Professional Documents

Culture Documents

Cost to Run a Waterjet Machine

Uploaded by

Anonymous VRspXsmOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cost to Run a Waterjet Machine

Uploaded by

Anonymous VRspXsmCopyright:

Available Formats

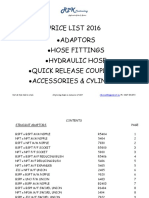

180 South Ave./P.O.Box 517, Tallmadge, Ohio 44278 USA www.wardjet.

com

Phone: (330) 677-9100 Fax: (330) 677-9121 Email: sales@wardjet.com

Hourly Cost to Run A Waterjet

There are several items to keep in mind when looking at the cost per hour to run a waterjet. These

costs should be relatively universal regardless of the manufacturer of your waterjet. When we provide

costs to our customers we always give a conservative target, which we believe can actually be

achieved. We don’t have any commissioned sales people; therefore no one here is going to give you

an overly optimistic best-case scenario with regards to the cost to run your machine. Our goal is to see

you succeed with your machine, not just to sell one to you. We are focused on what is best for you, not

what is best for WARDJet. Talk with us and test us out.

Keep in mind that a waterjet manufacturer, whose survival is dependent upon commissioned sales

people convincing you to purchase their product, tends to be swayed in their presentation of waterjets.

They may describe it as the only ideal, perfect, lowest cost, sole solution to both your engineering as

well as your life’s problems. We all know at the end of the day the waterjet is just a tool to help you

succeed in your business goals.

The facts are the same regardless of manufacturer:

• Fact: Abrasive is not supplied by the waterjet company and is the largest consumable cost.

• Fact: The abrasive flow rate is determined by the size of your pump, not the manufacturer.

• Fact: You should plan on your ruby orifice lasting approx 40 hrs – sales people may say 80 hrs.

• Fact: You should plan on a diamond orifice lasting approx 500 hrs – sales people may say

1,000 hrs.

• Fact: You should be conservative when calculating your cost. If there is not enough room to add

$10 or more to your operating cost - then waterjet may not be your best option.

For example, you determine your operating cost using the chart below to be $60/hr, then later discover that actual

operating cost is $70/hr. If that extra $10 means the difference between profit and loss for your company, then

maybe a waterjet is not the right answer for your business...

To calculate your costs per hour follow the steps below:

1. Select the pump size and approx cost per lb. of abrasive you will be using.

25 hp 30 hp 50 hp

Flow Rate .6 lbs/min .8 lbs/min 1.4 lbs/min

Abrasive cost

$0.15/min $0.19/min $0.34/min

low $0.24/lb

Abrasive cost

$0.25/min $0.34/min $0.59/min

high $0.42/lb

NOT JUST A WATERJET…

2. Find the chart for your pump type and determine how many minutes per hour you

actually plan to be cutting. Use the pink line if you are using abrasive costing around

$0.35/lb. or the blue line if using abrasive costing around $0.18/lb. This will give you

your abrasive cost per hour.

NOT JUST A WATERJET…

3. Take the cost of your abrasive per hour and plug it in to the chart below. Add all of the

items in the far right hand column including your abrasive amount to generate your total

cost per hour to run the machine.

Price Breakdown Per Hour

Orifices $14-20 Lasts 40 hrs $0.50/hr

Nozzles $85 Last 80 hrs $1.00/hr

Inserts $155 Last 400 hrs $0.39/hr

High Pressure $81 Last 250 hrs to $0.32/hr

Seals 1000 hrs

Low Pressure $100 Last 5000-10,000 $0.02/hr

Seals hrs

Power 50 HP pump $0.10/kw hour $4/hr

Water 50 HP pump Estimate based on $2/hr

avg.

Abrasive $0.35 to $0.18 25 HP, 30 HP, Insert value from

per lb. or 50 HP chart

General Repairs Grate $4/hr

Replacement,

Dropped Nozzles

(General Real

World Issues)

Operator Insert value

Capital (Monthly payment) Insert value

Total: $12.23

+ abrasive

+ operator

+ capital repayment

NOT JUST A WATERJET…

You might also like

- Actg Lab 6Document12 pagesActg Lab 6RAJA ZARRAR100% (1)

- Jola PublishingDocument4 pagesJola PublishingSabrina LaganàNo ratings yet

- Save With Robb Jack ToolsDocument1 pageSave With Robb Jack ToolshuntserNo ratings yet

- Cost N ProdDocument17 pagesCost N ProdvinodkatariaNo ratings yet

- Philippine Asphalting CostDocument4 pagesPhilippine Asphalting CostBobby BaybayNo ratings yet

- Start Sugarcane BusinessDocument3 pagesStart Sugarcane BusinessAMINNo ratings yet

- Dhaka University of Engineering & Technology: Course Title: Course NoDocument7 pagesDhaka University of Engineering & Technology: Course Title: Course NoUnjila PromiNo ratings yet

- Accounting For Direct MaterialsDocument5 pagesAccounting For Direct MaterialsAyb SysiangcoNo ratings yet

- Creating Your Dream Business 2 - Break Even Point HonorsDocument3 pagesCreating Your Dream Business 2 - Break Even Point Honorsapi-657656552No ratings yet

- Cold Milling Rate AnalysisDocument8 pagesCold Milling Rate AnalysisJahanzeb KhanNo ratings yet

- Calculate The Total Variance For Labor For The Month The StandardDocument1 pageCalculate The Total Variance For Labor For The Month The StandardMiroslav GegoskiNo ratings yet

- Introduction To EconomicsDocument5 pagesIntroduction To EconomicsSanjeev NehruNo ratings yet

- Cost of Owning and Operating Constructio PDFDocument10 pagesCost of Owning and Operating Constructio PDFsunleon31No ratings yet

- ABC Costing Reveals Losses from PURPLE and RED PensDocument5 pagesABC Costing Reveals Losses from PURPLE and RED PensbharathtgNo ratings yet

- BUDGET SG CHERATING Rev 1Document1 pageBUDGET SG CHERATING Rev 1Tong SepamNo ratings yet

- Bicos - Sprying SystemsDocument44 pagesBicos - Sprying SystemsbafileNo ratings yet

- Prefeasibility Study For Nordberg MineDocument32 pagesPrefeasibility Study For Nordberg Minezhen zhangNo ratings yet

- Problem DefinitionDocument4 pagesProblem DefinitionDiksha SinghNo ratings yet

- Skasale Co - LTD. (00025532) Car: Honda PCX 150Document1 pageSkasale Co - LTD. (00025532) Car: Honda PCX 150Iurii SinnerNo ratings yet

- Accounting For Decision Making and Control 8th Edition Zimmerman Solutions ManualDocument26 pagesAccounting For Decision Making and Control 8th Edition Zimmerman Solutions ManualSandraHensonbtwd100% (47)

- Calculating Mach Op Costs PDFDocument23 pagesCalculating Mach Op Costs PDFSaira UsmanNo ratings yet

- Deciding Appropriate Water Rate: Karauli CityDocument30 pagesDeciding Appropriate Water Rate: Karauli CityShashank BahiratNo ratings yet

- Packaging Equipment ROI Calculator v2018Document4 pagesPackaging Equipment ROI Calculator v2018pangregisterlang99No ratings yet

- Car Wash Capacity Analysis Recommends One Wash LineDocument3 pagesCar Wash Capacity Analysis Recommends One Wash LineAthahNo ratings yet

- Dwnload Full Accounting For Decision Making and Control 8th Edition Zimmerman Solutions Manual PDFDocument36 pagesDwnload Full Accounting For Decision Making and Control 8th Edition Zimmerman Solutions Manual PDFdietzbysshevip813100% (13)

- Indian Institute of Management Kozhikode Post Graduate Program PGP 25Document5 pagesIndian Institute of Management Kozhikode Post Graduate Program PGP 25Chirayu VijaywargiyaNo ratings yet

- Effective CNG logistics drive Indonesian industry costs lowerDocument32 pagesEffective CNG logistics drive Indonesian industry costs lowerEis NovidhaNo ratings yet

- Source Launch VALUE 300 PLUS Same VALUE500 PLUS R1234YF&R134 Refrigerant Machine OnDocument1 pageSource Launch VALUE 300 PLUS Same VALUE500 PLUS R1234YF&R134 Refrigerant Machine OnhasbulohNo ratings yet

- Financial PlanDocument9 pagesFinancial PlanMaather AlabriNo ratings yet

- Save $30 Flying to Visit a FriendDocument4 pagesSave $30 Flying to Visit a FriendLê Tuấn AnhNo ratings yet

- Instructions - Managerial Capstone-KeaneDocument4 pagesInstructions - Managerial Capstone-KeaneAhmed MahmoudNo ratings yet

- Production Technical Aspects of Ice Cream BusinessDocument22 pagesProduction Technical Aspects of Ice Cream BusinessMarvin GamboaNo ratings yet

- Sunair Boat BuildersDocument9 pagesSunair Boat BuildersWei DaiNo ratings yet

- Interactive budget instructionsDocument3 pagesInteractive budget instructionsmealysrNo ratings yet

- Planta DosificadoraDocument2 pagesPlanta DosificadoraOCIEL VALDIVIANo ratings yet

- Ooc HD785-7Document1 pageOoc HD785-7ErwinLBudiNo ratings yet

- Chapter 4 decision making guideDocument28 pagesChapter 4 decision making guideranjithaNo ratings yet

- MFA - Assignment 2: Management and Financial Accounting - Individual Assignment 2Document9 pagesMFA - Assignment 2: Management and Financial Accounting - Individual Assignment 2Mohan sunderNo ratings yet

- Service Charges PDFDocument2 pagesService Charges PDFnasr yassinNo ratings yet

- Mist EliminatorDocument4 pagesMist Eliminatorherysyam1980No ratings yet

- Factors Affecting The Cost Include:: Cost of Owning and Operating Construction EquipmentDocument11 pagesFactors Affecting The Cost Include:: Cost of Owning and Operating Construction EquipmentManny AnsariNo ratings yet

- Budget Estimation WorksheetDocument3 pagesBudget Estimation WorksheetMary Joy A. FrancoNo ratings yet

- A Level Accounting Topic 2 Even AnswersDocument17 pagesA Level Accounting Topic 2 Even AnswersMishal ZainabNo ratings yet

- Gross Margin Analysis - Example 1 - Wheat - 1Document1 pageGross Margin Analysis - Example 1 - Wheat - 1Noah NgenyNo ratings yet

- SM - Sec A - Group 5 - PMDocument6 pagesSM - Sec A - Group 5 - PMAnirudh SinghNo ratings yet

- ADMC Practice Problems - Accounting For Decision Making and Control 10th EditionDocument17 pagesADMC Practice Problems - Accounting For Decision Making and Control 10th EditionDaveNo ratings yet

- FS Flip Calculator Free V1.3Document5 pagesFS Flip Calculator Free V1.3karlmehu28No ratings yet

- Budget Estimation WorksheetDocument3 pagesBudget Estimation WorksheetMary Joy A. FrancoNo ratings yet

- Air Treatment - Filter Selection Cost Analysis Ed03Document6 pagesAir Treatment - Filter Selection Cost Analysis Ed03GabrielSanchezMtzNo ratings yet

- Engineering Economy 16th Edition Sullivan Test BankDocument5 pagesEngineering Economy 16th Edition Sullivan Test BankThomas Seamon100% (40)

- Hidden Compressor ProblemsDocument6 pagesHidden Compressor ProblemsLahouari FatahNo ratings yet

- Environment One Corporation Pressure Sewer Preliminary Cost and Design Analysis For APIDocument5 pagesEnvironment One Corporation Pressure Sewer Preliminary Cost and Design Analysis For APIdiego alberto perez torreNo ratings yet

- Estimate Owning and Operating Costs: Standard BucketDocument1 pageEstimate Owning and Operating Costs: Standard BucketMartha PratamaNo ratings yet

- ExplainationsDocument4 pagesExplainationssadat.anontoNo ratings yet

- Alat Dan Bahan DSSCDocument1 pageAlat Dan Bahan DSSCTeguh ArifinNo ratings yet

- Rate of ReturnDocument17 pagesRate of ReturnAkash MukherjeeNo ratings yet

- Crunchy ChipsDocument4 pagesCrunchy ChipsMae BalandanNo ratings yet

- Paper Cup Making MachineDocument4 pagesPaper Cup Making Machinesmail brihmatNo ratings yet

- Cost & Managerial Accounting II EssentialsFrom EverandCost & Managerial Accounting II EssentialsRating: 4 out of 5 stars4/5 (1)

- Forging Die Design For Gear BlankDocument4 pagesForging Die Design For Gear BlankAnonymous kw8Yrp0R5rNo ratings yet

- Welding Cost Estimation For 12 Joints in 8 NPS SCH 80 PDFDocument1 pageWelding Cost Estimation For 12 Joints in 8 NPS SCH 80 PDFAnonymous VRspXsmNo ratings yet

- Forging Die Design For Gear BlankDocument4 pagesForging Die Design For Gear BlankAnonymous kw8Yrp0R5rNo ratings yet

- MM Reference Guide 2016Document72 pagesMM Reference Guide 2016InaamNo ratings yet

- KMT Orifice-Cutting Speeds DataDocument1 pageKMT Orifice-Cutting Speeds DataAnonymous VRspXsmNo ratings yet

- Machining Time Required For Taper Grinding and Its Cost Analysis in G17-22U Grinding MachineDocument5 pagesMachining Time Required For Taper Grinding and Its Cost Analysis in G17-22U Grinding MachineAnonymous VRspXsmNo ratings yet

- Fulfill Instructions Quotation Analysis FormDocument5 pagesFulfill Instructions Quotation Analysis FormAnonymous VRspXsmNo ratings yet

- KMT Orifice-Cutting Speeds Data PDFDocument2 pagesKMT Orifice-Cutting Speeds Data PDFAnonymous VRspXsmNo ratings yet

- An Integrated Framework For Die and Mold Cost Estimation Using Design Features and Tooling ParametersDocument12 pagesAn Integrated Framework For Die and Mold Cost Estimation Using Design Features and Tooling ParametersAnonymous VRspXsmNo ratings yet

- Fulfill Instructions Quotation Analysis FormDocument5 pagesFulfill Instructions Quotation Analysis FormAnonymous VRspXsmNo ratings yet

- Machining Time Required For Taper Grinding and Its Cost Analysis in G17-22U Grinding MachineDocument5 pagesMachining Time Required For Taper Grinding and Its Cost Analysis in G17-22U Grinding MachineAnonymous VRspXsmNo ratings yet

- Fulfill Instructions Quotation Analysis FormDocument2 pagesFulfill Instructions Quotation Analysis FormAnonymous VRspXsm100% (1)

- DimensionsDocument22 pagesDimensionsanmol6237No ratings yet

- Section 2 Tooling Fo Die Casting OptDocument22 pagesSection 2 Tooling Fo Die Casting OptAnonymous VRspXsmNo ratings yet

- Fulfill Instructions Quotation Analysis FormDocument5 pagesFulfill Instructions Quotation Analysis FormAnonymous VRspXsmNo ratings yet

- CUTTING DATA RECOMMENDATIONS FOR TURNING AND MILLING UDDEHOLM RAMAX HHDocument6 pagesCUTTING DATA RECOMMENDATIONS FOR TURNING AND MILLING UDDEHOLM RAMAX HHAnonymous VRspXsmNo ratings yet

- Section 2 Tooling Fo Die Casting OptDocument22 pagesSection 2 Tooling Fo Die Casting OptAnonymous VRspXsmNo ratings yet

- Cutting Data Ramax HH EngDocument7 pagesCutting Data Ramax HH EngAnonymous VRspXsmNo ratings yet

- Principle of Powder Metallurgy PDFDocument10 pagesPrinciple of Powder Metallurgy PDFAnonymous VRspXsmNo ratings yet

- Book 1Document2 pagesBook 1Anonymous VRspXsmNo ratings yet

- 1000 names of Vishnu from Vishnu SahasranamaDocument40 pages1000 names of Vishnu from Vishnu SahasranamaAnonymous VRspXsmNo ratings yet

- CUTTING DATA RECOMMENDATIONS FOR TURNING AND MILLING UDDEHOLM RAMAX HHDocument6 pagesCUTTING DATA RECOMMENDATIONS FOR TURNING AND MILLING UDDEHOLM RAMAX HHAnonymous VRspXsmNo ratings yet

- EML2322L-Tolerances Vs ProcessDocument7 pagesEML2322L-Tolerances Vs ProcessAnonymous VRspXsmNo ratings yet

- CUTTING DATA RECOMMENDATIONS FOR TURNING AND MILLING UDDEHOLM RAMAX HHDocument6 pagesCUTTING DATA RECOMMENDATIONS FOR TURNING AND MILLING UDDEHOLM RAMAX HHAnonymous VRspXsmNo ratings yet

- Ring Gear Blank Case BriefDocument6 pagesRing Gear Blank Case BriefAnonymous VRspXsmNo ratings yet

- r2k Contracting Price List 2016Document129 pagesr2k Contracting Price List 2016Anonymous VRspXsmNo ratings yet

- LangeDocument13 pagesLangeAnonymous VRspXsmNo ratings yet

- CastingDocument18 pagesCastingAnonymous VRspXsmNo ratings yet

- 7 Shpaper PlanerDocument29 pages7 Shpaper PlanerfamilyumaNo ratings yet

- Sprint Capacity Planner 27 NovDocument11 pagesSprint Capacity Planner 27 NovAnonymous VRspXsmNo ratings yet

- Outbound LogisticsDocument7 pagesOutbound LogisticschandugaNo ratings yet

- 2019 Labor Law Bar Q and ADocument9 pages2019 Labor Law Bar Q and AFranz Montero IIINo ratings yet

- Hurst Signals - Introducing The FLD Trading StrategyDocument7 pagesHurst Signals - Introducing The FLD Trading StrategyvewejNo ratings yet

- Trade Map - List of Importers For The Selected Product in 2017 (Tomatoes Fresh or Chilled)Document7 pagesTrade Map - List of Importers For The Selected Product in 2017 (Tomatoes Fresh or Chilled)Jose RuizNo ratings yet

- BTEC Level 4 HND Diploma in Business Assignment 2 Front SheetDocument57 pagesBTEC Level 4 HND Diploma in Business Assignment 2 Front SheetQuỳnh Anh KaliasaNo ratings yet

- VDA 6 - 3 Questionnaire Summary of Changes PDFDocument6 pagesVDA 6 - 3 Questionnaire Summary of Changes PDFAnonymous CW8L9FkuNo ratings yet

- Sun and Earth Corporation: Notes To The Financial Statements-AmendedDocument57 pagesSun and Earth Corporation: Notes To The Financial Statements-AmendedBeatrice ReynanciaNo ratings yet

- Green MarketingDocument12 pagesGreen MarketingNadeem GanaiNo ratings yet

- Transportation Elasticities: How Prices and Other Factors Affect Travel BehaviorDocument60 pagesTransportation Elasticities: How Prices and Other Factors Affect Travel BehaviorFrancisco GranadosNo ratings yet

- Human Behav and Emerg Tech - 2019 - Zhao - Technology and Economic Growth From Robert Solow To Paul RomerDocument4 pagesHuman Behav and Emerg Tech - 2019 - Zhao - Technology and Economic Growth From Robert Solow To Paul RomerRizki AlfebriNo ratings yet

- Financial ScandalsDocument26 pagesFinancial ScandalsReina Nina Camano25% (4)

- CH 6 & CH 7 John R. Schermerhorn - Management-Wiley (2020)Document10 pagesCH 6 & CH 7 John R. Schermerhorn - Management-Wiley (2020)Muhammad Fariz IbrahimNo ratings yet

- OBrien MIS Map1Document25 pagesOBrien MIS Map1Ali KhandanNo ratings yet

- Blade Inc Case Assessment Government On Exchange RateDocument7 pagesBlade Inc Case Assessment Government On Exchange RateNguyễn Linh TrangNo ratings yet

- Investment Declaration ManualDocument10 pagesInvestment Declaration ManualAbhinav VivekNo ratings yet

- Security Bank Credit Card Supplementary FormDocument3 pagesSecurity Bank Credit Card Supplementary FormRBCD INDUSTRIAL SUPPLYNo ratings yet

- Philippine Development Plan 2017-2022: Chapter 20: Ensuring EcologicalDocument21 pagesPhilippine Development Plan 2017-2022: Chapter 20: Ensuring EcologicalimanolkioNo ratings yet

- Warid Telecom's History, Services and PartnershipDocument30 pagesWarid Telecom's History, Services and PartnershipMakkia ShaheenNo ratings yet

- Final Requirement in BAM 242Document55 pagesFinal Requirement in BAM 242bluer thanblueNo ratings yet

- Women and Banks Are Female Customers Facing Discrimination?Document29 pagesWomen and Banks Are Female Customers Facing Discrimination?Joaquín Vicente Ramos RodríguezNo ratings yet

- International Master Franchise Agreement Cross-BorderDocument62 pagesInternational Master Franchise Agreement Cross-BorderIlya100% (1)

- Investment Banking Spring 2021 Case Study #1 Mercury Athletic Footwear: Valuing The OpportunityDocument3 pagesInvestment Banking Spring 2021 Case Study #1 Mercury Athletic Footwear: Valuing The OpportunityRavi PatelNo ratings yet

- Distribution Strategies: Calyx & Corolla: MARK4210: Strategic Marketing 2014 Spring, Section L1/L2Document19 pagesDistribution Strategies: Calyx & Corolla: MARK4210: Strategic Marketing 2014 Spring, Section L1/L2prakshiNo ratings yet

- The Main Principles of Total Quality Management: Andrei DiamandescuDocument7 pagesThe Main Principles of Total Quality Management: Andrei DiamandescuipraoNo ratings yet

- PWC Global Project Management Report SmallDocument40 pagesPWC Global Project Management Report SmallDaniel MoraNo ratings yet

- Gold Standard and Bretton Woods SystemsDocument39 pagesGold Standard and Bretton Woods SystemsChintakunta PreethiNo ratings yet

- Discussion Problems: FAR.2831-Leases MAY 2020Document13 pagesDiscussion Problems: FAR.2831-Leases MAY 2020Eira ShaneNo ratings yet

- Hire Purchase System: Presidency CollegeDocument9 pagesHire Purchase System: Presidency CollegeNoor ameenaNo ratings yet

- Protect Your Family's Future with Customisable Term Insurance OptionsDocument6 pagesProtect Your Family's Future with Customisable Term Insurance Optionsprudhvi guddetiNo ratings yet

- BMCDocument8 pagesBMCSureshkumar VelusamyNo ratings yet