Professional Documents

Culture Documents

6372drawing - Orifice Gate ANSI

Uploaded by

alexiscofield1820 ratings0% found this document useful (0 votes)

95 views1 pageDe sa

Original Title

6372Drawing - Orifice Gate ANSI

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentDe sa

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

95 views1 page6372drawing - Orifice Gate ANSI

Uploaded by

alexiscofield182De sa

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

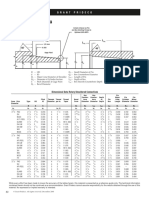

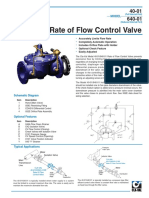

Standard Assembly Unit Installation Data:

• Designed for gravity flow and dilute phase pneumatic conveying

systems.

• Connections: Inlet and outlet have an ANSI #125/150 flange pattern

with blind tapped holes for flange connection.

• Actuation: Double acting air cylinder. The air cylinder requires a

minimum of 80 psig (5.4 bar), filtered, compressed air for most reliable

service. Air lubrication is not required but is recommended for extended

wear life.

• Air Control: A 2 position, 4 way lever or solenoid operated compressed

air control is required to operate the air cylinder.

• Temperature: Base model rated at 180º f (82º c) continuous service,

250º f (121º c) intermittent (10 minutes maximum). Higher

temperatures can be achieved with high temperature modifications.

• Air Usage: Calculated at 80 psig (5.4 bar) for 1 open or 1 closed stroke

of the air cylinder.

• Hardware: Imperial models contain imperial hardware & metric models

contain metric hardware.

• Avoid supporting conveying lines and equipment exceeding 200 lbs

(90kg) with the diverter gate valve.

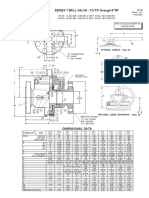

BASE VALVE A B C D E F G H J K L M N CV KV AIR USAGE WEIGHT

Imperial / Metric Model (F,G,J) in mm in mm in mm in mm in mm in mm in mm in in mm in mm NPT G in mm SCF L Lbs Kg

GRA02-AP / GRA50-AP 1 3/4 45 3 3/8 86 6 3/4 171 7 1/2 189 6 152 7 1/8 181 3 1/2 87 4 5/8-11NC 4 3/4 121 6 152 3/8 3/8 4 1/2 114 1.0 0.86 0.080 2.27 22 10

GRA02.5-AP / GRA65-AP 2 1/4 57 3 3/8 86 8 1/2 216 8 7/8 225 7 7/8 200 8 1/8 206 4 1/8 105 4 5/8-11NC 5 1/2 140 7 178 1/2 1/2 5 127 1.0 0.86 0.143 4.05 32 15

GRA03-AP / GRA75-AP 2 3/4 70 3 3/8 86 8 1/2 216 8 7/8 225 7 7/8 200 8 1/8 206 4 1/8 105 4 5/8-11NC 6 152 7 1/2 191 1/2 1/2 5 127 1.0 0.86 0.143 4.05 32 15

GRA04-AP / GRA100-AP 3 3/4 96 3 76 9 1/2 241 11 278 9 1/4 235 9 1/8 232 5 1/8 131 8 5/8-11NC 7 1/2 190 9 229 1/2 1/2 6 152 1.4 1.20 0.302 8.55 38 17

GRA05-AP / GRA125-AP 4 7/8 123 3 1/2 89 10 1/2 266 12 1/2 317 10 7/8 276 10 1/8 257 5 1/8 131 8 3/4-10NC 8 1/2 216 10 254 1/2 1/2 6 152 1.4 1.20 0.362 10.25 42 19

GRA06-AP / GRA150-AP 5 7/8 149 3 1/2 89 11 3/4 298 14 358 12 3/8 314 11 1/8 283 5 1/2 140 8 3/4-10NC 9 1/2 241 11 279 1/2 1/2 6 1/8 156 2.6 2.22 0.515 14.58 50 23

GRA08-AP / GRA200-AP 7 7/8 199 3 1/2 89 13 3/4 349 17 432 15 3/8 391 13 1/8 333 5 1/2 140 8 3/4-10NC 11 3/4 298 13 1/2 343 1/2 1/2 6 1/8 156 2.6 2.22 0.662 18.75 61 28

GRA10-AP / GRA250-AP 9 7/8 250 4 3/8 111 16 3/4 424 20 508 18 3/8 487 15 1/4 387 6 1/2 165 12 7/8-9NC 14 1/4 362 16 406 1/2 1/2 7 1/8 181 2.6 2.22 1.155 32.70 95 43

GRA12-AP / GRA300-AP 11 7/8 301 4 3/8 111 18 3/4 475 23 584 21 3/8 543 17 3/8 441 6 1/2 165 12 7/8-9NC 17 432 19 483 1/2 1/2 7 1/8 181 2.6 2.22 1.365 38.65 115 52

GRA14-AP / GRA350-AP 13 7/8 352 4 5/8 117 20 3/4 526 26 1/2 672 24 3/8 619 19 3/8 492 6 1/2 165 12 1-8NC 18 3/4 476 21 533 1/2 1/2 7 1/8 181 2.6 2.22 1.575 44.60 145 66

GRA16-AP / GRA400-AP 15 7/8 403 5 3/8 138 24 1/8 611 32 7/8 835 30 1/4 768 23 1/2 595 8 1/2 216 16 1 3/8-12NC 21 1/4 540 N/A N/A 1/2 1/2 17 1/2 445 2.6 2.22 1.575 44.60 300 136

*GRA02-F-AP / GRA50-F-AP USES 3/8NPT IMPERIAL, G 3/8 METRIC FITTINGS

*Information subject to change without notice | Above information is Vortex standard dimensional information | Contact us if your application needs a non-standard valve | Available specifications and modifications available at www.vortexvalves.com

20 QUANTUM ORIFICE GATE ANSI FLANGE © DMOGA-0912

You might also like

- Valvula Vortex BausanoDocument1 pageValvula Vortex BausanoOmar ZeladaNo ratings yet

- Regulador Pilotado Mod. GP2000Document2 pagesRegulador Pilotado Mod. GP2000vanguevNo ratings yet

- Filtros Monitor VelconDocument2 pagesFiltros Monitor VelconDaniel FarfanNo ratings yet

- Vertical HP Receivers: Specifications - Engineering Data - DimensionsDocument4 pagesVertical HP Receivers: Specifications - Engineering Data - DimensionsVeska VratchevaNo ratings yet

- ButterflyDocument6 pagesButterflysachin2010No ratings yet

- API - Iadc Recommended Drill String Make-Up TorqueDocument2 pagesAPI - Iadc Recommended Drill String Make-Up TorqueQuality controller100% (6)

- KF Trunnion Ball Valve 1-8 900lbsDocument2 pagesKF Trunnion Ball Valve 1-8 900lbsDiegoNo ratings yet

- ABM Travel DrivesDocument29 pagesABM Travel Drivestiele_barcelos100% (1)

- Ampco Centrifugal PumpsDocument2 pagesAmpco Centrifugal PumpsvisitabhinavNo ratings yet

- L-Series: Male Connector 24° Flareless / BSPT or BSPPDocument1 pageL-Series: Male Connector 24° Flareless / BSPT or BSPPpett2012No ratings yet

- Dkun DemagDocument40 pagesDkun DemagErc Nunez V0% (1)

- 24 Roller Gate: Standard Assembly Unit Installation DataDocument1 page24 Roller Gate: Standard Assembly Unit Installation DataIulian Florin PeşuNo ratings yet

- Compresor Copeland DiscusDocument16 pagesCompresor Copeland Discushector saavedraNo ratings yet

- Pilot Operated NRVDocument1 pagePilot Operated NRVBiswanath LenkaNo ratings yet

- Catalogo de GusanosDocument33 pagesCatalogo de GusanosPedro JuradoNo ratings yet

- zpk5 Service Compressor Kits 17 18 en Us 5082464Document12 pageszpk5 Service Compressor Kits 17 18 en Us 5082464fjeroNo ratings yet

- 50hz Kulthorn CompressorsDocument8 pages50hz Kulthorn Compressorsrhozel2010100% (1)

- GP Tool Joint Dimensional ValueDocument3 pagesGP Tool Joint Dimensional ValuecalamarejoNo ratings yet

- GP Tool Joint Dimensional Value PDFDocument2 pagesGP Tool Joint Dimensional Value PDFamerNo ratings yet

- All Sizes and TorquesDocument13 pagesAll Sizes and TorquesMohammad RizwanNo ratings yet

- Ametek Technical - PublicationDocument105 pagesAmetek Technical - PublicationWallyNo ratings yet

- Bomba Jockey Rci VPS-13 HP3.0Document4 pagesBomba Jockey Rci VPS-13 HP3.0JASMITHSIERRA sierraNo ratings yet

- Ensival MoretDocument6 pagesEnsival MoretPatricia J ÁngelesNo ratings yet

- Valvulas ASCO PDFDocument4 pagesValvulas ASCO PDFelkin880604No ratings yet

- Aurora Model 481 Pumps: Single-Stage Fire ServiceDocument1 pageAurora Model 481 Pumps: Single-Stage Fire ServiceNiong DavidNo ratings yet

- ZR36KC PFJ 522Document2 pagesZR36KC PFJ 522أبو زينب المهندسNo ratings yet

- Fdtech FD-1 T FD TDocument4 pagesFdtech FD-1 T FD TSony CNo ratings yet

- Nema Electrical Motors FrameDocument11 pagesNema Electrical Motors FrameLuckie IbrahimNo ratings yet

- Washers - Standard Flat WasherDocument1 pageWashers - Standard Flat WasherMohammed KhalidNo ratings yet

- ICEAGE CompressorDocument3 pagesICEAGE CompressorRandyTsaoNo ratings yet

- Offers January 2013 PowerstormDocument19 pagesOffers January 2013 PowerstormShannan MontgomeryNo ratings yet

- Aluminum Terminals: Type Afnc2Document1 pageAluminum Terminals: Type Afnc2Waldir GavelaNo ratings yet

- AMETEKDocument103 pagesAMETEKChristian0% (1)

- Aluminum Terminals: Type Afnc90Document1 pageAluminum Terminals: Type Afnc90Waldir GavelaNo ratings yet

- FKC Lake Shore Rope AttDocument8 pagesFKC Lake Shore Rope AttFelipe SantibáñezNo ratings yet

- Valvula de Diafragma PDFDocument4 pagesValvula de Diafragma PDFGustavo CasillasNo ratings yet

- CPF-EM-81-01 5.5KV: Key KeyDocument9 pagesCPF-EM-81-01 5.5KV: Key Keyyezid nourNo ratings yet

- GP23TBDocument3 pagesGP23TBshinegirl lay101No ratings yet

- Gabbioneta RDocument6 pagesGabbioneta Rvrider81No ratings yet

- A As Suction Accumulators Catalog en Us 1570140Document1 pageA As Suction Accumulators Catalog en Us 1570140Nazrul RahmanNo ratings yet

- Munsell Standard Colour CodeDocument7 pagesMunsell Standard Colour Codehon choong chong0% (1)

- Munsell Standard ColorDocument7 pagesMunsell Standard Colornasif andriantoNo ratings yet

- Detention Lime Slaker: Series 85Document2 pagesDetention Lime Slaker: Series 85Marcelo GuarachiNo ratings yet

- 2012 Hoyt Vantage LTDDocument1 page2012 Hoyt Vantage LTDSara RussellNo ratings yet

- 3G3JV Series Models Discontinuation: Product NewsDocument3 pages3G3JV Series Models Discontinuation: Product Newsyoga dwiNo ratings yet

- Stainless Steel Socket Weld FittingsDocument4 pagesStainless Steel Socket Weld FittingsJimmy Alfaro HernandezNo ratings yet

- Flange SeriesSKRDocument6 pagesFlange SeriesSKRHendra JurbonNo ratings yet

- Air Tug Planetary Gear BoxDocument2 pagesAir Tug Planetary Gear BoxEduardo Mario NuñezNo ratings yet

- Product Catalogue: Page Summary TableDocument22 pagesProduct Catalogue: Page Summary TableJhon ConnorNo ratings yet

- Antenna Hustler Two Meter G7 Instrucciones de EnsamblajeDocument5 pagesAntenna Hustler Two Meter G7 Instrucciones de Ensamblajemrsingler100% (1)

- L Series BrochureWebDocument16 pagesL Series BrochureWebmadhavikNo ratings yet

- Series 919 Specification SheetDocument4 pagesSeries 919 Specification SheetWattsNo ratings yet

- Nipcib 000038Document31 pagesNipcib 000038AlfoFS100% (1)

- Product Specifications: Environmentally Sound R 410A RefrigerantDocument21 pagesProduct Specifications: Environmentally Sound R 410A RefrigerantHugo OnoroNo ratings yet

- Piper SguideDocument278 pagesPiper SguideJordy PerezNo ratings yet

- Rail Chart: Nominal Weight Per Yard Type of Rail Dimensions in Inches Section Designation HT BW HW W HD FD BD EDocument5 pagesRail Chart: Nominal Weight Per Yard Type of Rail Dimensions in Inches Section Designation HT BW HW W HD FD BD ECarlos A. RocaNo ratings yet

- Seal Master SC-32Document1 pageSeal Master SC-32Walter CoresNo ratings yet

- The Technical, Aerodynamic & Performance Aspects of a Helicopter: A Manual for Helicopter Pilots and Engineers Who Want to Know MoreFrom EverandThe Technical, Aerodynamic & Performance Aspects of a Helicopter: A Manual for Helicopter Pilots and Engineers Who Want to Know MoreRating: 3 out of 5 stars3/5 (2)

- XPS Materials Technology PublicationsDocument2 pagesXPS Materials Technology Publicationsalexiscofield182No ratings yet

- Lumio: User ManualDocument19 pagesLumio: User Manualalexiscofield182No ratings yet

- C1903 PS DWG EST.109 Layout1Document1 pageC1903 PS DWG EST.109 Layout1alexiscofield182No ratings yet

- RISA 3D v11.0.2 English 32-64 BitDocument1 pageRISA 3D v11.0.2 English 32-64 Bitalexiscofield1820% (1)

- AMastersGuidetoContainerSecuring2ndEdition 3Document50 pagesAMastersGuidetoContainerSecuring2ndEdition 3rajumj66No ratings yet

- Tutorial ETABSDocument60 pagesTutorial ETABSValentin VrabieNo ratings yet

- Ems Sep-2017 Buen VivirDocument75 pagesEms Sep-2017 Buen Viviralexiscofield182No ratings yet

- Valvula de FlujoDocument4 pagesValvula de Flujoalexiscofield182No ratings yet

- 2013 IahsDocument58 pages2013 Iahsalexiscofield182No ratings yet

- ASME B31.4a PDFDocument69 pagesASME B31.4a PDFhussein100% (1)

- Cat KGV 07 17Document16 pagesCat KGV 07 17GILBERTO YOSHIDANo ratings yet

- s211-07 Raffirmed 2012-E1 PDFDocument2 pagess211-07 Raffirmed 2012-E1 PDFalexiscofield182No ratings yet

- Bore Line Detailed Installation ProcedureDocument13 pagesBore Line Detailed Installation Procedurealexiscofield182No ratings yet

- CoefficientsDocument1 pageCoefficientsLeidy Saavedra PrietoNo ratings yet

- 95c 10897Document12 pages95c 10897CP2922No ratings yet

- For Chocking Between Steel & Concrete: Bulletin DescriptionDocument2 pagesFor Chocking Between Steel & Concrete: Bulletin Descriptionamitparabolicdrugs3No ratings yet

- Grade 6 Lesson 4Document21 pagesGrade 6 Lesson 4Feljan Robert OriendoNo ratings yet

- Hotpoint Hv7l 1451 ManualDocument16 pagesHotpoint Hv7l 1451 ManualValeriu GinghinaNo ratings yet

- Butene 1 PDFDocument2 pagesButene 1 PDFdhiraj dhargaveNo ratings yet

- Elastomer Brochure 2010Document52 pagesElastomer Brochure 2010mlombardiTONo ratings yet

- As 3735-2001 Concrete Structures Retaining LiquidsDocument27 pagesAs 3735-2001 Concrete Structures Retaining Liquidsmod67% (3)

- Section 13 Part 2 Mortar and GroutDocument6 pagesSection 13 Part 2 Mortar and GroutRotsapNayrbNo ratings yet

- DES-WA50 Manual V04VNAI0531Document24 pagesDES-WA50 Manual V04VNAI0531Distrimar LimitadaNo ratings yet

- PALIMEX R - 855 Product Information PR00331304Document2 pagesPALIMEX R - 855 Product Information PR00331304Muhammad ThohirNo ratings yet

- Komet Milling TurningDocument132 pagesKomet Milling Turningstore.hrNo ratings yet

- Aliplast Katalog enDocument140 pagesAliplast Katalog enJelena GraovčevićNo ratings yet

- Is 402 Pipe BuoyancyDocument3 pagesIs 402 Pipe BuoyancyDGWNo ratings yet

- Elements of Mechanical EngineeringDocument5 pagesElements of Mechanical EngineeringnavitgmNo ratings yet

- Productivity Improvement Through Lean ManufacturingDocument30 pagesProductivity Improvement Through Lean ManufacturingmanikandaprabuNo ratings yet

- 2016 EXPT BluDocument1 page2016 EXPT BluToto MidgleyNo ratings yet

- Outgassing Versus Flashing - What Are The Differences?: Issue 2Document4 pagesOutgassing Versus Flashing - What Are The Differences?: Issue 2Ashok SankarNo ratings yet

- Handbook of Lost Wax or Investment Casting Sopcak TextDocument34 pagesHandbook of Lost Wax or Investment Casting Sopcak TextAttila FischerNo ratings yet

- Msi 50003931-02 Web EPaper LowresPdf DownloadDocument36 pagesMsi 50003931-02 Web EPaper LowresPdf DownloadceljkoNo ratings yet

- E CombusDocument2 pagesE CombusalexNo ratings yet

- Business Impact AssessmentDocument10 pagesBusiness Impact Assessmentदीपक सैनीNo ratings yet

- 380kV DiagonalConnection Brochure 50hertzDocument15 pages380kV DiagonalConnection Brochure 50hertzburvanovNo ratings yet

- DD Folio p01170 CC TuxpanDocument102 pagesDD Folio p01170 CC TuxpanErnesto VazquezNo ratings yet

- MAGNI 565: Product Data SheetDocument1 pageMAGNI 565: Product Data SheetjulianaNo ratings yet

- Temperature MeasurementDocument70 pagesTemperature MeasurementMGHIRBI HAYKELNo ratings yet

- Gear Data 20-6Document3 pagesGear Data 20-6Kallol MahalanabisNo ratings yet

- ICMEEE2020 PaperID 509Document8 pagesICMEEE2020 PaperID 509Usama MughalNo ratings yet

- Elect Rob Raid InstallDocument36 pagesElect Rob Raid Install1amlapmanNo ratings yet

- 7 - Storage and Handling of Transformer OilDocument8 pages7 - Storage and Handling of Transformer OilRavneet BanyalNo ratings yet

- Michael Faraday - On The Liquefaction of GasesDocument111 pagesMichael Faraday - On The Liquefaction of GasesSubhojit AdhikaryNo ratings yet