerful PC-based computer system such as the FPDS with data

acquisition electronics and a battery pack to enable the analysis of

dynamic pile testing. Two pairs of transducers attached below the pile

head area used to measure the dynamic forces and velocity wave

during a hammer strike on the pile head. These transducers are

connected to the PDA via a transducer cable. Field data is digitized

and stored in a random file in the computer hard disk. The random.

files are automatically generated with accordance to the hammer

blow number detected by the computer software. The digitized

dynamic forces or velocity or time information recorded are operated

on by CAPWAP, TNOWAVE or FEIWEAP software to @ number of

pile parameters. These parameters include the estimated static pile

resistance, driving resistance, maximum compression stress,

‘maximum tensile stress and energy transmitted past the transducers.

TEST PARAMETERS

Dynamic load testing will be conducted on prestressed spun piles with

the following preliminary control parameters:-

Pie Szeo WL Test Load Hammer Weight Drop Fight

(rm) (KN) (KN) (Ten) (m)

300 30 200%WL 5 06

Actual test load will be confirmed by the Supervisor Engineer.

Subject to the respond of the test pile after first blow and when

necessary, the hammer weight and drop height may be adjusted at

the site.

5.5.1.4 TEST PROCEDURES

© Dynamic pile test can be conducted on spun piles by means of a

heavy impact at the pile head. The impact is often provided by a

suitable drop weight and the response is measured in terms of

force and acceleration close to the pile head.

© Prior to testing, the immediate surroundings of file may require

some excavation to enable the installation of transducers

Approximately 3 to 4 numbers of approximate 6mm diameter

holes are drilled on two opposite sides of the pile to facilitate the

attachment of transducers below the pile head. Two pairs of force

transducers and accelerometers are bolted onto the pile using

plugs or anchor bolts. The transducers and accelerometers are

then connected to the PDA via a cable.

The pile head will be protected to resist the dynamic impact force

by means of stee! casing and normally is done while casting the

pile. As such test pile shall be pre-selected prior to the installation

of pile so as pile will be cast to the platform level to facilitate the

testing

14[Page

METHOD STATEMENT

PILING WORKS

5.51.5

5.5.1.6

© steel guide shaft or frame is then positioned onto the pile. The

guide shaft or frame is used to guide the drop weight.

Either timber or MS plate is placed on top of the pile head as

packing to protect the pile head from damage under the hammer

fall, This may also help to reduce some extent of vibration during

the course of testing

‘© Upon the preparation of pile head, installation and connection of

transducers and the setting-up of guide shaft or frame are ready;

the drop weight is then gradually lifted and positioned inside the

guide shaft or frame.

© Upon confirmation is obtained, the drop weight is dropped onto

the pile under a controlled height (different drop height can be

applied for various blow) as per estimation. The transducers and

accelerometers attached to the pile will instantly record the

magnitude of dynamic force and velocity, respectively. The data

will be processed by the PDA to give immediate visual and

permanent records on site

© Each drop monitored by the PDA will be displayed on the

computer or the built-in LCD screenvoscilloscope in the form of

force and velocity traces for immediate data quality control and

computation.

© Field PDA data will be transferred and stored inside the hard disk

or floppy disk for subsequent report and analysis.

© Upon completion of test, the transducers and accelerometers will

be dismantied. When necessary, a survey of the pile top level can

be taken before and after the testing to obtain the approximate

permanent set after testing

DATA ASSESSMENT AND CAPWAP, TNOWAVE OR FEIWEAP

ANALYSIS

A representative field PDA record of force and velocity from a

hammer blow delivered to the pile tested will be used as the input for

signal matching using the CAPWAP, TNOWAVE or FEIWEAP

‘computer software,

The analysis involves applying the measured pile top force or time

recorded to the mode! pile. The model consists of lumped mass,

spring, dampers and surrounding soil. The CAPWAP, TNOWAVE or

FEIWEAP software computers the resultant force and velocity / time

for the model pile and then compared with the actual measured force

and velocity / time during the test. The pile model and soil models are

then adjusted in an interactive manner until a good match is obtained.

The signal matching could be between the measured and computed

velocity or / and between the measured and computed displacement.

Once @ matched is achieved, good dynamic model of the pile / soil

system at the time of testing could be obtained,

PRESENTATION OF TEST RESULTS

After completion of the PDA, a fully report will be submitted which

contain the following information:-

a Best estimated static capacity of pile

b. Force and velocity versus time trace

1$|Page

METHOD STATEMENT

PILING WORKS

c. Modelled load ~ settlement curve

5.8.2 MAINTAINED LOAD TEST

5.5.24

55.2.2

55.23

5.5.24

INTRODUCTION

The testing procedure is to increase the load in stages until the

proposed working load is reached and then to unload to leave the

load off unti the rise or rebound substantially ceases,

‘The prestressed spun pile shall be tested in two (2) cycles. The first

cycle tests the pile to its working load one (1) times working load (30,

tonne) and the second cycle tests the pile to two (2) times its working

load (60 tonne). This test pile shall be installed in accordance with

good normal practice and without special care so as to simulate

conditions close to normal working pile.

MATERIAL,

Generally, the material required to use for this test as listed below:-

4d. Concrete supporverib

Mild stee! plate

Support beam

Secondary beam

Main beam

Concrete Kent ledge

EQUIPMENT

Generally, the equipment required to use for this work generally are

load measuring and applying devices as listed below:-

Hydraulic pressure jack

Load cell

Dial gauge

Dumpy level (Automatic level instrument)

All load measuring devices will be calibrated and send/lodge with

Resident Engineer before commencement.

METHOD

‘a The test pile head shall be prepared with casing to be above the

ground by a sufficient length or a minimum of 300mm.

b. Assemble the Kent ledge system as shown in the diagram which

had designed and satisfied the standard and requirement

c. The area of the crib shall be sufficient to avoid bearing failure or

excessive settiement of the ground. Mild steel plate is provided

under the concrete support) crib to prevent differential

settlements, bending or deflection of the equipment.

d The geometry of the arrangement shall be aim to minimize

interaction between the test pile as listed below--

© The supporvlerib shall not be less than two (2) meters or

three (3) times the width of the test pile; whichever is

larger, from the edge of the test pile

16|Pege

METHOD STATEMENT

PILING WORKS

+ The weight of the Kent ledge shall be of a higher

magnitude than the maximum test load or 1.2 times the

two (2) times the working load.

fe. The calibrated hydraulic pressure jack and load cell are placed

concentrated with the center of pile head

f. The main and secondary beams (universal columns) will be

stacked up and placed at its position and required spacing.

9. The stacking procedure shall be layer by layer to ensure the

stabilty of the concrete blocks.

h. An independent reference beam will be installed near the test pile

head to enable the establishment of four (4) no of dial gauges to

measure the pile head displacement, relative to an external

datum which on a firm ground and away from disturbance by the

use of automatic level instrument or dumpy level during the

progress of test,

i. Asscale ruler will be fixed on top of the pile head

j. Once the Kent ledge system establishment is completed and

inspected, the test load on the pile will be applied in equal

incrementidecrement up to the required test load at a constant

strain rate of 0.25mm per hours or duration as tabulated in the

table 1. Loading cycies for preliminaries piles.

k. For any period when the load is constant, time and settlement

shall be recorded immediately on reaching the load and prior to

the next step of load. At twenty-four (24) hours holding time, the

load shall be recorded at one (1) hour. Records shall be kept

promptly throughout the testing period. A copy shall be extended

to the Resident Engineer at the end of test

5.8.2.5 STANDARD FOR THE ACCEPTANCE OF TEST PILES

‘The performance of the test pile shall be deemed to have satisfied

the requirement of specification as:-

a When loaded to one (1) times the designed working load, the total

settlement of test pile head shall not more than 2.5mm,

b. When loaded to two (2) times the working load, the settlement of

the test pile head shall not exceed 10% of the pile diameterisize

or 38mm whichever lower.

©. After removal of the working load, the residual settlement shall

not exceed diameter /120 + 4 or 12.5mm whichever lower

7)Page

METHOD STATEMENT

PILING WORKS.

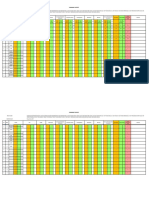

Table 1: Loading Cycles for Preliminaries Pile

Cycle Load Percentage of Working Load Time of Holding Load (minutes)

o 10

40 10

20 70

30 10

40 10

50 10

a 10

First 70 10

80 10

80 10

100 ‘60 min or settlement rate Tess than

(0.25mnvhr (whichever is longer)

75 10

50 - 70

25 10

0 30

25 40

50 10

8 __10

100 10

110 10

120 40

130 10

[ 140 40

150 10

Second 160 10

170 40

180 10

190 10

200 60 min or longer as instructed by SE

150 10

400 | 10

50 10

0 10

1a|Page

(add) quauudinbg aanzaroid jauUosed

youu} aalrens

(s)

(

wore IOs}

uormnsqns

uoreuiwin)3

()

ALRIBA3S:

SBUNSV3W TOULNOD 40 AHDUVYSIH

pauina20 Janau sey pue

ayqyssoduyy Ayjeara2euC 5} Sayqeala>u0zU

funfuy | z sieak Kuru saye | 7

3 quauewiiad you yng Sungesig {s0UW 4n990 01 UMOLY} U32q JOU Se} !SIOW>y

3

= Auigesip | ¢ amnuawn | ¢ |

a quauewiad ‘Aunfuy 1e32j-u0N ‘snouias ‘@Wos 32 1N>30 aq IYBIW ‘a}qRAIa2U0> |

+r yensn oust pue | >

Suyuna20 jo aouey> Pook v sel {2)q18504

Ayanonpod a

pue aBewep Auadoid ajquianozaii | paziyeas Suiaq quand /puezey ay ¢

saree) snosewnN S>1ydonnseye> Jo )nsau Ajay) sow! ayy ‘AAI! ISOW

XRLLYW ST ‘ALIIBAaS SNLLYA GOoHITayN ‘ONLLWa

WoRa}di0 Jo ayep Suipnjauj WO) JUAUISSASSe S| ay} UO payuaUIND0p

‘2q ysnw uayer suoNoy “Jo.quo> Jo Ay>iesa1Y aug UL paylexap se PeZeY ay} JO.2U09 07 UONDe ayeIpSWiUl! s9zINbAY YSLI HOI V (H) HOH

“GoRa|duOD jo ayep SUIPN|DUL WO} JUALISSASSE S11 a) UO PAIUDUINDOP aq IsNU!

aye} suon ay “pasinbas j1 saunseawi Asesodway satjdde pue pezey ay) }0.qU02 0} Yeoudde pauueld e sayinbau ys woiGaW Vv | _ (Ww) WnIdaW |

- “papaoda1 pur paquaule}dusl aq pynoys sainseaus jo.nuo> “Anuaryje pue Apy>1 7

ued SLi aun 41 UaASMO} “AiessaDau JOU aq Kew! UOLINPD4 JaYLINy PUL aygeida2a" se parapisuo> aq Aw MOT SE ) MOT

Dv NOLdtw9S30 |

= ‘ONILVE ASI |

(QUVUIH) TOMLNOD SIH GNV LNAWSSASSY ¥SIY ‘NOLLVDISLINSG! GYVZVH

] _

| vais sauem anes | |

| Suipeojun ayy yap

audso| | | or adoa pins Buss

uauianous yo11U09 adoa |

‘pind pue ueureUsis | parsadsuy 2 poyruas

‘Suns up - papiaosd

Suyaua xoqieo, | | 29 03 Buys auya aigeuns

wayen

wowidinby aanoaraig wos} uisop Bun;

woumsogaun | w | a |» | ¢ Suunp so nde at | wou soydurs yo tape |

ie Suen omens anpsrod

| | poop 36 aa

swounxomo, | | ;

| vont arynapas senynse | __aysor suede

susuteba orig astra semana supsounSuinp ued | nn scans ante

L _ yowuosiag wla|y |¢ | aepacwogans ans ue auiyoeus Ao ah ‘Sndomnenty jovoremaey | 1

asia sainseay 2/3) 2 oe spay yosney vero sandy yo

wiuosieg | taAuey papuauuesey 2\<|8 nwo) ysiy Bunspey | ue) You pez Ta

He MaTADy - 107 40quiaD80 OF aid

(esenBuag lemeSuag [Dem

| fq maunay yeldd JH APY efsay UeVeer YeseBUSg fq panouddy

Ziz 25qw3500 OF | area | BUS TEIN / 410M BUNlid | —_UOIIEDO] /589901¢

| (4221440 ynneaH pue Ayes)

| - they efay uereqer |

spipauag smu q paxanpuos |

ug UPS ASoj|OUYI> | je}eq |

‘SDRIOM ONMTId

aigesip

say unds jo Buy,

we spond poe yD

Aan sof wasn 0S ie ET

unos wo Supp Bad fans

esa wand Bun 0) 4094S

uaudinds

3 Avauyypew sun

Surscue BALNEA LONER

srs FE

Auras

ooyntary F>

spss xueW

Ayany wom,

Pownaw 20M ayes

pe Suan 00 po (28.09 hayes)

woud annoy

wouidnba annoroig aus gene

mosmsmealaty [2 | 2 | pepe Anu sro 95399 sxiptmy | 9

pOURaW >HOM a}eS

ppue Suyaug x09 yoo) |

aoutdnbg axroenig Sug sodod sania 10

ereneried i 2 | puevonsoie aro om | uns vag | Supisnuny yds soriname pipe |

Po sanseoy 2/3|2 (i poy sme) ca say 0

uruosiog | 124U09 popuowuorsy 2 B | joauoy ys Busey | ue youn puezey annoy 410m CN

301 GUVZVH

389} 40 uoreulurexs ‘Uo!>adsUI Jo s1]N531 MaLAaY

MOU

“paraidwos axe uorpe pays2ads jun proy pue nd pue paddors aq ysnw AyAnre

Ue Jo aauewuopod aya yaiym 12 “(s)ued yay pue uoRIadsu ax uL juWODLBe payers JoLsd Aq pareUBIsap “yuIOd e sUESUI (1) 2UIOd PJOH

POH oH

‘au paunbas ayn ve ayqeyene

you 5} Aowane queArdyas ain 4} paasoud Kewl OM “aAaMoH “AUOIANY UOAZ2dsuL qUEAZ}21 aYp Jo ssOUIM JOPUN pOULOJJad aq TeYS PuE

quounsedag uol2n.nsuo9 s,1033e:U09 ay) Aq 2oUeAPe UI PalsNOU ag j]eys aBers siya 1593 10 “UoHIEUUIeEXE “oRIadSUL Jo SulOy{ ALOYEPUEW SY

som

“pamyins

Bujaq aue squawa,jnbay payloads yey asnsua 03 siseq yea1poliad e uO spu0Ia4 Jo Sasfjeue PUB s|eLIDIBW PU HOM Jo smIeIs ayy JOUUOW

aoueenns

“spuepueas pue sapo> pareyau pue uorreoisioads ‘sSuimeup ‘syuawasinbas 138/40)

‘4p 04 a2ueWi9suo0 aunsse 0 1593 puk ol Dadsuy Kressa0au uLO}iad 0} quaUTuEdad Aaljen s,10198!1U0 Jo fajtiglsuodsay Asewtid 24 5% 21

:sure3] uonsedsuy 1

*(ai) ueyd 3894 pue vonoadsuy ayy UNAM AYANDE UONDOdSUL Y>DeE 40) UONAdsUI Jo U—TxE axA AJLIUSPI 02 Pash 9g j}eYs SaLIOBaIED uONadsU) SuIMOT}O} BULL

sauoBaye) vol zedsul

‘SORIOM ONMid NVId 1531 GNV NOILD3dSNI

sumnesa was sunpoyy | voneaypeds /auynesa

swmera dous zudéns |__| a | 1 | worsnnsuy exciday | Aawazy aioyoe | _wownsog | voronsimo9 paroidey enoidde 5 uBisop ay6 Aon | 9°

bry wis

Buppo1p) 19688 58 /98rrsa

aveouruan wn soncins | | mM | t | voneryeessed sy | Kuanyog ued | auoumea | uesesio uoneayieds joars Sussansoug | g't

suweia Suppayy | uogeayrrads (Boyne

aypsoy aang asa sonddns | om |. wonsansuozed sy | Auamjeq uody | _swownoq | uonpnnsioy pavosddy | (aug) yeuerwW yo yifuans 2x2:2009 |p

(urewpovsd eye 998 4A 0 2984 Kay

exSyiad) nfl 744 EH

‘Buena aLU0y you ‘wup > 9q 04 pious | wopuny wone>y ads / Sumesa

eboxueeswouns seo | a | a | 1 | wuowsuoupvomesssa | Awmeaucdn | wawanseay | uosonsisvey yenoiddy aug jo vosuoung |e

{weyd woneoude)

{in pow ueesspowed ess Sumeig

ue UesTmay 820g | 1 | uonesyiads iad sy | Aawnay i0jo98 uoganssuey paroxdéy | aug uanug soy euorew jo vone>yuen | 2°v

Tuawawes poxyoul

uouores Panay, suns 0 anid enoxdde

sosruerienry jirortdy | y |v |» fuwmy siog | puemawnsy | _voneayids og dy 20) wows: pownouAuen | 4p

sp2i9 Aaanoy aid | orb

za_[mo> | ¥99

uaunseg Burke euaMiy anu janbou, powron squpunoeg 220019 paypoun

woumond BUNA uous ouexdasy | fouanboug uopsadsuy | ¥BMDEA 22U219}2x | oq oy apsuszzeeND pue AiAioy | ONS

proooy aig wang

dep 195

Aveima| DIVO

99 pros

ebay ueesquousysueog | y | y | y ana Aion uausinseoy ssoveld and uanua Suuowow | 2

‘ansns aa 3109 9

(ueeunsouad yexBuned)

oy

anu ata sumesa

s 1 souy /aiojog | ywewarrseay | _uousnnsu0) paroicdy vontsog suone2oy ana jo Kouns | 2:7

310}>q

Tweuoyouog suesog | | i ep tu yon ahd vanua yo uone>ynon |

spay Aumnay aid |_ 0°

3a_[ moo | 9

wounsog BuKjH9A, ‘eueuun souerdeozy | fouonbas | pouew uormedsul | suaunsog souevejey | PRPeYD eq cI 2nSHEIDEIeYD PUR KAY | ON/S

siujog wonaedsuy

uoday LLIW) 3594 peo] quawasnbay ] woneayi2ads

pout sey ee) bens at an

Saiioumy susie |v |v | 1 | umeaadtty | meroyéing | amdoy ses nanoy | nition say ann pooswes | oe

rons

vee noe 504

(oes go

vey

Can pr igo reriatiog | ape rtontn

webuuescusiees | y |v | 1 | SAC | ago, sog | laisystmoia | vrtnsly fuy | au Buon.) eusun sew ¥oL id |_ yt

sem emnen | wnoyoas

es taney | utlsnopey | sesy Anta

suovemun | | | 1 | pomp meer | Same | SURI | iS tty i

sora

ag ws stay on

pesmi |v |v | swche Seg vail py ue

— vos

owen pani ves | sowsayeyeatve | sony hae

pommoymeay | y | a | sovcoe ova | “pur away” | visto pasdoy oom me, pwonruion | ve

_ tym | ot

my [noo] >

ouroea san sisunsuniony | ounbers | sommnuorndsy | suoureg mein | popapaderoaueemn peavey | ows

sujog voppedsuy

BORANG 9- SSM

AATA SYARIKAT 1985 [sete 0

No Syartat

noes |

PERAKUAN PEMERBADANAN SYARIKAT SENDIRIAN

eh iperbadantse i bavah Akta Syarbat 1966, pads dan mula) dr

bur di bawsh tandatnger dar mites} sara

|NOR‘ANI BIN( IBRAHIM

‘HOQONG PENDAFTAR SYARIKAT

KLLPILING & JACK IN SDN. BHD (820165.7) | COMPANY PROFLE

CIDB REGISTRATION CERTIFICATE

CIDB) manera»

PERAKUAN PENDAFTARAN

RLLPLING £JACK.N SON. BHO.

USAT PERNIAGAAN RASA UDA

‘zane BUTTERWORTH

STATUS: ARTA Kona ang cern proj somese

akan pencaoen i Bela’.

LL PILING & JACK IN SDN. BHO (810165-T) | COMPANY PROFILE

TECHINICAL ORGANIZATION

DIRECTOR HING BOK KIM.

YAP SIEAW LING.

ACCOUNT EXECUTIVE ‘YEW POH HOON

GENERAL MANAGER : HOW CHI WEI

MANAGER : CHAI CHUAN YEAW

PROJECT EXECUTIVE : LEE WEILOON

QUANTITY SURVEYOR NURUL HANNANY BINTI AHMAD SHUKRY

ASSIST. QUANTITY SURVEYOR NORASHIKIN BINT! ABDUL HAMID

Sr. PROJECT COORDINATOR LENG KAM SENG

MUHAMAD RUDZI BIN ABDUL RASID

SITE SUPERVISOR MOHD ARIF HASHIM BAKHTIAR

WORKERS MUHAMMAD NAZRI

ROZALI BIN ABDUL RASID

NAZAR BIN BAKAR

LIEW PAK CHEW

KUL PILING & JACK IN SDN, BHD (810165-T) | COMPANY PROFLE

COMPANY PERSONNEL

T - Working |

Academic |

No Name | Experience |

Qualification Tere) |

|

1_| Hing Bok Kim - E 36

[2 [Yap Sieaw Ling - | 48 |

{3 [Yew Poh Hoon ‘STPM [30

| Bsc. (Hons) Civil

| 4 | How chi we | General Manager | Ergineonng UTM | 12

| T Bsc. (Hons) Civil

5 | Chai Chuan Yeaw Engineer Engineering, 1"

| | |

, ive | Construction

6 | Lee Wei Loon | Project Executive | Gfoutton College, 6

| UK) '

. Bsc. (Hons),

7 | Nural Hanneny Bint Ahmad | Quanity Surveyor | Quantity 6

ukry | Surveyor, UITM_ |

| Diploma in

|

8 | Norashikin Binti Abdul Hamid | Asst as Sea eet ton 2 |

| | (uiTM)

9 | Leng Karn Seng Senior Project | STPM 25

| Coordinator | | |

10 | Muhamad Rudzi Bin Abdul Senior Machine | SPM 56

| Rasid | Coordinator po |

11_| Mohd Arif Hashim Bakhtiar | Site Supervisor__| SPM a

12 | Rozali Bin Abdul Rasid Operator |SPM co

13 | Muhd Nazri | Operator 2 {se )

14 | Liew Pak Chew Oper - 30

{ — 4 {

45 Nazar Bin Bakar Mechanic "SPM 5

KUL PILING &JACK IN SDN. BHO (810165-T) | COMPANY PROFLE

COMPANY PROFILE

nat

“yOuP piling Solution

KLL PILING & JACK IN SDN. BHD. «isn

147A, JALAN RAJA UDA

12300 BUTTERWORTH, PULAU PINANG

TEL: 04-3244 111

FAX: 04-3244 666

EMAIL: kiI3638@gmail.com

Website: www.kilpiling.com

Company Registered With Construction Industry Board Malaysia (CIDB)

PREFACE

INTRODUCTION

KLL sa well-known piling company in the northern region of Malaysia, with over 25 years of experience

in piling work. We pride ourselves on the quality and value of the services and we offer whilst striving to

meet and exceed all of our customer's expectations. This achievement is reflected in the amount of repeat

business we win and the number of projects we undertake for clients to whom we have been

recommended.

As part of our company development, we have invented in the one and only first bored-jack machine in

the country to enhance our professional services to the forever growing demand of construction

technology.

We are always very keen as pling contractors to be involved at an early stage to offer advice on cost, the

best techniques and possible value engineering solutions.

MISSION

We aim to incorporate our professionalism, experience, expertise, uncompromised quality and safety

standards in our mission for success and our customer satisfaction.

THANKYOU,

HING BOK KIM

DIRECTOR

KLLPILING & JACK IN SDN. BHD (810365-T] | COMPANY PROFLE

REGISTERED NAME OF COMPANY

REGISTERED ADORESS.

‘CORRESPONDENCE ADDRESS

COMPANY STRUCTURE

‘COMPANY REGISTRATION NUMBER

DATE INCORPORATION

piRecroRs

‘AUTHORISED CAPITAL / PAID UP CAPITAL

CIDB REGISTRATION NUMBER/GRADE

TELEPHONE NUMBER,

FAX NUMBER

EMAIL

BANKERS

BRANCH

BRANCH

COMPANY SECRETARY

‘AUDITORS

TAX AGENT

COMPANY INFORMATION

KLL PILING & JACK IN SDN. BHD.

NO. 584, JALAN CANTONMENT,

110250 PULAU PINANG.

NO. 147A, JALAN RAJA UDA,

PUSAT PERNIAGAAN RAJA UDA,

12300 BUTTERWORTH,

PULAU PINANG

PRIVATE LIMITED

810165-T

17 MARCH 2008

HING BOK KIM

YAP SIEAW LING

RM 1,000,000.00 / RM 750,000.00

(0120091201-PP126918 / G7

04-3244 111

04-3246 666

K1I3638@gmail.com

UOB BANK BERHAD, BUTTERWORTH

A/C NUMBER: 147-302-016-0

RHB BANK SERHAD, JALAN RAJA UDA

‘A/C NUMBER: 2071200044492

J, HENG CORPORATE ADVISORS SDN. BHD.

4S. $00 & CO

J, HENG TAX PLANNERS SDN, BHD.

LLPILING & JACK IN SDN. BHO (810165-7} | COMPANY PROFLE

NATURE OF WORKS & SERVICES OFFERED

KLL PILING & JACK IN SDN. BHD. provides a wide range of general construction solution. Our services

are as follows:

‘A. PILING SYSTEM (Main Service Range)

1. Hydraulic Hammer Piling Works

ii, Hydraulic Injection Piling Works

ii, Bored piling works

iv. Micro piling works

vy. Hand-dug caisson piles

EARTHWORK & SITE CLEARING WORKS

SUBSTRUCTURE CONSTRUCTION WORKS

i. Pile cap works

il. Sub-structural works & basement

KLL PILING & JACKIN SON. BHD (810165-T] | COMPANY PROFLE

BORED-JACK SERVICES

Svcs Ranger 86 ton Bored

LL PILING & JACK IN SDN. BHO (810165-T] | COMPANY PROFLE

HYDRAULIC HAMMER

Services Rangos- ton, 3 ton, 7ton,

ton machine

KLLPILING & JACK.IN SON. BHO (810265-T) | COMPANY PROFLE

INJECTION JACK-IN

Services Ranges: 30Ton, 80 on, 120 ton, 280 tn, 320 ton,

LL PILING & JACK IN SDN. BHO (810265-7) | COMPANY PROFLE

MARINE PILING

Services Ranges-3 ton, 7 ton, ton machine.

OTHERS FOUNDATION MANAGEMENT WORK

We provide foundation management work in - micro pile,

‘bored pile, structural foundation work

KLLPILING & JACK IN SDN. BHD (810165-7) | COMPANY PROFLE

PILE TESTING WORK

‘Services Ranges: PDA(Pile Driving Analyzer, PIT(Ple Integrity Tes),

‘MLT(Malniain Load Teed.

ULPILING & JACK IN SDN. BHD (810165-1) | COMPANY PROFLE

KLL PILING & JACK IN SDN BHD gerotes-r)

ORGANIZATION CHART

t

GENERAL MANAGER

MANAGER

YEAW.

+

KUL PILING & JACK IN SDN. BHD (810165-T) | COMPANY PROFILE

KEY PERSONNEL

CURRICULUM VITAE

FULL NAME : HING BOK KIM

POSITION DIRECTOR

EMPLOYMENT HISTORY / EXPERIENCE:

YEAR : 2008 - PRESENT

COMPANY NAME : —— KLL PILING & JACK IN SDN. BHD.

POSITION : DIRECTOR

YEAR 1989 - 2007

COMPANY NAME FONG HEE HOCK

UL PILING & JACK IN SON, BHD (B10165-7) | COMPAWY PROFLE

KEY PERSONNEL

CURRICULUM VITAE

FULL NAME YAP SIEAW LING

POSITION DIRECTOR

EMPLOYMENT HISTORY / EXPERIENCE:

YEAR 1 2015

COMPANY NAME : KL PILING & JACK IN SDN. BHD.

POSITION : DIRECTOR

LL PILING & JACK:IN SON. BHO (810165-7) | COMPANY PROFILE

FULL NAME

POSITION

QUALIFICATION

KEY PERSONNEL

CURRICULUM VITAE

HOW CHI WE!

GENERAL MANAGER

Bachelor of Engineering (Hons. ) Civil, UTM with second class

honours (upper division)

Graduate member of The Institution of Engineers, Malaysia

(eM)

Registered as civil engineer with Board of Engineer, Malaysia

(BEM)

EMPLOYMENT HISTORY / EXPERIENCE:

YEAR

COMPANY NAME,

YEAR

COMPANY NAME

POSITION

YEAR

COMPANY NAME

POSITION

YEAR

COMPANY NAME,

POSITION

April 2017 - CURRENT

KLL PILING & JACK IN SDN. BHD.

May 2016 ~ March 2017

MAGJAYA RESOURCES (M) SDN. BHD.

CONSTRUCTION MANAGER

June 2004 — April 2015

RIMBACO SDN. BHD.

SITE MANAGER

September 2002 ~ May 2004

ZIBINA JAYA SDN. BHD.

SITE ENGINEER

KUL PILING & JACK IN SDN. BHO (810265-T) | COMPANY PROFILE

YEAR

COMPANY NAME

POSITION

YEAR

COMPANY NAME

POSITION

June 2000 — August 2002

REALM CONSTRUCTION

SITE ENGINEER

April 1999 June 1999

SENG SENG CONSTRUCTION SDN. BHD.

TRAINEE ENGINEER

KUL PILING & JACK. SDN. BHD (810165-T) | COMPANY PROFILE

KEY PERSONNEL,

CURRICULUM VITAE

FULL NAME YEW POH HOON

POSITION ACCOUNT OFFICER

QUALIFICATION STPM

EMPLOYMENT HISTORY / EXPERIENCE:

YEAR : 2008-PRESENT

COMPANY NAME: KLL PILING & JACK IN SDN. BHD.

YEAR : 1985-2007

COMPANY NAME FONG HEE HOCK

POSITION ACCOUNT OFFICER

KLLPILING & JACK IN SDN, BHO (810165-T) | COMPANY PROFILE

KEY PERSONNEL

CURRICULUM VITAE

FULL NAME : CHAI CHUAN YEAW

POSITION 7 Engineer

QUALIFICATION: Bachelor of Engineering (Hons.) Civil, Uniten

EMPLOYMENT HISTORY / EXPERIENCE:

YEAR 1 February 2017 - CURRENT

COMPANY NAME : KL PILING & JACK IN SDN. BHD.

YEAR June 2014 - Dec 2016

COMPANY NAME BM City Realty & Construction Sdn. Bhd

POSITION : Senior Project Engineer

YEAR July 2013 - June 2014

COMPANY NAME Lumbini Consultancy

POSITION : Civil Engineer

YEAR : dune 2010 - July 2013

COMPANY NAME Lumbini Consultancy

POSITION Project Engineer

YEAR June 2007 - June 2010

COMPANY NAME Jurucita Consultant

POSITION Civil Engineer

YEAR Feb 2006 - June 2007

COMPANY NAME JNK Consultant Sdn Bhd

POSITION Civil Engineer

LL PILING & JACK IN SON, BHO (810165-T) | COMPANY PROFLE

KEY PERSONNEL

CURRICULUM VITAE

FULL NAME LEE WEI LOON

POSITION PROJECT EXECUTIVE

QUALIFICATION; DIPLOMA IN CONSTRUCTION (MOULTON COLLEGE, UK)

EMPLOYMENT HISTORY / EXPERIENCE:

YEAR 2014 - CURRENT

COMPANY NAME KLL PILING & JACK IN SDN. BHD.

YEAR 2009 - 2014

COMPANY NAME RNC

POSITION : PROJECT COORDINATOR

LL PILING & JACK IN SDN, BHO (810165-T) | COMPANY PROFLE

FULL NAME

QUALIFICATION

KEY PERSONNEL

CURRICULUM VITAE

NURUL HANNANY BINTI AHMAD SHUKRY

BSc. (Hons) QUANTITY SURVEYOR, UiTM

EMPLOYMENT HISTORY / EXPERIENCE:

YEAR

COMPANY NAME,

POSITION

YEAR

COMPANY NAME

POSITION

YEAR

COMPANY NAME

POSITION

SEPTEMBER 2015 - CURRENT

KLL PILING & JACK IN SDN. BHD.

QUANTITY SURVEYOR

JUNE 2015 - AUGUST 2016

KNEWLAND CONSTRUCTION SDN. BHD.

CONTRACT OFFICER

APRIL 2012 ~ JUNE 2015

JUBM SDN. BHD.

PROJECT EXECUTIVE

KUL PILING & JACK IN SON. BHO (810165-T) | COMPANY PROFLE

A. PILING MACHINE

10.

11,

12.

13.

14

15.

16.

Equipment/Machine

Nissan D 207 LC

Nissan D 208 LC

Nissan D 308 SA

Hitachi KH 400

Hitachi Excavator EX300LC-1 clw 8Tonne IPH 750

Hydraulic Hammer

Hitachi Excavator EX300H-3 c/w 7.5Tonne IPH 750

Hydraulic Hammer

Hitachi Excavator UHO7-7 clw 3Tonne IPH 250

Hydraulic Hammer

P&H320

P&H 100

Jack in machine - ZY 80

Jack in machine - ZY 120

Jack in machine - ZYJ 250

Jack in machine ~ ZYJ 320

Jack in machine - ZY 420

Jack in machine - ZYJ 600

Jack in machine - ZY 800 K

UL PILING & JACK IN SDN. BHO (810165-1) | COMPANY PROFILE

PLANT & MACHINERIES

Qty/unit

waae

RR NNBRNNNK

B. HAMMER MACHINE

No.

Equipment/Machine

Junnttan Hammer

2. Junnttan Hammer

3, Junttan Hammer

4, Twinwood Hammer

5, BSP Hammer

6 BSP Hammer

7, BSP Hammer

8. Hydraquip Hammer HO 9

9. Hydraquip Hammer HO 7

10. Hydraquip Hammer HO 3.5

11. Hydraquip Hammer HO 2.5

12. IPH Hammer

13. Kobe Hammer K 13

14. Kobe Hammer K 22

15. Kobe Hammer K 25

16. Kobe Hammer K 32

17. Kobe Hammer K 35

18. Mitsubishi Hammer M 43

19. “A" Frame ciw 4 ton hammer

G. HYDRAULIC CRANE

1. P&HCrane

2 P&HCrane

3. Tomado 7250

4, P&HCrane

5. P&HCrane

D. WELDING MACHINE SET

Capacity

7 ton

8 ton

42ton

10 ton

T ton

9 ton

11 ton

ton

Tton

3.5 ton

25 ton

3ton

16 ton

20 ton

25 ton

25ton

36 ton

PLANT 6 MACHINERIES

atyrunit

ano -

Bevyreeoeorxeone

30

KUL PILING & JACK IN SON, BHD (810265-

| company prove

THOM ANsHuCD | (-S9TOTS] GHE NOS NI NDVI ONNMATOL

‘SaIEDOSSY B UEMY) UuNyy BUSS

‘BUBUIE TEIN “PION WeTEHBUaG

oszee’ory 'P ug ‘wmoye6u099 sepueg ‘ez 19S OZP B LLP

|__soyeyewen ueppoH PeWUN, 307 Se1eIp yeYBULL p eqeleqepsy yorg | UBDUEPED |

“pug ‘Ups ABaIERS

Aouewnsuog wiqun 2peUIpUE] SIN 40} y20u9, Ye9q BuBIOGaS “nIeR UBIer

| “L WIN “(Pb 10] PIO) 9969 ¥ 99b ‘BSL ‘ISL ‘GGL 107

osule'ory | pug “ups Jo Wed uo awayag Buisno} (yun Ose - V OIg) |

uorannsuog deopue7 puejs} IiOpuod AesoIs % 12 pasodoud 0} SoM Bulli

| “PE UPS WA Burpurueg pug ]

00 ¥62'er6 | “ups eye Suequiy 40) Bueuig neing ‘UeWIeg 18d | 9 |

Ug UPS Uononasucy UeWU) eUeH | BuEJeGes 6 WMI ‘ZE/ 107 18 Wauidojanep pasodord |_|

“pus UPS 18 1 BeININE ‘Bueuig neIng “Oz nKeg

e6:20z'LL2 reusg “1 ‘Bueulg Buniuey sepueg "y uoIes ‘zg6pL

40u9 Buag 5uQ (G) ‘S'H ‘ON “801 Id 107 vo moje6unq pesodolg

T exein

PUG UPS WA Bulpunied | e1eq Bueseqag “ypomseyng sepueg 'z Ueksyeg ‘eked

so's/z'66e, Sundwey ueler "296 8 796 107-107 Sere Ip (JUN gg)

Ug UPS UoHonasuoD EIU) EVE | eUeYIapas Soy yeNBuN ZL UNdesGued YoIg | UebUEPED

Bein (eied BUBIEGES “TvoNvenng

yueynsuog eyonune Jepueg "| UBksx9§ ‘£001 107 Uo (anIsnoU! |

eerez'esz | 01 Pus 01 Lo pup) £9 ¥90I8 — yUOUILEd

_bUa “UPS unpreg uenfewioy ‘a10)8-h JO ¥O019 aU0 JO} S3:0m

| Saieroossy @ ueM win, BuoKD BueUig neing "US6EN piseW LoIer “La.

“Buoinjar sepueg ‘¢ ‘Yes ‘S001 107 ueIBeYEqas seIep

00°000's61 pebiy puy | epetpes ey6un g Acuuop 019 UeBuep Bunquesieq

Wwiyu BY 404 WOH BueUeg su UEP yeyBun y Kiouuwop Yorq | UeYeqe UeBUEpeD |

Bubuig nein “LLG “wno\961005 sepueg |

| SerRpossy BEM wn BoD | '¢ yes 699L UEP E6EL oT SeIe IP (ese) epeIpES ||

| yeu f yeIoyes yoIq UeBuep UebuNquIesieg 1exBUn

oo'ras'ele | ueanjuog emi BUNUW' W'S: ¥ YBIOYOS URYEPNWAY YoIg | UEMUIPUEYY, |

yevelly Bueboweg-BueSowed | epepes iexBul uuey epedoy werpu |

0M ANaWNOD | (-S8tOTS) GHB NUS NIXD¥E® 9

"Te oseUid) UBL eG Yepay “UIny yeIIEG

oo z9'619 PUB “UPS IHOWHEH YEIID "SUN WPAN ‘p18 407 SeIe Ip ueYeUITIEd weBuneD eb

ppoKg

oo'sso'eo8't SeoIAlog jeU99) Aza [axed ‘YeIOg ‘Buldie yeudsoy| zp

‘pug ‘ups eulg VS eynwes ueunBuequied uep Jexerweuow uebuepeD

“uenZpre UEC HEI UENO | |

Yyereed ‘JeuNg Wed WHAM ‘2192 107 SeIeIp YeXBUR

ooezv'ost pu | yengeses yewns yun ¢ uep yeyBun | sequeyiog | Lb

upg Buyeauibug Kaen 2143 Yew yun 96 Yeyeursed UeunBuequied ueBuEpeD

ug UPS 09 sieqNOIG UND

"Pua "Ung SaieooSsY SUS’ @US | 40) BueUIg neIng ‘sene3 UeIEr “LLC ‘BuOx0,. BunfueL

oorzzz'ezt Jepueg ‘| uomeg ‘gr0z UE SPOZ '6SEL '89EL | OL

“PUG ‘UPS (WW) Jo1ENUOD HAS 307 uo eouyo 9 jo\doys Aaioys ¢ Jo SYN || pesodoig | |

Bueug nen ‘Buo%0, Gunluey deter “ine

“pua “Ups WWA Bulpunieg shui yei9eq ‘Buoy Bunlues sepueg 'zuoksyag |

oo'sss'szz | “ELG UEP ZGGL 'LSSI ‘OSSL IO SeIe ID ieYoUNE «6G

“pug “ups Ayeoy jewweuo | wz (wun 1€) fee» yoo € UeNUIpUAW yun UEEUSDED

INOS) TSHOWS OFFTAWOD OTOL

{7IUOMA ANWaOD | (I-S5TOTS) GHB NOS NI DV" 8 ONIE TO

i T Bueuig neing Weg soveHS Bue }

| “yebue 12104 Sueseqas ‘yebue, Yereeq i

oowee'oue Yvonannsuog ssenong wequess — | yeu ang UeLIENpULed UeIer (8) GE O14 SeIE ID YeNOUN |

| _ziwaeiod we extu | Buepy veges eyo ueBuEDeD

ui

n'y W304 ‘sedo7 uekeg uewsMpUUed ||

osto'sar Lvoronsueg seasons exes "g Buenjoye6ung 1H 'SOF O14 Sele 9

I 1ey6un » weaelad/Bueyy yengas ueyuIpuaW yun vebUEDED ||

I j Bueuig nee

svseus6u3 Buynsuog cou Aw 61099 *sojsueL] UEIeT “ILC PL Y9S pre LEP SPB

00°000'920'2 s

pa upg uononuisuen iBuejag Bunn

ug ups sweynsuog di) | 2 "UOneIS ang EN, YedUes Odep ‘esnoy pend

| ‘yued Jeo fauois $40 00 | >

$6620'9S0'2 | PUG UPS juowdojereg eyseueTUY ‘SU0 ‘sjuaWyEde Aa10}8 Z1/E1 JO YO0Iq oUO pasodosd 40)

* I ‘Siom Bund jo e2ueuajuleW pue uoRejdwsod ‘voyans3suo}

"BUBUSY “UVONUGIINg Jepueg “p USKSIES

“puarups sueyrsve9 ato “ye66uag 6undwey uejer "gz 107 Uo Yeduies odep pue

oe voe'z6v'2 | ‘asnoy pien6 ‘uauede Kasois @ JO ¥90%9 avo pasodaid 0} |

_ PUB UPS weurdojenaq UEWEIOpUAD |

| “pug “UPS WA Surpuniog ewe 2 yepul Bunlue] 640107 ‘>t wHINW SB9E:

| | Ip weyeeKseus ueyenney ees e110} ¥EI9| edu z

oorvac'ize | pug ups seuiedoig wwomeg — | (q) Uep wun yp1 Undesbued yexBuL! 6 (e) epedueD UIpse)

| Sued un EL undestued yolg | UeyUIpueW UebLEDED |

| ~Bueuig | |

NejNg “YOIQWED YING UEP YeUUed UEIEP TLC “EL “MW SBSZ

unBeyeqes uep ggz ueiBeyedes 'JaS/ ‘999/107 Sele

“PYa “UPS Vv» Bulpuruag 1 Yemeg yeySul) 1p 1epex yuN yz UEP (dy 089) OWTIUN |b

082 “BlJoy yeI07 WedWo, yeyGu!) p UEP IEYBUL, 1Z EVO

oores'ea'z Pug "UPS e1eMON, 7 s6unpueBuaw Buek yepuey eveyiepag soy esbuEd

yetumy yex5u

£—9 vol | eurquow ynjun uebuepe

‘DHOWT CILITaNOT TOL

You might also like

- Kire Pelantar PDFDocument3 pagesKire Pelantar PDFFaeez ZainNo ratings yet

- SikaTopSeal107 UsDocument6 pagesSikaTopSeal107 UsFaeez ZainNo ratings yet

- Concrete Continuous Footing Quantity Take-Off WorksheetDocument17 pagesConcrete Continuous Footing Quantity Take-Off WorksheetFaeez ZainNo ratings yet

- Method of Statement Pda Test PDFDocument9 pagesMethod of Statement Pda Test PDFFaeez ZainNo ratings yet

- Method of Statement Piling WorksDocument4 pagesMethod of Statement Piling WorksFaeez Zain0% (1)

- Ceiling WorksDocument3 pagesCeiling WorksFaeez ZainNo ratings yet

- Muhamad Ariff Bin Zainuddin: Site Supervisor (1 Year)Document3 pagesMuhamad Ariff Bin Zainuddin: Site Supervisor (1 Year)Faeez ZainNo ratings yet

- Method Statement For Piling Work (Edited)Document18 pagesMethod Statement For Piling Work (Edited)Faeez Zain100% (6)

- STP 2 Cube Test Update Until 6.2.2018Document1 pageSTP 2 Cube Test Update Until 6.2.2018Faeez ZainNo ratings yet

- Soil Investigation Method Statements for Vietnam King-Whale ProjectDocument17 pagesSoil Investigation Method Statements for Vietnam King-Whale ProjectbprimusNo ratings yet

- Appendix B Piling Record FormDocument1 pageAppendix B Piling Record FormFaeez ZainNo ratings yet

- Method of Statement Piling WorksDocument4 pagesMethod of Statement Piling WorksFaeez Zain0% (1)

- How to Build a 115mm Brick Wall with Less Than 40 CharactersDocument1 pageHow to Build a 115mm Brick Wall with Less Than 40 CharactersFaeez ZainNo ratings yet

- Method Statement For PilingDocument13 pagesMethod Statement For Pilingfree4bruce100% (1)

- Method Statement For PilingDocument13 pagesMethod Statement For Pilingfree4bruce100% (1)

- ProjectDocument6 pagesProjectFaeez ZainNo ratings yet

- Method of Statement Pda TestDocument9 pagesMethod of Statement Pda TestFaeez ZainNo ratings yet

- Method Statement For Piling Work (Edited)Document18 pagesMethod Statement For Piling Work (Edited)Faeez Zain100% (6)

- Method 0f Statement of Earthworks NCRDocument2 pagesMethod 0f Statement of Earthworks NCRFaeez ZainNo ratings yet

- T.off ReinforcementDocument20 pagesT.off ReinforcementFaeez ZainNo ratings yet

- Nisbah Konkrit g40Document3 pagesNisbah Konkrit g40Faeez ZainNo ratings yet

- Internal and External FinishesDocument7 pagesInternal and External FinishesFaeez ZainNo ratings yet

- Abs TrakDocument2 pagesAbs TrakFaeez ZainNo ratings yet

- Teknikal ReportDocument6 pagesTeknikal ReportFaeez ZainNo ratings yet

- Pda Method StatementDocument12 pagesPda Method StatementFaeez ZainNo ratings yet

- Steel DesignDocument24 pagesSteel DesignFaeez ZainNo ratings yet

- Summary Defect List 28.7.2017Document2 pagesSummary Defect List 28.7.2017Faeez ZainNo ratings yet

- SteelDocument10 pagesSteelFaeez ZainNo ratings yet

- SteelDocument10 pagesSteelFaeez ZainNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)