Professional Documents

Culture Documents

OB2273 On Bright

Uploaded by

Carlos PosadaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

OB2273 On Bright

Uploaded by

Carlos PosadaCopyright:

Available Formats

OB2273

High Performance Current Mode PWM Controller

GENERAL DESCRIPTION FEATURES

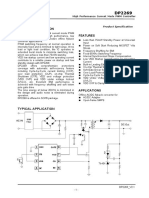

OB2273 is a highly integrated current mode PWM ■ Power on Soft Start Reducing MOSFET Vds

control IC optimized for high performance, low Stress

standby power and cost effective offline flyback ■ Frequency shuffling for EMI

converter applications. ■ Extended Burst Mode Control For Improved

科

PWM switching frequency at normal operation is Efficiency and Minimum Standby Power

internally fixed and is trimmed to tight range. At no Design

load or light load condition, the IC operates in ■ Audio Noise Free Operation

乐

extended ‘burst mode’ to minimize switching loss. ■ Fixed 65KHZ Switching Frequency

Lower standby power and higher conversion ■ Comprehensive Protection Coverage

efficiency is thus achieved. o VDD Under Voltage Lockout with

VDD low startup current and low operating current Hysteresis (UVLO)

contribute to a reliable power on startup and low

to

o Cycle-by-cycle over current threshold

standby design with OB2273. setting for constant output power limiting

OB2273 offers complete protection coverage with over universal input voltage range

auto-recovery including Cycle-by-Cycle current o Overload Protection (OLP) with auto-

limiting (OCP), over load protection (OLP), and recovery

al

VDD under voltage lockout (UVLO). It also o Over Temperature Protection (OTP) with

provides the protections with latched shut down latch shut down

including over temperature protection (OTP), and o VDD Over voltage Protection(OVP) with

over voltage (fixed or adjustable) protection (OVP).

i latch shut down

nt

Excellent EMI performance is achieved with On- o Adjustable OVP through external Zener

Bright proprietary frequency shuffling technique.

The tone energy at below 20KHZ is minimized in

APPLICATIONS

e

the design and audio noise is eliminated during

operation. Offline AC/DC flyback converter for

id

■ Battery Charger

OB2273 is offered in SOT23-6 and DIP-8 package. ■ Power Adapter

nf

■ Set-Top Box Power Supplies

■ Open-frame SMPS

Co

TYPICAL APPLICATION

t

i gh

Br

On

©On-Bright Electronics Confidential Preliminary Datasheet

OB_DOC_DS_227305

-1-

Free Datasheet http://www.datasheet4u.com/

OB2273

High Performance Current Mode PWM Controller

Ordering Information

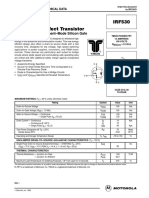

GENERAL INFORMATION Part Number Description

Pin Configuration OB2273MP SOT23-6, Pb-free in T&R

The OB2273 is offered in SOT23-6 and DIP8 OB2273AP DIP8, Pb-free in Tube

package, shown as below.

Package Dissipation Rating

科

Package RθJA(℃/W)

SOT23-6 200

DIP8 90

乐

Absolute Maximum Ratings

Parameter Value

to

VDD DC Supply Voltage 30 V

VDD Zener Clamp

VDD_Clamp+0.1V

VoltageNote

VDD DC Clamp Current 10 mA

al

FB Input Voltage -0.3 to 7V

Sense Input Voltage -0.3 to 7V

RT Input Voltage -0.3 to 7V

i Min/Max Operating

Junction Temperature TJ

-40 to 150 ℃

nt

Min/Max Storage

-55 to 160 ℃

Temperature Tstg

Lead Temperature

e

260 ℃

(Soldering, 10secs)

id

Note: VDD_Clamp has a nominal value of 32V.

Stresses beyond those listed under “absolute maximum

ratings” may cause permanent damage to the device. These

nf

are stress ratings only, functional operation of the device at

these or any other conditions beyond those indicated under

“recommended operating conditions” is not implied. Exposure

to absolute maximum-rated conditions for extended periods

Co

may affect device reliability.

t

gh

OB2273 X X

i

Br

Current Mode PWM Controller with Package Package Pb free

Frequency shuffling

M:SOT23-6 Blank:Normal

A: DIP8 P:lead-free

On

©On-Bright Electronics Confidential Preliminary Datasheet

OB_DOC_DS_227305

-2-

Free Datasheet http://www.datasheet4u.com/

OB2273

High Performance Current Mode PWM Controller

Marking Information

73YWW

科

S

乐

Y:Year Code

WW:Week Code(01-52)

S:Internal Code(Optional)

to

i al

nt

TERMINAL ASSIGNMENTS

Pin Name I/O Description

e

GND P Ground

id

Feedback input pin. The PWM duty cycle is determined by voltage level into this pin

FB I

and the current-sense signal at Pin 4.

Dual function pin. Either connected through a NTC resistor to ground for over

nf

RT I temperature shutdown/latch control or connected through Zener to VDD for

adjustable over voltage protection

CS I Current sense input

Co

VDD P Power Supply

Gate O Totem-pole gate driver output for power Mosfet

RECOMMENDED OPERATING CONDITION

t

gh

Symbol Parameter Min/Max Unit

VDD VDD Supply Voltage 12 to 25 V

TA Operating Ambient Temperature -40 to 85 ℃

i

Br

On

©On-Bright Electronics Confidential Preliminary Datasheet

OB_DOC_DS_227305

-3-

Free Datasheet http://www.datasheet4u.com/

OB2273

High Performance Current Mode PWM Controller

BLOCK DIAGRAM

科

乐

to

i al

e nt

id

nf

Co

t

i gh

Br

On

©On-Bright Electronics Confidential Preliminary Datasheet

OB_DOC_DS_227305

-4-

Free Datasheet http://www.datasheet4u.com/

OB2273

High Performance Current Mode PWM Controller

ELECTRICAL CHARACTERISTICS

(TA = 25℃, VDD=18V, unless otherwise noted)

Symbol Parameter Test Conditions Min Typ Max Unit

Supply Voltage (VDD)

VDD=UVLO(OFF)-

Istartup VDD Start up Current 1V, measure leakage 5 20 uA

科

current into VDD

VDD=18V,VFB=3V,

I_VDD_Operation Operation Current 1.8 2.5 mA

CS=0V,Cgate=1nF

乐

VDD Under Voltage Lockout

UVLO(ON) 8 9 10 V

Enter

VDD Under Voltage Lockout

UVLO(OFF) 14.3 15.3 16.3 V

Exit (Recovery)

to

Vpull-up Pull-up PMOS active 13 V

Vdd_clamp Ivdd=10mA 30 32 34 V

CS=0V,FB=3V

Over voltage protection

OVP(ON) Ramp up VDD until 26 28 30 V

voltage

gate clock is off

al

Vlatch_release Latch release voltage 5 V

Feedback Input Section(FB Pin)

VFB_Open VFB Open Loop Voltage

PWM input gain Δ VFB/ Δ

i 3.9 4.2 V

nt

Avcs 2 V/V

VCS

Maximum duty Max duty cycle @

75 80 85 %

cycle VDD=18V,VFB=3V,VCS=0V

e

The threshold enter green

Vref_green 2 V

id

mode

Vref_burst_H The threshold exit burst mode 1.275 V

The threshold enter burst

Vref_burst_L 1.175 V

nf

mode

Short FB pin to GND

IFB_Short FB pin short circuit current 0.4 mA

and measure current

Co

Power Limiting FB Threshold

VTH_PL 3.7 V

Voltage

Power limiting Debounce

TD_PL 80 88 96 mSec

Time

t

ZFB_IN Input Impedance 16 Kohm

gh

Current Sense Input(CS Pin)

SST Soft start time 4 ms

T_blanking Leading edge blanking time 220 ns

i

ZSENSE_IN Input Impedance 40 Kohm

From Over Current

Br

Over Current Detection and Occurs till the

TD_OC 120 nSec

Control Delay Gatedrive output start

to turn off

Internal Current Limiting

On

VTH_OC Threshold Voltage with zero 0.75 V

duty cycle

Vocp_clamping CS voltage clamper 0.9 V

Oscillator

VDD=18V, FB=3V,

FOSC Normal Oscillation Frequency 60 65 70 KHZ

CS=0V

△f_OSC Frequency jittering +/-4 %

F_shuffling Shuffling frequency 32 Hz

©On-Bright Electronics Confidential Preliminary Datasheet

OB_DOC_DS_227305

-5-

Free Datasheet http://www.datasheet4u.com/

OB2273

High Performance Current Mode PWM Controller

Frequency Temperature

△f_Temp 1 %

Stability

△f_VDD Frequency Voltage Stability 1 %

F_Burst Burst Mode Switch Frequency 22 KHZ

Gate driver

Output low level @ VDD=18V,

VOL 1 V

Io=5mA

科

Output high level @

VOH 6 V

VDD=18V, Io=20mA

V_clamping Output clamp voltage 12 V

乐

Output rising time 1V ~ 12V

T_r 175 nS

@ CL=1000pF

Output falling time 12V ~ 1V

T_f 85 nS

@ CL=1000pF

to

Over temperature protection

IRT Output current of RT pin 95 100 105 uA

VOTP Threshold voltage for OTP 0.95 1 1.05 V

Td_OTP OTP debounce time 32 Cycle

VRT_FL Float voltage at RT pin 2.3 V

al

External OVP threshold

Vth_OVP 4 V

voltage

i

e nt

id

nf

Co

t

i gh

Br

On

©On-Bright Electronics Confidential Preliminary Datasheet

OB_DOC_DS_227305

-6-

Free Datasheet http://www.datasheet4u.com/

OB2273

High Performance Current Mode PWM Controller

CHARACTERIZATION PLOTS

VDD = 18V, TA = 25℃ condition applies if not otherwise noted.

Istartup(uA) vs Temperature(℃ ) Vth_otp(V) vs Temperature(℃ )

5.0

1.02

科

4.5

Istartup(uA)

1.01

Vth_otp(V)

4.0

乐

1.00

3.5 0.99

3.0 0.98

to

-40 0 40 80 120 -40 0 40 80 120

Temperature(℃) Temperature(℃)

al

UVLO(on)(V) vs Temperature(℃ ) UVLO(off)(V) vs Temperature(℃ )

9.6 15.4

i

UVLO(on)(V)

15.2

UVLO(off)(V)

9.4

nt

15

9.2

14.8

e

9

14.6

id

8.8 14.4

-40 0 40 80 120 -40 0 40 80 120

nf

Temperature(℃ ) Temperature(℃ )

Co

Vth_OC(V)vs duty(%) Fosc(KHz) vs Temperature(℃ )

0.95 64.0

0.90 63.8

Fosc(KHz)

t

Vth_OC(V)

63.5

gh

0.85

0.80 63.3

i

63.0

0.75

Br

-40 0 40 80 120

0 14 28 42 56 70

Duty(%) Temperature(℃)

On

©On-Bright Electronics Confidential Preliminary Datasheet

OB_DOC_DS_227305

7

Free Datasheet http://www.datasheet4u.com/

OB2273

High Performance Current Mode PWM Controller

OPERATION DESCRIPTION

OB2273 is a highly integrated current mode PWM Vref_burst_L (the threshold enter burst mode) and

control IC optimized for high performance, low device enters Burst Mode control. The Gate drive

standby power and cost effective offline flyback output switches when FB input rises back to

converter applications. The ‘Extended burst Vref_burst_H (the threshold exit burst mode).

科

mode’ control greatly reduces the standby power Otherwise the gate drive remains at off state to

consumption and helps the design easily to meet minimize the switching loss and reduces the

the international power conservation requirements. standby power consumption to the greatest

乐

extend.

• Startup Current and Start up Control The switching frequency control also eliminates

Startup current of OB2273 is designed to be very the audio noise at any loading conditions.

low so that VDD could be charged up above

UVLO threshold level and device starts up quickly. • Oscillator Operation

to

A large value startup resistor can therefore be The switching frequency is internally fixed at

used to minimize the power loss yet achieve a 65KHZ. No external frequency setting

reliable startup in application. components are required for PCB design

simplification.

al

• Operating Current

The Operating current of OB2273 is low at 1.8mA. • Current Sensing and Leading Edge Blanking

Good efficiency is achieved with OB2273 low Cycle-by-Cycle current limiting is offered in

operating current together with the ‘Extended

iOB2273 current mode PWM control. The switch

nt

burst mode’ control features. current is detected by a sense resistor into the CS

pin. An internal leading edge blanking circuit

• Soft Start chops off the sensed voltage spike at initial

e

OB2273 features an internal 4ms soft start to internal power MOSFET on state due to snubber

soften the electrical stress occurring in the power diode reverse recovery and surge gate current of

id

supply during startup. It is activated during the power MOSFET. The current limiting comparator

power on sequence. As soon as VDD reaches is disabled and cannot turn off the internal power

UVLO(OFF), the CS peak voltage is gradually MOSFET during the blanking period. The PWM

nf

increased from 0.05V to the maximum level. duty cycle is determined by the current sense

Every restart up is followed by a soft start. input voltage and the FB input voltage.

Co

• Frequency shuffling for EMI improvement • Internal Synchronized Slope Compensation

The frequency Shuffling (switching frequency Built-in slope compensation circuit adds voltage

modulation) is implemented in OB2273. The ramp onto the current sense input voltage for

oscillation frequency is modulated so that the tone PWM generation. This greatly improves the close

t

energy is spread out. The spread spectrum loop stability at CCM and prevents the sub-

minimizes the conduction band EMI and therefore harmonic oscillation and thus reduces the output

gh

eases the system design. ripple voltage.

• Drive

i

• Extended Burst Mode Operation

At light load or zero load condition, most of the The power MOSFET is driven by a dedicated gate

Br

power dissipation in a switching mode power driver for power switch control. Too weak the gate

supply is from switching loss on the MOSFET, the drive strength results in higher conduction and

core loss of the transformer and the loss on the switch loss of MOSFET while too strong gate

snubber circuit. The magnitude of power loss is in drive results the compromise of EMI.

On

proportion to the switching frequency. Lower A good tradeoff is achieved through the built-in

switching frequency leads to the reduction on the totem pole gate design with right output strength

power loss and thus conserves the energy. and dead time control. The low idle loss and good

The switching frequency is internally adjusted at EMI system design is easier to achieve with this

no load or light load condition. The switch dedicated control scheme.

frequency reduces at light/no load condition to

improve the conversion efficiency. At light load or

no load condition, the FB input drops below • Protection Controls

©On-Bright Electronics Confidential Preliminary Datasheet

OB_DOC_DS_227305

8

Free Datasheet http://www.datasheet4u.com/

OB2273

High Performance Current Mode PWM Controller

Good power supply system reliability is achieved At overload condition when FB input voltage

with auto-recovery protection features including exceeds power limit threshold value for more than

Cycle-by-Cycle current limiting (OCP), Over Load TD_PL, control circuit reacts to shut down the

Protection (OLP), and Under Voltage Lockout on converter. It restarts when VDD voltage drops

VDD (UVLO), and latch shutdown features below UVLO limit. For protection with latch shut

including over temperature protection (OTP), fixed down mode, control circuit shutdowns (latch) the

or adjustable VDD over voltage protection (OVP). power MOSFET when an Over Temperature

With On-Bright Proprietary technology, the OCP is condition or Over Voltage condition is detected

科

line voltage compensated to achieve constant until VDD drops below 5V (Latch release voltage) ,

output power limit over the universal input voltage and device enters power on restart-up sequence

range. thereafter.

乐

to

i al

e nt

id

nf

Co

t

i gh

Br

On

©On-Bright Electronics Confidential Preliminary Datasheet

OB_DOC_DS_227305

-9-

Free Datasheet http://www.datasheet4u.com/

OB2273

High Performance Current Mode PWM Controller

PACKAGE MECHANICAL DATA

科

乐

to

i al

e nt

id

nf

Co

Dimensions In Millimeters Dimensions In Inches

t

Symbol

Min Max Min Max

gh

A 1.000 1.300 0.039 0.051

A1 0.000 0.150 0.000 0.006

A2 1.000 1.200 0.039 0.047

i

b 0.300 0.500 0.012 0.020

c 0.100 0.200 0.004 0.008

Br

D 2.800 3.020 0.110 0.119

E 1.500 1.700 0.059 0.067

E1 2.600 3.000 0.102 0.118

e 0.950 (BSC) 0.037 (BSC)

On

e1 1.800 2.000 0.071 0.079

L 0.300 0.600 0.012 0.024

θ 0º 8º 0º 8º

©On-Bright Electronics Confidential Preliminary Datasheet

OB_DOC_DS_227305

- 10 -

Free Datasheet http://www.datasheet4u.com/

OB2273

High Performance Current Mode PWM Controller

科

乐

to

i al

e nt

id

nf

Co

Dimensions In Millimeters Dimensions In Inches

Symbol

Min Max Min Max

t

A 3.710 5.334 0.146 0.210

gh

A1 0.381 0.015

A2 2.921 4.953 0.115 0.195

B 0.350 0.650 0.014 0.026

i

B1 1.524 (BSC) 0.06 (BSC)

Br

C 0.200 0.360 0.008 0.014

D 9.000 10.160 0.354 0.400

E 6.096 7.112 0.240 0.280

E1 0.288 0.325

On

7.320 8.255

e 2.540 (BSC) 0.1 (BSC)

L 2.921 3.810 0.115 0.150

E2 7.620 10.920 0.300 0.430

©On-Bright Electronics Confidential Preliminary Datasheet

OB_DOC_DS_227305

- 11 -

Free Datasheet http://www.datasheet4u.com/

OB2273

High Performance Current Mode PWM Controller

IMPORTANT NOTICE

RIGHT TO MAKE CHANGES

On-Bright Electronics Corp. reserves the right to make corrections, modifications, enhancements,

improvements and other changes to its products and services at any time and to discontinue any product

or service without notice. Customers should obtain the latest relevant information before placing orders

科

and should verify that such information is current and complete.

WARRANTY INFORMATION

乐

On-Bright Electronics Corp. warrants performance of its hardware products to the specifications

applicable at the time of sale in accordance with its standard warranty. Testing and other quality control

techniques are used to the extent it deems necessary to support this warranty. Except where mandated

by government requirements, testing of all parameters of each product is not necessarily performed.

On-Bright Electronics Corp. assumes no liability for application assistance or customer product design.

to

Customers are responsible for their products and applications using On-Bright’s components, data sheet

and application notes. To minimize the risks associated with customer products and applications,

customers should provide adequate design and operating safeguards.

al

LIFE SUPPORT

On-Bright Electronics Corp.’s products are not designed to be used as components in devices intended to

support or sustain human life. On-bright Electronics Corp. will not be held liable for any damages or

i

claims resulting from the use of its products in medical applications.

nt

MILITARY

On-Bright Electronics Corp.’s products are not designed for use in military applications. On-Bright

Electronics Corp. will not be held liable for any damages or claims resulting from the use of its products in

e

military applications.

id

nf

Co

t

i gh

Br

On

©On-Bright Electronics Confidential Preliminary Datasheet

OB_DOC_DS_227305

- 12 -

Free Datasheet http://www.datasheet4u.com/

You might also like

- On-Bright Confidential To ACT: General Description FE AturesDocument10 pagesOn-Bright Confidential To ACT: General Description FE AturesJose BenavidesNo ratings yet

- OB2273A On BrightDocument10 pagesOB2273A On BrightHamza Abbasi AbbasiNo ratings yet

- OB2263 On-Bright PDFDocument13 pagesOB2263 On-Bright PDFamaliah bamesuNo ratings yet

- PRDF OB5269CPDocument11 pagesPRDF OB5269CPtomopiNo ratings yet

- Sunrom 814104Document13 pagesSunrom 814104Valentin LeonteNo ratings yet

- Ob 2269 CapDocument13 pagesOb 2269 Caporkun burkayNo ratings yet

- General Description Features: High Performance Current Mode PWM ControllerDocument11 pagesGeneral Description Features: High Performance Current Mode PWM ControllerPhạm Tấn HảiNo ratings yet

- OB2353 Data InglesDocument11 pagesOB2353 Data InglesEAKIT SPAINNo ratings yet

- DP2269Document7 pagesDP2269GABRIEL AMORIM ARAUJONo ratings yet

- OB2362 DatasheetDocument10 pagesOB2362 DatasheetTín SmpsNo ratings yet

- Ob2262 Ver2.0 Datasheet PDFDocument13 pagesOb2262 Ver2.0 Datasheet PDFjesus cautivoNo ratings yet

- Ob2262 Datasheet PDFDocument13 pagesOb2262 Datasheet PDFjesus cautivoNo ratings yet

- General Description: EMI Filter Ac in DC OutDocument13 pagesGeneral Description: EMI Filter Ac in DC Outjesus cautivoNo ratings yet

- 1h6VuxLQ OB2216APDocument10 pages1h6VuxLQ OB2216APjaimeNo ratings yet

- Sheet 12Document9 pagesSheet 12nlNo ratings yet

- Obgz10mp (z10j19)Document11 pagesObgz10mp (z10j19)SashaNo ratings yet

- Ob 2223 HCDocument11 pagesOb 2223 HCRivaldyNo ratings yet

- Ob2262 Usado em Fonte Proview MLT 198aDocument13 pagesOb2262 Usado em Fonte Proview MLT 198aHeron Cesar VieiraNo ratings yet

- On-Bright Confidential To Bona: Quasi-Resonant Flyback PWM Controller General Description FeaturesDocument14 pagesOn-Bright Confidential To Bona: Quasi-Resonant Flyback PWM Controller General Description FeaturesFlavio Tonello TavaresNo ratings yet

- Current Mode PWM Controller: General DescriptionDocument12 pagesCurrent Mode PWM Controller: General DescriptionAlex GerasimenkoNo ratings yet

- Ob5269cp Ob5269cpa PDFDocument11 pagesOb5269cp Ob5269cpa PDFGiovanni Carrillo Villegas100% (1)

- OB2530P On BrightElectronicsDocument10 pagesOB2530P On BrightElectronicsrrNo ratings yet

- OB2203 On-BrightElectronicsDocument13 pagesOB2203 On-BrightElectronicsعلي محمدعبدالله الردينيNo ratings yet

- G1138 GlobalSemiconductorDocument4 pagesG1138 GlobalSemiconductorNiltonNo ratings yet

- LD7523 PDFDocument18 pagesLD7523 PDFAmalio MamaniNo ratings yet

- General Description Features: High Precision Low Cost MCM Power SwitchDocument10 pagesGeneral Description Features: High Precision Low Cost MCM Power SwitchNguyễn TrungNo ratings yet

- On-Bright Confidential To Lycon: General Description FeaturesDocument10 pagesOn-Bright Confidential To Lycon: General Description FeaturesРуслан СафиуллинNo ratings yet

- Cargador Enercell cr623xDocument11 pagesCargador Enercell cr623xcuco777No ratings yet

- Stra6252m SKDocument13 pagesStra6252m SKLeonildo CostaNo ratings yet

- OB2301W On BrightElectronicsDocument11 pagesOB2301W On BrightElectronicsIlago BenignoNo ratings yet

- STR-A6252M: Switching RegulatorsDocument13 pagesSTR-A6252M: Switching RegulatorsAntonioPeriniNo ratings yet

- NE5230, SA5230, SE5230 Low Voltage Operational Amplifier: PDIP 8 N Suffix CASE 626 SOIC 8 D Suffix CASE 751Document18 pagesNE5230, SA5230, SE5230 Low Voltage Operational Amplifier: PDIP 8 N Suffix CASE 626 SOIC 8 D Suffix CASE 751Marcelo OemNo ratings yet

- Current Mode PWM Controller With Frequency Shuffling ME8202Document12 pagesCurrent Mode PWM Controller With Frequency Shuffling ME8202Kukla LossNo ratings yet

- High Performance Low Cost Off-Line PWM Power Switch: Features General DescriptionDocument1 pageHigh Performance Low Cost Off-Line PWM Power Switch: Features General DescriptionDesenvolvimento Qualitronix0% (1)

- Ait Semiconductor Inc.: Description FeaturesDocument11 pagesAit Semiconductor Inc.: Description FeaturesSamerNo ratings yet

- APX9131A: Features General DescriptionDocument12 pagesAPX9131A: Features General DescriptionChek OmarovNo ratings yet

- AP8012ADocument13 pagesAP8012ASamerNo ratings yet

- Circuito Regulador de Voltaje Ob2216Document9 pagesCircuito Regulador de Voltaje Ob2216Wcarlos Ob RodriguezNo ratings yet

- tps73201 EpDocument22 pagestps73201 EpDavid WangNo ratings yet

- Catalogue-CGV-24C-UV-OV Relay-CAT-CGV24C-01Document4 pagesCatalogue-CGV-24C-UV-OV Relay-CAT-CGV24C-01waveengg.coNo ratings yet

- Datasheet OB3350 LED DriverDocument10 pagesDatasheet OB3350 LED DriverEnya Andrea Ribba Hernandez0% (1)

- Str-W625xseries An enDocument17 pagesStr-W625xseries An enFederico GiordanoNo ratings yet

- Str-A6251M: Universal-Input/15 W 67 KHZ Flyback Switching RegulatorDocument7 pagesStr-A6251M: Universal-Input/15 W 67 KHZ Flyback Switching RegulatorAlexisNo ratings yet

- HIP6302CBDocument18 pagesHIP6302CBrjbordaNo ratings yet

- AD52580B Audio AmplifierDocument3 pagesAD52580B Audio Amplifierhamada13No ratings yet

- DP2525 DevelopermicroelectronicsDocument11 pagesDP2525 DevelopermicroelectronicsNghia PhanNo ratings yet

- LD7523Document18 pagesLD7523AssembleiaDeDeusSepherEloahNo ratings yet

- 3200W PFC Rack Mountable Front End Battery Charger For SLA & Li-Ion Batteries 27.6V 110ADocument6 pages3200W PFC Rack Mountable Front End Battery Charger For SLA & Li-Ion Batteries 27.6V 110AsiogNo ratings yet

- Fan 7317Document23 pagesFan 7317Lauswalk WalkNo ratings yet

- OB2279 On Bright PDFDocument13 pagesOB2279 On Bright PDFAmit Biswas0% (1)

- WS3418 WinsemiDocument8 pagesWS3418 WinsemiPaul MejiaNo ratings yet

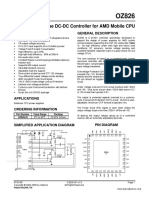

- Dual-Phase DC-DC Controller For AMD Mobile CPU: Features General DescriptionDocument7 pagesDual-Phase DC-DC Controller For AMD Mobile CPU: Features General Descriptionlordycarlos8588No ratings yet

- Bd9470xxx eDocument38 pagesBd9470xxx eJose GargaglioneNo ratings yet

- MC44608 Few External Components Reliable and Flexible SMPS ControllerDocument15 pagesMC44608 Few External Components Reliable and Flexible SMPS Controllervali dNo ratings yet

- LD5537 LeadtrendTechnologyDocument17 pagesLD5537 LeadtrendTechnologyphetronyo ferreira de oliveiraNo ratings yet

- TPS70928DBVT PDFDocument20 pagesTPS70928DBVT PDFLukaszNo ratings yet

- D 0 - 2 4 Buf2: 24V/20A DIN Rail Type Buffer ModuleDocument7 pagesD 0 - 2 4 Buf2: 24V/20A DIN Rail Type Buffer ModuleadrianioantomaNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Multirange, +5V, 12-Bit DAS With 2-Wire Serial Interface: General Description FeaturesDocument16 pagesMultirange, +5V, 12-Bit DAS With 2-Wire Serial Interface: General Description FeaturesCarlos PosadaNo ratings yet

- P6ke6v8 (C) A - P6ke440 (C) ADocument3 pagesP6ke6v8 (C) A - P6ke440 (C) ACarlos PosadaNo ratings yet

- Max 1003Document12 pagesMax 1003Carlos PosadaNo ratings yet

- Max 1011Document12 pagesMax 1011Carlos PosadaNo ratings yet

- Max 1002Document12 pagesMax 1002Carlos PosadaNo ratings yet

- Max 1114Document12 pagesMax 1114Carlos PosadaNo ratings yet

- CS4360 Cirrus LogicDocument37 pagesCS4360 Cirrus LogicCarlos PosadaNo ratings yet

- 250Msps, 8-Bit ADC With Track/Hold: Evaluation Kit AvailableDocument16 pages250Msps, 8-Bit ADC With Track/Hold: Evaluation Kit AvailableCarlos PosadaNo ratings yet

- Max114 Max118Document12 pagesMax114 Max118Carlos PosadaNo ratings yet

- Icl7135c - TLC7135CDocument11 pagesIcl7135c - TLC7135CCarlos PosadaNo ratings yet

- Adc 081000Document29 pagesAdc 081000Carlos PosadaNo ratings yet

- Tea 2025Document9 pagesTea 2025Duong HusterNo ratings yet

- MCP3204 MCP3208 PDFDocument20 pagesMCP3204 MCP3208 PDFCarlos PosadaNo ratings yet

- CS4338 PDFDocument26 pagesCS4338 PDFCarlos PosadaNo ratings yet

- NJM4565 JRCDocument5 pagesNJM4565 JRCCarlos PosadaNo ratings yet

- BB PCM 61pdatasheetDocument4 pagesBB PCM 61pdatasheetenergiculNo ratings yet

- CS4360 Cirrus LogicDocument37 pagesCS4360 Cirrus LogicCarlos PosadaNo ratings yet

- LM2900 - LM3900 PDFDocument9 pagesLM2900 - LM3900 PDFCarlos PosadaNo ratings yet

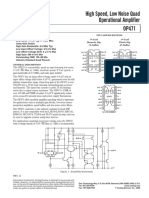

- OP471 PDFDocument16 pagesOP471 PDFCarlos PosadaNo ratings yet

- TDA1387 PhilipsDocument16 pagesTDA1387 PhilipsCarlos PosadaNo ratings yet

- OP777 - Analog DevicesDocument12 pagesOP777 - Analog DevicesCarlos PosadaNo ratings yet

- NE5532 ON Semiconductor PDFDocument10 pagesNE5532 ON Semiconductor PDFCarlos PosadaNo ratings yet

- Ba10324 Rohm PDFDocument5 pagesBa10324 Rohm PDFCarlos PosadaNo ratings yet

- TDA1311ADocument20 pagesTDA1311ACarlos PosadaNo ratings yet

- MC 33174Document12 pagesMC 33174Carlos PosadaNo ratings yet

- TDA2030ADocument15 pagesTDA2030AAtsivatlaNo ratings yet

- Tda 8588 AjDocument54 pagesTda 8588 AjAngel Fig100% (1)

- TDA2009a DatasheetDocument12 pagesTDA2009a Datasheeticecore02100% (2)

- Tda7294 PDFDocument16 pagesTda7294 PDFRoger NunesNo ratings yet

- 22W Bridge / Stereo Audio Amplifier With Clipping Detector: ProtectionsDocument22 pages22W Bridge / Stereo Audio Amplifier With Clipping Detector: ProtectionsManase RomeoNo ratings yet

- Irs2101 (S) PBF: High and Low Side DriverDocument15 pagesIrs2101 (S) PBF: High and Low Side Driverdesin01No ratings yet

- An 5232Document17 pagesAn 5232chatty85No ratings yet

- 3055VL DDocument8 pages3055VL DAnonymous t2LU6MiNo ratings yet

- IRFR3709Z IRFU3709Z: V R Max QGDocument12 pagesIRFR3709Z IRFU3709Z: V R Max QGu3a96e na1susNo ratings yet

- Mil STD 750eDocument685 pagesMil STD 750eTalmon FirestoneNo ratings yet

- AON6710 - N-Channel Enhancement Mode Field Effect TransistorDocument5 pagesAON6710 - N-Channel Enhancement Mode Field Effect TransistorLangllyNo ratings yet

- Understanding Power MOSFET Avalanche OperationDocument12 pagesUnderstanding Power MOSFET Avalanche OperationJorge Alberto Romero CoronaNo ratings yet

- Innoswitch-Ep Family Datasheet PDFDocument34 pagesInnoswitch-Ep Family Datasheet PDFanand shekhawatNo ratings yet

- Irf530, Sihf530: Vishay SiliconixDocument9 pagesIrf530, Sihf530: Vishay Siliconixdeyede2003No ratings yet

- MMF60R580Q Datasheet v1.2 20210610Document10 pagesMMF60R580Q Datasheet v1.2 20210610Ferney Martinez Romero Martinez RomeroNo ratings yet

- GaN BaligaDocument9 pagesGaN BaligaWayne MartisNo ratings yet

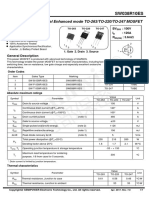

- N-Channel Enhanced Mode TO-263/TO-220/TO-247 MOSFET: SW038R10ESDocument7 pagesN-Channel Enhanced Mode TO-263/TO-220/TO-247 MOSFET: SW038R10ESPanagos PanagiotisNo ratings yet

- 100 V N-Channel Nexfet™ Power Mosfets: FeaturesDocument13 pages100 V N-Channel Nexfet™ Power Mosfets: Featuresisomeso21No ratings yet

- Datasheet 3L2Document6 pagesDatasheet 3L2juan carlos diaz cardozoNo ratings yet

- IGBTDocument22 pagesIGBTumeshgangwar100% (1)

- 8N60Document6 pages8N60AlejandroNo ratings yet

- Experience The Difference in Power: Special ReportDocument31 pagesExperience The Difference in Power: Special ReporttorinomgNo ratings yet

- Innoswitch3-Ce Family Datasheet PDFDocument30 pagesInnoswitch3-Ce Family Datasheet PDFfaridha bhanuNo ratings yet

- Non-Isolated Buck APFC LED Driver Description FeaturesDocument9 pagesNon-Isolated Buck APFC LED Driver Description FeaturesRisoSilvaNo ratings yet

- Advanced Power Electronics Corp.: AP4835GMDocument5 pagesAdvanced Power Electronics Corp.: AP4835GMSun TNT FlexNo ratings yet

- 4V Drive PCH MOSFET: RRH090P03Document6 pages4V Drive PCH MOSFET: RRH090P03MoisesNo ratings yet

- Module-2: Power TransistorsDocument25 pagesModule-2: Power TransistorsLokesh LokeshNo ratings yet

- 10 1080@00207217 2019 1625973Document27 pages10 1080@00207217 2019 1625973Clement RajNo ratings yet

- Irf530 DDocument8 pagesIrf530 DnooneezNo ratings yet

- RadhardDocument148 pagesRadhardH SMNo ratings yet

- MOSFET P7NK80ZFP DatasheetDocument17 pagesMOSFET P7NK80ZFP DatasheetYuridia De la RosaNo ratings yet

- LL014N InternationalRectifierDocument9 pagesLL014N InternationalRectifierAnkitNo ratings yet

- Simple Power Sequencer Design For MAX10 Rev2Document19 pagesSimple Power Sequencer Design For MAX10 Rev2VenkatGollaNo ratings yet

- Obsolete Product(s) - Obsolete Product(s) : STI10NM60NDocument12 pagesObsolete Product(s) - Obsolete Product(s) : STI10NM60N2019 Der CHINO GUTIERREZ EDUARDONo ratings yet

- IRFP240Document8 pagesIRFP240Hugo JimenezNo ratings yet