Professional Documents

Culture Documents

5to25 4GTSM

Uploaded by

ecsuperal0 ratings0% found this document useful (0 votes)

18 views14 pagesGTSM

Original Title

5TO25.4GTSM

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentGTSM

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

18 views14 pages5to25 4GTSM

Uploaded by

ecsuperalGTSM

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 14

Jubail Export Refinery

igi

Bios Engineering Standards an

RSW | Wangnequenenseronatrone | zAovi0

Request FOR WELDWVG PROCEDURE APPROVAL mee

|fireasnes te owing wear reesresechnson Ws] be reves and pro

= = ART

Ermamesnt aie monte fa

Freemason anos

aoe fern

a ST -|

St Gees cae

“Submitng aba Export alinery Organon

pate:_22 vow zero

Deparment: Svat SEPT

grate: Dam Attra pe. ace Goseit|

elephonest EGS Slug <3 sous ied one i

dake Sale ese TARGA Oe/agn Kee

‘onsiuion Guay Team Roproval

frame Unit/Di/ Dept 2

[erature es

Welding Procedure Specification

wes) —

pret Cecrmsloner vane easyer cri aa eee oe

= corse

= oe

{ASE METALS QW)

eile age— GROONE: Same

sce fue ostTiON (Qu)

Pedi aw Pri e aw

be Wataetmeenee: UP ow

PRENEAT(QW-406)

FLAK MEALS ow .

"POST WELD EAT TREATMENT (W407)

rage: Grove E) crtsem in St sin | to Rae wa

cn Name a See

rai et / sata Seon on

cae ne 2 ane Amn) 9910-20

wasLaet| Pe : = Tear | ten

ets ‘Welding Procedure Specifies

aa (vrs)

TPLECTRICAL CHARACTERISTICS QW)

aren iAC 90) cor-pc.sM:0C | Tanptelerte Se

cp CH) Here We Fed Sed Rage A

"TECHMTQUE OW

Suing oe ene oui) | Medea Cane sove

os and eps Clarn_Brusing i Grin “

a os Saher Maines __ SINGLE

TUFF mt TE WELD DEPOSIT

= QW. MUISING CURRENT AND IMPACT TEST

a a

= a

oo

ssatates Sip | Prete contention Record] as

(QR) sin er

PORN. Pre,

Welter) a Dee

vemn | Bewede | Sue Aap | Va

Cee tom

4

cd

"DASE METALS (QW) | Post WELD HEAT TREATMENT OWA

al Se srs von | Tenpeatee NONE

‘hpeeeGrte —

‘Thickness of Tes Coupon 27 en

‘eas (ow-48)

Diamar Teton Bt

cule Pact Congo Flow Rae

ALLER METALS (QW) : =

Biching _Aryon_—_9059% —-200min

AwScinsiaton IGOHL, E5016 ELECTRICAL CHARACTERISTICS (QW03)

Dep WelMeol GT 438M am - :

ale ‘EcHNIQUE @w-At9

: _ Sg ree Bead

POSITION (QW Orion

ein free Malin Sige Pe

_WedPpein Siecr Maile caer

PREHEAT QN-09

‘Semsung Enginearing Ga Li

cagite Procedure Qualifica

aa (PQR)

owt -

spenme wth) | ten | ec) et int Tea

eee

gare

"TOUGHNESS TESTS (QUIT NA

Nes Sect Tet | tmp tel

srcimeNes penn Seinen Temp), aes 1) 98h Ms

"FILLET WELD TEST QW-IN NA

dns Tent¥0) ssn ana, az 183.226, was 7.20

Mae te SATISFACTORY GULL SECTION)

Soot =o

TerConlased By MMos AHS HOH SEC

hl etme bl oe a ae et el eer wel and ek

‘Saco wh he oto of Stn te ASME Coe,

Des anannceene 7 G A

AL HOTY-STANGER ‘SAMSUNG ENGINEERING eee

= TENSILE & BEND TESTING fares

‘A TENSILE TORTS REBUT

Teweipeanerte Bae

rm 0-00 arian

_ et wom

Te Speck 7a

see ae

9. 2

[AL HOTY-STANGER | eee ree ee

ss

+ weer | wo | tL ASME | ome |

ba eet fecal

[oo [aie [OT | aigtie |

a

a

[AL HOTY-STANGER

“SAMSUNG ENGINEERING es

Sesieen

ERB Suit Koreon Inspection &

SB Testing Co. Lied

RADIOGRAPHIC EXAMINATION REPORT = sdk de

Jeo se cone owemaanae ESS.

a veneer Oy ee

g

— _—=—™—.

See owe Bed sn Bevo oon Ba

ee Be ae

vs Boowersce | Owner Bl Bear Bt Br

aera — lore fren am

“as as re Fa

On

Dawe

Bane san Toda so

8086

ena #0

“|

Bleverousn

Di wmesseo ae

Crewe sr

(Gult_ Korean inapection &

GBS Testing Co Lie

RADIOGRAPHIC EXAMINATION REPORT

aes

wa

rite |

Ppa

= ee ar

cB

8

women > cee S

2 se ra)

Me ieae some i

_ a

You might also like

- Power House 1Document1 pagePower House 1ecsuperalNo ratings yet

- Power HouseDocument1 pagePower HouseecsuperalNo ratings yet

- Hydro Sample Site PlanDocument1 pageHydro Sample Site PlanecsuperalNo ratings yet

- Ambient Noise Level Std.Document1 pageAmbient Noise Level Std.ecsuperalNo ratings yet

- Dam & DesanderDocument1 pageDam & DesanderecsuperalNo ratings yet

- Alstom HP 1103 PerformanceDocument2 pagesAlstom HP 1103 PerformanceecsuperalNo ratings yet

- Copper Water and Gas Tube According ASTM B 88 - Imperial UnitsDocument3 pagesCopper Water and Gas Tube According ASTM B 88 - Imperial UnitsecsuperalNo ratings yet

- BS4504 PN 16 Flange DimensionsDocument3 pagesBS4504 PN 16 Flange DimensionsecsuperalNo ratings yet

- Electrical Test Sheet: Ele/Tss/At 300 X Commissioning E 4Document18 pagesElectrical Test Sheet: Ele/Tss/At 300 X Commissioning E 4ecsuperalNo ratings yet

- Electrical Test Sheet: Standard For Combined Cycle Power PlantDocument26 pagesElectrical Test Sheet: Standard For Combined Cycle Power PlantecsuperalNo ratings yet

- Central Philippine University College of Engineering SECOND SEMESTER S.Y. 2005-2006 Work Term ReportDocument17 pagesCentral Philippine University College of Engineering SECOND SEMESTER S.Y. 2005-2006 Work Term ReportecsuperalNo ratings yet

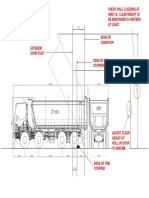

- Dump Truck IllustrationDocument1 pageDump Truck IllustrationecsuperalNo ratings yet

- 哈尔滨汽轮机厂有限责任公司指导性技术文件 Harbin Turbine Company Limited Guiding Technical DocumentDocument18 pages哈尔滨汽轮机厂有限责任公司指导性技术文件 Harbin Turbine Company Limited Guiding Technical DocumentecsuperalNo ratings yet

- Request For Welding Procedure ApprovalDocument13 pagesRequest For Welding Procedure ApprovalecsuperalNo ratings yet

- Request For Welding Procedure ApprovalDocument18 pagesRequest For Welding Procedure Approvalecsuperal100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)