Professional Documents

Culture Documents

(ESD) B3 General Notes (3 of 3)

Uploaded by

l_aguilar_mCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

(ESD) B3 General Notes (3 of 3)

Uploaded by

l_aguilar_mCopyright:

Available Formats

ON

PTI

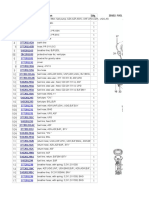

WELDING: STAY-IN-PLACE METAL DECK FORMS:

DESCRI

1. THE PROPORTIONING OF WELD DETAILS AND THE OPERATION OF WELDING SHALL BE IN 1. DESIGN INCLUDES ALLOWANCE FOR 20 POUNDS PER SQUARE FOOT OVER THE PROJECTED

ACCORDANCE WITH THE CURRENT EDITION OF THE AASHTO/AWS D1.5 BRIDGE WELDING CODE. RFI PLAN AREA OF THE METAL FORMS FOR THE UNIT WEIGHT OF THE METAL FORMS AND

WELDING PROCEDURES SHALL BE SUBMITTED AND APPROVED PRIOR TO WELDING ON THE THE CONCRETE REQUIRED TO FILL THE FORM FLUTES FOR THE DECK SLAB ONLY.

21

SION

PROJECT. ALL WELDS SHALL BE CONTINUOUS UNLESS OTHERWISE NOTED. NON-DESTRUCTIVE

REVI

TESTING SHALL BE PERFORMED AS REQUIRED BY THE CURRENT EDITION OF THE AASHTO/AWS 2. STAY-IN-PLACE FORMS ARE NOT PERMITTED ON EXTERIOR CANTILEVERS OR SIDEWALK

D1.5 BRIDGE WELDING CODE. NO FIELD WELDING SHALL BE PERMITTED UNLESS NOTED. SLABS. NO PERMANENT WEIGHT ALLOWANCE HAS BEEN MADE FOR STAY-IN-PLACE FORMS

AT THESE AREAS.

DATE

2. SHOP SPLICES SHALL BE FULL PENETRATION BUTT JOINTS, GROOVE WELDED, AND

FINISHED SMOOTH AND FLUSH WITH THE BASE METAL BY GRINDING IN THE DIRECTION JOINTS IN CONCRETE:

OF APPLIED STRESSES.

BY

1. CONSTRUCTION JOINTS WILL BE PERMITTED ONLY AT THE LOCATIONS INDICATED IN THE

REV.

NO.

3. FIELD OR SHOP WELDING TO ANY STRUCTURAL STEEL FOR THE PURPOSE OF ATTACHING PLANS.

ERECTION HARDWARE SHALL NOT BE PERMITTED.

2. ADDITIONAL CONSTRUCTION JOINTS OR ALTERATIONS TO THOSE SHOWN SHALL OF TE

E

AT X

RFI

ST

A

S

4. ALL BACKER BARS TRANSVERSE TO THE LONGITUDINAL AXIS OF THE ARCH RIB ARE REQUIRE WRITTEN APPROVAL OF THE ENGINEER.

TO BE REMOVED AT CJP WELDS AND THE WELD SURFACES GROUND FLUSH. 495 ROBERT B. ANDERSON

HIGH STRENGTH BARS:

ER

111066

PR

L

E

D

O

IC

5. THE FOLLOWING MEMBERS ARE CLASSIFIED AS ANCILLARY MEMBERS IN ACCORDANCE ENSE

N

F

E

S I

SI G

ONAL EN

WITH THE CURRENT EDITION OF THE AASHTO/AWS D1.5 BRIDGE WELDING CODE: 1. HIGH STRENGTH BARS SHALL BE PROVIDED AS FOLLOWS:

ASTM A722 (GRADE 150, TYPE II) - POST-TENSIONED ANCHORAGES AT THRUST BLOCKS.

A. EXPANSION JOINT WELDS ASTM F1554 (GRADE 105) - ANCHOR BOLTS FOR BEARINGS

10/29/2013

B. DRAINAGE SYSTEM WELDS - HIGH STRENGTH ANCHOR RODS AT TUB GIRDER HANGER ASSEMBLES.

FRACTURE CRITICAL MEMBERS: 2. THE SIZE AND JACKING FORCES FOR HIGH STRENGTH BARS ARE DENOTED ON THE PLANS.

RFI

1. ARCH RIB MEMBERS, HANGER CONNECTION ASSEMBLIES AND CONNECTIONS AND TUB 3. HEAVY HEX NUTS AND HARDENED WASHERS SHALL BE OF A DESIGN AND MATERIAL RECOMMENDED

GIRDERS AND CROSS FRAMES ARE NOT CLASSIFIED AS FRACTURE CRITICAL MEMBERS (FCM) 220 BY THE MANUFACTURER TO DEVELOP THE FULL TENSILE STRENGTH OF THE HIGH STRENGTH BAR.

BUT SHALL REQUIRE FABRICATION AND TESTING PER THE REQUIREMENTS FOR FRACTURE

CRITICAL MEMBERS NOTED IN THE PROJECT SPECIFICATIONS. 4. HIGH STRENGTH BARS, NUTS, AND WASHERS SHALL BE HOT-DIPPED GALVANIZED IN ACCORDANCE

WITH ASTM A123 AND ASTM A143 FOR THE HIGH STRENGTH BAR, AND ASTM A153 FOR THE NUTS,

STEEL TUB GIRDER AND OUTRIGGER BEAM ERECTION: WASHERS, AND BEARING PLATES. THE GALVANIZING PLANT SHALL IMPLEMENT APPROPRIATE

ON

QUALITY CONTROL MEASURES TO SAFEGUARD AGAINST HYDROGEN EMBRITTLEMENT.

DGE AND EXTENSI

SHOAL CREEK TO W EST AVENUE

RFI

GENERAL NOTES (3 OF 3)

C W ORKS

1. THE CONTRACTOR SHALL MAINTAIN STABILITY OF THE GIRDERS UNTIL THE CROSS FRAMES

ON

OF AU STIN , TEXAS

AND END DIAPHRAGMS HAVE BEEN ERECTED AND THE CONCRETE DECK HAS BEEN PLACED 5. MATERIALS AND GROUTING OF POST-TENSIONING BARS AT THE THRUST BLOCK SHALL BE IN

SI

AND CURED. 175 ACCORDANCE WITH TxDOT STANDARD SPECIFICATION ITEM 426 "PRESTRESSING"

VI

AND AS SUPPLEMENTED BY THE PROJECT SPECIAL SPECIFICATIONS. THE CONTRACTOR

CES DI

2. THE CONTRACTOR SHALL MAINTAIN STABILITY OF THE OUTRIGGER BEAMS UNTIL THE IS NOTIFIED THAT A FULL SCALE MOCK-UP IS REQUIRED TO SUCESSFULLY DEMONSTRATE THE

DEPARTM ENT OF PUBLI

SIDEWALK PRECAST FASCIA AND CURB UNITS HAVE BEEN ERECTED AND THE CONCRETE GROUTING OF THE POST-TENSIONING BARS.

POUR HAS BEEN PLACED AND CURED.

NG SERVI

BEARINGS:

APPLIED CONCRETE FINISH COATING:

1. THE CONTRACTOR SHALL FURNISH AND INSTALL ALL BEARINGS IN ACCORDANCE WITH THE

2ND STREET BRI

1. APPLY SURFACE TREATMENT CLASS I IN CONFORMANCE WITH TxDOT STANDARD PROJECT SPECIAL SPECIFICATIONS.

SPECIFICATION ITEM 428.

NEERI

2. BEARINGS SHALL BE MULTI-ROTATIONAL DISK BEARINGS. SEE PLANS FOR NUMBER, TYPE AND

2. APPLY RUB FINISH SPECIAL SURFACE FINISH TO ALL EXPOSED FACES OF THE THRUST LOCATION,

CITY

BLOCK IN CONFORMANCE WITH TxDOT STANDARD SPECIFICATION ITEM 427. APPLY

ENGI

APPROVED EPOXY WATERPROOFING TO ABUTMENT BEAM SEATS. 3. THE BEARINGS SHALL BE DESIGNED IN ACCORDANCE WITH THE 2012 AASHTO LFRD SPECIFICATIONS

AND AS SUPPLEMENTED BY THE PROJECT SPECIAL SPECIFICATIONS.

PLAN DIMENSIONS:

4. EXPOSED METAL PORTIONS OF BEARINGS INCLUDING SOLE PLATES IN CONCRETE SHALL BE HOT

1. ALL DIMENSIONS IN THESE PLANS ARE MEASURED IN FEET EITHER HORIZONTALLY OR DIPPED GALVANIZED PER ASTM A153 OR ASTM B833 AND TxDOT STANDARD SPECIFICATION

VERTICALLY UNLESS NOTED OTHERWISE. ITEM 449.

2. ALL ELEVATIONS IN THESE PLANS ARE IN FEET. JACKING OF SUPERSTRUCTURE:

dgn

\2nd_ Street\dgn\SCND- S- SJ- GNTS- 03.

3. ALL DIMENSIONS AND JOINT OPENINGS IN THE STRUCTURE ARE MEASURED AT MEAN 1. JACKING OF SUPERSTRUCTURE AND BEARING REPLACEMENT ARE INCLUDED IN THE DESIGN.

TEMPERATURE OF 70 DEGREES FAHRENHEIT. SEE SHEET "BEARING REPLACEMENT DETAILS".

UTILITIES: MISCELLANEOUS METALS:

URS CORPORATION

1. FOR PLAN LOCATIONS OF EXISTING UTILITIES, SEE PLAN AND ELEVATION SHEETS. 1. ALL STAINLESS STEEL SHALL BE ASTM A240 TYPE 304 UNLESS NOTED OTHERWISE. 9400 AMBERGLEN BLVD

AUSTIN, TEXAS 78729

LOCATIONS OF UTILITIES, INCLUDING UNDER DECK LIGHTING, SHOWN IN THE PLANS STAINLESS BOLTS SHALL BE ASTM F593 ALLOY 316 UNLESS NOTED OTHERWISE.

Phone: 512-454-4797

ARE APPROXIMATE. FOR DISPOSITION OF UTILITIES, SEE THE ROADWAY DRAWINGS.

TX FIRM REGISTRATION NO. 3162

THE CONTRACTOR SHALL FIELD VERIFY UTILITY LOCATIONS BEFORE COMMENCING WITH

CONSTRUCTION. NOTES NAME DATE

SURVEY BY

BRIDGE NAME:

DRAWN BY KAC 12-12

DESIGNED BY BTC 12-12

dges_ V8i

1. SEE ARCHITECTURAL DRAWINGS FOR DETAILS AND PLACEMENT OF BRIDGE PLAQUES.

CHECKED BY RBA 12-12

SCREEDING DECK AND BEDDING SIDEWALK SLABS: REVIEWED BY

\Bri

E:

1. SCREED THE RIDING SURFACE OF THE BRIDGE DECK AND APPROACH SLABS TO ACHIEVE

THE FINISH GRADE ELEVATIONS SHOWN IN THE PLANS. ACCOUNT FOR THEORETICAL

DEFLECTIONS DUE TO SELF WEIGHT, DECK CASTING SEQUENCE, DECK FORMING SYSTEMS,

CONSTRUCTION LOADS, OVERLAYS AND TEMPORARY SHORING, ETC. AS REQUIRED.

2. PROVIDE CONCRETE HAUNCH FOR THE SIDEWALK SLAB TO ACHIEVE THE FINISH GRADE

10/30/2013

REVIEWED BY:

ELEVATIONS SHOWN IN THE PLANS. ACCOUNT FOR THEORETICAL DEFLECTIONS DUE TO

SELF WEIGHT, PAVERS, SLAB FORMING SYSTEMS, ETC. AS REQUIRED.

PLANNING AND DEVELOPMENT REVIEW DEPARTMENT DATE SHEET

OF

DEVELOPMENT PERMIT NUMBER SPC-2013-0179D NUMBER

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Fag Smartcheck: Machinery Monitoring For Every MachineDocument20 pagesFag Smartcheck: Machinery Monitoring For Every Machinel_aguilar_mNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Vibration StandardsDocument16 pagesVibration Standardsramnadh803181100% (5)

- Prueba Ist Manejo DefensivoDocument7 pagesPrueba Ist Manejo Defensivol_aguilar_mNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Heat Treatment of Steel PDFDocument10 pagesHeat Treatment of Steel PDFAnonymous 3akQhQFJSLNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- IxcuponDocument1 pageIxcuponl_aguilar_mNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Heat Treating The SteelDocument12 pagesHeat Treating The Steelyasir_anjumNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Section 461 Multirotational Bearings 461-1 DescriptionDocument3 pagesSection 461 Multirotational Bearings 461-1 Descriptionl_aguilar_mNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Coating TestDocument7 pagesCoating TestSriram VjNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Fag Smartcheck: High Process Security by Means of Decentralised Machinery MonitoringDocument26 pagesFag Smartcheck: High Process Security by Means of Decentralised Machinery Monitoringl_aguilar_mNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Application, Instructions, AND Program Rules: SSPC Qp6Document28 pagesApplication, Instructions, AND Program Rules: SSPC Qp6Victor Hugo PexoNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- s8.2 2017 Specification For Application of Thermal Spray Coating For Steel BridgesDocument50 pagess8.2 2017 Specification For Application of Thermal Spray Coating For Steel Bridgesl_aguilar_m100% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- VW Gol 2005 Gearbox Listado de PartesDocument16 pagesVW Gol 2005 Gearbox Listado de Partesl_aguilar_mNo ratings yet

- SpotQAassessments 2Document25 pagesSpotQAassessments 2l_aguilar_mNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Bolted, Sleeve-Type Couplings For Plain-End Pipe: Awwa StandardDocument28 pagesBolted, Sleeve-Type Couplings For Plain-End Pipe: Awwa Standardl_aguilar_m100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- VW GOL 2005 FUEL Listado de PartesDocument14 pagesVW GOL 2005 FUEL Listado de Partesl_aguilar_mNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- SS 845 Field Metallizing of Structural Steel 1. SpecificationDocument1 pageSS 845 Field Metallizing of Structural Steel 1. Specificationl_aguilar_mNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- 704 09 Fenner Gearboxes SMSRDocument20 pages704 09 Fenner Gearboxes SMSRl_aguilar_mNo ratings yet

- VW GOL 2005 ENGINE Listado de PartesDocument80 pagesVW GOL 2005 ENGINE Listado de Partesl_aguilar_mNo ratings yet

- VW GOL 2005 BODY Listado de PartesDocument256 pagesVW GOL 2005 BODY Listado de Partesl_aguilar_m100% (1)

- Dodge FL5013 PDFDocument8 pagesDodge FL5013 PDFl_aguilar_mNo ratings yet

- VW GOL 2005 WHEEL Listado de PartesDocument37 pagesVW GOL 2005 WHEEL Listado de Partesl_aguilar_mNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- VW Gol 2005 Rear Axle Listado de PartesDocument6 pagesVW Gol 2005 Rear Axle Listado de Partesl_aguilar_mNo ratings yet

- VW Gol 2005 Front Axle Listado de PartesDocument37 pagesVW Gol 2005 Front Axle Listado de Partesl_aguilar_mNo ratings yet

- MAAGGear OpenGearingDocument4 pagesMAAGGear OpenGearingl_aguilar_mNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- MPTA-B4c-2008R 2013: Mechanical Power Transmission Association 5672 Strand Court, Suite 2, Naples, FL 34110Document3 pagesMPTA-B4c-2008R 2013: Mechanical Power Transmission Association 5672 Strand Court, Suite 2, Naples, FL 34110l_aguilar_mNo ratings yet

- MPTA B8i 2011Document9 pagesMPTA B8i 2011l_aguilar_mNo ratings yet

- MPTA B9i 2013 TL Bushing StandardDocument8 pagesMPTA B9i 2013 TL Bushing Standardl_aguilar_mNo ratings yet

- MPTA C1c 2014 1Document10 pagesMPTA C1c 2014 1l_aguilar_mNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- MPTA B13i 2013Document4 pagesMPTA B13i 2013l_aguilar_mNo ratings yet

- Complete Practical DistillingDocument254 pagesComplete Practical DistillingMR X100% (5)

- Formulation Development and Evaluation of Unit Moulded Herbal Semisolid Jelly Useful in Treatment of Mouth UlcerDocument9 pagesFormulation Development and Evaluation of Unit Moulded Herbal Semisolid Jelly Useful in Treatment of Mouth UlcerLaeeq R MalikNo ratings yet

- TM 10-4930-220-13PDocument133 pagesTM 10-4930-220-13PAdvocateNo ratings yet

- Bioburden Recovery Method Using Swabbing TechniqueDocument8 pagesBioburden Recovery Method Using Swabbing TechniquePiruzi MaghlakelidzeNo ratings yet

- CentrifugationDocument43 pagesCentrifugationSudeeksha RavikotiNo ratings yet

- Pharmacognostical and Preliminary Phytochemical Screening On Leaves of Trianthema Decandra Linn.Document3 pagesPharmacognostical and Preliminary Phytochemical Screening On Leaves of Trianthema Decandra Linn.anto_pharma7784No ratings yet

- Drugdistributionfinal 151003021801 Lva1 App6891Document12 pagesDrugdistributionfinal 151003021801 Lva1 App6891Raju NiraulaNo ratings yet

- Eisco Industrial Catalogue - FinalDocument276 pagesEisco Industrial Catalogue - FinalSOHAM AlhatNo ratings yet

- 10 Scientist Contributed in ChemistryDocument4 pages10 Scientist Contributed in ChemistryJefferd PaetNo ratings yet

- Microwave Pyrolysis of Polystyrene and Polypropylene Mixtures Using Different Activated Carbon From BiomassDocument14 pagesMicrowave Pyrolysis of Polystyrene and Polypropylene Mixtures Using Different Activated Carbon From BiomassTrisna Kumala DhaniswaraNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Tooth DecayDocument28 pagesTooth DecayRyan Carlo CondeNo ratings yet

- Reduction of Environmental ImpactDocument16 pagesReduction of Environmental ImpactJohn Vincent MalvarNo ratings yet

- Inherited Overflow Metabolic Overflow RenalDocument11 pagesInherited Overflow Metabolic Overflow RenalChrissa Mae Tumaliuan CatindoyNo ratings yet

- HW 03 On IUPAC NamingDocument1 pageHW 03 On IUPAC NamingEMERALDARCANISTNo ratings yet

- Chlorine and Water-A Table ResearchDocument5 pagesChlorine and Water-A Table ResearchrajaratnaNo ratings yet

- Amphenol ARINC 600: Rack and Panel ConnectorsDocument18 pagesAmphenol ARINC 600: Rack and Panel ConnectorsCopperAustraliaNo ratings yet

- Regents Homeostasis and EnzymesDocument5 pagesRegents Homeostasis and Enzymesapi-3031203990% (1)

- 444 Data SheetDocument2 pages444 Data SheetSabareesh MylsamyNo ratings yet

- Fick Second LawDocument9 pagesFick Second LawJohnny WoodsNo ratings yet

- Module 2 - Fire SafetyDocument68 pagesModule 2 - Fire Safetyjairath100% (1)

- Specifications: Customer Item Model Name Part No DateDocument11 pagesSpecifications: Customer Item Model Name Part No Datejoroma58No ratings yet

- PC 0189 - Heat Resisting Silicone Aluminium Paint - Apcotherm 540Document3 pagesPC 0189 - Heat Resisting Silicone Aluminium Paint - Apcotherm 540onshore purchase100% (1)

- Chemical Changes LabDocument5 pagesChemical Changes LabGildardo SalazarNo ratings yet

- 51314-3985-Methanol-Induced Internal Stress CorrosDocument18 pages51314-3985-Methanol-Induced Internal Stress CorrosMahmoud GamalNo ratings yet

- A Rapid Accurate Method For The Analysis of An Iron OreDocument5 pagesA Rapid Accurate Method For The Analysis of An Iron Oreilham_metallurgy6744No ratings yet

- Machinability of BS S132Document2 pagesMachinability of BS S132goggerNo ratings yet

- We Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsDocument15 pagesWe Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistssbiasotoNo ratings yet

- Born Oppenheimer ApproximationDocument15 pagesBorn Oppenheimer ApproximationElizabeth HarrisonNo ratings yet

- Carbon Fiber - CoursDocument33 pagesCarbon Fiber - Courstrannhu1293599No ratings yet

- 3 PRE BOARD GENERAL EDUCATION Some College StudentsDocument14 pages3 PRE BOARD GENERAL EDUCATION Some College StudentsMary-Rose CasuyonNo ratings yet