Professional Documents

Culture Documents

Zinc Chromate Paint PDF

Uploaded by

Bash MatOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Zinc Chromate Paint PDF

Uploaded by

Bash MatCopyright:

Available Formats

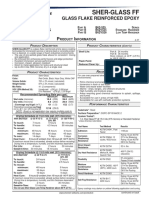

Zinc Chromate Primer

CM0723404

ADVANTAGES

DESCRIPTION

• Excellent water and corrosion

resistance. CM0723404 is a single component corrosion-inhibiting primer primarily for use on

aluminum aircraft or airborne equipment surfaces. This product may be topcoated

• Fast dry. with lacquer or enamel. This product may be used without a topcoat. This

product is for spray application.

• Recoatable with lacquer or

enamel. COATING PROPERTIES

Color: Green

• Meets the performance criteria

set forth in TT-P-757B, Type 1, Base Component

Class C. Solids: 28-32%

By volume

Wt./Gal. 9.0 – 9.4 lbs.

Specific Gravity 1.08-1.13

Viscosity:

#2 Zahn, Gardner Series 15-25 seconds

ISO 2431 3mm Cup – Sheen 45-80 seconds

VOC: 4.52 lbs./gal. (542 g/L)

Dry Time:

Air Dry (0.8 DFT), At 77ºF (25ºC), 50% RH

Dry hard 15 minutes

To recoat Within 7 days

Recommended Mil

Thickness

Mils Dry 0.6 – 0.9

Theoretical Coverage:

2

Per dry 0.8 mil 608 ft. /gal.

2

Per 25 μm 15.0 g/m

SHELF LIFE

Shelf Life is applicable only for material stored in unopened and undamaged original

factory filled containers.

Minimum Storage Temp. 40ºF / 4ºC

Maximum Storage Temp. 90ºF / 32ºC

CM0723404: 1 year

Sherwin–Williams Aerospace Coatings • 415 E. Commerce Street • Andover, KS 67002

Tel: 316.733.7576 • Toll Free: 888.888.5593 • Fax: 316.733.1348

www.swaerospace.com Revision 3, 7/1/2009, Page 1 of 2

SURFACE PREPARATION___________________

Steel – Surface must be clean and free of grease, dirt, oil, rust

fingerprints, and other contaminants to insure optimum adhesion

and performance properties. Chemical pretreatment, zinc

phosphate or CM0484684 Wash primer gives best adhesion and

performance results. Where blasting is appropriate, blast in

accordance with SSPC-SP6. For optimum adhesion pretreat

blasted surface immediately. Prime with wash primer

CM0484684 within two hours after blasting.

Aluminum – Clean with acidic cleaner or other appropriate

cleaner depending on contamination. Pretreat with chromate

conversion coating, wash primer CM0484684, or anodize per

MIL-A-8625. Galvanized and other metals: Clean and remove

oxidation contamination on surface, followed by treatment with

CM0484684 wash primer. Due to the variability in these

surfaces, testing adhesion on each situation is recommended.

MIXING INSTRUCTIONS

Pre-shake the primer for 5-10 minutes.

No reduction is required. If desired, reduce up to 10% with

CM0110944.

APPLICATION

This product can be applied using conventional spray, or HVLP.

Please consult your Sherwin-Williams Aerospace representative

for proper equipment settings.

Note: Cured film should not be subjected to strong solvents like

MEK. Should primer require cleaning prior to topcoating

CM0110120 pre-paint wipe is recommended (See data sheet)

EQUIPMENT CLEANUP

Clean tools/equipment immediately after use with toluene,

xylene, or lacquer thinner. Follow manufacturer’s safety

recommendations when using any solvent.

PRODUCT INFORMATION

Product Data Sheets are periodically updated to reflect new information

relating to the product. It is important that the customer obtain the most

recent Product Data Sheet for the product being used. The information,

rating, and opinions stated here pertain to the material currently offered

and represent the results of tests believed to be reliable. However, due

to variations in customer handling and methods of application which are

not known or under our control, The Sherwin–Williams Company cannot

make any warranties as to the end result.

Sherwin–Williams Aerospace Coatings • 415 E. Commerce Street • Andover, KS 67002

Tel: 316.733.7576 • Toll Free: 888.888.5593 • Fax: 316.733.1348

www.swaerospace.com Revision 3, 7/01/2009, Page 2 of 2

You might also like

- 4010 TDS EnglishDocument1 page4010 TDS EnglishJose Luis Ramirez RamirezNo ratings yet

- Steel Shield 1200Document2 pagesSteel Shield 1200Moin AltafNo ratings yet

- Carboguard 635 Thinned 50% - Sealer PDSDocument5 pagesCarboguard 635 Thinned 50% - Sealer PDSjakeNo ratings yet

- Jazeera Damp MasticDocument3 pagesJazeera Damp MasticAhmad BougeisNo ratings yet

- Carboguard 893 PDSDocument5 pagesCarboguard 893 PDSUtomoNo ratings yet

- Sigma 36Document2 pagesSigma 36EngTamerNo ratings yet

- G4258 Silver - Pds-EnDocument3 pagesG4258 Silver - Pds-EnuraliNo ratings yet

- Carboguard 893 PDSDocument5 pagesCarboguard 893 PDSTrịnh Minh KhoaNo ratings yet

- Carbozinc 858: Selection & Specification DataDocument4 pagesCarbozinc 858: Selection & Specification DataNico RoisnerNo ratings yet

- Technical Data Sheet Jazeera Selfmastic JI-66009: DescriptionDocument3 pagesTechnical Data Sheet Jazeera Selfmastic JI-66009: Descriptionsalam nazarNo ratings yet

- WWW - Techsil.co - Uk: Stainless Steel Putty Product BulletinDocument2 pagesWWW - Techsil.co - Uk: Stainless Steel Putty Product BulletinVinodKandukuriNo ratings yet

- Carboguard 893: Selection & Specification DataDocument5 pagesCarboguard 893: Selection & Specification DataQuy RomNo ratings yet

- Carbozinc 11 WB: Selection & Specification Data Substrates & Surface PreparationDocument2 pagesCarbozinc 11 WB: Selection & Specification Data Substrates & Surface PreparationPurwanto ritzaNo ratings yet

- Carbozinc 858 PDSDocument4 pagesCarbozinc 858 PDShuycongvuNo ratings yet

- Macropoxy 646 SEDocument4 pagesMacropoxy 646 SESleyda MunozNo ratings yet

- Technical Data: Plastic Steel Putty (A)Document4 pagesTechnical Data: Plastic Steel Putty (A)francisNo ratings yet

- 113.007 - Zinc Clad Xi WB BR PDFDocument2 pages113.007 - Zinc Clad Xi WB BR PDFFernando VittoNo ratings yet

- Sigmacover 300 PDFDocument5 pagesSigmacover 300 PDFJorge Alberto MontalatNo ratings yet

- Protective & Marine Coatings: Magnalux 40VDocument2 pagesProtective & Marine Coatings: Magnalux 40VMd Usama100% (1)

- Technical Data Sheet Jazeera Marine Primer JM-31001: Description: Recommended Use: CharacteristicsDocument3 pagesTechnical Data Sheet Jazeera Marine Primer JM-31001: Description: Recommended Use: CharacteristicsMark DingalNo ratings yet

- Technical Data: Plastic Steel 5-Minute Putty (SF)Document4 pagesTechnical Data: Plastic Steel 5-Minute Putty (SF)Hoàng DũngNo ratings yet

- Acrolon 218 HsDocument4 pagesAcrolon 218 HsKARENNo ratings yet

- Protective & Marine Coatings: Pro-Cryl Universal PrimerDocument4 pagesProtective & Marine Coatings: Pro-Cryl Universal PrimerAna CabreraNo ratings yet

- Pds Zincanode 690 VocDocument2 pagesPds Zincanode 690 VocmuthukumarNo ratings yet

- Zincanode 402: Two Pack Zinc Rich Epoxy PrimerDocument2 pagesZincanode 402: Two Pack Zinc Rich Epoxy PrimerlivefreakNo ratings yet

- Carboguard 635: Selection & Specification DataDocument5 pagesCarboguard 635: Selection & Specification DataPrakashNo ratings yet

- Carboguard 890 PDSDocument2 pagesCarboguard 890 PDSLinnie McleodNo ratings yet

- 112.025 - SUMAZINC S-659 PRIMER RICO EM ZINCO - Inglês PDFDocument2 pages112.025 - SUMAZINC S-659 PRIMER RICO EM ZINCO - Inglês PDFFernando VittoNo ratings yet

- Protective & Marine Coatings: Zinc Clad Iv EuDocument2 pagesProtective & Marine Coatings: Zinc Clad Iv Eusrinath vNo ratings yet

- Carboguard 890 GFDocument4 pagesCarboguard 890 GFDuongthithuydungNo ratings yet

- Carboguard 636 XT PDSDocument4 pagesCarboguard 636 XT PDSCarlos Rojas HandalNo ratings yet

- Carboguard 89dfsfs0 PDSDocument2 pagesCarboguard 89dfsfs0 PDSMayur PatelNo ratings yet

- Carbocoat 8239: Selection & Specification DataDocument4 pagesCarbocoat 8239: Selection & Specification DataSHAIK ASIMUDDINNo ratings yet

- Carboguard 893 SG MIO PDSDocument4 pagesCarboguard 893 SG MIO PDSMuthuKumarNo ratings yet

- Coal Tar EpoxyDocument6 pagesCoal Tar EpoxyMagoo MarjonNo ratings yet

- Carbozinc 859 (Organic Zinc-Rich Epoxy)Document4 pagesCarbozinc 859 (Organic Zinc-Rich Epoxy)helioxavier2No ratings yet

- Sigmacover 380Document18 pagesSigmacover 380eitan-dalia4971No ratings yet

- Sikagard - 62 EngDocument3 pagesSikagard - 62 Engbassem kooliNo ratings yet

- Carboguard 880 MIO PDSDocument4 pagesCarboguard 880 MIO PDSHerman EngelbrechtNo ratings yet

- Protective & Marine Coatings: Acrolon™ 218 HsDocument4 pagesProtective & Marine Coatings: Acrolon™ 218 HsAna CabreraNo ratings yet

- Steel Shield 1100Document3 pagesSteel Shield 1100Moin AltafNo ratings yet

- DuraplateDocument4 pagesDuraplatelovaldes62No ratings yet

- Sigmacover 525: Description Principal CharacteristicsDocument2 pagesSigmacover 525: Description Principal CharacteristicsEngTamerNo ratings yet

- Corothane® I Galvapac 1K Zinc Primer PDFDocument4 pagesCorothane® I Galvapac 1K Zinc Primer PDFImam Situmeang100% (1)

- Technical Data Sheet for 1-Part Silicone Sealant Silcoset 151Document2 pagesTechnical Data Sheet for 1-Part Silicone Sealant Silcoset 151Arun VaideeswaranNo ratings yet

- Spread n' Spray Spot Primer: Versatile Filler & PrimerDocument2 pagesSpread n' Spray Spot Primer: Versatile Filler & PrimerDoti Tri PrasetioNo ratings yet

- EPIMASTIC 5100-March 2019 Version 2Document2 pagesEPIMASTIC 5100-March 2019 Version 2PraveenNo ratings yet

- DATA SHEET Industrial Enamel BlancoDocument4 pagesDATA SHEET Industrial Enamel BlancoAlfredo OrellanaNo ratings yet

- Steelshield Ve: Product DescriptionDocument2 pagesSteelshield Ve: Product DescriptionMoin AltafNo ratings yet

- SigmaZinc 100 zinc primer guideDocument4 pagesSigmaZinc 100 zinc primer guideJohnson Chng Hou KiatNo ratings yet

- Berger: Product SpecificationsDocument2 pagesBerger: Product SpecificationsAabhas UpadhyayaNo ratings yet

- Smarter Building Systems SBS-R30 Insulating Paint InstructionsDocument5 pagesSmarter Building Systems SBS-R30 Insulating Paint InstructionsJJ Sherem MoraNo ratings yet

- Sherglass FFDocument4 pagesSherglass FFJhose BonillaNo ratings yet

- Carboguard 890 PDSDocument5 pagesCarboguard 890 PDScrisNo ratings yet

- Carboguard 891 Product Data SheetDocument4 pagesCarboguard 891 Product Data SheetPrakashNo ratings yet

- PARATHERM 600 HEAT RESISTING FINISHDocument2 pagesPARATHERM 600 HEAT RESISTING FINISHyarth880% (1)

- Xylan 80-018-g6706 Black - BeDocument2 pagesXylan 80-018-g6706 Black - BeSYED MAZHARNo ratings yet

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- GRP and Buildings: A Design Guide for Architects and EngineersFrom EverandGRP and Buildings: A Design Guide for Architects and EngineersNo ratings yet

- Unit8 Phoning The PlumberDocument1 pageUnit8 Phoning The PlumberBash MatNo ratings yet

- TB01909001E Tab 17 PDFDocument22 pagesTB01909001E Tab 17 PDFBash MatNo ratings yet

- Mona John vocabulary matchingDocument1 pageMona John vocabulary matchingBash MatNo ratings yet

- Mona and John Listening AssessmentDocument2 pagesMona and John Listening AssessmentBash MatNo ratings yet

- TB01909001E Tab 17 PDFDocument22 pagesTB01909001E Tab 17 PDFBash MatNo ratings yet

- Technical B-H SaturationDocument6 pagesTechnical B-H SaturationBash MatNo ratings yet

- Differences Between The Grammar Translation Approach and The Direct ApproachDocument1 pageDifferences Between The Grammar Translation Approach and The Direct ApproachBash MatNo ratings yet

- Mona and John Listening AssessmentDocument2 pagesMona and John Listening AssessmentBash MatNo ratings yet

- Mona John vocabulary matchingDocument1 pageMona John vocabulary matchingBash MatNo ratings yet

- Flyer Current TransformerDocument24 pagesFlyer Current TransformerBash MatNo ratings yet

- The Tennessee Valley Authority's (Tva's) Experience and Action Plans With Freestanding Oil-Filled Current Transforgers (CT'S)Document7 pagesThe Tennessee Valley Authority's (Tva's) Experience and Action Plans With Freestanding Oil-Filled Current Transforgers (CT'S)Bash MatNo ratings yet

- TM Preface PDFDocument6 pagesTM Preface PDFBash MatNo ratings yet

- Differences Between The Reading Approach and The Audio Lingual ApproachDocument1 pageDifferences Between The Reading Approach and The Audio Lingual ApproachBash MatNo ratings yet

- TC Failure SkomDocument135 pagesTC Failure SkomSalvador ArcosNo ratings yet

- American Powder Coatings, Inc.: Product Data SheetDocument1 pageAmerican Powder Coatings, Inc.: Product Data SheetBash MatNo ratings yet

- USDOD Protective Coatings and PaintsDocument249 pagesUSDOD Protective Coatings and PaintsSpace_Hulker100% (4)

- Surface Preperation SSPCDocument4 pagesSurface Preperation SSPCGTpianomanNo ratings yet

- LFE M K WadhwaniDocument38 pagesLFE M K WadhwaniShahid KhanNo ratings yet

- Zinc Chromate Primer Excellent Corrosion ResistanceDocument2 pagesZinc Chromate Primer Excellent Corrosion ResistanceBash MatNo ratings yet

- Electrostatic Phenomena in Powder CoatingDocument10 pagesElectrostatic Phenomena in Powder CoatingBash Mat100% (1)

- TManual Chapter 01 PDFDocument22 pagesTManual Chapter 01 PDFJay Rameshbhai ParikhNo ratings yet

- Ehv Power Transformer Testing PDFDocument72 pagesEhv Power Transformer Testing PDFRamesh Epili100% (1)

- Shot Blasted and Primer Coated Heavy PlatesDocument7 pagesShot Blasted and Primer Coated Heavy PlatesBash MatNo ratings yet

- Technical Information Sheet: General Information: ISO 12944 TI - G 9 / UsaDocument6 pagesTechnical Information Sheet: General Information: ISO 12944 TI - G 9 / UsaBash MatNo ratings yet

- Etch Primers PDFDocument1 pageEtch Primers PDFBash MatNo ratings yet

- ColoursDocument5 pagesColoursAnoop N KuttyNo ratings yet

- Testex Tape Product Data Sheet 122Document2 pagesTestex Tape Product Data Sheet 122Bash MatNo ratings yet

- Etch Primers PDFDocument1 pageEtch Primers PDFBash MatNo ratings yet

- USDOD Protective Coatings and PaintsDocument249 pagesUSDOD Protective Coatings and PaintsSpace_Hulker100% (4)

- Tender Notice For Repair of Dts - Pts & Maint1Document22 pagesTender Notice For Repair of Dts - Pts & Maint1Bash MatNo ratings yet

- Nature of Acidity and Lime Requirement in Acid Soils of ManipurDocument8 pagesNature of Acidity and Lime Requirement in Acid Soils of ManipurIJASRETNo ratings yet

- Ford Essex V6 EngineDocument8 pagesFord Essex V6 EngineJoakamaster 16No ratings yet

- Specifications: 3516C - SS Marine PropulsionDocument5 pagesSpecifications: 3516C - SS Marine PropulsionAidel MustafaNo ratings yet

- Physics ExamDocument30 pagesPhysics Examjomar bolasocNo ratings yet

- IEC CsODESDocument2 pagesIEC CsODESArun KumarNo ratings yet

- Rockaway Beach Branch Community Impact StudyDocument98 pagesRockaway Beach Branch Community Impact StudyHanaRAlbertsNo ratings yet

- Node diagnostics report for RBS6601WDocument9 pagesNode diagnostics report for RBS6601WWilson DiazNo ratings yet

- Unit-I: Introduction To J2EEDocument29 pagesUnit-I: Introduction To J2EEsurakshaNo ratings yet

- Compact 1NC+1NO limit switch data sheetDocument2 pagesCompact 1NC+1NO limit switch data sheetJose AkinoNo ratings yet

- ReleDocument3 pagesRelevitor4santos_6No ratings yet

- Osha 1926.452Document14 pagesOsha 1926.452Binoy GopinathanNo ratings yet

- Batch Profile - 2017Document57 pagesBatch Profile - 2017Praneet TNo ratings yet

- Lesson 7: Cylinders: Basic Hydraulic SystemsDocument12 pagesLesson 7: Cylinders: Basic Hydraulic Systemsoscar el carevergaNo ratings yet

- Amphenol Musician Range PDFDocument8 pagesAmphenol Musician Range PDFtrc_wmNo ratings yet

- Advanced Data Structures and ImplementationDocument56 pagesAdvanced Data Structures and ImplementationSyam Prasad Reddy BattulaNo ratings yet

- Sap MM LSMWDocument18 pagesSap MM LSMWMani balan100% (1)

- Bilge Alarm Monitor OMD 11Document22 pagesBilge Alarm Monitor OMD 11Lucian Iftemie100% (3)

- Fosroc Conbextra EP10: Constructive SolutionsDocument2 pagesFosroc Conbextra EP10: Constructive SolutionsVincent JavateNo ratings yet

- Piping Vibration: Causes, Limits & Remedies: Public Courses In-House Courses Operator TrainingDocument12 pagesPiping Vibration: Causes, Limits & Remedies: Public Courses In-House Courses Operator Trainingmember1000100% (1)

- New Schedule For Sunset Limited Benefits Passengers and Improves Financial PerformanceDocument3 pagesNew Schedule For Sunset Limited Benefits Passengers and Improves Financial Performanceapi-26433240No ratings yet

- INTERCOMP Pt300 Users Manual Rev GDocument44 pagesINTERCOMP Pt300 Users Manual Rev GCTN2010No ratings yet

- FGGDocument12 pagesFGGSridharan VenkatNo ratings yet

- Thinking ForthDocument311 pagesThinking ForthCristianNo ratings yet

- How to Operate AAS with SignPal & PhotoPRINTDocument25 pagesHow to Operate AAS with SignPal & PhotoPRINTLucian DogariuNo ratings yet

- Classification of FluidDocument29 pagesClassification of FluidAbdur RehmanNo ratings yet

- Foundation LayoutDocument1 pageFoundation LayoutrendaninNo ratings yet

- Murray Loop Test To Locate Ground Fault PDFDocument2 pagesMurray Loop Test To Locate Ground Fault PDFmohdNo ratings yet

- NDI Manual 2013 - v10Document13 pagesNDI Manual 2013 - v10Yudha Bhakti NugrahaNo ratings yet

- Account Manager Business Development in San Jose CA Resume Mark WestonDocument2 pagesAccount Manager Business Development in San Jose CA Resume Mark WestonMarkWeston2No ratings yet

- 3 Phase Induction Motors Objective Questions With AnswersDocument3 pages3 Phase Induction Motors Objective Questions With AnswersMohan Raj0% (2)