Professional Documents

Culture Documents

SB18 03

Uploaded by

Elmer VillegasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SB18 03

Uploaded by

Elmer VillegasCopyright:

Available Formats

CONTINENTAL MOTORS® AIRCRAFT ENGINE CATEGORY 3

SERVICE BULLETIN SB18-03

Supersedes M74-16

Compliance Will Enhance Safety T E CH N IC AL PO RT IO NS

FAA APPROVED

SUBJECT: Valve Spring Identification

PURPOSE: To ensure correct identification and usage of valve springs.

COMPLIANCE: At the next maintenance requiring complete disassembly of the engine,

no later than published TBO.

MODELS

AFFECTED: All Continental Motors, Inc. (CMI) A65, C75, C85, C90, C125, C145, E165,

E185 model aviation gasoline (AvGas) engines

I. GENERAL INFORMATION

This Service Document summarizes and consolidates the valve spring combination changes

presented in previous releases.

CMI recommends that all valve springs retain color-coded stripe identification (see Figure 1 and

Table 1). All valve springs in stockrooms should be color striped. Where necessary, reapply the

Dykem® color stripe after the disassembly from an engine and thorough cleaning.

NOTE: Never apply enamel paint to color-code springs.

In order to ensure proper marking, valve springs on hand should be checked against the spring

identification and test data shown in Table 1. The stripe should be approximately 1/4" wide and

should touch only the outside of each coil.

NOTE: Carefully apply the stripe to ensure it is clearly visible. Do

not apply striping in excess to cause runs or drips.

Figure 1. Identifying Characteristics, Springs, typical

ISSUED REVISED PAGE NO DOC NO REVISION

2018/04/05 1 of 4 SB18-03

P.O. Box 90 Mobile, AL 251-436-8299

©2018 Continental Motors, Inc.

Table 1. Identifying Characteristics, Springs

Engine Models A65 C75, C85

Spring Type Inner Spring Outer Spring Inner Spring Outer Spring

21366

Part Number (P/N) 21365 24029 24030

RFQ Only

White or

Color (Dykem® only, Do Not Use Enamel) Yellow Yellow Purple Orange

Direction of Windings L.H. R.H. L.H. R.H.

Spring Free Length, Approx. 1.922 2.203 2.312 2.125

Identification (In.)

Inside Dia. (Min.) 0.870 1.167 0.880 1.165

Wire Dia. (Nom.) 0.105 0.135 0.111 0.142

Compress to... 1.25 1.344 1.528 1.559

Test Data Load (Lbs.) 20.0-22.0 32.5-35.5 25.0-28.0 33.0-37.0

(Spring Loads) Compress to... 0.860 0.953 1.137 1.168

Load (Lbs.) 34.5-37.5 52.0-56.0 40.0-44.0 58.0-63.0

Engine Models C90, C125, C145 E165, E185

Intermediate

Spring Type Inner Spring Outer Spring Inner Spring Outer Spring

Spring1

Part Number (P/N) 24031 24029 24030 631521 637837

Color (Dykem® only, Do Not Use Enamel) Green Purple White or LT Blue Pink

Orange

Direction of Windings R.H. L.H. R.H. R.H. L.H.

Spring Free Length (Approx.) 1.781 2.312 2.125 2.125 2.100

Identification (In.)

Inside Dia. (Min.) 0.630 0.880 1.165 0.917 1.300

Wire Dia. 0.091 0.111 0.142 0.142 0.177

Compress to... 1.466 1.528 1.559 1.746 1.791

Test Data Load (Lbs.) 10.0-13.0 25.0-28.0 33.0-37.0 32.0-38.0 49.0-55.0

(Spring Loads) Compress to... 1.075 1.137 1.168 1.230 1.275

Load (Lbs.) 27.0-30.0 40.0-44.0 58.0-63.0 87.0-97.0 126.0-140.0

1. Optional cast iron camshaft configuration is no longer applicable. Three spring combination must be used with later type steel camshafts.

ISSUED REVISED PAGE NO DOC NO REVISION

2018/04/05 2 of 4 SB18-03

P.O. Box 90 Mobile, AL 251-436-8299

II. PART SUPERSEDURE HISTORY

The following tables are for historical reference information only. This section does not advise the

use of products that must be installed together or used in combination with other specified parts

when replacing a superseded product. You must consult the latest CMI service information and

aircraft regulatory agency publication to validate the use of any product listed in this section.

CMI assumes no responsibility or liability for the improper use of information contained in the

Part Supersede History section.

Table 2. Identifying Characteristics, Superseded Springs

Engine Models C90

Spring Type Outer Spring

Superseded Part Number (P/N) 24669

Color (Dykem® only, Do Not Use Enamel) Black

Direction of Windings R.H.

Spring Free Length, Approx. 2.125

Identification (In.)

Inside Dia. (Min.) 1.165

Wire Dia. (Nom.) 0.148

Compress to... 1.559

Test Data Load (Lbs.) 43-47

(Spring Loads) Compress to... 1.168

Load (Lbs.) 71-76

Engine Models E165, E185

Optional Optional

Spring Type Inner Spring Outer Spring

Inner Springs Outer Spring

Superseded Part Number (P/N) 637836 5201061 359882 520105 359892

Color (Dykem® only, Do Not Use Enamel) Aluminum Blue Plain Blue Plain

Direction of Windings L.H. R.H. R.H. R.H. L.H.

Spring Free Length (Approx.) 2.312 2.406 2.156 2.125 2.187

Identification (In.)

Inside Dia. (Min.) 0.880 .912 .912 1.165 1.287

Wire Dia. 0.111 .142 .142 0.142 .177

Compress to... 1.528 1.809 1.809 1.559 1.840

Test Data Load (Lbs.) 25.0-28.0 43-49 28-34 33.0-37.0 41-47

(Spring Loads) Compress to... 1.137 1.329 1.329 1.168 1.360

Load (Lbs.) 40.0-44.0 78-88 71-81 58.0-63.0 100-113

1. Permissible with cast iron camshaft, three spring combination preferred and must be used with later type steel camshafts.

2. Use aluminum spacer part number 520023 (not available) with number 35988 and number 35989 spring combination. DO NOT use spacer

with spring combination consisting of part numbers 520105, 520106 or 637836.

ISSUED REVISED PAGE NO DOC NO REVISION

2018/04/05 3 of 4 SB18-03

P.O. Box 90 Mobile, AL 251-436-8299

Intentionally Left Blank

ISSUED REVISED PAGE NO DOC NO REVISION

2018/04/05 4 of 4 SB18-03

P.O. Box 90 Mobile, AL 251-436-8299

You might also like

- ZF 15 M Series: Product DetailsDocument4 pagesZF 15 M Series: Product DetailsSabrina Graziela FerreiraNo ratings yet

- ZF25ADocument4 pagesZF25A1380485No ratings yet

- CS-510 Service DataDocument5 pagesCS-510 Service DatarexNo ratings yet

- Brochure ZF 2801Document4 pagesBrochure ZF 2801Justo LopezNo ratings yet

- 6 4029 - Print - 04 09 2015Document3 pages6 4029 - Print - 04 09 2015Shahzad AhmadNo ratings yet

- Air Cylinder: Series A20, A21 Double End Double Acting Cylinders (Square Type) Ø32 - 125 MMDocument4 pagesAir Cylinder: Series A20, A21 Double End Double Acting Cylinders (Square Type) Ø32 - 125 MMBiswanath LenkaNo ratings yet

- 362Document2 pages362Ajay AsodariyaNo ratings yet

- CAPT. PREMIUM ENGINE VALVE GUIDEDocument61 pagesCAPT. PREMIUM ENGINE VALVE GUIDEmvv-sspNo ratings yet

- Hyundai Diesel Engine Hd4dd Service ManualDocument20 pagesHyundai Diesel Engine Hd4dd Service Manualbrian100% (44)

- Shur Joint Class 300 FittingsDocument7 pagesShur Joint Class 300 FittingsSajid SaleemNo ratings yet

- 13 - VX800P (Mod93)Document13 pages13 - VX800P (Mod93)zaq94No ratings yet

- D03 ElecDocument40 pagesD03 ElecServis PartsNo ratings yet

- Jinford 2017 - eDocument102 pagesJinford 2017 - eEleazar Benjamin Castro PavonNo ratings yet

- Item:130ST Series Servo Motor: SpecificationsDocument4 pagesItem:130ST Series Servo Motor: Specificationsn13t0314No ratings yet

- 3.1B Certificat - ModèleDocument1 page3.1B Certificat - Modèlescribdhas2006No ratings yet

- ZF 45 Marine Transmission Technical SpecsDocument4 pagesZF 45 Marine Transmission Technical SpecsArthur SchoutNo ratings yet

- Engineering DetailDocument30 pagesEngineering DetailSatyaprakash PrakashNo ratings yet

- ZF 2000 Series: Product DetailsDocument4 pagesZF 2000 Series: Product DetailsJhonAlexRiveroNo ratings yet

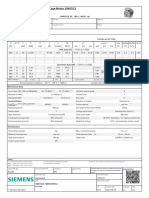

- Data Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1CV2252B Simotics SD - 250 M - Im B5 - 4PDocument1 pageData Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1CV2252B Simotics SD - 250 M - Im B5 - 4PrezaNo ratings yet

- Acoples Lovejoy CS-LS (Jaw)Document1 pageAcoples Lovejoy CS-LS (Jaw)marcelo castilloNo ratings yet

- Aa2fm Rexroth PDFDocument36 pagesAa2fm Rexroth PDFComassur SA de CVNo ratings yet

- Air Cylinder: Series A10, A11 AIR CYLINDERS Double Acting (Ø32 - 100) MM FeaturesDocument4 pagesAir Cylinder: Series A10, A11 AIR CYLINDERS Double Acting (Ø32 - 100) MM FeaturesBiswanath LenkaNo ratings yet

- A18 A19 CylinderDocument4 pagesA18 A19 CylinderBiswanath LenkaNo ratings yet

- ZF 2050 Technical Data SheetDocument4 pagesZF 2050 Technical Data SheetSabrina Graziela FerreiraNo ratings yet

- Marine Propulsion Systems: DescriptionDocument4 pagesMarine Propulsion Systems: Descriptionstefan tulucNo ratings yet

- A16 A17 CylinderDocument7 pagesA16 A17 Cylinderjaneesh RNo ratings yet

- Install and operate TAC activated carbon towerDocument12 pagesInstall and operate TAC activated carbon towerMột Lằn QuangNo ratings yet

- Mitsubishi Engine 4DQ3 4DQ30 Service Manual 99609-50000Document61 pagesMitsubishi Engine 4DQ3 4DQ30 Service Manual 99609-50000Miroslav TabakovskiNo ratings yet

- Df200ap E01 015 (9900B-45325)Document100 pagesDf200ap E01 015 (9900B-45325)Jorge LopesNo ratings yet

- A25 A26 CylinderDocument5 pagesA25 A26 CylinderBiswanath LenkaNo ratings yet

- Lionn Auto SoftwaresDocument2 pagesLionn Auto SoftwaresLIONN ONESOLUTIONNo ratings yet

- S-SB-0033-13 DifficultyStarting RoughIdle CamPosition MisfireDocument8 pagesS-SB-0033-13 DifficultyStarting RoughIdle CamPosition MisfireEl rincón de RaulNo ratings yet

- Piston Crown Inspection: Operating InstructionDocument6 pagesPiston Crown Inspection: Operating InstructionRonald Bienemi Paez100% (1)

- Cs 330evlDocument4 pagesCs 330evlfrancesco.accinni.onlineNo ratings yet

- Impreza Service ManualDocument95 pagesImpreza Service ManualTaxiarhis ZoubosNo ratings yet

- Trorfiro: Drive Shaft Phase AnglesDocument31 pagesTrorfiro: Drive Shaft Phase AnglesSonthi MooljindaNo ratings yet

- ZF 325 Series: Product DetailsDocument4 pagesZF 325 Series: Product DetailsSebastian FagoagaNo ratings yet

- 4g93 Lancer EngineDocument52 pages4g93 Lancer Enginecsberny98% (45)

- TG S50 PDFDocument1 pageTG S50 PDFIvan RocoNo ratings yet

- CO Component Description: Carbon Dioxide Cylinder SpecificationsDocument1 pageCO Component Description: Carbon Dioxide Cylinder SpecificationsAhmed Mohamed RashedNo ratings yet

- ZF 9000 Series: Product DetailsDocument4 pagesZF 9000 Series: Product DetailsArama Eduard AlexandruNo ratings yet

- DENAIR Oil-Free Air CompressorDocument10 pagesDENAIR Oil-Free Air CompressorSAUL OSPINONo ratings yet

- 1% Thick Film Chip Resistors CR1 SeriesDocument4 pages1% Thick Film Chip Resistors CR1 SeriesDil NawazNo ratings yet

- Standards and Service Limits: 2005-06 General InformationDocument21 pagesStandards and Service Limits: 2005-06 General Informationvadim vadim100% (1)

- 1MB1533-1EB49-0FB4-Z B43+M4B Datasheet enDocument2 pages1MB1533-1EB49-0FB4-Z B43+M4B Datasheet enrianandiyahooNo ratings yet

- ZF 7600 Series: Product DetailsDocument4 pagesZF 7600 Series: Product DetailsPlingu RazvanNo ratings yet

- SBPT Catalogue DC CouplingDocument11 pagesSBPT Catalogue DC CouplingEserNo ratings yet

- d991 Picv Cranefs Ds 230418Document1 paged991 Picv Cranefs Ds 230418Anonymous 6hptH95No ratings yet

- Impreza 2002 2.0LDocument273 pagesImpreza 2002 2.0LDaniel MendezNo ratings yet

- ZF 3050Document4 pagesZF 3050Aan IstiawanNo ratings yet

- SMC-IMG-Specifications For Connecting Rods and Bearings Used in 3600 and C280 Family of EnginesDocument5 pagesSMC-IMG-Specifications For Connecting Rods and Bearings Used in 3600 and C280 Family of EnginesVictor NoschangNo ratings yet

- ZF 360 Series: Product DetailsDocument4 pagesZF 360 Series: Product DetailsjhprimamudaNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Trig 1Document8 pagesTrig 1Joselle Grino0% (1)

- SL L114BG Technical PublicationsDocument24 pagesSL L114BG Technical PublicationskanwarNo ratings yet

- Circular Motion and Torque - AP Physics B Problems OnlyDocument2 pagesCircular Motion and Torque - AP Physics B Problems OnlyElmer VillegasNo ratings yet

- Time RatesDocument29 pagesTime RatesElmer VillegasNo ratings yet

- Special Tools and Equipment - Description and OperationDocument3 pagesSpecial Tools and Equipment - Description and OperationElmer VillegasNo ratings yet

- 407 Garmin G1000H PG PDFDocument548 pages407 Garmin G1000H PG PDFLavern P. SipinNo ratings yet

- PART 2 Personnel Licensing 2019 PDFDocument240 pagesPART 2 Personnel Licensing 2019 PDFKen Ian TalagNo ratings yet

- Integral ProblemDocument2 pagesIntegral ProblemElmer VillegasNo ratings yet

- Aviation Safety Courses Available Through The FAADocument4 pagesAviation Safety Courses Available Through The FAAJeff BragançaNo ratings yet

- Draft May2017Document72 pagesDraft May2017Niraj YogiNo ratings yet

- Math Problem 1Document3 pagesMath Problem 1Elmer VillegasNo ratings yet

- Chapter5 - General InspectionDocument2 pagesChapter5 - General InspectionElmer VillegasNo ratings yet

- Math Problem 2Document3 pagesMath Problem 2Elmer VillegasNo ratings yet

- Math Problem 3Document4 pagesMath Problem 3Elmer VillegasNo ratings yet

- AC 07 001 Acceptable Arrangements For Flight RecordersDocument26 pagesAC 07 001 Acceptable Arrangements For Flight RecordersElmer VillegasNo ratings yet

- AC 07 001 Acceptable Arrangements For Flight RecordersDocument26 pagesAC 07 001 Acceptable Arrangements For Flight RecordersElmer VillegasNo ratings yet

- 402 Pilot's Handbook Publication StatusDocument6 pages402 Pilot's Handbook Publication StatusElmer VillegasNo ratings yet

- Service Bulletin 1 Avia PropDocument14 pagesService Bulletin 1 Avia PropElmer VillegasNo ratings yet

- Continental SIL99-1 PDFDocument4 pagesContinental SIL99-1 PDFElmer VillegasNo ratings yet

- CONTINENTAL TBO Page SIL98-9C PDFDocument4 pagesCONTINENTAL TBO Page SIL98-9C PDFElmer VillegasNo ratings yet

- What Is Linear Text and Non Linear Text - Brainly - PHDocument4 pagesWhat Is Linear Text and Non Linear Text - Brainly - PHElmer Villegas67% (3)

- SMS Details:: Safety Assurance ComponentDocument20 pagesSMS Details:: Safety Assurance ComponentElmer VillegasNo ratings yet

- Conditional - English Grammar - EFDocument5 pagesConditional - English Grammar - EFElmer VillegasNo ratings yet

- Maule TCDSDocument49 pagesMaule TCDSElmer VillegasNo ratings yet

- FAA Type Certificate for Allied Ag Cat Aircraft ModelsDocument34 pagesFAA Type Certificate for Allied Ag Cat Aircraft ModelsElmer VillegasNo ratings yet

- Mooney M20 Aircraft Specification from DOTDocument64 pagesMooney M20 Aircraft Specification from DOTElmer VillegasNo ratings yet

- Continental SIL99-1 PDFDocument4 pagesContinental SIL99-1 PDFElmer VillegasNo ratings yet

- Cessna 206 AD ScheduleDocument25 pagesCessna 206 AD ScheduleElmer VillegasNo ratings yet

- Engine Operation Log Formula For Calculation of Equivalent CyclesDocument1 pageEngine Operation Log Formula For Calculation of Equivalent CyclesElmer VillegasNo ratings yet

- Continental SIL99-1 PDFDocument4 pagesContinental SIL99-1 PDFElmer VillegasNo ratings yet

- Copper Alloys and Their PropertiesDocument39 pagesCopper Alloys and Their Properties1209540046No ratings yet

- Cartas de IsocorrosiónDocument4 pagesCartas de IsocorrosiónOliiroy Cruz TormenNo ratings yet

- Industrial Building Components and PEB Systems ExplainedDocument9 pagesIndustrial Building Components and PEB Systems ExplainedSharon Shine100% (1)

- Inosindt Seamless Tubes 22Document40 pagesInosindt Seamless Tubes 22fawad_kazNo ratings yet

- Rubber Pad FormingDocument11 pagesRubber Pad FormingvelavansuNo ratings yet

- E428Document6 pagesE428valentinNo ratings yet

- Steel Forgings For Pressure PurposesDocument18 pagesSteel Forgings For Pressure PurposesnikolicjelenaNo ratings yet

- API Schmidt BrettenDocument28 pagesAPI Schmidt Brettenvictor abrajan100% (1)

- Case Hardening Alloy Steel Bar 6587Document3 pagesCase Hardening Alloy Steel Bar 6587CelsoNo ratings yet

- Electrical Grounding System Safety GuideDocument24 pagesElectrical Grounding System Safety Guidemrfawad100% (1)

- Technical Specification FOR 220Kv Isolators: Gujarat State Electricity Corporation LTDDocument22 pagesTechnical Specification FOR 220Kv Isolators: Gujarat State Electricity Corporation LTDVelu SamyNo ratings yet

- Stainless Steel For Bridge ApplicationDocument57 pagesStainless Steel For Bridge ApplicationDtscNo ratings yet

- Investigatory Project (Clay As Source of Electricity)Document13 pagesInvestigatory Project (Clay As Source of Electricity)jhozepmendoza83% (6)

- 830 SpecDocument2 pages830 Specmonarchy1103No ratings yet

- Element of Machines Dsign, LEUTWILER, 1917Document636 pagesElement of Machines Dsign, LEUTWILER, 1917Achmad ShobirienNo ratings yet

- Everything You Need to Know About Iron-Carbon Phase DiagramsDocument13 pagesEverything You Need to Know About Iron-Carbon Phase DiagramsAbhishek SakatNo ratings yet

- สไตลัสเรนิชอร์สำหรับ เครื่อง Carl Zeiss: Renishaw Stylus for Zeiss CatalogsDocument36 pagesสไตลัสเรนิชอร์สำหรับ เครื่อง Carl Zeiss: Renishaw Stylus for Zeiss CatalogsRenishaw-ThaiNo ratings yet

- Astm B 505 PDFDocument8 pagesAstm B 505 PDFprodn123No ratings yet

- Caster PDFDocument2 pagesCaster PDFRatko KečaNo ratings yet

- Special Metals - Product CatalogDocument65 pagesSpecial Metals - Product Catalogilham_metallurgy6744No ratings yet

- LAB Manual PDFDocument35 pagesLAB Manual PDFAbhinav Shukla100% (1)

- Weifang East Steel Pipe Co., LTDDocument8 pagesWeifang East Steel Pipe Co., LTDdfpjliuNo ratings yet

- Expanded MetalDocument2 pagesExpanded Metalebastien2No ratings yet

- Rule of Mixing CompositeDocument30 pagesRule of Mixing CompositeFaiq El100% (1)

- Design of Power ScrewsDocument19 pagesDesign of Power ScrewsSOURAV JADHAVNo ratings yet

- Welding WorkshopDocument43 pagesWelding WorkshopJasmeet KaurNo ratings yet

- Erdemir Product Catalogue 2017Document334 pagesErdemir Product Catalogue 2017Burak Kececi0% (1)

- RKG University Corrosion Inhibitors TestDocument3 pagesRKG University Corrosion Inhibitors Testalphamale3No ratings yet

- Locking DevicesDocument28 pagesLocking Devicesraj mohan100% (1)

- 6-12-0006 Rev 5Document7 pages6-12-0006 Rev 5cynideNo ratings yet