Professional Documents

Culture Documents

The Fresh Connection Document

Uploaded by

Neill BraybrookeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Fresh Connection Document

Uploaded by

Neill BraybrookeCopyright:

Available Formats

THE FRESH

CONNECTION

BUSINESS GAME TEAM 2

ANA CORREA

CLAUDIA GOMEZ

K A M I L A H U R KO V A

M E R V E N U R TA Ş

TOMMI VEROMAA

THE FRESH CONNECTION | TEAM 2 1

EXECUTIVE SUMMARY

WHAT DID WE ACHIEVE:

✓ The company obtained profit in each period, growing uninterruptedly in the first 4 rounds and with

a slight decrease in the last 2 rounds.

✓ Since round 1, ROI has always been positive.

WHAT WAS THE GENERAL STRATEGY :

✓ Make decisions integrating all departments, evaluating the possible positive or negative effects on

them in order to minimize costs and maximize the benefit to the company.

✓ Evaluate the decisions made in each period, provide feedback and take corrective actions to make

better use of company resources.

PROBLEMS ENCOUNTERED:

✓ Difficulties in predicting how some decisions will impact the performance of the company.

(The simulator restrained some functionalities at the first stages of the game)

✓ Align strategic decisions of departments in a common goal

THE FRESH CONNECTION | TEAM 2 2

CONTENTS

TEAM & RESPONSIBILITIES

◦ SALES

◦ OPERATIONS

◦ SUPPLY CHAIN

◦ PURCHASING

FINANCIAL RESULTS & CONCLUSIONS

THE FRESH CONNECTION | TEAM 2 3

TEAM & RESPONSIBILITIES

SUPPLY

SALES OPERATIONS PURCHASING

CHAIN

ROI %

Cube utilization % Components % Rejection Components %

Service level %

Prod.Plan Adherence % Stock Components Raw Material Costs %

Obsoletes %

Unused capacity % Stock Products Delivery Reliability

Gross Margin

Nr. of shifts Suppliers

Responsibilities: Responsibilities:

Responsibilities: Coordinate different Responsibilities:

Sell all produced goods

Optimize and control departments, inventory Purchasing components,

with highest possible

production and control and production negotiating with suppliers

price

warehouses

THE FRESH CONNECTION | TEAM 2 4

SALES – GROSS MARGIN

I. STRATEGY II. RESULTS

✓ Increase gross margin as much as possible 27303

prioritizing biggest customers

✓ Try not to lose gross margin on smaller customers 22486

significantly

✓ Introduce promotional pressure for customers

during later rounds

III. ANALYSIS 14510

✓ Gross began to grow on F&C and Dominick’s during 11610

round 3 when customer order priorization was

implemented

✓ Further increases in later rounds with promotional

pressure

✓ Overall increase in gross for F&C and Dominick’s

was attained without losing gross margin on Land

Market

✓ F&C gross increased by almost 5 000 and

Dominick’s by 3000 during 6 periods

THE FRESH CONNECTION | TEAM 2 5

SALES – NEGOTIATIONS

I. STRATEGY II. RESULTS

✓ Align capacity of SC and Operations to match

negotiated service and shelf life levels

✓ Take advantage of one customer with full product

range to decrease potential obsoletes

✓ Trade unit: Pallets for all and VMI for F&C and

Dominick’s to reduce outbound stress

✓ Customer priorities: 1. F&C, 2. Dominick’s, 3. LM

III. ANALYSIS

✓ Obsoletes were solved with having LM with shelf

life of 62-65%

✓ Negotiated service level % was calculated and

estimated based on improvements in SC and

Operations

✓ Decision-making in Sales was first based on

improvements made in SC and Operations, further

the decisions in SC and Operations were changed

based on Sales.

THE FRESH CONNECTION | TEAM 2 6

OPERATIONS - WAREHOUSES

I. STRATEGY II. RESULTS

✓ Optimise pallet allocations (to avoid overflow and

120%

outsourcing / too large unsued capacity) 108%

1400

99% 100%

✓ Allocate adequate number of shifts 98%

94% 96% 97%

100%

✓ Reduce variability in processes and smooth raw 1200

101% 101%

Warehouse Capacity

95% 97%

materials income and finished goods storage (align

Cube Utilisation

1000 79% 80%

85%

with Supply Chain and Purchasing) 71%

✓ Be ready to handle all demand (align with Sales) 800

60%

1050 1000

1500 975

600 1200 950 930

920

40%

900 900 900 900 900 900

III. ANALYSIS 400

✓ Round 4 was the most successful 20%

200

✓ Starting in Round 5, the demand overpassed the

warehouses‘ capacities and it was not adjusted 0 0%

correctly Round 0 Round 1 Round 2 Round 3 Round 4 Round 5 Round 6

✓ Outsourcing of warehouses would lead to Inbound Capacity Outbound Capacity

significantly higher costs Inbound Cube Utilisation Outbound Cube Utilisation

THE FRESH CONNECTION | TEAM 2 7

OPERATIONS - PRODUCTION

I. STRATEGY

´ II. RESULTS

✓ Allocate adequate number of shifts

✓ Select wisely new investments to smooth 100.0%

production and increase ROI (mixing and botteling) 94% 92% 93% 94%

90.0% 89%

✓ Minimize production costs, unused capacity, 87%

changeover and breakdown times 80.0% 79%

78% 81%

73% 73% 73%

✓ Maximize production plan adherence 70.0%

✓ Align with all other functions to be ready to satisfy 60.0% 58%

all demand at lowest cost 50.0% 53%

40.0%

III. ANALYSIS 39%

✓ In Round 5, the bottling line was changed and 30.0%

25%

shifts increased too much this mistake was 20.0%

corrected in round 6 10.0% 10% 11% 10%

✓ New investment lead to higher production costs 5% 6%

0.0%

and consequently lower ROI (lack of alignment

Round 0 Round 1 Round 2 Round 3 Round 4 Round 5 Round 6

with other functions) on longterm, the company

would improve its business results (lower variability in

production, less rejection component rate, less breakdown, Production Plan Adherence Runtime Unused Capacity

low unused capcity, high runtime %, etc.)

THE FRESH CONNECTION | TEAM 2 8

SUPPLY CHAIN - COMPONENTS

I. STRATEGY II. RESULTS

✓ Guarantee availability of components to meet

demand (depending on supplier reliability, lot sizes

ANALYSIS PER COMPONENTS

and safety stock ) 50 Low availability of Vitamin 102.0%

✓ Keep cost of stock at min level (in accordance with 45

C – High stock PET and

Pack 1

operations decisions) – Pet and Pack 1L (1-2 99.8% 99.9% 99.8% 100.0%

40 99.6%

rounds) 35 98.8% 98.9%

✓ Adequate lot sizes depending on the stock cost and Increased Stock 98.0%

30 Adjust Pack 1 – per Week PET –

transport costs given by procurement Reduction of lot sizes increase demand

25 96.0%

III. ANALYSIS 20

94.0%

✓ It was possible to guarantee availability over 99% 15

but in some cases compromising average stock – 10

92.0%

which increased the cost 5

✓ Increasing supplier reliability in some products 0 90.0%

(vitamin C) was key to have a better stock control Round 1 Round 2 Round 3 Round 4 Round 5 Round 6

✓ Round 3 and 4 best results obtained Mango Orange Pack 1 liter

✓ Round 6 problem lack alignment with other

PET Vitamin C Stock Availability %

departments

THE FRESH CONNECTION | TEAM 2 9

SUPPLY CHAIN – FINISHED GOODS

I. STRATEGY II. RESULTS

✓ Lower average stock weeks of demand and %

obsolete products without compromising service

level - in accordance with contract index per 10 120.00%

customer 9 98%

97% 95% 96% 96% 97% 100.00%

✓ Adjust production interval to decrease overall cost

Stock (weeks of demand)

8

94%

and increase utilization rate (7 day) 7 94% 87% 92% 93% 89%

80.00%

✓ Frozen period allows to keep flexibility to react to 6 5.64 5.24 5.50 5.56 5.67 5.32

demand changes 5 60.00%

4

III. ANALYSIS 3 40.00%

✓ Achieved to keep obsoletes between (0%-1%) –

2 20% 20.00%

Round 6 increase -> due to plan adherence bottling

1

line involving PET related products and production 0% 0% 1% 1% 3%

0 0.00%

interval

Round 1 Round 2 Round 3 Round 4 Round 5 Round 6

(Increasing production due to increase in demand)

✓ Round 2 and Round 6 lowest prod plan adherence Stock per week Average % Obsoletes

– higher production interval increase average stock Average % Service Level Average % Product Plan Adherance

THE FRESH CONNECTION | TEAM 2 10

PURCHASING –Component Focus

I. STRATEGY II. RESULTS

✓ Ensure high delivery reliability and low rejection Pack 1 Liter

100.00% 1.025

rates, for the best price.

✓ Make sure lead times & trade units and expected 90.00%

1.02

amounts are planned and aligned with operations. 80.00%

70.00% 1.015

60.00%

1.01

50.00%

1.005

40.00%

III. ANALYSIS 30.00% 1

✓ Round 4: Supplier is changed 20.00%

✓ Round 5: Supplier Development Plan is introduced 0.995

10.00% 3.50% 3.60%

3.40% 3.20%

Lower rejection rate is obtained 2.40% 2.30%

0.00% 0.99

Other benefits of the SDP may be observed in

1 2 3 4 5 6

further rounds

Delivery reliability (%) Rejection(%) Contract Index

THE FRESH CONNECTION | TEAM 2 11

PURCHASING – Component Focus

PET Orange

100.00% 1.04 100.00% 1.01

90.00% 1.03 90.00%

1.008

80.00% 1.02 80.00%

70.00% 1.01 70.00% 1.006

60.00% 1 60.00% 1.004

50.00% 0.99 50.00%

40.00% 0.98 40.00% 1.002

30.00% 0.97 30.00% 1

20.00% 0.96 20.00%

5.60% 5.70% 0.998

10.00% 3.10% 3.30% 2.10% 2.00% 0.95 10.00% 1.00% 1.00% 0.90% 0.90% 0.80% 0.70%

0.00% 0.94 0.00% 0.996

1 2 3 4 5 6 1 2 3 4 5 6

Delivery reliability (%) Rejection(%) Contract Index Delivery reliability (%) Rejection(%) Contract Index

✓ Round 2: Trade unit is changed ✓ Round 2: Trade unit is changed

✓ Round 3: Supplier is changed ✓ Round 4: Higher delivery reliability rate is negotiated.

✓ Round 5: Supplier is changed & Bottling Line is changed with a

more tolerant one.

THE FRESH CONNECTION | TEAM 2 12

PURCHASING – Component Focus

✓ Round 2: Higher delivery reliability rate is negotiated. ✓ Round 3: Supplier is changed & Higher deliveriy reliability

rate is negotiated.

THE FRESH CONNECTION | TEAM 2 13

PURCHASING – Raw Material Costs (%)

I. STRATEGY II. RESULTS

✓ Raw material cost (%) (purchase costs as a Purchase Costs (%) - Purchase Value

percentage of total revenue) is one of the crucial 1,100,000 40.00

37.48

KPI’s of the company

✓ It is calculated taking into consideration the bonus 1,000,000

34.14

35.00

32.47 32.14

& penalties 30.96

31.70

✓ Strategy: Lower Values 900,000 30.00

800,000 25.00

1,014,346

III. ANALYSIS 700,000 20.00

857,446 861,096

✓ Decreasing Trend during the first 5 rounds 828,373 839,319 840,809

✓ High obsolete products in round 6 Causes 600,000 15.00

unnecessary purchases

✓ Unmatched Service Level Agreements in round 6 500,000 10.00

Causes high penalties 1 2 3 4 5 6

✓ Best performance: Round 4 & 5 Purchase Value Purchase Costs (%)

THE FRESH CONNECTION | TEAM 2 14

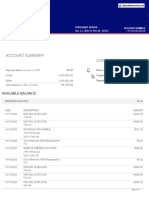

FINACIAL RESULTS & CONCLUSIONS

I. RESULTS II. CONCLUSIONS

FINANCE ✓ The average of goods sold in the 6 rounds was $ 2.66 million. The periods

with the highest sales were rounds 1, 5 and 6.

✓ The cost of goods sold drastically influenced the gross margin, the average of

this in the 6 rounds was $ 1.37 million. It can be seen that the periods with

the highest cost of goods sold were 1 and 5.

✓ The ROI went from negative in the first period to positive in the second,

having the best percentages in periods 3 and 4 and lower results in periods 5

and 6 caused by lack of alignment on following factors:

ROI EVOLUTION • Change of filling line

• Increased demand

• Decreased production interval

• Not sufficiently increased warehouse capacity

Not allocating the capacity correctly lead to

• High obsoletes % and penalty costs

• High cube utilisation % in warehouses

• Low production plan adherence

✓ The weighted average was 4%

THE FRESH CONNECTION | TEAM 2 15

BACK UP:

Decisions per each round

THE FRESH CONNECTION | TEAM 2 16

SALES - Decisions

ROUND 1 ROUND 2 ROUND 3

✓ Understand how the game works ✓ Get rid of high % of obsoletes by ✓ Calculate service level and shelf life based

✓ Use real life experience in decisions drastically decreasing shelf life and on changes made in SC and Operations

✓ Find correlations between other introducing FIFS shortage rule ✓ Obsoletes value at 0,2%

departments when making decisions ✓ Calculate service level based on changes ✓ Set goal to increase obsoletes to 1-2% in

made in SC and Operations order to find how much « air » is in

between actual capacity and negotiated

ROUND 4 ROUND 5 ROUND 6

✓ Obsoletes still at 0,2% -> Increase shelf ✓ Install VMI for 1 customer ✓ Calculate service level to align with

life more ✓ Trade unit to Pallet for all customers achieved service levels from round 5

✓ Calculate service level and shelf life based ✓ Communicate promotional pressure and ✓ VMI for 2 customers

on changes made in SC and Operations implemented changes VMI to SC and ✓ Communicate promotional pressure and

Operations implemented VMI to SC and Operations

THE FRESH CONNECTION | TEAM 2 17

OPERATIONS - Decisions

Period 1 Period 2 Period 3 Period 4 Period 5 Period 6

Decision Period 0

30.03.17 06.04.17 20.04.17 20.04.17 27.04.17 27.04.17

Pallets location 900 920 900

Inbound Shifts 5 3 2 3

(Raw materials) IntakeTime days N/A 5 6

Inspection N/A No Pets,Pack 1 liter Pets, Plastics

Mixing Mixer Type Fruit Mix MQ

Shifts 2 3 2 3 2

Projects - SMED - -

Preventive

N/A A little A lot

Maintenance

Bottling

Solve

Breakdown N/A Yes No

Training

Bottling Line Swiss Fill 2 Multi Flex 1

Outbound Pallets location 1500 1200 1050 950 930 975 1000

(finished

goods) Shifts 4 3 4

THE FRESH CONNECTION | TEAM 2 18

SUPPLY CHAIN - Decisions

ROUND 1 ROUND 2 ROUND 3

✓ Safety Stock: increased Vitamin C, decrease safety ✓ Safety Stock: reduced Pack 1L and brought back ✓ Safety Stock: increased Vitamin C, Fressie Orange/C-

for all finish products (depending on the shelf life) Vitamin C , unified to 2 SS of finished goods power

✓ Lot Size: decreased for PET and Pack 1 ✓ Lot Size: Decreased Pack 1 liter, orange, mango and ✓ Lot Size: decrease Vitamin C

✓ Production Interval: Increased production interval of Vitamin C ✓ Production Interval: Changed back to 7 Fressie

Freassie Orange/c-Power 1 liter, Fressie Orange PET, ✓ Production Interval: unified to 8 Orange 1 liter, Fressie Orange/c-Power 1 liter, Fressie

Fressie Orange/C- power PET ✓ Frozen Period: 3 Orange/Mango PET, Fressie Orange/C - power PET

✓ Frozen Period: 3 ✓ Frozen Period: 4

ROUND 4 ROUND 5 ROUND 6

✓ Safety Stock: lower vitamin C ✓ Safety Stock: Fressie Orange 1 liter, Fressie Orange ✓ Safety Stock: decreased orange, mango, vitamin c

✓ Lot Size: no changes /C-Power ✓ Lot Size: no changes

✓ Production Interval: no changes ✓ Lot Size: Reduced for orange and mango ✓ Production Interval: no changes

✓ Frozen Period: 3 ✓ Production Interval: unified to 7 ✓ Frozen Period: 3

✓ Frozen Period: 3

THE FRESH CONNECTION | TEAM 2 19

PURCHASING – Detailed Information

Contract Index - Purchase Value Graph

Obsolete Products (%) -Average

0.210

24.00%

0.180

0.183

0.150 20.00% 20.00%

0.120

16.00%

0.090

0.064

12.00%

0.060 0.035

0.030

0.004 0.004 8.00%

0 0.000

0.000

0.000 -0.002 0.007 4.00% 2.52%

-0.030 -0.013 1.23%

-0.024 0.95%

0.23% 0.22%

-0.060 0.00%

1 2 3 4 5 6 1 2 3 4 5 6

Purchase Value (%D) Contract Indexes (%D)

✓ Percentage Change Graph ✓ Obsolete Products

THE FRESH CONNECTION | TEAM 2 20

You might also like

- Supply Chain Coordination Summer Semester - 2021 Final Presentation - Team KratosDocument29 pagesSupply Chain Coordination Summer Semester - 2021 Final Presentation - Team Kratosshreyas raoNo ratings yet

- Fresh Connection Game PDFDocument20 pagesFresh Connection Game PDFRahul Kalra80% (5)

- Step 1 - 0 MANUAL FOR INSTRUCTORS The Fresh ConnectionDocument30 pagesStep 1 - 0 MANUAL FOR INSTRUCTORS The Fresh ConnectionRicky Ramirez67% (3)

- VILAS - The Fresh Connection Manual PDFDocument45 pagesVILAS - The Fresh Connection Manual PDFNguyễn Đức QuangNo ratings yet

- TFC LearningsDocument5 pagesTFC LearningsTejaswi Kasturi100% (1)

- Assingment 2 CompleteDocument10 pagesAssingment 2 CompleteDavid Van De FliertNo ratings yet

- Simulation Variabels Document (Round 1-3)Document16 pagesSimulation Variabels Document (Round 1-3)Kom BoonnaNo ratings yet

- TFC InfocenterDocument37 pagesTFC InfocenterCeline Yap50% (2)

- The Fresh Connection: Team 14 Abhishek Mishra (19S6 Akhil Pillai (NIRANJANA A (19S631) Somil Gupta (19SDocument4 pagesThe Fresh Connection: Team 14 Abhishek Mishra (19S6 Akhil Pillai (NIRANJANA A (19S631) Somil Gupta (19SSomil GuptaNo ratings yet

- Assingment 2 CompletDocument10 pagesAssingment 2 CompletDavid Van De FliertNo ratings yet

- The Fresh Connection - Business Simulation For Experiential LearningDocument2 pagesThe Fresh Connection - Business Simulation For Experiential LearningAshish Mendiratta0% (1)

- TFC Roles VP OperationsDocument5 pagesTFC Roles VP OperationsbaheliciousNo ratings yet

- The New Normal Case Study TFC ScribdDocument2 pagesThe New Normal Case Study TFC ScribdTasneemNo ratings yet

- Fresh ConnectionDocument5 pagesFresh Connectionİlhami ArıkanNo ratings yet

- The Fresh Connection - Simulation Based Supply Chain Learning PlatformDocument15 pagesThe Fresh Connection - Simulation Based Supply Chain Learning PlatformFrinsonFrancis50% (2)

- The Fresh ConnectionportfolioDocument32 pagesThe Fresh ConnectionportfolioRaja SekarNo ratings yet

- TFC 2012Document34 pagesTFC 2012Will ChenNo ratings yet

- Hans Kremer Inchaigne PDFDocument44 pagesHans Kremer Inchaigne PDFArmanbekAlkinNo ratings yet

- Global Supply Chain Management: The Fresh Connection Simulation ReportDocument5 pagesGlobal Supply Chain Management: The Fresh Connection Simulation ReportnishantNo ratings yet

- Final TFC Round 1 and 2Document8 pagesFinal TFC Round 1 and 2AMRUT PATELNo ratings yet

- Initial 2 Final Consultants Report 2Document51 pagesInitial 2 Final Consultants Report 2IntiJoséNo ratings yet

- The Fresh Connection Draft Version 2Document15 pagesThe Fresh Connection Draft Version 2dang ngoc quangNo ratings yet

- Supply Chain MappingDocument9 pagesSupply Chain MappingRafi Hyder100% (1)

- Global Supply ChainDocument5 pagesGlobal Supply ChainyinueNo ratings yet

- The Fresh Connection - The CompanyDocument5 pagesThe Fresh Connection - The CompanyChrisNo ratings yet

- Barilla Case Study SolutionDocument6 pagesBarilla Case Study SolutionJayati AgrawalNo ratings yet

- Cataumet Boats Inc - Case Analysis TemplateDocument16 pagesCataumet Boats Inc - Case Analysis TemplateDebanjan Mukherjee100% (1)

- Kristen's Cookies AnalysisDocument10 pagesKristen's Cookies AnalysisPrisha Chetan ThakkarNo ratings yet

- DocDocument4 pagesDocchhavi123No ratings yet

- Leitax - Case SolutionDocument4 pagesLeitax - Case SolutionChirag BoghaniNo ratings yet

- The Fresh Connection - Draft Version 2Document13 pagesThe Fresh Connection - Draft Version 2peng wang0% (1)

- Decisions y Referencias - TFC - Initial - D2LDocument72 pagesDecisions y Referencias - TFC - Initial - D2LCristhian JavierNo ratings yet

- National Cranberry Case SolutionDocument4 pagesNational Cranberry Case SolutionAli Umer MughalNo ratings yet

- Seven Eleven of Japan Co.Document5 pagesSeven Eleven of Japan Co.gauravNo ratings yet

- What Is The Right Supply Chain For Your Product?Document2 pagesWhat Is The Right Supply Chain For Your Product?rjaliawala100% (4)

- Group 1 SCM Assignment 2 VF BrandsDocument5 pagesGroup 1 SCM Assignment 2 VF BrandsRahul Mayank88% (8)

- Executive Summary Process Elements Issue Identification Environmental and Root Cause AnalysisDocument10 pagesExecutive Summary Process Elements Issue Identification Environmental and Root Cause AnalysisMano AthulathmudaliNo ratings yet

- ITT AutoDocument4 pagesITT AutoKarthik ArumughamNo ratings yet

- Barilla Case StudyDocument43 pagesBarilla Case StudyPravin KumarNo ratings yet

- DAV CaseDocument4 pagesDAV Casesathyanl90100% (1)

- Supply Chain Game Round 2Document5 pagesSupply Chain Game Round 2douding41163.com100% (1)

- 2 Weeks Supply: Capacity Analysis On Current Production CapabilityDocument6 pages2 Weeks Supply: Capacity Analysis On Current Production CapabilityPuran NarwaniNo ratings yet

- Sport Obermeyer Final PDFDocument10 pagesSport Obermeyer Final PDFpiyushNo ratings yet

- OPIM101 - Spring 2010 - R4 SolutionsDocument4 pagesOPIM101 - Spring 2010 - R4 Solutionsjoe91bmwNo ratings yet

- Kristen's Cookie CompanyDocument19 pagesKristen's Cookie CompanySiddharth Garg0% (2)

- HP DeskJet Case ReportDocument9 pagesHP DeskJet Case ReportSimon Nguyen100% (2)

- American Connector CompanyDocument5 pagesAmerican Connector CompanyAnand Prakash JhaNo ratings yet

- Reebok NFL Replica Jerseys Case Group IDocument30 pagesReebok NFL Replica Jerseys Case Group ISebastián Andrés Salinas Sepúlveda88% (8)

- The Beer Distribution GameDocument4 pagesThe Beer Distribution GameAbhishek SrivastavaNo ratings yet

- OM - I National Cranberry CooperationDocument7 pagesOM - I National Cranberry Cooperationamritj100% (1)

- Cataumet Boat Case StudyDocument6 pagesCataumet Boat Case StudyKapil Musale80% (5)

- Group 7 - VF BrandsDocument4 pagesGroup 7 - VF BrandsANSHUL SINGH PARIHARNo ratings yet

- Barilla SpA Case StudyDocument5 pagesBarilla SpA Case Studybinzidd007No ratings yet

- Barilla Spa CaseDocument21 pagesBarilla Spa CaseMichael Pashos100% (4)

- Capsim Simulation: Team Eerie (Group 5)Document4 pagesCapsim Simulation: Team Eerie (Group 5)Dhruv KumbhareNo ratings yet

- C132862 Eerie Round 1-4 CapsimDocument9 pagesC132862 Eerie Round 1-4 CapsimDhruv KumbhareNo ratings yet

- Capsim Simulation: Team Eerie (Group 5)Document3 pagesCapsim Simulation: Team Eerie (Group 5)Dhruv KumbhareNo ratings yet

- Investor Day Presentation en 0Document44 pagesInvestor Day Presentation en 0mukeshindpatiNo ratings yet

- Cost Report ContohDocument24 pagesCost Report ContohagungNo ratings yet

- Isrs PDFDocument15 pagesIsrs PDFUmrotus SyadiyahNo ratings yet

- FIN542 Ind. AssignmentDocument10 pagesFIN542 Ind. AssignmentCici KakaNo ratings yet

- Module 2Document60 pagesModule 2lizNo ratings yet

- Social Security CalculatorDocument20 pagesSocial Security CalculatorHamood HabibiNo ratings yet

- CommunismDocument2 pagesCommunismhezekiahNo ratings yet

- Best Practice Solutions: Managing Stakeholder ExpectationsDocument18 pagesBest Practice Solutions: Managing Stakeholder ExpectationsabdelmutalabNo ratings yet

- Charting A Company'S Direction:: Its Vision, Mission, Objectives, and StrategyDocument58 pagesCharting A Company'S Direction:: Its Vision, Mission, Objectives, and Strategyashrafalam1986No ratings yet

- Sbi NeftformatDocument5 pagesSbi NeftformatPPCPL Chandrapur0% (1)

- Principles of Acc. II Lecture NoteDocument54 pagesPrinciples of Acc. II Lecture NoteJemal Musa83% (6)

- Cocktail ReceptionDocument2 pagesCocktail ReceptionSunlight FoundationNo ratings yet

- Ac3143 ch1-4 PDFDocument62 pagesAc3143 ch1-4 PDFNero PereraNo ratings yet

- Statement of Account: Date Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalanceDocument22 pagesStatement of Account: Date Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalanceRohit RajagopalNo ratings yet

- Somaliland Food and Water Security StrategyDocument58 pagesSomaliland Food and Water Security StrategyMohamed AliNo ratings yet

- PDFDocument5 pagesPDFMa Josielyn Quiming0% (1)

- Compensation Survey 2021Document14 pagesCompensation Survey 2021Oussama NasriNo ratings yet

- CPG SampleDocument43 pagesCPG SampleRabindra Rajbhandari100% (2)

- HW Microeconomics)Document3 pagesHW Microeconomics)tutorsbizNo ratings yet

- Ged105 MRR1Document3 pagesGed105 MRR1Cy100% (1)

- Case Study - Brazil and US - CottonDocument7 pagesCase Study - Brazil and US - CottonDISHA MALHOTRANo ratings yet

- Revisiting Talent Management Practices in A Pandemic Driven Vuca Environment - A Qualitative Investigation in The Indian It IndustryDocument6 pagesRevisiting Talent Management Practices in A Pandemic Driven Vuca Environment - A Qualitative Investigation in The Indian It Industrydevi 2021100% (1)

- Raghunath Internet: Name - Address SL - No DateDocument1 pageRaghunath Internet: Name - Address SL - No DateAlok NayakNo ratings yet

- Means of Avoiding or Minimizing The Burdens of TaxationDocument6 pagesMeans of Avoiding or Minimizing The Burdens of TaxationRoschelle MiguelNo ratings yet

- 5-Vendors Are The King MakerDocument2 pages5-Vendors Are The King Makersukumaran3210% (1)

- Jio Fiber Tax Invoice TemplateDocument5 pagesJio Fiber Tax Invoice TemplatehhhhNo ratings yet

- Corporate Finance MCQDocument35 pagesCorporate Finance MCQRohan RoyNo ratings yet

- An Introduction To Supply Chainmanagement: William J. StevensonDocument7 pagesAn Introduction To Supply Chainmanagement: William J. StevensonpraveenNo ratings yet

- FM - Kelompok 4 - 79D - Assignment CH9, CH10Document8 pagesFM - Kelompok 4 - 79D - Assignment CH9, CH10Shavia KusumaNo ratings yet

- Pija Doc 1581907800Document8 pagesPija Doc 1581907800lamp vicNo ratings yet

- ACC 307 Final Project Part IIDocument4 pagesACC 307 Final Project Part IISalman Khalid100% (4)

- Strategies To Reduce Supply Chain Disruptions in GhanaDocument126 pagesStrategies To Reduce Supply Chain Disruptions in GhanaAlbert HammondNo ratings yet

- BankDocument7 pagesBankSheeza NoorNo ratings yet