Professional Documents

Culture Documents

MB Fordec & Nites

Uploaded by

Marcos BragaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MB Fordec & Nites

Uploaded by

Marcos BragaCopyright:

Available Formats

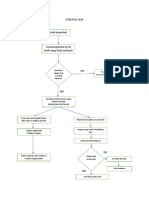

FORDEC

FORDEC is an acronym for decision making. It is the model used by the

EU/EASA/JAR NOTECHS (non-technicals) Behaviour Marker CRM Skills

measurement system and is required to be assessed during recurrent simulator

training (LPC/OPC) as part of CRM.

F – Facts (what is the problem)

O – Options (hold, divert, immediate landing etc.)

R – Risks/(Benefits sometimes included) (what is the downside of each option, what is the upside, i.e. a runway may be further away but is longer)

D – Decide (which option)

E – Execute (carry out selected option)

C – Check (did everything work/go to plan, what else needs to be done)

Facts is the first step to solve a problem or make a decision. It is necessary to find out what is has happened, what is wrong (i.e. define the problem) and if possible

what causes it. Often an aircraft’s computers (EICAS – Boeing, ECAM – Airbus) will diagnose the fault but it is important to confirm and to avoid “confirmation bias”.

The Facts stage involves determining and confirming the problem.

Options is determining what choices you have given the problem and circumstances. Not all faults are urgent or require immediate action. If action is required, such

as a diversion there may be choices in airfields such as one where there is engineering or company support, length of runway given the fault(s).

Risks is assessing the potential downsides and benefits of each viable option. Often there are several choices available and there needs to be a reasonable decision

made. This is normally associated with airport and runway choice but there are other scenarios as well. Even the act of diverting requires risk assessment and it may

be less risk adverse to continue (short runways, bad weather etc.) When all options are equally safe, an airport with maintenance or company support has greater

benefit.

Decide is choosing the best option available to you. In a modern cockpit environment this should be discussed with both crew members.

Execution is carrying out the appropriate action and to assign tasks to people who are to execute them.

Check is a constant process, not solely when the actions are complete. It is needed to ensure that everything is proceeding according to

plan, and the desired safe outcome is likely. If this is not the case the process can be started again to fact check what has changed or

what is not working and then adapt as necessary.

There is also time critical FORDEC and non-time critical FORDEC. The difference is when evaluating the risks and benefits you are

looking for the best option with no time constraints. When you have time constraints you need to choose the quickest suitable option,

which may not be the most desirable.

You might also like

- Fordec Analyse Diagram & DodarDocument3 pagesFordec Analyse Diagram & DodarDavidNo ratings yet

- 737 Performance Reference Handbook - EASA EditionFrom Everand737 Performance Reference Handbook - EASA EditionRating: 4.5 out of 5 stars4.5/5 (3)

- Airbus NotesDocument130 pagesAirbus Notespresencia62No ratings yet

- Vietnam A320 Line TrainingDocument11 pagesVietnam A320 Line TrainingJuanaleNo ratings yet

- A320 Max Altitude PDFDocument19 pagesA320 Max Altitude PDFallex_nathanielNo ratings yet

- A320 Abnormal Notes SummaryDocument13 pagesA320 Abnormal Notes SummaryDevdatt SondeNo ratings yet

- Choice of Take Off Config.: Preparation For Vac Oral InterviewDocument24 pagesChoice of Take Off Config.: Preparation For Vac Oral Interviewflybearvaleriy100% (1)

- This Brief Is Provided For Information and Guidance. in The Event of Conflicting Information or Instructions, Company Manuals Take PrecedenceDocument5 pagesThis Brief Is Provided For Information and Guidance. in The Event of Conflicting Information or Instructions, Company Manuals Take PrecedenceDevdatt SondeNo ratings yet

- Low Visibility - QuizDocument1 pageLow Visibility - QuizhhgaffadfNo ratings yet

- A320 Fuel Leak Detection ProcessDocument1 pageA320 Fuel Leak Detection ProcesssvmNo ratings yet

- Aviate Navigate ManageDocument1 pageAviate Navigate ManagerpommerNo ratings yet

- A320 Abnormal Procedures PDFDocument26 pagesA320 Abnormal Procedures PDFM DarwishNo ratings yet

- CAB PR EXCESS CAB ALTDocument18 pagesCAB PR EXCESS CAB ALTDevdatt SondeNo ratings yet

- Briefing TCP PDFDocument13 pagesBriefing TCP PDFNadjib Jimmy KrtNo ratings yet

- A320 Memory Items ChecklistDocument3 pagesA320 Memory Items ChecklistAntoine DeucatNo ratings yet

- How To Check Go-Around PerformanceDocument50 pagesHow To Check Go-Around Performanceali4957270100% (3)

- EDTODocument34 pagesEDTOAugustine Thomas100% (1)

- Try AP1 or AP2 and Autothrust: EventDocument4 pagesTry AP1 or AP2 and Autothrust: EventAb Log100% (1)

- Think in Low VisibilityDocument9 pagesThink in Low VisibilityAmirAli Mohebbi100% (1)

- Abnormal NotesDocument90 pagesAbnormal NotesHaseeb Abu Alwan100% (2)

- Unofficial A320 SimulatorDocument23 pagesUnofficial A320 SimulatorAmirAli MohebbiNo ratings yet

- A320 Abnormal ProceduresDocument26 pagesA320 Abnormal ProceduresCarlos RicoNo ratings yet

- A 0 Rejected Takeoff NotesDocument3 pagesA 0 Rejected Takeoff NotessuriyaNo ratings yet

- Automatic FlightDocument8 pagesAutomatic FlightAziz AimadNo ratings yet

- A320 Limitations Summary Aug 2012 PDFDocument2 pagesA320 Limitations Summary Aug 2012 PDFsimcity300075% (4)

- Take Off BriefDocument25 pagesTake Off BriefKhurram NaseemNo ratings yet

- A320-Unreliable Speed IndicationDocument6 pagesA320-Unreliable Speed IndicationDavid Xue50% (2)

- ENG FAILURE AFTER TAKEOFF PROCEDUREDocument17 pagesENG FAILURE AFTER TAKEOFF PROCEDUREsaudia686No ratings yet

- A319/320/321 Type Rating Oral Study Guide: LimitationsDocument40 pagesA319/320/321 Type Rating Oral Study Guide: LimitationsLuiz Cabral100% (2)

- Capt. S R Meena's guide to all weather operationsDocument86 pagesCapt. S R Meena's guide to all weather operationsOmshree PatelNo ratings yet

- 2022+a350+Periodic+Proficiency+Test Q Type+AbcdeDocument20 pages2022+a350+Periodic+Proficiency+Test Q Type+AbcdeJuKyung ParkNo ratings yet

- BriefingDocument4 pagesBriefingTural HasanovNo ratings yet

- List of Conditions in Which MAYDAY & PANPAN Call Should Be Made: May Day Pan PanDocument1 pageList of Conditions in Which MAYDAY & PANPAN Call Should Be Made: May Day Pan PanAarohi SoodNo ratings yet

- A330 Rec TRNG 1-C Apr.2013Document14 pagesA330 Rec TRNG 1-C Apr.2013Rocky2488100% (2)

- A320 Memory ItemsDocument9 pagesA320 Memory ItemsJoao Melo100% (3)

- A320 PIC PagesDocument21 pagesA320 PIC Pagesumesh phaugat100% (1)

- Eazy Jet QuizDocument13 pagesEazy Jet Quizthe_gov100% (2)

- A320 Memory Items PDFDocument1 pageA320 Memory Items PDFPai NangNo ratings yet

- Flysmart User GuideDocument277 pagesFlysmart User GuideAnwar MuhammadNo ratings yet

- A320 OralDocument4 pagesA320 OralNam NguyễnNo ratings yet

- B737-800 Thrust ReductionDocument5 pagesB737-800 Thrust ReductionTariq khosoNo ratings yet

- B 737 LVO ProceduresDocument6 pagesB 737 LVO ProceduresAbdel Hafid Lahreche100% (1)

- Smoke ProcedureDocument16 pagesSmoke ProcedureNejmeddine HalfaouiNo ratings yet

- A320 ADIRS and flight control definitionsDocument13 pagesA320 ADIRS and flight control definitionsmorteeza1986100% (1)

- China RVSMDocument21 pagesChina RVSMJehad Badawi100% (3)

- Takeoff Briefing ALT 737NGDocument2 pagesTakeoff Briefing ALT 737NGRAJESHKANNAN KM100% (1)

- EK LVO's Summary 1-7Document1 pageEK LVO's Summary 1-7Guy A. TeulonNo ratings yet

- A320-Engine Failure (Damage)Document10 pagesA320-Engine Failure (Damage)tugayyoung100% (2)

- A 0 Rejected Takeoff NotesDocument3 pagesA 0 Rejected Takeoff NotesWeirpNo ratings yet

- B777 FCOM Summery Rev 35Document24 pagesB777 FCOM Summery Rev 35mirzasamirNo ratings yet

- Memory Items Left-Right Seat V3Document19 pagesMemory Items Left-Right Seat V3HeshNo ratings yet

- SkyTest® Airline Interview - The Exercise Book: Interview questions and tasks from real life selection procedures for pilots and ATCOsFrom EverandSkyTest® Airline Interview - The Exercise Book: Interview questions and tasks from real life selection procedures for pilots and ATCOsRating: 4 out of 5 stars4/5 (12)

- Airbus Flight Control Laws: The Reconfiguration LawsFrom EverandAirbus Flight Control Laws: The Reconfiguration LawsRating: 4.5 out of 5 stars4.5/5 (16)

- A330 Normal Law: Putting Fly-by-Wire Into PerspectiveFrom EverandA330 Normal Law: Putting Fly-by-Wire Into PerspectiveRating: 5 out of 5 stars5/5 (2)

- Human Performance and Limitations in AviationFrom EverandHuman Performance and Limitations in AviationRating: 4.5 out of 5 stars4.5/5 (2)

- #1 Airbus Safety First Mag - Jan 2005Document14 pages#1 Airbus Safety First Mag - Jan 2005upsasaNo ratings yet

- JEPP's Briefing - The Chart Clinic - 8th - Airway Designation SymbolsDocument2 pagesJEPP's Briefing - The Chart Clinic - 8th - Airway Designation SymbolsMarcos BragaNo ratings yet

- Wet With Sand or Dust: LPC Calculation Take-Off Is Not Authorised (Om A 8.3 8.3.3)Document1 pageWet With Sand or Dust: LPC Calculation Take-Off Is Not Authorised (Om A 8.3 8.3.3)Marcos Braga100% (1)

- DODAR or FORDEC - Which Is Better?Document2 pagesDODAR or FORDEC - Which Is Better?Marcos Braga100% (1)

- JEPP's Briefing - The Chart Clinic - 6th - Controlled AirspaceDocument2 pagesJEPP's Briefing - The Chart Clinic - 6th - Controlled AirspaceMarcos Braga100% (1)

- MB Holding EntryDocument6 pagesMB Holding EntryMarcos BragaNo ratings yet

- MB A32F FOQA Parameters A319 320Document3 pagesMB A32F FOQA Parameters A319 320Marcos BragaNo ratings yet

- MB A32F Ground Speed Mini - BulletinDocument7 pagesMB A32F Ground Speed Mini - BulletinMarcos Braga100% (1)

- MB A32F Engine Failure ECAMDocument42 pagesMB A32F Engine Failure ECAMMarcos Braga100% (4)

- JEPP's Briefing - The Chart Clinic - 10th - Off-Airway Navigation Long DistancesDocument2 pagesJEPP's Briefing - The Chart Clinic - 10th - Off-Airway Navigation Long DistancesMarcos BragaNo ratings yet

- The Wright Brothers, A History From Beginning To EndDocument38 pagesThe Wright Brothers, A History From Beginning To EndMarcos BragaNo ratings yet

- The Chart Clinic - Fifth in A Series: Center FrequenciesDocument2 pagesThe Chart Clinic - Fifth in A Series: Center Frequencies222hornetNo ratings yet

- MB Eng Failure ECAM - PpsDocument42 pagesMB Eng Failure ECAM - PpsMarcos Braga100% (1)

- Airbus Versus Boeing RevisitedDocument11 pagesAirbus Versus Boeing RevisitedArif PranandaNo ratings yet

- The Chart Clinic - Ninth in A Series: Vors For Direct Route NavigationDocument2 pagesThe Chart Clinic - Ninth in A Series: Vors For Direct Route Navigation222hornetNo ratings yet

- The Chart Clinic - Ninth in A Series: Vors For Direct Route NavigationDocument2 pagesThe Chart Clinic - Ninth in A Series: Vors For Direct Route Navigation222hornetNo ratings yet

- JEPP's Briefing - The Chart Clinic - 1st - Chart LayoutDocument2 pagesJEPP's Briefing - The Chart Clinic - 1st - Chart LayoutMarcos BragaNo ratings yet

- JEPP's Briefing - The Chart Clinic - 4th - Communications TabulationsDocument2 pagesJEPP's Briefing - The Chart Clinic - 4th - Communications TabulationsMarcos BragaNo ratings yet

- JEPP's Briefing - The Chart Clinic - 2nd - Enroute ChartsDocument2 pagesJEPP's Briefing - The Chart Clinic - 2nd - Enroute ChartsMarcos BragaNo ratings yet

- Brazil's Airline HistoryDocument52 pagesBrazil's Airline HistoryMarcos BragaNo ratings yet

- JEPP's Briefing - The Chart Clinic - 7th - Special Use Airspace (SUA)Document2 pagesJEPP's Briefing - The Chart Clinic - 7th - Special Use Airspace (SUA)Marcos BragaNo ratings yet

- JEPP'S Briefing - The Chart Clinic - 3rd - Navigation Aids PDFDocument2 pagesJEPP'S Briefing - The Chart Clinic - 3rd - Navigation Aids PDFMarcos Braga100% (1)

- Rules of Thumb 2Document3 pagesRules of Thumb 2Marcos BragaNo ratings yet

- A32F Electrical PriorityDocument1 pageA32F Electrical PriorityMarcos BragaNo ratings yet

- A32F Electrical Priority - JPGDocument1 pageA32F Electrical Priority - JPGMarcos BragaNo ratings yet

- MB Adirs & Apu BleedDocument14 pagesMB Adirs & Apu BleedMarcos BragaNo ratings yet

- Advanced Solutions in Surveillance: Presentation ToDocument39 pagesAdvanced Solutions in Surveillance: Presentation ToMarcos BragaNo ratings yet

- A320 FMGS Codes BragaDocument25 pagesA320 FMGS Codes BragaMarcos Braga92% (13)

- Wing Tip ShapesDocument6 pagesWing Tip ShapesMarcos BragaNo ratings yet

- Battery Impedance Test Equipment: Biddle Bite 2PDocument4 pagesBattery Impedance Test Equipment: Biddle Bite 2PJorge PinzonNo ratings yet

- The SAGE Handbook of Digital JournalismDocument497 pagesThe SAGE Handbook of Digital JournalismK JNo ratings yet

- Gary Mole and Glacial Energy FraudDocument18 pagesGary Mole and Glacial Energy Fraudskyy22990% (1)

- Weibull Statistic and Growth Analysis in Failure PredictionsDocument9 pagesWeibull Statistic and Growth Analysis in Failure PredictionsgmitsutaNo ratings yet

- RAP Submission Form, OBIDocument3 pagesRAP Submission Form, OBIAhmed MustafaNo ratings yet

- 6vortex 20166523361966663Document4 pages6vortex 20166523361966663Mieczysław MichalczewskiNo ratings yet

- Gates em Ingles 2010Document76 pagesGates em Ingles 2010felipeintegraNo ratings yet

- Lista Precio Septiembre 0609Document75 pagesLista Precio Septiembre 0609gNo ratings yet

- Sta A4187876 21425Document2 pagesSta A4187876 21425doud98No ratings yet

- Palmetto Bay's Ordinance On Bird RefugeDocument4 pagesPalmetto Bay's Ordinance On Bird RefugeAndreaTorresNo ratings yet

- Siemens Documentation - Modeling ComponentsDocument1 pageSiemens Documentation - Modeling ComponentsanupNo ratings yet

- Chapter 7 - Cash BudgetDocument23 pagesChapter 7 - Cash BudgetMostafa KaghaNo ratings yet

- Tata Chemicals Yearly Reports 2019 20Document340 pagesTata Chemicals Yearly Reports 2019 20AkchikaNo ratings yet

- BlueDocument18 pagesBluekarishma nairNo ratings yet

- Simplex Addressable Breakglass PDFDocument12 pagesSimplex Addressable Breakglass PDFNurrul Ahmad Hidayat100% (1)

- Portable dual-input thermometer with RS232 connectivityDocument2 pagesPortable dual-input thermometer with RS232 connectivityTaha OpedNo ratings yet

- Developing a Positive HR ClimateDocument15 pagesDeveloping a Positive HR ClimateDrPurnima SharmaNo ratings yet

- Introduction To Succession-1Document8 pagesIntroduction To Succession-1amun dinNo ratings yet

- 28 Government Service Insurance System (GSIS) vs. Velasco, 834 SCRA 409, G.R. No. 196564 August 7, 2017Document26 pages28 Government Service Insurance System (GSIS) vs. Velasco, 834 SCRA 409, G.R. No. 196564 August 7, 2017ekangNo ratings yet

- DHPL Equipment Updated List Jan-22Document16 pagesDHPL Equipment Updated List Jan-22jairamvhpNo ratings yet

- Super Flexible, Super Fast, Super Value: Gigabit PTMP Client and PTP With Modular AntennasDocument5 pagesSuper Flexible, Super Fast, Super Value: Gigabit PTMP Client and PTP With Modular AntennasAbdallaNo ratings yet

- UW Computational-Finance & Risk Management Brochure Final 080613Document2 pagesUW Computational-Finance & Risk Management Brochure Final 080613Rajel MokNo ratings yet

- HI - 93703 Manual TurbidimetroDocument13 pagesHI - 93703 Manual Turbidimetrojesica31No ratings yet

- Diana's Innermost House: MagazineDocument42 pagesDiana's Innermost House: MagazinealexgoagaNo ratings yet

- Overall Dimensions and Mounting: Solar Water Pump Controller Mu - G3 Solar Mu - G5 Solar Mu - G7.5 Solar Mu - G10 SolarDocument2 pagesOverall Dimensions and Mounting: Solar Water Pump Controller Mu - G3 Solar Mu - G5 Solar Mu - G7.5 Solar Mu - G10 SolarVishak ThebossNo ratings yet

- Credentials List with Multiple Usernames, Passwords and Expiration DatesDocument1 pageCredentials List with Multiple Usernames, Passwords and Expiration DatesJOHN VEGANo ratings yet

- The Value of Repeat Biopsy in SLEDocument8 pagesThe Value of Repeat Biopsy in SLESergio CerpaNo ratings yet

- Competency-Based Learning GuideDocument10 pagesCompetency-Based Learning GuideOliver BC Sanchez100% (2)

- Dinsmore - Gantt ChartDocument1 pageDinsmore - Gantt Chartapi-592162739No ratings yet

- Unit 1 2marksDocument5 pagesUnit 1 2marksLokesh SrmNo ratings yet