Professional Documents

Culture Documents

PMC Tech: Department of Eee

Uploaded by

Ebin Peter0 ratings0% found this document useful (0 votes)

75 views6 pagesBiogas is produced by the fermentation of animal dung, human sewage or agricultural residues. Methane within biogas can be concentrated via a biogas upgrader to the same standards as fossil natural gas, and becomes biomethane. If concentrated it can also be used in vehicle transportation.

Original Description:

Original Title

1.PMC TECH1

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentBiogas is produced by the fermentation of animal dung, human sewage or agricultural residues. Methane within biogas can be concentrated via a biogas upgrader to the same standards as fossil natural gas, and becomes biomethane. If concentrated it can also be used in vehicle transportation.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

75 views6 pagesPMC Tech: Department of Eee

Uploaded by

Ebin PeterBiogas is produced by the fermentation of animal dung, human sewage or agricultural residues. Methane within biogas can be concentrated via a biogas upgrader to the same standards as fossil natural gas, and becomes biomethane. If concentrated it can also be used in vehicle transportation.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 6

PMC TECH

Er.PERUMAL MANIMEKALAI

COLLEGE OF ENGINEERING

HOSUR

DEPARTMENT OF EEE

BIOGAS AS VEHICLE

FUEL

(AN ALTERNATIVE SOURCE FOR DRIVING

TORQUE)

SUBMITTED BY,

EBIN GEORGE .K. PETER J. MANIKANDAN

IV YEAR BE (EEE) IV YEAR BE (EEE)

PMC TECH PMC TECH

HOSUR HOSUR

PH_NO: 9042694252 PH_NO: 9894368575

Email : ebin.gkp@gmail.com Email : manishivab@gmail.com

BIOGAS AS VEHICAL FUEL

(An Alternative source for driving torque)

EBIN GEORGE K PETER and compressed it can also be used

PMC TECH in vehicle transportation.

HOSUR

ebin.gkp@gmail.com

INTRODUTION

J MANIKANDAN

PMC TECH

HOSUR As we know that

manishivab@gmail.com petroleum products are play very

improtant role in our daily life.

ASTRACT

In recent days the price

of petrol & diesel are increasing.So

we must think about an altternatiive

source for running the vehicels.One

effective way to avoid these

probelm is biogas-plants;actually

the biogas, which is produced by

the fermentation of animal

dung,human sewage or agricultural

residues, is rich in methane and has Graph(i) usage of fuels

the same characteristics as the

natural gas. In this paper we are

try to discuss ”BIOGAS AS From the graph shown

VEHICELS FUEL” Methane above we can see that the use of

within biogas can be concentrated petroluem products are increase day

via a biogas upgrader to the same by day. According to new survey

standards as fossil natural gas, and result, petroluem products may be

becomes biomethane. If the local available only for next 40 to50

gas network allows for this, the years. So we are going to face a big

producer of the biogas may utilize engery crisis in the near future. One

the local gas distribution networks. effective way to avoid these

Gas must be very clean to reach problems is biogas-plants; actually

pipeline quality, and must be of the the biogas, which is produced by the

correct composition for the local fermentation of animal dung, human

distribution network to accept. sewage or agricultural residues, is

Carbon dioxide, water, hydrogen rich in methane and has the same

sulfide and particulates must be characteristics as the natural gas.

removed if present. If concentrated The use of biogas as a clean fuel

answers to current concerns dealing

with economics, ecology and

energetic: The methane fermenting

is a long known conversion process

Search on renewable of the organic substance into energy

energies while the fossil in anaerobic conditions under the

deposits are draining. influence of bacterial flora. The

Reduction of the energetic biogas generated during the

dependence. methanation represents itself the

liquid methane, carbonic acid, up to

Limitation of the

1% of sulphured hydrogen, not a

atmospheric pollution

large amount of nitrogen oxygen,

linked to the gas emissions.

hydrogen, ammonia and oxide of

Decrease of the smell and carbon.

noise annoyances.

Reduction of the green COMPOSITION OF

house effects.

Biogas fuels usually cause low BIOGAS

pollution to the atmosphere and

because they come from renewable Typical composition of biogas

energy resources, they have a great Compound Chem %

potential for future use. Methane CH4 50–75

Carbon

CO2 25–50

WHY BIOGAS IS dioxide

PREDOMINATING? Nitrogen N2 0–10

Hydrogen H2 0–1

Hydrogen

H2S 0–3

Biogas is considered sulfide

clean energy, which means it does Oxygen O2 0–2

not gives off much air pollution

which is used for energy Table (i) composition of biogas

production. There is significantly

less amount of green house gas The composition of

emissions from bio energy. Another biogas varies depending upon the

alternative energy source like origin of the anaerobic digestion

nuclear power made a big problem process. Landfill gas typically has

in the disposal of waste. methane concentrations around

50%. Advanced waste treatment

Biogas: production and use technologies can produce biogas

with 55–75% CH4 or higher using

Conditions of production in situ purification techniques .As-

produced, biogas also contains

The waste collected at water vapor, with the fractional

the plant undergoes a chemical water vapor volume a function of

treatment in order to be turned into biogas temperature; correction of

biogas. It is the anaerobic digestion, measured volume for water vapor

or methanisation. content and thermal expansion is

Methanisation is an anaerobic easily done via algorithm.

digestion process that follows a

double incentive: PRODUCTION LAYOUT

• Energetic upgrading by

production of methane

(CH4)

• Stabilization of the organic

waste.

5. The non-suitable gas is

sent back to the

beginning of the plant.

The main upgrading solutions

The scrubbing techniques

Whatever the final

use of the biogas is, it is nearly

Fig. 1 The biogas plant principle impossible to use it as it is

produced. The only valuable

WORKING: fraction is the methane contained

into the biogas; the other

1. The gas is compressed components are useless,

under 10 to 15 objectionable or noxious.

bars and injected in a Consequently one or several

washing pressure tower treatment stages are necessary:

into which the water

solubilizes the carbon Upgrading use Components to

dioxide and the H2S of eliminate

the biogas. Heat Water, sulphur

2. Then the gas is dried on

Electricity Water, sulphur,

2 molecular screens

organo-halogens

under 250 bars.

3. The washing water is Fuel Water, sulphur (H2S),

recycled by gas organo-halogens,

freeing in two steps: carbon (CO2)

(i) The recuperated

gas of the Gas grid Water, sulphur,

highest gas- organo-halogens,

freeing, rich in carbon, oxygen, metal

CO2, H2S and

CH4 is injected as

raw gas into

the pressure Table (ii) upgrading of biogas

stages.

(ii) The gas salted out in • It exist numerous solutions

the lowest gas- to eliminate the water, as

freeing tour is sent using a diphase separator.

back to the biologic When using the biogas for

filter where bacteria the gas grid injection, the

eat H2S. main techniques are the

glycol absorption or the

4. The dry and pure gas is molecular screens. When

stocked at 250 bars the biogas is turned into

into steel bottles that fuel, the water

feed the filling station. concentration must be

inferior to 15 mg/Nm3: the

best solution is the

Pressure System mg/Nm3, the H2S content does not

adsorption. exceed 100mg/Nm3 and the particle

• A pass on iron oxide or size is limited at 40 microns.

activated carbon easily The typical sequence for the

eliminates the sulphur preparation is:

(H2S). A water scrubbing

can also eliminate both

sulphur and carbon • Compression at 15-20 bars.

dioxide. • Desulfuriz- ation and

• Scavenging of the organo- decarbonation by water

halogen components and scrubbing (loss of 8% of

the heavy metals is done methane)

thanks to a pass on • Dehydration by the process

activated carbon. Pressure System

• The oxygen is eliminated Adsorption.

with a catalytic treatment. • Deshalogenation by a pass

on activated carbon.

• Compression up to 250-350

bars.

Heat recovery from biogas

Economical conditions

Burning biogas in a

boiler or industrial furnace is the The economical analysis

most commonly valorization underlines that the gains are earned

method developed. The methane with the benefits done by

content can go down until 20%, and comparison with an equivalent

the scrubbing techniques are light. consumption of diesel fuel. In this

The machinery used for the heat valorization the scale benefits are

production is very common: burners very important.

or classical injectors.

BI-FUEL SYSTEM

Economical conditions

It is admitted that the

thermal upgrading of the biogas is

profitable when the flow overpasses

100Nm3/h.

Once the biogas is

picked-up or produced, the best way

to use it is enhancing its value.

Several ways are possible:

producing heat, electricity,

cogeneration, vehicle fuel or

injection in the natural gas grid.

Fig(ii)bi-fuel system

PRODUCING FUEL

For this use, the purity Biogas Heat Replacement

specifications of the gas are stricter value

than the previous ones.

Indeed, the biogas used as a fuel When the biogas is

must contain a minimum of 96% of replaced to other energy source,

methane. Moreover the vapor the equivalent amount of energy get

content must be lower than 15 from 1 cu.m biogas is listed below.

1 CU.M BIOGAS HEAT If we continue the

REPLACEMENT VALUE use of fuel like we are using day-to-

SOURCE Eq.Amt UNITS day, this type boards will appear

LPG 0.46 Kg everywhere. The era of fossil fuels

GASOLINE 0.67 Liter is over now; we have to go for

DIESEL 0.60 Liter alternative source. By using biogas

HEATING 0.55 Liter we can reduce the use of fossil

OIL fuels, and in this way we can reduce

the pollution. So our slogan is

FIRE WOOD 1.50 Kg

“USE BIOGAS; SAVE EARTH”

ELECTRICIT 1.20 KW-H

Y

Table (iii) replacement value REFRENCE

MERITS OF BIOGAS • www.biogas.virtualave.net

• www.atee.biogaz.fr

It’s a clean form of energy. • www. biogastech-cmu.com

It reduces the bio waste.

Less amount of greenhouse • ATEE-ENERGIE PLUS

gas emission. “Biogas, the upgrading

It reduces air pollution. solutions”, May 2003

• Dr. Wolfgang Tentscher

DEMERITS OF BIOGAS “biogas in the internal

market gas”, June 2002

• ENGVA, European Natural

Drudgery involved in

Gas Vehicle Association

collection of fuel

Availability of bio waste is Authors:

a problem. EBIN GEORGE .K .PETER

It didn’t decompose plastic. J .MANIKANDAN

It leads to environmental PMC TECH

HOSUR

degradation. ebin.gkp@gmail.com

CONCLUSION

Fig(iii) no fuel

You might also like

- Hydrogen From BiomassDocument24 pagesHydrogen From BiomassDIPAK VINAYAK SHIRBHATENo ratings yet

- Methanol Synthesis From SyngasDocument38 pagesMethanol Synthesis From SyngasShahabuddin Khan NiaziNo ratings yet

- Press MUd To Bio GasDocument5 pagesPress MUd To Bio GasAyush AgrawalNo ratings yet

- Biogas Production and UtilizationDocument28 pagesBiogas Production and UtilizationWijetunga Somasiri100% (2)

- Concept Paper-Humss BDocument19 pagesConcept Paper-Humss Banon_256867255100% (1)

- Greywater HandbookDocument98 pagesGreywater Handbookpwills1234100% (2)

- Biogas Upgrading TechnologiesDocument20 pagesBiogas Upgrading Technologiespippo2378793100% (2)

- chp7 DO Sag Curves StreamsDocument40 pageschp7 DO Sag Curves StreamsMarlon Gomez Casicote100% (1)

- Singapore Green LabelDocument88 pagesSingapore Green LabelTansri HarimanNo ratings yet

- Biogas Production-A Review On Composition, Fuel Properties, Feed Stock and Principles of Anaerobic DigestionDocument13 pagesBiogas Production-A Review On Composition, Fuel Properties, Feed Stock and Principles of Anaerobic DigestionTrần Thanh SơnNo ratings yet

- Biogas Power PlantDocument130 pagesBiogas Power PlantRahul Tomar100% (3)

- ETP GP 48-1 Finalized Rev Feb05Document53 pagesETP GP 48-1 Finalized Rev Feb05gestion integral80% (5)

- Bioenergy: Biomass to Biofuels and Waste to EnergyFrom EverandBioenergy: Biomass to Biofuels and Waste to EnergyAnju DahiyaNo ratings yet

- Biogas Upgrading Haffmans Case-Study Schaap-Tirns enDocument2 pagesBiogas Upgrading Haffmans Case-Study Schaap-Tirns enVinicius NoronhaNo ratings yet

- CFD Modeling of A Downdraft Gasifier WitDocument18 pagesCFD Modeling of A Downdraft Gasifier Witray mayyerNo ratings yet

- BiogasDocument46 pagesBiogasSiddharth KrishnaNo ratings yet

- Biogas Plant: Biogas Digester Design, Gas Production and PurificationFrom EverandBiogas Plant: Biogas Digester Design, Gas Production and PurificationRating: 3 out of 5 stars3/5 (1)

- Comparison of Different Waste To Energy TechnologiesDocument6 pagesComparison of Different Waste To Energy Technologiesk.pradeepaNo ratings yet

- Mathematical Model For Commercial Production of Bio-Gas From Sewage Water and Kitchen WasteDocument8 pagesMathematical Model For Commercial Production of Bio-Gas From Sewage Water and Kitchen Wasteadeel rafiqNo ratings yet

- Assignment: Name Class Subject Topic Reg No# Submitted ToDocument12 pagesAssignment: Name Class Subject Topic Reg No# Submitted ToAli AyanNo ratings yet

- How To Setup Bio Gas PlantDocument5 pagesHow To Setup Bio Gas PlantMunish BansalNo ratings yet

- Biogas and BiofuelDocument14 pagesBiogas and Biofuelvedant hiwarkarNo ratings yet

- MiniLow CostBio GasDigesterforHouseholdWasteDocument7 pagesMiniLow CostBio GasDigesterforHouseholdWasteAbdulkader HusseinNo ratings yet

- 1 s2.0 S136403211730182X MainDocument12 pages1 s2.0 S136403211730182X Mainabhishek sharma0% (1)

- A Review On Production of Biogas From SL PDFDocument5 pagesA Review On Production of Biogas From SL PDFJosephine ChirwaNo ratings yet

- Recent Advances On Palm Oil Mill Effluent (POME) Pretreatment and Anaerobic Reactor For Sustainable Biogas ProductionDocument14 pagesRecent Advances On Palm Oil Mill Effluent (POME) Pretreatment and Anaerobic Reactor For Sustainable Biogas ProductionAldo IqbalNo ratings yet

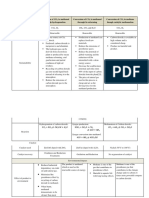

- Comparison TableDocument6 pagesComparison Tableeven leeNo ratings yet

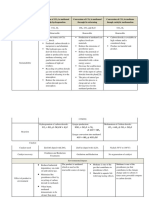

- Comparison TableDocument6 pagesComparison Tableeven leeNo ratings yet

- Bottling Biogas Into Cylinders As An Alternative Sustainable Energy Source To Mitigate Climate ChangeDocument5 pagesBottling Biogas Into Cylinders As An Alternative Sustainable Energy Source To Mitigate Climate Changeshravan nyalamNo ratings yet

- Biohythane As A High Potential Fuel From Anaerob 2021 Renewable and SustainaDocument13 pagesBiohythane As A High Potential Fuel From Anaerob 2021 Renewable and SustainaNurul Fatin UmairahNo ratings yet

- Effect of Carbon Dioxide On The Performance of Spark Ignition Engine by Hydrogen Inject With Biogas FuelDocument5 pagesEffect of Carbon Dioxide On The Performance of Spark Ignition Engine by Hydrogen Inject With Biogas FuelEditor IJTSRDNo ratings yet

- Carbon Dioxide ManufacturingDocument8 pagesCarbon Dioxide Manufacturingeven leeNo ratings yet

- R V College of EngineeringDocument16 pagesR V College of EngineeringSantosh DoddamaniNo ratings yet

- Biodiesel Production From Waste Cooking Oil - A Comprehensive Review On The Application of Heterogenous CatalystsDocument20 pagesBiodiesel Production From Waste Cooking Oil - A Comprehensive Review On The Application of Heterogenous CatalystsDevasagar ThangavelanNo ratings yet

- Biogas - An Overview - ScienceDirect TopicsDocument12 pagesBiogas - An Overview - ScienceDirect TopicsanirudhNo ratings yet

- Biogas IntroductionDocument75 pagesBiogas IntroductionRohan JindalNo ratings yet

- BOEFpaper Amserdam 2002Document5 pagesBOEFpaper Amserdam 2002Camilo VargasNo ratings yet

- Ijet V3i6p18Document9 pagesIjet V3i6p18International Journal of Engineering and TechniquesNo ratings yet

- International Journal of Greenhouse Gas Control: Liyuan Deng, May-Britt Ha GGDocument9 pagesInternational Journal of Greenhouse Gas Control: Liyuan Deng, May-Britt Ha GGMiguel RibeiroNo ratings yet

- Energies: Biogas Upgrading Approaches With Special Focus On Siloxane Removal-A ReviewDocument17 pagesEnergies: Biogas Upgrading Approaches With Special Focus On Siloxane Removal-A ReviewJia Yuan ChngNo ratings yet

- Production of Ammonia by Biomass GasificationDocument220 pagesProduction of Ammonia by Biomass GasificationAdeel ArifNo ratings yet

- Stainless Steel Tanks For Biogas Production: Publication P412Document20 pagesStainless Steel Tanks For Biogas Production: Publication P4124MT17ME160 VIGHNESHNo ratings yet

- Thermodynamics-Ii Lab Oel: Submitted ToDocument13 pagesThermodynamics-Ii Lab Oel: Submitted Toharis khalilNo ratings yet

- A Review On Recent Gasification Methods For Biomethane Gas ProductionDocument12 pagesA Review On Recent Gasification Methods For Biomethane Gas ProductionsumitrochakrabortiNo ratings yet

- Biogas PurificationDocument5 pagesBiogas PurificationHarsh GutgutiaNo ratings yet

- Tannery ReportDocument6 pagesTannery ReportdevajithNo ratings yet

- Biomass: The Ultimate Source of Bio Energy: Sushmita Mohapatra, Kasturi GadgilDocument4 pagesBiomass: The Ultimate Source of Bio Energy: Sushmita Mohapatra, Kasturi GadgilRaghu RamNo ratings yet

- Emmission and Peformance Analysis of The Ternary DDocument21 pagesEmmission and Peformance Analysis of The Ternary DSHYAM SUNDARNo ratings yet

- Energies: Storage and Upgrading of Biogas by Physicochemical Purification in A Sudano-Sahelian ContextDocument11 pagesEnergies: Storage and Upgrading of Biogas by Physicochemical Purification in A Sudano-Sahelian Contextdhineshbabu ramasamyNo ratings yet

- Hypothesis On Using Biogas and HydrogenDocument4 pagesHypothesis On Using Biogas and HydrogeniaetsdiaetsdNo ratings yet

- Bio Filtration OverviewDocument5 pagesBio Filtration OverviewLarry BothamNo ratings yet

- Biogas Enrichment & Bottling Technology For Vehicular UseDocument4 pagesBiogas Enrichment & Bottling Technology For Vehicular Useउमेश पाण्डेयNo ratings yet

- Article 1Document9 pagesArticle 1Abderrahim Najah ElidrissiNo ratings yet

- Energies: New Solvents For CO and H S Removal From Gaseous StreamsDocument40 pagesEnergies: New Solvents For CO and H S Removal From Gaseous StreamsmahmoudNo ratings yet

- Separation of Phenol From Biooil Produced From Pyrolysis of Agriculturalwastes 2329 6798 1000199Document8 pagesSeparation of Phenol From Biooil Produced From Pyrolysis of Agriculturalwastes 2329 6798 1000199Deasy Rahma WahidaNo ratings yet

- 1 s2.0 S0959652619301908 MainDocument12 pages1 s2.0 S0959652619301908 MainLking LokeshNo ratings yet

- Design Nano For HydrogenDocument10 pagesDesign Nano For Hydrogenanditama NPNo ratings yet

- Experimental Study of Biogas-Hydrogen Mixtures CombustionDocument18 pagesExperimental Study of Biogas-Hydrogen Mixtures Combustionluisa menenguerNo ratings yet

- Operational Study and Simulation of A Biogas Upgrading PlantDocument7 pagesOperational Study and Simulation of A Biogas Upgrading PlantAnand SaaNo ratings yet

- BioSNG-Process SimulationDocument9 pagesBioSNG-Process SimulationJoao MinhoNo ratings yet

- 1.1 Introduction To Biogas: Electrical DepartmentDocument38 pages1.1 Introduction To Biogas: Electrical DepartmentYogesh KhairnarNo ratings yet

- 1306 Biogas Factsheet PDFDocument7 pages1306 Biogas Factsheet PDFpowerNo ratings yet

- 1 s2.0 S096014812100210X MainDocument10 pages1 s2.0 S096014812100210X MainSumit ManwarNo ratings yet

- A Presentation On Biogas As Fuel: Submitted To: Richa Mishra Asst. Proffessor Ic EnginesDocument10 pagesA Presentation On Biogas As Fuel: Submitted To: Richa Mishra Asst. Proffessor Ic EnginesChandan ChowdaryNo ratings yet

- Clean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementFrom EverandClean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementNo ratings yet

- 1 Investigation FullDocument6 pages1 Investigation FullTJPRC PublicationsNo ratings yet

- Fitbit Charge HR User ManualDocument33 pagesFitbit Charge HR User Manualalekad65No ratings yet

- ACTION PLAN in YES-o 2022-2023Document17 pagesACTION PLAN in YES-o 2022-2023Josephine Gonzales Basilio-De VeraNo ratings yet

- A Study On The Consecutive Preparation of Silica Powders and Active Carbon From Rice Husk AshDocument8 pagesA Study On The Consecutive Preparation of Silica Powders and Active Carbon From Rice Husk AshFitra Isni RositaNo ratings yet

- Dr. Y. B.Sontakke: Joint Director (WPC) Maharashtra Pollution Control Board Mumbai-400022Document37 pagesDr. Y. B.Sontakke: Joint Director (WPC) Maharashtra Pollution Control Board Mumbai-400022Sanjukta MajhiNo ratings yet

- Hospital Biomedical Waste Management 31-08-2006Document59 pagesHospital Biomedical Waste Management 31-08-2006Hasan AnsariNo ratings yet

- Basel Convention UPSC NotesDocument3 pagesBasel Convention UPSC NotesENGINEER SHAHID LODhiNo ratings yet

- Brand Design Final - CompressedDocument8 pagesBrand Design Final - CompressedGladwin JosephNo ratings yet

- SGL PT Brochure Systems OverviewDocument24 pagesSGL PT Brochure Systems OverviewCésarSánchezRosasNo ratings yet

- Good EArth AanganDocument22 pagesGood EArth AanganSamuel AxiomNo ratings yet

- Pengelolaan Sampah Di Daya Tarik Wisata Pantai Candikusuma, Desa Candikusuma, Kecamatan Melaya, Kabupaten JembranaDocument6 pagesPengelolaan Sampah Di Daya Tarik Wisata Pantai Candikusuma, Desa Candikusuma, Kecamatan Melaya, Kabupaten JembranaIrenLayNo ratings yet

- Plumbing FundamentalsDocument23 pagesPlumbing FundamentalsSouthDirector SekharBabuNo ratings yet

- Schedule Final MergedDocument24 pagesSchedule Final MergedFranklyn ManggapisNo ratings yet

- 密密送 4 - Issue 26 - 活化工廈Document9 pages密密送 4 - Issue 26 - 活化工廈Leocean NgNo ratings yet

- Geosynthetics in Coastal Engineering Protection and Placement IssuesDocument15 pagesGeosynthetics in Coastal Engineering Protection and Placement Issues蓉蓉No ratings yet

- MCR - Roofing System: Technical DataDocument14 pagesMCR - Roofing System: Technical DatashiraNo ratings yet

- ExcretionDocument16 pagesExcretionNor Baizura Binti AzizNo ratings yet

- Assignment 1591363368 SmsDocument21 pagesAssignment 1591363368 SmsGovindappaNo ratings yet

- Training PLANDocument3 pagesTraining PLANsumeet sharmaNo ratings yet

- Economizer and CondenserDocument47 pagesEconomizer and CondenserJulius AndrewNo ratings yet

- AR LSG003 02 Chattukapara PDFDocument27 pagesAR LSG003 02 Chattukapara PDFGk MenonNo ratings yet

- Laboratory Safety Laboratory Analysis #1: Rubrics: Content (50%)Document7 pagesLaboratory Safety Laboratory Analysis #1: Rubrics: Content (50%)Nicole Edelweiss Liza100% (2)

- ThesislangDocument7 pagesThesislangInbalidNo ratings yet

- E-Styrenics Polystyrene GPPS MSDSDocument19 pagesE-Styrenics Polystyrene GPPS MSDSLaura Naziru CotovanuNo ratings yet

- Geopolymer SynthesisDocument6 pagesGeopolymer SynthesisAhmad UllahNo ratings yet