Professional Documents

Culture Documents

Modern Control

Uploaded by

BMCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Modern Control

Uploaded by

BMCopyright:

Available Formats

Power Station and Process Control Systems

Modern Control Algorithms

in Process Control Systems

Observer-based State Control

Contents Page

Modern Control Algorithms in Steam Generator and

Auxiliary Plant Control

Calculation-guided Closed-loop Control Systems 4

Observer-based State Control 4

Unit Model (Steam Generator and Turbine) 5

Fuzzy Control Algorithms 5

Practical Utilization 5

PID Controller versus State Controller with Observer 6

Performance Comparison using an Application Example 6

Conventional State Controller with Observer 7

Mauell State Controller with Observer (MZR) 8

Tools for the Calculation of the Controlled System Parameters 9

Measuring Value Acquisition of the Controlled System

Response 10

Identification of the Controlled System and Indication of the

Characteristic Parameters 10

Load Level Balancing of the Superheater Time Response 11

Comparison Between PID and MZR 12

PID Controller 12

Mauell State Controller (MZR) 14

Retrofitting Projects 15

Conclusions 15

Observer-based State Control 3

Modern Control Algorithms for Steam Generator and Auxiliary Plant Control

District heating

3

1 2

5

6

4

Heat value G

correction 6

- Brown coal

- Refuse

1 Unit model (smooth load control) 4 Fuzzy control

2 Condensate stop control 5 Turbine speed and power control

3 Calculation-guided control 6 Observer-based state control

Unit control concept and use of modern control algorithms

Calculation-guided Closed-loop Control Systems furnace operation setpoint control. Model errors are corrected by

the secondary setpoint controllers of all major process areas, such

Fields of application and characteristics as FD floating pressure, turbine extraction pressure, heating

condenser pressure.

• Condensate stop control

• District heating supply from cogeneration Observer-based State Control

Calculation-guided closed-loop controls are primarily used in Field of application and characteristics

complex power station heat circuits where often contrasting task

definitions have to be taken into account: • Live steam temperature control

• Fast and opposite load variations at the consumer end, • Intermediate superheater temperature control

e.g., turbines / generator and district heating system

• Control loops with highly load-dependent time constants and of

• Slow increase of the steam generator output higher system order

Using conventional closed-loop control circuits responding to The state controller with observer is used for higher-level processes

system deviations, these tasks can only be solved with a maximum with self-regulation, but can also be used for processes with dead

effort in the planning and commissioning phases. They also hinder time. The process/plant-specific disturbance analysis is carried out

a dynamic operation of the plant. by an internal state observer and the analysis result is taken into

The block model assigns parameters on the basis of the account when the manipulated variable is generated. Actuator

technological design specifications, supplies reference input non-linearity, system dead time, etc. are taken into account by

variables for all control loops of the meshed system - right up to the internal compensation circuits so that a persisting system deviation

is avoided. An online parameter adaptation derives the optimal

4 Observer-based State Control

state controller parameters from the controlled system The method of multi-variable control based on a Fuzzy algorithm

characteristics. can be used for non-linear and linear processes. Reference

setpoints are derived from the various actual values for all furnace-

relevant control loops (e.g., control of the roller/ travelling grate

The use of a state controller results in an aperiodic and asymptotic

speed, primary/secondary/tertiary air quantities, refuse feeding

damping of the controlled variable characteristics which leads to a

speed, backup firing).

smooth actuator operation and therefore a smooth response of the

linked variables.

Practical Utilization

Unit Model (Steam Generator and Turbine)

The described control strategies are implemented on the standard

processors of the ME 4012 process control system so that the

Fields of application and characteristics

practical utilization of these modern control concepts is greatly

facilitated.

• Anticipation of the boiler and turbine output development, gradient

limiting for the load balancing through the block capacity control

(to avoid irregular block operation).

Large-scale power station components only allow certain load

characteristics. A setpoint control that is not optimally adjusted to

the possible actual conditions will lead to unnecessary fluctuations

in the control response and thus to unauthorized controller actions.

This puts unnecessary strain on the materials and reduces plant

efficiency. If the time characteristics for the setpoint control of the

essential components is derived on the basis of plant-specific

parameters (load level setpoint gradient, storage capacity, etc.), the

block model can be used to implement a specific setpoint control of

all large-scale components which takes into account the actual

process conditions. This will result in an optimal utilization of the

dynamic performance and a higher overall efficiency at load

variations. Untimely correction of the control process through the

secondary setpoint control systems can be avoided.

Fuzzy Control Algorithms

Fields of application and characteristics

• FGD plant optimization of the deposition degree of the SO2

content in the raw gas by selecting and specifying the number of

the spraying levels in operation

• Correction of the furnace operation control due to fluctuations in

the heat value and mass current measurement errors, e.g., solid

waste or refuse-fired furnace.

Plant areas producing inconsistent process variable fluctuations

which cannot be measured are difficult to control satisfactorily, even

if complex control loops with a high degree of intermeshing and

complex feedforward control are employed. The calorific value of

refuse or brown coal, for example, cannot be determined

satisfactorily due to the fluctuations in the composition of these

fuels. The operation of incinerators in particular requires various

fuelling parameters to be taken into account in order to achieve a

high energy utilization factor. Such parameters would be, for

instance, the furnace temperature range, the minimum retention

time of the gaseous products at specific temperatures, air excess

or starvation in the various burning zones, the quality of the steam

parameters.

Observer-based State Control 5

PID Controller versus State Controller with Observer

PID Controller versus State Controller with Observer • User-friendly and objective parameter setting and optimization

concept

Analog, standard algorithm PID control on a pneumatic, hydraulic

or electronic basis has proved its worth over many years, and is still Performance Comparison using an Application Example

first choice in daily control circuit design even in the days of digital

process control systems. Despite the fact that the PID controller In this section we compare the performance of a Mauell state

structure is not adapted to the controlled process and its setting controller with that of a PID controller. In our example the

parameters do not allow to draw direct conclusions on the control controllers are used for the live steam temperature control of a

quality, points in favour of its use are the detailed knowledge on steam generator, which is characterized by large and highly load-

how the PID controller works, and the many years of experience dependent time constants, a higher system order (n = 3....5 typ.),

that provide plant engineers with the intuitive feel for tuning. external disturbances due to fluctuations in the heating of the

superheater, and high demands on the control quality.

In this report, we confront the well-established technique (PID

control) with the new technique (observer-based state control) and The application example will also demonstrate the versatility of the

show that an alternative exists for the PID controller that is equally Mauell state controller with respect to the fields of application and

practical but more robust to unpredictable changes in the behaviour its suitability for all aperiodic systems with compensation or dead

of the controlled system (e.g., superheater processes). times. It will show that the state controller offers clear advantages

when used in higher-order systems and control loops with long

Based on the state controller described in technical literature and dead times and actuator-dependent non-linearities.

many application reports, Mauell extended the observer concept of

the state controller by implementing essential features that have not The effect of the two alternative control concepts is illustrated for a

been fully documented in the past. steam generator with a two-line superheater (see figure below).

Essential modules of the observer concept:

• State observer

• Disturbance observer

• Actuator observer

• Dead time compensation

Example of a steam generator with a two-line superheater, displayed on the ME-VIEW operator control and monitoring system. Line 1 is

equipped with a PID controller, line 2 with state controller.

6 Observer-based State Control

In the following we will only look at the structure of the Mauell state However, this conventional state control has the following short-

controller as the structure and principle of operation of the PID comings:

controller is common knowledge.

• The state observer cannot fully compensate for the observation

We start with a summary of the concept of conventional observer- error ∆Ta - T3 and is thus not able to completely reproduce the

based state control so that you will be able to compare it with the required state variables.

Mauell state controller and easily recognize its advantages and • In the steady state, the state controller produces a permanent

innovative features. control deviation.

• Adaptation of the internal parameters to the load is practically not

Conventional State Controller with Observer

possible.

The figure below shows the basic structure of a conventional state • The state controller is adapted to the structure of the controlled

controller with state observer and secondary injection controller system. However, as secondary control loops and actuators with

their mostly non-linear behavior are also part of the system to be

implemented in a 3rd order controlled system.

controlled, they too must be taken into account. Adaptation is

therefore more difficult to achieve and the controller adjustment is

From a complete set of state variables that clearly describe the less exact.

system state, the conventional state controller generates a

manipulated variable by means of linear combination. • Dead times of the controlled system cannot be taken into account.

• There is no tool for user-friendly and objective parameter setting

Owing to the fact that only the state variable can be measured, the and optimization.

state observer derives the other required state variables T1 and T2

and transmits them to the state controller. The variable T3 is The commissioning of the conventional state controller therefore

derived by the state observer and is the equivalent to the system requires extensive knowledge of the state space representation.

deviation ∆Ta = Ta - Ta, soll.

We see that the practical use of the conventional controller is

From the observer deviation ∆Ta -T3 and the input variable Te, the limited because of the drawbacks described above. Also, plant

state observer then tries to determine the external disturbances designers and commissioning engineers, even the service

(manipulated-variable independent changes of the output variable) personnel, must have special knowledge of state space systems.

on the controlled system.

Te Ta

- Ta soll

State observer DTa

+

-

h1 x h2 x h3

x

+ + +

T1 T2 T3

k1 k2 k3

x x x

Te, soll + +

PI -

State controller

Conventional state controller with observer

Observer-based State Control 7

PID Controller versus State Controller with Observer

Mauell State Controller with Observer (MZR) The additive connection of the state observer’s integrator output for

the elimination of the steady-state deviation is expressed by the

The Mauell state controller has inherited the basic structure of the factor k0. As the calculation of the factor k0 takes the transfer

conventional state controller which has been extended by function of the controlled system into account, inaccuracies in the

additional structural features. These new features are described in elimination of the system deviation must be expected.

the following.

Due to the fact that deviations in the steady state between the

Elimination of the Steady-state Observer Error controlled system and the model in the state observer are taken

into account by the disturbance observer, model errors, especially

In order to eliminate the steady-state observer error (∆Ta - T3), the gain factor deviations, have no influence on the control precision of

basic structure of the observer concept is extended by a the steady-state controlled system.

disturbance observer so that the observer error ∆Ta - T3 converges

towards zero. Compensation of the Non-linearities of Secondary Follower

Controllers and Actuators

Elimination of the Steady-state System Deviation

To make the state controller robust to non-linear variations of the

For known disturbances on the controlled system, the steady-state follower controller and actuator, a so-called actuator observer has

deviation of a state controller can be determined from the transfer been implemented.

function of the controlled system and the parameters of the state

controller. The actuator observer has the task of varying the state variables

T1 to T3 so that they can be used for the determination of the state

As the disturbances are statically mapped by the state observer, it controller’s manipulated variable without showing any signs of the

is possible to evaluate the contents of the integrator and as a result secondary control loop’s dynamic behavior.

compute the ‘± change’ of the state controller’s state variable in

order to eliminate the steady-state system deviation. Therefore, within the framework of the overall cascade, the

secondary control loop has only a delaying effect. It does not affect

In this context, the reference input variable can also be considered the stability of the state controller.

as a disturbance in the sense of a shift of the neutral position.

These observations formed the basis for the development of the

Mauell state controller.

Te Ta

Ta,soll

Load balancing

Disturbance observer State observer

System parameters:

n Order

h0 h1 h2 h3

X X X X ks Gain

T Denominator

time constant

T1 T2 T3 Tt Dead time

State controller Tz Numerator

k0 k1 k2 k3

time constant

X X X X

from the system

PI identification

model

l1 l2 l3

X X X v

-

Actuator observer Speed

Mauell state controller (implemented in a 3rd order controlled system) with its internal structure adapted to the order of the controlled

system

8 Observer-based State Control

Dead Time Compensation of the Controlled System controller, obtains the following controlled system parameters by

applying a step change and recording the response to this step

The actuator observer divides the entire feedback system into the change:

two decoupled subsystems ‘PI follow-up control’ and ‘State setpoint

control’. n = Order

k = Gain

If the controlled member of the setpoint control (in our example this T = Time constant

is the superheater) has a dead time (from the superheater inlet Tt = Dead time

temperature Te to the outlet temperature Tt), this cannot be taken

into account by the state observer. Function generators adapt these parameters to the current

operating point as a function of load.

This will also be compensated for by the actuator observer. The

actuator observer represents the third decoupled subsystem, the The only parameter of the Mauell state controller that remains to be

so-called ‘Dead time system’. Like the secondary PI follow-up set is the speed factor V. This parameter defines by what factor

control, it has only a delaying effect on the feedback control the feedback control loop is to be faster than the controlled system.

(corresponding to the dead time) and does not in any way affect

the stability of the state controller. Next, we shall briefly discuss the steps to go through to determine

the controlled system parameters.

Tools for the Calculation of the Controlled System Parameters

and the Optimization of the Mauell State Controller

Parameters

A concept had to be developed that allows to determine the

controlled system parameters n, k, T and Tt and to set up and

optimize the controller parameters in a convenient and practical

way. This concept was implemented in the Mauell controller setup

tool AE 4012BS-EH.

A special algorithm based on online computing of the numerous

parameters of the disturbance quantities, actuator and state

observers and state controller and its integration in the Mauell state

Controlled system

Controlled system model

Step change

inquiry System parameters:

M - System order n

MU

- Gain factor k s

- Denominator time constant Tn

- Numerator time constant Tz

- Dead time Tt

analog

X D

A Y A

Controller model

D W

Setpoint

Controller in PLS Kp tn tv generator

Structure of the controlled system and controller model generation for the optimization of the setting parameters

Observer-based State Control 9

PID Controller versus State Controller with Observer

Measuring Value Acquisition of

the Controlled System

Response

The measuring value acquisition

records the response of the

controlled system to a step

change of the manipulated

variable. Before the step change

is applied the controlled system

must be in the steady-state

condition, or at master controller

optimization, the follow-up control

(e.g., inlet temperature control)

must operate in automatic mode.

The amplitude of the step input to

the manipulated variable should

differ clearly from that of any

superimposed disturbances.

While the measuring values are

being recorded, the diagram axes

are automatically zoomed and

scaled to offer a good overview of

the measured data.

The transfer function of the

Measuring value acquisition of a step response

controlled system is obtained

when the controlled system has settled and returned to the steady- Identification of the Controlled System and Indication of the

state following the application of the step change. The data record Characteristic Parameters

of the measured values can now be saved together with a

comment (e.g., the corresponding load point or operating point). A mathematical model is created from the measuring data set of

the controlled system step response that clearly describes the

dynamic behavior of the controlled system.

Via menu the stored measuring values are loaded for the

identification of the controlled

system together with their time

specification and recording

information. The actual

identification starts with the

marking of the point of time

when the step change was

applied (change of the

manipulated variable).

The automatic determination of

the model parameters is

completed as soon as the optimal

model quality is reached, i.e., if

the error area between the

simulated behavior of the

controlled system on the basis of

the mathematical model and the

measuring data set of the step

response is at a minimum.

The parameters of the controlled

system are also displayed.

After the identification of the

controlled system, the parameter

set of the controlled system

model can be stored together

with a comment for

documentation purposes.

System identification during the computing of the step response with mathematical description

10 Observer-based State Control

Load Level Balancing of the

Superheater Time Response

The derived values can be used

directly for adjusting the Mauell

state controller. Only the time

constant T is varied load-

dependently, as shown in the

figure, based on the assumption

that the time constant T changes

inversely proportional to the steam

quantity. This behavior results

from the higher steam flow

velocities at a high steam quantity.

The parameters for the Mauell

state controller can be set online

by directly transmitting the derived

values.

Load level balancing

Graphical configuration interface with online process data for entering the controlled system parameters as well as the speed factor V.

Observer-based State Control 11

PID Controller versus State Controller with Observer

Comparison between PID and MZR

PID Controller

The alternative control loop with PID controller has also been The optimization procedure starts with the simulation of the closed

optimized on the basis of the data of the controlled system control loop as a response to a step change of the reference

identification. Supplementary to the procedure for the state variable. The program provides you with a continuous graphical

controller, the program module Controller Design has been representation of the optimization sequence.

employed.

The optimization procedure is completed as soon as the specified

The program module Controller Design allows you determine quality criteria are reached, supplying the optimal controller setting

optimal parameters for P, I, PI, PD and PID controllers on the basis parameters (see diagram below):

of the system model from the controlled system identification.

P component Proportion. coefficient kP

The first step is to select the system model of the ‘Controlled I component Reset time Tn [s]

system identification’ process. The program loads a graphical D component Setup time TV [s]

representation of the system model.

The desired control algorithm is specified by enabling the

parameters (kp, Tn, Tv).

The control quality can be specified by entering the maximum

overshoot and adapting the dynamic behavior of the actuator signal

to that of the actuator. Also, only moderate actuator speeds should

be selected to avoid unnecessary wear of the servo drive and

gland.

Deriving the optimal setting parameters kp, Tn, Tv for a PID controller with the help of the Controller Setup Tool

12 Observer-based State Control

Optimization Complexity

The PID controller tuning is based on the characteristic quantities n,

k, T and the parameter T of the controlled system. These

parameters can be determined in a convenient and straightforward

way using the AE4012BS-EH controller setup tool, and adjusted

load-dependently.

Using the program module Controller Design, the PID controller

can be optimized by deriving optimal kp, Tn and Tv parameters.

Assessment of the PID Controller

The controller results can be characterized as follows:

• Rise time Longer than for the MZR

• Settling time Longer than for the MZR

• Overshoot Depending on the parameter

adaptation

• Error area Larger than for the MZR

• Actuator movement Uneven, highly intervening

• Commissioning Similar to the MZR, more

complex for highly nonlinear

systems

• Operating point dependency Partially controllable through

controlled adaptation of the

parameters kp, Tn, Tv (very

complex)

Detail diagram of the PID controller in the ME-VIEW operator control and monitoring system (line 1 of the superheater)

Observer-based State Control 13

PID Controller versus State Controller with Observer

Mauell State Controller (MZR) It was not necessary to implement feed forward control.

The analysis of the model parameters n and k and the load- Assessment of the Mauell State Controller

dependent parameter T specified for the state controller revealed a

very good model adaptation. The controller results can be characterized as follows:

The advantages of the actuator observer have been proved true as • Rise time Shorter than for the PID

only the superheater behavior from the superheater inlet • Setting time Much shorter than for the PID

temperature to the superheater outlet temperature had to be taken

into account for the parameter assignment of the state controller. • Overshoot 0%, always with asymptotic

damping and thus a good

condition for a smooth process

Possible variations from the secondary injection control, the

injection cooler and the actuator, are not taken into account in this • Error area Much smaller than for the PID

model. This increases the model quality considerably as difficult to • Actuator movements Accurate, even, allowing

model nonlinearities can be neglected. temperature adjustment with

minimum feed water quantity.

The initially selected presetting for the speed factor V (initial value • Commissioning Similar to the PID

1.5), that corresponds to the maximum value of the concurrent PID

• Operating point independence Can be compensated for by

controller, could be increased to the speed factor V = 3.5.

adjusting the load-dependent

system time constant T.

Optimization complexity

The Mauell state controller tuning is based on the characteristic

quantities n, k, T and the parameter Tt of the controlled system.

These parameters can also be determined using the AE4012BS-

EH controller setup tool, and adjusted load-dependently.

The speed factor V is the only setting parameter that affects the

dynamic behavior of the control loop. The adaptation of this

parameter does not require any specific knowledge.

Detail diagram of the MZR controller in the ME-VIEW operator control and monitoring system (line 2 of the superheater)

14 Observer-based State Control

Measured data monitoring

[°C] TA - Tr/SC TA - Tr/PID TWA - Tr : Outlet temperature

TSetpoint

[t/h] Time

FEW/PID FEW : Injection water quantity

Momentarily superposed control

FEW/SC (interfering) command. The commands are

set off with a time delay to get clear

readings.

Time

Qualitative comparison of the controller results TA - Tr / ZR (state controller) and TA - Tr PID (PID controller)

Retrofitting Projects Conclusions

The state controller with observer can be retrofitted to boilers with The above comparison between a PID controller and a Mauell

conventional process control system (hard-wired control and state controller showed that the Mauell state controller with

analog feedback system with control console operating elements) observer has clear advantages when used in complex systems that

as well as to newer plants with digital process control system and would be difficult to control using standard algorithms.

video terminals, simply by integrating a module of the ME 4012

digital process control system in the existing control systems. The The control behavior illustrated in the example has been verified by

existing connections between the control room, controller modules concrete industrial applications and proven its worth. Mauell

and servo drives remain unchanged. The integration can be observer-based control is for example implemented since October

carried out while the system is operating provided the necessary 1996 in block 5 (coal-/oil-fueled, 420t/h steam capacity) of the

preparations have been made. Hafen power plant, Stadtwerke Bremen AG.

It is also possible to integrate the Mauell state controller on the Other applications, like for example the four boilers and the 1000t/h

basis of a Mauell hardware platform so that the plant operator is steam generator of the waste-fueled power station of AWG

provided with the familiar operator control and signalizing concept. Wuppertal, confirm the successful employment of the Mauell state

The communication with the third-party system is established over controller with observer.

a serial or parallel-wire connection. The parameters can be

assigned online.

Observer-based State Control 15

Representatives

Power station control and process control

Power distribution control, station control and remote control

Automation and communication systems

Industrial automation and building systems automation

Alarm indication, event recording and annunciator systems

Mosaic systems, control room technology and large-screen projection

Engineering, installation, commissioning, maintenance and training

Helmut Mauell GmbH Helmut Mauell B.V. Helmut Mauell GmbH

Am Rosenhügel 1-7 Postbus 89 Nová 967

D-42553 Velbert NL-3840 AB Harderwijk CZ-28522 Zruc nad Sázavou

Germany Netherlands Czech. Republic

Tel. +49 (0)20 53 1 30 Tel. +31 (0)3 41 41 15 80 Tel./Fax +420 (0)3 27 93 42 80

Fax +49 (0)20 53 1 34 03 Fax +31 (0)3 41 41 15 81 Mobiltel. 06 02 38 97 70

E-Mail info@mauell.com E-Mail info@mauell.nl E-Mail mir-v@cboc.cz

Werk Weida Mauell GmbH Helmut Mauell GmbH

Papiermühlenweg 10 Triester Straße 10/1/121 SULTAN INTERNATIONAL

D-07570 Weida A-2351 Wiener Neudorf P.O. Box 3486

Germany Österreich Abu Dhabi U.A.E.

Tel. +49 (0)3 66 03 4 80 Tel. +43 (0)22 36 2 11 01-0 Tel. +9712 6 22 44 11

Fax +49 (0)3 66 03 4 83 10 Fax +43 (0)22 36 2 11 01-30 Fax +9712 6 22 44 55

E-Mail kle@mauell.com Mobiltel. +43 (0) 664 14 28 371 E-Mail farag@emirates.net.ae

E-Mail fje@mauell.at

Mauell AG

Furtbachstraße 17 Mauell Ltd.

CH-8107 Buchs P.O. Box No. 183

Switzerland GB-Calne, SN11 9BZ

Tel. +41 (0)1 847 42 42 Wiltshire/Great Britain

Fax +41 (0)1 844 44 56 Tel. +44 (0)12 49 81 20 46

E-Mail info@mauell.ch Fax +44 (0)12 49 81 70 96

E-Mail mauell@globalnet.co.uk

Mauell Corporation

31 Old Cabin Hollow Road

Dillsburg PA 17019

USA

Tel. +1717 4 32 86 86

Fax +1717 4 32 86 88

E-Mail gms@mauell-us.com To obtain our latest list of branch offices and

sales representatives in both Germany and abroad:

Helmut Mauell do Brasil Ltda. visit us at: www.mauell.com

Estr. Est. Salvador de Leone, 2998 email us at: info@mauell.com

06850-000 Itapecerica

da Serra São Paulo / Brazil or call us: +49 (0) 20 53 - 13 405

Tel. +55 (0)11 79 47-17 77

Fax +55 (0)11 79 47-17 74 please adress technical inquiries to:

E-Mail mauell@mauell.com.br vertrieb@mauell.com

01.4012.33E00

You might also like

- Turbine Control PINDocument4 pagesTurbine Control PINAnonymous NwnJNO100% (1)

- Paper 5-CMC Implementation Unchahar PDFDocument48 pagesPaper 5-CMC Implementation Unchahar PDFumeshNo ratings yet

- TechnicalDiary SGTPPDocument45 pagesTechnicalDiary SGTPPJoydev GangulyNo ratings yet

- CalderaDocument44 pagesCalderaIvan SanchezNo ratings yet

- Lecture9 Arm MoocsDocument14 pagesLecture9 Arm MoocsKommaraju BhavanaNo ratings yet

- Presentation On DVR, JS Saroya, CS Singh, 03.12.11Document75 pagesPresentation On DVR, JS Saroya, CS Singh, 03.12.11Amit BiswasNo ratings yet

- CONDENSER Air ExtractionDocument2 pagesCONDENSER Air Extractiontrung2iNo ratings yet

- Turbine Control and Efficiency ImporovementDocument6 pagesTurbine Control and Efficiency ImporovementUdhayakumar Venkataraman100% (1)

- Jay Giri (Alstom) PDFDocument61 pagesJay Giri (Alstom) PDFPrasanth MKNo ratings yet

- FT3000 SKF Compact Speed Monitoring and ProtectionDocument11 pagesFT3000 SKF Compact Speed Monitoring and ProtectionUssamaNo ratings yet

- Loss in Weight TrainingDocument22 pagesLoss in Weight TrainingSantrupta PandaNo ratings yet

- Better Fuel Distribution To Improve Combustion During Flexible Load OperationDocument12 pagesBetter Fuel Distribution To Improve Combustion During Flexible Load OperationRajeswaranNo ratings yet

- SC37-SM-26052022 R0-Recomm Spare Parts For WFDocument5 pagesSC37-SM-26052022 R0-Recomm Spare Parts For WFValipireddy NagarjunNo ratings yet

- Steam Turbine and Its Auxiliary Systems: Course PurposeDocument19 pagesSteam Turbine and Its Auxiliary Systems: Course PurposeMuhammad luqmanNo ratings yet

- AhmadJavaid (TZIDC ABB Positioner)Document17 pagesAhmadJavaid (TZIDC ABB Positioner)ahmedNo ratings yet

- Ger 4222a New High Efficiency Simple Cycle Gas Turbine Lms100Document20 pagesGer 4222a New High Efficiency Simple Cycle Gas Turbine Lms100raghavendran raghuNo ratings yet

- Steam Turbine: Life Time Calculations and Life Limitings FactorsDocument38 pagesSteam Turbine: Life Time Calculations and Life Limitings FactorsPPG CoverNo ratings yet

- Flsmidth Pvt. LTDDocument36 pagesFlsmidth Pvt. LTDValipireddy NagarjunNo ratings yet

- 531GS155Document7 pages531GS155Valipireddy NagarjunNo ratings yet

- Location: Mill: Sagar Cement, Jajpur Jcpl/Inst/Cl MillDocument15 pagesLocation: Mill: Sagar Cement, Jajpur Jcpl/Inst/Cl MillValipireddy NagarjunNo ratings yet

- Maximizing Plant Performance with Coordinated Boiler and Turbine ControlDocument28 pagesMaximizing Plant Performance with Coordinated Boiler and Turbine ControlJhoNo ratings yet

- # AhpDocument21 pages# AhprahulNo ratings yet

- 0000868263Document611 pages0000868263Raden MasNo ratings yet

- Turbine Governing SystemDocument77 pagesTurbine Governing SystemGrishma WarkeNo ratings yet

- BoilerOpt Overview and Results 7-18-16-UsefulDocument53 pagesBoilerOpt Overview and Results 7-18-16-Usefultrung2iNo ratings yet

- ADB (2009) Sustainable Energy Efficiency Development Program PDFDocument542 pagesADB (2009) Sustainable Energy Efficiency Development Program PDFaanchanNo ratings yet

- 1st Amendment Operating Frequency Range CERCDocument19 pages1st Amendment Operating Frequency Range CERCashish jainNo ratings yet

- Lecture 27 Model Steam Turbine Gov SystemDocument60 pagesLecture 27 Model Steam Turbine Gov Systempk cfctkNo ratings yet

- Locomotive Safety DevicesDocument5 pagesLocomotive Safety DevicesmajjisatNo ratings yet

- Training Report at NFL PanipatDocument22 pagesTraining Report at NFL PanipatKapil AroraNo ratings yet

- Air Pollution Control: Understanding Bag FiltersDocument54 pagesAir Pollution Control: Understanding Bag FiltersVishal HiremathNo ratings yet

- GE's 330MW Digital Electro-Hydraulic Control System for Steam TurbinesDocument22 pagesGE's 330MW Digital Electro-Hydraulic Control System for Steam Turbineskeerthi dayarathnaNo ratings yet

- Basic Governer ControlsDocument14 pagesBasic Governer ControlspankajNo ratings yet

- Thermal Plant Control Instrumentation IDocument41 pagesThermal Plant Control Instrumentation IVishal KhachaneNo ratings yet

- 7.1 Introduction of BoilerDocument35 pages7.1 Introduction of BoilerSon Thuy Tran100% (1)

- Dokumen - Tips Coal Handling Plant 589be8a41d9eaDocument29 pagesDokumen - Tips Coal Handling Plant 589be8a41d9eaWasim MalkaniNo ratings yet

- General Electric Power Business Unit: Strategic Analysis Tools and Techniques - Coursework 2Document13 pagesGeneral Electric Power Business Unit: Strategic Analysis Tools and Techniques - Coursework 2Ibilola IbisankaleNo ratings yet

- Smartfill: Do You Already Have Enough Information On Your Grinding Process?Document2 pagesSmartfill: Do You Already Have Enough Information On Your Grinding Process?youssef tabetNo ratings yet

- Chapter-2 Steam Cycle TheoryDocument20 pagesChapter-2 Steam Cycle TheoryPhanindra Kumar J100% (1)

- Fgmo Rev WriteupDocument4 pagesFgmo Rev Writeupsunil100% (1)

- Introduction To Steam Seal System of 800Mw Kudgi TurbineDocument10 pagesIntroduction To Steam Seal System of 800Mw Kudgi TurbineSCEKUDGI 800No ratings yet

- 30 Stall Parallel OperationDocument29 pages30 Stall Parallel Operationtrung2iNo ratings yet

- SIDE ARM CHARGER Design-R0 PDFDocument8 pagesSIDE ARM CHARGER Design-R0 PDFSripara KrishnaNo ratings yet

- Cost & Cost ConceptsDocument51 pagesCost & Cost ConceptsEzhil Vendhan PalanisamyNo ratings yet

- Belt Weighing WT10 - en - Kap04 PDFDocument60 pagesBelt Weighing WT10 - en - Kap04 PDFomarNo ratings yet

- Governing Systems MSRMDocument10 pagesGoverning Systems MSRMBIRANCHINo ratings yet

- Eddy 2Document8 pagesEddy 2mahetrpNo ratings yet

- Milltronics MFA 4p en-USDocument57 pagesMilltronics MFA 4p en-USRavenShieldXNo ratings yet

- NTPC Vindhyachal conveyor crushing package price formatsDocument4 pagesNTPC Vindhyachal conveyor crushing package price formatsistyloankurNo ratings yet

- Turbine & Cooling System: Presented by - AVIJEET PRATAP 07ME12 Iet AgraDocument28 pagesTurbine & Cooling System: Presented by - AVIJEET PRATAP 07ME12 Iet AgraAd Man GeTig100% (1)

- Burner Target Check Procedure - Revised - 220114Document4 pagesBurner Target Check Procedure - Revised - 220114reza212No ratings yet

- Weighfeeder DetailsDocument4 pagesWeighfeeder DetailsAnonymous p4GdtQpNo ratings yet

- Coal FeedDocument8 pagesCoal FeedaakashtrivediNo ratings yet

- C& I For SupercriticalDocument93 pagesC& I For SupercriticalPrudhvi RajNo ratings yet

- BHELDocument4 pagesBHELNageswara Reddy GajjalaNo ratings yet

- AU-Seal OilDocument4 pagesAU-Seal OilPradeep_VashistNo ratings yet

- 90.25771-SFF-001 As BuiltDocument45 pages90.25771-SFF-001 As BuiltValipireddy NagarjunNo ratings yet

- Control Steam Turbine Combined Cycle Power Plant Based On Soft ComputingDocument6 pagesControl Steam Turbine Combined Cycle Power Plant Based On Soft Computingleanhhai1080No ratings yet

- Sliding Control Retrofit Power: Thermal PlantDocument6 pagesSliding Control Retrofit Power: Thermal PlantghostamirNo ratings yet

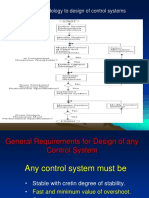

- Stander Methodology To Design of Control SystemsDocument43 pagesStander Methodology To Design of Control SystemstojogofirNo ratings yet

- Power Quality Measurement GuideDocument5 pagesPower Quality Measurement GuideBMNo ratings yet

- D KIDFIXSLSICTDocument2 pagesD KIDFIXSLSICTBMNo ratings yet

- Comparison of Flue Gas Desulphurization ProcessesDocument10 pagesComparison of Flue Gas Desulphurization ProcessesBMNo ratings yet

- Understanding PH in Practical Terms CP 997C 24 Ae 10.08Document14 pagesUnderstanding PH in Practical Terms CP 997C 24 Ae 10.08BMNo ratings yet

- ISO 10816-1 Normativa VibracionesDocument10 pagesISO 10816-1 Normativa Vibracionesumendibil100% (1)

- Communications PDFDocument3 pagesCommunications PDFBMNo ratings yet

- Fan Laws: Reference InformationDocument1 pageFan Laws: Reference InformationBMNo ratings yet

- Level Tank Gauging Test FacilitiesDocument4 pagesLevel Tank Gauging Test FacilitiesBMNo ratings yet

- Mathematics and Art-Marc FrantzDocument61 pagesMathematics and Art-Marc FrantzEirini ChatzaraNo ratings yet

- Water quality monitoring in power plantsDocument13 pagesWater quality monitoring in power plantsAurenio RibeiroNo ratings yet

- Kolmogorov-Smirnov Normality Test (Data Analysis Task Force)Document9 pagesKolmogorov-Smirnov Normality Test (Data Analysis Task Force)BMNo ratings yet

- Pi DiagramDocument1 pagePi DiagramBMNo ratings yet

- KBIHellasDocument18 pagesKBIHellasBMNo ratings yet

- ROC800-Series IEC 62591 Interface: ScalabilityDocument10 pagesROC800-Series IEC 62591 Interface: ScalabilityBMNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Safety-Related Automation: Advant Controller 31-SDocument1 pageSafety-Related Automation: Advant Controller 31-SBMNo ratings yet

- IEC 62591 Wireless Interface Instruction Manual: Part D301708X012Document74 pagesIEC 62591 Wireless Interface Instruction Manual: Part D301708X012BMNo ratings yet

- ROC800-Series IEC 62591 Interface: ScalabilityDocument10 pagesROC800-Series IEC 62591 Interface: ScalabilityBMNo ratings yet

- Advant Controller 160Document4 pagesAdvant Controller 160BMNo ratings yet

- Oc 6000 eDocument16 pagesOc 6000 eTien Dung TranNo ratings yet

- Sketch-a-Net That Beats HumansDocument11 pagesSketch-a-Net That Beats HumansBMNo ratings yet

- GE OC 6000e Distributed Control SystemDocument2 pagesGE OC 6000e Distributed Control SystemBMNo ratings yet

- Advant Controller 160 Version 2 1 Product GuideDocument84 pagesAdvant Controller 160 Version 2 1 Product GuideBM50% (2)

- Release Notes AdvaSoft For Windows Version 1.3 4Document38 pagesRelease Notes AdvaSoft For Windows Version 1.3 4BMNo ratings yet

- Advant Controller 160Document4 pagesAdvant Controller 160BMNo ratings yet

- IntroductionDocument18 pagesIntroductionBMNo ratings yet

- Advant AC450 ConnectDocument2 pagesAdvant AC450 ConnectBMNo ratings yet

- InstallationDocument102 pagesInstallationBMNo ratings yet

- Communit TI en 20Document11 pagesCommunit TI en 20BMNo ratings yet

- Algorithmic Design: A Future Tool for Architecture Optimization and Form GenerationDocument28 pagesAlgorithmic Design: A Future Tool for Architecture Optimization and Form GenerationSriraamNo ratings yet

- Analysis of Data in Python - ALXDocument3 pagesAnalysis of Data in Python - ALXMos DetNo ratings yet

- Toolbox Paper COM 120 800Document4 pagesToolbox Paper COM 120 800melmo703No ratings yet

- Skin Disease Classification Using CNNsDocument5 pagesSkin Disease Classification Using CNNsFunZoa LifeNo ratings yet

- Neural NWDocument3 pagesNeural NWKapil KumarNo ratings yet

- Intelligent Agents in AIDocument41 pagesIntelligent Agents in AIrwt91848No ratings yet

- Single-Cell Data On PollyDocument12 pagesSingle-Cell Data On Pollyelucidata1No ratings yet

- ID3 Algorithm: Michael CrawfordDocument28 pagesID3 Algorithm: Michael CrawfordMuhammad MudassirNo ratings yet

- Discrete Time SystemsDocument151 pagesDiscrete Time Systemsdoaah hakim100% (1)

- Machine Learning: April 2022Document32 pagesMachine Learning: April 2022Rajachandra VoodigaNo ratings yet

- Assignment RoboticsDocument14 pagesAssignment RoboticsKesava ShankarNo ratings yet

- 10 Apple SQL Interview QuestionsDocument15 pages10 Apple SQL Interview QuestionsvanjchaoNo ratings yet

- Guide to Artificial Intelligence BasicsDocument11 pagesGuide to Artificial Intelligence BasicsLalit BhagatNo ratings yet

- 13-Precise Praise Feedback SheetDocument1 page13-Precise Praise Feedback Sheetapi-331619242No ratings yet

- How Chile's Socialist Government Used Cybernetics to Regulate the EconomyDocument37 pagesHow Chile's Socialist Government Used Cybernetics to Regulate the EconomyAnneOliphantNo ratings yet

- Audio Cover Song Identification Using Convolutional Neural NetworkDocument5 pagesAudio Cover Song Identification Using Convolutional Neural NetworkNeel KothariNo ratings yet

- Kalyan 1 s2.0 S2949719123000456 MainDocument48 pagesKalyan 1 s2.0 S2949719123000456 MainjitterNo ratings yet

- CHAPTER III: Providing Input For Acquisition: The Potential of The Second Language ClassroomDocument11 pagesCHAPTER III: Providing Input For Acquisition: The Potential of The Second Language ClassroomPuthut FilthNo ratings yet

- K-Nearest Neighbor LearningDocument31 pagesK-Nearest Neighbor LearningEdward KenwayNo ratings yet

- AI Systems ExplainedDocument7 pagesAI Systems ExplainedPARLAPALLI HEMANTH -2019BCSIIITKNo ratings yet

- Ram Chandra Padwal - Pratical Guide To NLTK For Data ScienceDocument37 pagesRam Chandra Padwal - Pratical Guide To NLTK For Data ScienceZander Catta PretaNo ratings yet

- Artificial Intelligence in Medicine Book - 2022 - 1Document18 pagesArtificial Intelligence in Medicine Book - 2022 - 1pedroNo ratings yet

- Watershed Segmentation of Low Contrast ImagesDocument6 pagesWatershed Segmentation of Low Contrast Imagesrishi guptaNo ratings yet

- AML 04 BackpropagationDocument26 pagesAML 04 BackpropagationVaibhavNo ratings yet

- Evolving Artificial Neural Networks With Feedback - 2020 - Neural NetworksDocument10 pagesEvolving Artificial Neural Networks With Feedback - 2020 - Neural NetworksAssad AssadNo ratings yet

- SQL Interview Questions N Answers-EasyDocument13 pagesSQL Interview Questions N Answers-Easyshekarac785No ratings yet

- Building A Career in Data Science - The OverviewDocument2 pagesBuilding A Career in Data Science - The OverviewTushar GondaliaNo ratings yet

- Deep Learning in Power Systems Research A ReviewDocument12 pagesDeep Learning in Power Systems Research A ReviewGrettel QuintanaNo ratings yet

- Machine Learning: Welcome!Document85 pagesMachine Learning: Welcome!TabassumNo ratings yet

- Artificial Neural Networks and Machine Learning - ICANN 2016 Part IDocument585 pagesArtificial Neural Networks and Machine Learning - ICANN 2016 Part IBranko NikolicNo ratings yet