Professional Documents

Culture Documents

en-US 7443

Uploaded by

gregOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

en-US 7443

Uploaded by

gregCopyright:

Available Formats

PRODUCT DATA SHEET November 30, 2016 (Revision of November 3, 2016)

SIGMAGUARD™ CSF 650 / AMERCOAT® CSF 650

DESCRIPTION

Two-component, solvent-free, amine-cured epoxy coating

PRINCIPAL CHARACTERISTICS

• Tank coating for crude oil/ballast and aliphatic petroleum products

• Also suitable as a coating system for the storage and transportation of drinking water

• Good resistance to various chemicals

• One-coat protection for steel structures, ships and storage tanks with excellent corrosion resistance

• Can be applied by heavy-duty, single-feed, airless spray equipment (60:1)

• Reduced explosion risk and fire hazard

• Good visibility due to light color

• Also, a conductive version is available ; SigmaGuard CSF 660

• Can be reinforced with chopped glass fiber or mat

• Clear version for glass-mat reinforced, solvent-free tank bottom system (see SYSTEM SHEET 4144)

• Meets the requirements of EI 1541 (coating systems for aviation fuel storage tanks and pipes)

• Excellent resistance to crude oil up to 60°C (140°F)

COLOR AND GLOSS LEVEL

• Green, offwhite, clear

• Gloss

BASIC DATA AT 20°C (68°F)

Data for mixed product

Number of components Two

Mass density 1.3 kg/l (10.8 lb/US gal)

Volume solids 100%

VOC (Supplied) Directive 1999/13/EC, SED: max. 109.0 g/kg

max. 143.0 g/l (approx. 1.2 lb/US gal)

EPA Method 24: 120.0 g/ltr (1.0 lb/USgal)

Recommended dry film thickness 300 - 600 µm (12.0 - 24.0 mils) depending on system

Theoretical spreading rate 3.3 m²/l for 300 µm (134 ft²/US gal for 12.0 mils)

Dry to touch 8 hours

Overcoating Interval Minimum: 24 hours

Maximum: 20 days

Full cure after 5 days

Ref. 7443 Page 1/6

PRODUCT DATA SHEET November 30, 2016 (Revision of November 3, 2016)

SIGMAGUARD™ CSF 650 / AMERCOAT® CSF 650

Data for mixed product

Shelf life Base: at least 24 months when stored cool and dry

Hardener: at least 24 months when stored cool and dry

Notes:

- See ADDITIONAL DATA – Spreading rate and film thickness

- See ADDITIONAL DATA – Overcoating intervals

- See ADDITIONAL DATA – Curing time

RECOMMENDED SUBSTRATE CONDITIONS AND TEMPERATURES

Substrate conditions

• Steel; blast cleaned to ISO-Sa2½, blasting profile 50 – 100 µm (2.0 – 4.0 mils)

• Suitable primer; SIGMAGUARD 260, SIGMACOVER 280, SIGMAPRIME series or SIGMACOVER 522, depending on system

requirements

• Steel; power tooling to ISO-St3 for small and isolated areas (like repairs and joint welds) in fresh water and potable water

tanks where spot blasting might be impractical

Substrate temperature and application conditions

• Substrate temperature during application and curing should be above 5°C (41°F)

• Substrate temperature during application should be at least 3°C (5°F) above dew point

SYSTEM SPECIFICATION

• SIGMAGUARD CSF 650: 1 x 300 µm (12.0 mils); or a suitable primer of 50 µm (2.0 mils) + SIGMAGUARD CSF 650: 1 x 250

µm (10.0 mils)

INSTRUCTIONS FOR USE

Mixing ratio by volume: base to hardener 80:20 (4:1)

• At lower temperature, the viscosity will be too high for spray application

• For recommended application instructions, see working procedure

• The temperature of the mixed base and hardener should preferably be above 20°C (68°F)

• No thinner should be added

Induction time

None

Pot life

1 hour at 20°C (68°F)

Note: See ADDITIONAL DATA – Pot life

Ref. 7443 Page 2/6

PRODUCT DATA SHEET November 30, 2016 (Revision of November 3, 2016)

SIGMAGUARD™ CSF 650 / AMERCOAT® CSF 650

Airless spray

• Use heavy-duty, single-feed, airless spray equipment, preferably 60:1 pump ratio and suitable high-pressure hoses/in-line

heating or insulated hoses may be necessary to avoid cooling down of paint in hoses at low air temperature

• Application with 45:1 airless spray equipment is possible, provided in-line, heated high-pressure hoses are used

• Length of hoses should be as short as possible

Recommended thinner

No thinner should be added

Nozzle orifice

Approx. 0.64 mm (0.025 in)

Nozzle pressure

At 20°C (68°F) paint temperature min. 28.0 MPa (approx. 280 bar; 4061 p.s.i.). At 30°C (86°F) min. 22.0 MPa (approx. 220 bar;

3191 p.s.i.)

Note: In case of using 45:1 airless spray equipment, the paint must be heated to approximately 30°C (86°F) in order to obtain the

right application viscosity

Brush/roller

Recommended thinner

For stripe coating and spot repair only, no thinner should be added

Cleaning solvent

THINNER 90-53 or THINNER 90-83

Notes:

- All application equipment must be cleaned immediately after use

- Paint inside the spraying equipment must be removed before the pot life has been expired

ADDITIONAL DATA

Spreading rate and film thickness

DFT Theoretical spreading rate

250 µm (10.0 mils) 4.0 m²/l (160 ft²/US gal)

300 µm (12.0 mils) 3.3 m²/l (134 ft²/US gal)

600 µm (24.0 mils) 1.7 m²/l (67 ft²/US gal)

Note: Maximum DFT when brushing: 200 µm (8.0 mils)

Ref. 7443 Page 3/6

PRODUCT DATA SHEET November 30, 2016 (Revision of November 3, 2016)

SIGMAGUARD™ CSF 650 / AMERCOAT® CSF 650

Measuring wet film thickness

• A difference is often obtained between the measured apparent WFT and the real applied WFT. This is due to the thixotropy

and the surface tension of the paint, which retards the release of air, trapped in the paint film for some time

• A practical recommendation is to apply a WFT, which is equal to the specified DFT plus 60 µm (2.4 mils)

Measuring dry film thickness

• Because of low initial hardness the DFT cannot be measured within some days, due to the penetration of the measuring

device into the soft paint film

• The DFT should be measured using a calibration foil of known thickness placed in between the coating and the measuring

device

Overcoating interval for DFT up to 300 µm (12.0 mils)

Overcoating with... Interval 5°C (41°F) 10°C (50°F) 20°C (68°F) 30°C (86°F) 40°C (104°F)

itself Minimum 3.5 days 36 hours 24 hours 16 hours 12 hours

Maximum 20 days 20 days 20 days 14 days 7 days

Note: Surface should be dry and free from any contamination

Curing time for DFT up to 300 µm (12.0 mils)

Substrate temperature Dry to handle Full cure

5°C (41°F) 60 hours 15 days

10°C (50°F) 30 hours 7 days

20°C (68°F) 16 hours 5 days

30°C (86°F) 10 hours 3 days

40°C (104°F) 8 hours 48 hours

Notes:

- Adequate ventilation must be maintained during application and curing (please refer to INFORMATION SHEETS 1433 and 1434)

- For drinking water tanks, a tank wash should be carried out after full cure and before the tank goes into service

- When used as coating system for storage and transport of drinking water the recommended working and washing procedure should be

followed

Washing procedures

• The recommended washing procedure must be applied after completion of the application.

• Sufficient time for full-curing and ventilation must be allowed in accordance with the recommendations as stated in the

latest Product Data Sheets and working procedure.

• Always an adequate washing procedure should be followed.

• Several adequate washing procedures are available and may be used (see e.g. washing procedure described in relevant

certificate).

Ref. 7443 Page 4/6

PRODUCT DATA SHEET November 30, 2016 (Revision of November 3, 2016)

SIGMAGUARD™ CSF 650 / AMERCOAT® CSF 650

Example 1: Adequate washing procedure

• After full curing of the system as per the latest PDS, the tank should be filled completely with fresh tap water

• The fresh tap water should remain in the tanks at least 4 full days

• Afterwards all tank compartments such as inner hull sides, bottom and deck-heads etc. should be thoroughly washed using

high pressure water

• After washing, the tanks should be thoroughly drained

• After this procedure the tanks will be fit to carry drinking water

Example 2: Adequate washing procedure

• All personnel should wear watertight suits, boots and gloves properly cleaned with a sodium hypochlorite solution (1%

active chlorine per liter)

• All tank sides, bottom and deckheads etc. should be brush cleaned or high-pressure spray cleaned with 1% active chlorine

solution as above|note: this can also be done by butterworth washing

• All parts should be high pressure cleaned with tap water and tanks drained

• Concentrated active chlorine solution should be sprinkled on bottom; approx. 1 liter per 10 m² (1 quart per 100 ft²)

• Tanks should be filled with tap water to a depth of approx. 20 cm (8 inches) and the water should remain in the tank for at

least 2 hours (max. 24 hours)

• Tanks should be thoroughly flushed out with tap water

• Depending upon local regulations it may be necessary to take water samples, after filling tank completely, to check on

bacteria

• After this procedure the tanks will be fit to carry drinking water

Pot life (at application viscosity)

Mixed product temperature Pot life

20°C (68°F) 1 hour

30°C (86°F) 45 minutes

40°C (104°F) 25 minutes

Note: Due to exothermic reaction, temperature during and after mixing may increase

DISCLAIMER FOR STORAGE AND TRANSPORT OF DRINKING WATER:

• SIGMAGUARD CSF 650 is approved for purpose in accordance with the requirements of the relevant certificate

• PPG Protective & Marine Coatings does not accept any responsibility or liability for any odor, taste or contamination

imparted to the drinking water from the coatings or products retained in the coating

Ref. 7443 Page 5/6

PRODUCT DATA SHEET November 30, 2016 (Revision of November 3, 2016)

SIGMAGUARD™ CSF 650 / AMERCOAT® CSF 650

SAFETY PRECAUTIONS

• For paint and recommended thinners see INFORMATION SHEETS 1430, 1431 and relevant Material Safety Data Sheets

• Although this is a solvent-free paint, care should be taken to avoid inhalation of spray mist, as well as contact between the

wet paint and exposed skin or eyes

• Ventilation should be provided in confined spaces to maintain good visibility

• No solvent present; however, spray mist is not harmless, a fresh air mask should be used during spraying

WORLDWIDE AVAILABILITY

It is always the aim of PPG Protective and Marine Coatings to supply the same product on a worldwide basis. However, slight

modification of the product is sometimes necessary to comply with local or national rules/circumstances. Under these

circumstances an alternative product data sheet is used.

REFERENCES

• CONVERSION TABLES INFORMATION SHEET 1410

• EXPLANATION TO PRODUCT DATA SHEETS INFORMATION SHEET 1411

• SAFETY INDICATIONS INFORMATION SHEET 1430

• SAFETY IN CONFINED SPACES AND HEALTH SAFETY, EXPLOSION HAZARD – INFORMATION SHEET 1431

TOXIC HAZARD

• SAFE WORKING IN CONFINED SPACES INFORMATION SHEET 1433

• DIRECTIVES FOR VENTILATION PRACTICE INFORMATION SHEET 1434

• CLEANING OF STEEL AND REMOVAL OF RUST INFORMATION SHEET 1490

• SPECIFICATION FOR MINERAL ABRASIVES INFORMATION SHEET 1491

• RELATIVE HUMIDITY – SUBSTRATE TEMPERATURE – AIR TEMPERATURE INFORMATION SHEET 1650

WARRANTY

PPG warrants (i) its title to the product, (ii) that the quality of the product conforms to PPG’s specifications for such product in effect at the time of manufacture and (iii) that the product shall be delivered free of the rightful claim of any

third person for infringement of any U.S. patent covering the product. THESE ARE THE ONLY WARRANTIES THAT PPG MAKES AND ALL OTHER EXPRESS OR IMPLIED WARRANTIES, UNDER STATUTE OR ARISING OTHERWISE IN

LAW, FROM A COURSE OF DEALING OR USAGE OF TRADE, INCLUDING WITHOUT LIMITATION, ANY OTHER WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE OR USE, ARE DISCLAIMED BY PPG. Any claim under this

warranty must be made by Buyer to PPG in writing within five (5) days of Buyer’s discovery of the claimed defect, but in no event later than the expiration of the applicable shelf life of the product, or one year from the date of the

delivery of the product to the Buyer, whichever is earlier. Buyer’s failure to notify PPG of such non-conformance as required herein shall bar Buyer from recovery under this warranty.

LIMITATIONS OF LIABILITY

IN NO EVENT WILL PPG BE LIABLE UNDER ANY THEORY OF RECOVERY (WHETHER BASED ON NEGLIGENCE OF ANY KIND, STRICT LIABILITY OR TORT) FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES IN ANY WAY RELATED TO, ARISING FROM, OR RESULTING FROM ANY USE MADE OF THE PRODUCT. The information in this sheet is intended for guidance only and is based upon laboratory tests that PPG believes to

be reliable. PPG may modify the information contained herein at any time as a result of practical experience and continuous product development. All recommendations or suggestions relating to the use of the PPG product, whether in

technical documentation, or in response to a specific inquiry, or otherwise, are based on data, which to the best of PPG’s knowledge, is reliable. The product and related information is designed for users having the requisite knowledge

and industrial skills in the industry and it is the end-user’s responsibility to determine the suitability of the product for its own particular use and it shall be deemed that Buyer has done so, as its sole discretion and risk. PPG has no

control over either the quality or condition of the substrate, or the many factors affecting the use and application of the product. Therefore, PPG does not accept any liability arising from any loss, injury or damage resulting from such

use or the contents of this information (unless there are written agreements stating otherwise). Variations in the application environment, changes in procedures of use, or extrapolation of data may cause unsatisfactory results. This

sheet supersedes all previous versions and it is the Buyer’s responsibility to ensure that this information is current prior to using the product. Current sheets for all PPG Protective & Marine Coatings Products are maintained at

www.ppgpmc.com. The English text of this sheet shall prevail over any translation thereof.

The PPG Logo, Bringing innovation to the surface., and all other trademarks herein are property of the PPG group of companies.

Ref. 7443 Page 6/6

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Understanding Motor Controls 3rd Edition Herman Solutions ManualDocument2 pagesUnderstanding Motor Controls 3rd Edition Herman Solutions Manuala471886600No ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Sigma Buffer ChartDocument2 pagesSigma Buffer CharttianajokicNo ratings yet

- Method Statement For Interconnection of Permeate Pipe To The Existing PipeDocument20 pagesMethod Statement For Interconnection of Permeate Pipe To The Existing PipegregNo ratings yet

- Mpy315 FinalDocument21 pagesMpy315 FinalCharles ChivengahNo ratings yet

- Annex B - List of Diving EquipmentDocument7 pagesAnnex B - List of Diving EquipmentgregNo ratings yet

- Brake System FundamentalsDocument31 pagesBrake System FundamentalsmdkhayumNo ratings yet

- Methods of Installation For Steel StructureDocument6 pagesMethods of Installation For Steel Structurenanamallow100% (1)

- Operation Manual of AHUDocument17 pagesOperation Manual of AHUpiyushsingh7881020No ratings yet

- Atoms, Elements & Compounds 1 MS PDFDocument8 pagesAtoms, Elements & Compounds 1 MS PDFClinton ChikengezhaNo ratings yet

- 2017-05-16 RRAA MS 26 Intake StructureDocument2 pages2017-05-16 RRAA MS 26 Intake StructuregregNo ratings yet

- Project Title Discipline Project Stage Client Attendance CirculationDocument4 pagesProject Title Discipline Project Stage Client Attendance CirculationgregNo ratings yet

- Annex D - Diving Works PDFDocument11 pagesAnnex D - Diving Works PDFgregNo ratings yet

- Commercial Diving Equipment:: 1.0 Band Mask Underwater Communication SystemDocument8 pagesCommercial Diving Equipment:: 1.0 Band Mask Underwater Communication SystemgregNo ratings yet

- MS-0026 Intake Structure Modification WRGDocument49 pagesMS-0026 Intake Structure Modification WRGgreg100% (2)

- Annex A PDFDocument4 pagesAnnex A PDFgregNo ratings yet

- Commercial Diving Equipment:: 1.0 Band Mask Underwater Communication SystemDocument8 pagesCommercial Diving Equipment:: 1.0 Band Mask Underwater Communication SystemgregNo ratings yet

- Annex ADocument4 pagesAnnex AgregNo ratings yet

- 2017-05-16 RRAA MS 26 Intake StructureDocument2 pages2017-05-16 RRAA MS 26 Intake StructuregregNo ratings yet

- Annex E - Divers RegistrationDocument8 pagesAnnex E - Divers RegistrationgregNo ratings yet

- 288 15 PDFDocument22 pages288 15 PDFgregNo ratings yet

- Commercial Diving Equipment:: 1.0 Band Mask Underwater Communication SystemDocument8 pagesCommercial Diving Equipment:: 1.0 Band Mask Underwater Communication SystemgregNo ratings yet

- New Microsoft Excel WorksheetDocument3 pagesNew Microsoft Excel WorksheetgregNo ratings yet

- New Microsoft Excel WorksheetDocument3 pagesNew Microsoft Excel WorksheetgregNo ratings yet

- 2018-04-24 RRAA Structural Steel QCS (Baras) - Rev ADocument1 page2018-04-24 RRAA Structural Steel QCS (Baras) - Rev AgregNo ratings yet

- Quality Control System For The Plant Fabrication of Structural SteelDocument25 pagesQuality Control System For The Plant Fabrication of Structural SteelgregNo ratings yet

- AttachmentDocument10 pagesAttachmentgregNo ratings yet

- Revisioon Fir RCCHEMDocument4 pagesRevisioon Fir RCCHEMgregNo ratings yet

- 2018-05-10 RRAA Structural Steel QCS (Baras) - Rev BDocument2 pages2018-05-10 RRAA Structural Steel QCS (Baras) - Rev BgregNo ratings yet

- 2018-04-24 RRAA Structural Steel QCS (Baras) - Rev ADocument1 page2018-04-24 RRAA Structural Steel QCS (Baras) - Rev AgregNo ratings yet

- Front Page PDFDocument1 pageFront Page PDFgregNo ratings yet

- Manila To Cebuvia PlaneDocument1 pageManila To Cebuvia PlanegregNo ratings yet

- PWTP2-QA-CR-CON-ARU-0392: Quality Control SystemDocument1 pagePWTP2-QA-CR-CON-ARU-0392: Quality Control SystemgregNo ratings yet

- AttachmentDocument1 pageAttachmentgregNo ratings yet

- Xwell Testing Services, Inc.: Calibration ReportDocument1 pageXwell Testing Services, Inc.: Calibration ReportgregNo ratings yet

- Add Inventory IdDocument24 pagesAdd Inventory IdgregNo ratings yet

- Izumi Industrial Trading: Ss Grease TrapDocument1 pageIzumi Industrial Trading: Ss Grease TrapgregNo ratings yet

- 1800cpb2 Series Regulators American MeterDocument11 pages1800cpb2 Series Regulators American Meterultron2099ultronNo ratings yet

- (CAB 381 0.5) PDFDocument2 pages(CAB 381 0.5) PDFمحمد مقلدNo ratings yet

- Gas Piping System Layout: Isometric DiagramDocument1 pageGas Piping System Layout: Isometric DiagramJEZREEL MENDOZANo ratings yet

- Listino Sea RecoveryDocument117 pagesListino Sea RecoveryEduardo Harold ChapuzNo ratings yet

- Volvo Penta Tamd61a-72j-A WM Fuelsystem PDFDocument44 pagesVolvo Penta Tamd61a-72j-A WM Fuelsystem PDFOzgyur MehmedovNo ratings yet

- Daikin PA Catalogue Revised Low ResDocument32 pagesDaikin PA Catalogue Revised Low ResKartik PrabhakarNo ratings yet

- Safety AssignmentDocument5 pagesSafety AssignmentWK PangNo ratings yet

- NPCL-YBP-RFI-TEL-000x Conduit Installation & Initial Mandrel Test SAIC-T-5709Document3 pagesNPCL-YBP-RFI-TEL-000x Conduit Installation & Initial Mandrel Test SAIC-T-5709afareenkhanNo ratings yet

- Design Project 2013Document154 pagesDesign Project 2013Fahad HussainNo ratings yet

- A Summer Training ReportDocument9 pagesA Summer Training ReportNiteesh kumar ShuklaNo ratings yet

- ENA - 12 - 24 TS For Ducts - Buried Electric CablesDocument17 pagesENA - 12 - 24 TS For Ducts - Buried Electric CablessdvijayNo ratings yet

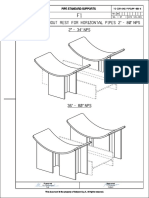

- Axial Stop Without Rest For Horizontal Pipes 2" - 80" NPS: Pipe Standard SupportsDocument4 pagesAxial Stop Without Rest For Horizontal Pipes 2" - 80" NPS: Pipe Standard SupportsMainuddin AliNo ratings yet

- Norsok STD PDFDocument1 pageNorsok STD PDFPhuong HoangNo ratings yet

- Nano LithographyDocument14 pagesNano LithographyMohammad RameezNo ratings yet

- Frigidaire Parts and Accessories CatalogDocument56 pagesFrigidaire Parts and Accessories CatalogPedro RuizNo ratings yet

- Certificado Brida 3Document1 pageCertificado Brida 3juan aguilarNo ratings yet

- Uccessful Deinking Plant Commissioning and Startup: Shop TalkDocument5 pagesUccessful Deinking Plant Commissioning and Startup: Shop TalkMuhammad SafwanNo ratings yet

- PFI HFB High Flow Pleated Bag Filter CartridgeDocument2 pagesPFI HFB High Flow Pleated Bag Filter Cartridgebennypartono407No ratings yet

- Revised Guidelines For Bio-Medical Waste IncineratorDocument34 pagesRevised Guidelines For Bio-Medical Waste Incineratorandik_yNo ratings yet

- HaTelit Presentation 2Document18 pagesHaTelit Presentation 2Bagas YandiNo ratings yet

- Mechanisms IllustrationsDocument310 pagesMechanisms IllustrationsManea Grosu100% (2)

- UOP 3-16-7 - Storage Tanks AtmosphericDocument9 pagesUOP 3-16-7 - Storage Tanks Atmosphericjev_vdNo ratings yet

- Control of Decarburization of Steel PDFDocument5 pagesControl of Decarburization of Steel PDFBhushan VermaNo ratings yet