Professional Documents

Culture Documents

PT Details

Uploaded by

Duy Linh NguyễnOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PT Details

Uploaded by

Duy Linh NguyễnCopyright:

Available Formats

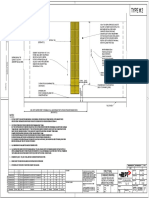

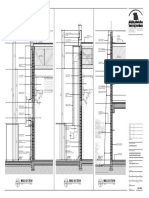

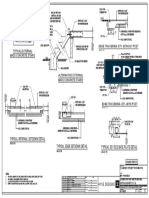

50mm NON-STRUCTURAL 50mm NON-STRUCTURAL

ENDS SQUARED

SLAB EDGE

3N12 T & B EXTEND 3N12 T & B EXTEND

BY BENDING AS SHOWN ENDS SQUARED BY

600mm PAST LAST 600mm PAST LAST

N10 HELIX OF 5 TURNS AT 60 BENDING AS SHOWN

2N12 EACH POCKET 1-N12 EACH POCKET ANCHOR. COG ANCHOR. COG

100

PITCH FOR UP TO AND

x 1500LG MINIMUM TOP x 1500LG MINIMUM 200mm IF REQUIRED 200mm IF REQUIRED

INCLUDING 5x12.7 dia. 260

1-N12 EACH POCKET TOP AND BOTTOM

x 1500LG MINIMUM BOTTOM

OR

110

N10 HELIX OF 7 TURNS AT 60 300

PITCH FOR 3x15.2 dia. & 4x15.2 dia.

N12 HELIX OF 6 300 300 N12 HELIX OF 6

TURNS AT 60 TURNS AT 60

1a 1b

250

250

PITCH PITCH

- -

PLAN ELEVATION PLAN ELEVATION

1000 MINIMUM

CONTINUE TO

1500 MINIMUM OBSTRUCTION / SUPPORT TYPICAL LIVE END DETAIL FOR SLAB TYPICAL DEAD END DETAIL FOR SLAB

THICKENINGS GREATER THAN 400mm THICKENINGS GREATER THAN 400mm

2N16x2500 MINIMUM TOP EACH SIDE OF POCKET. COG ENDS AT

THE EDGE OF THE SLAB TYPICAL. 2N16x2500 MINIMUM BOTTOM

EACH SIDE OF POCKET OR UNDER THE PAN WHERE POSSIBLE

COG ENDS AT THE EDGE OF THE SLAB TYPICAL.

COG AT EDGES

WHEN REQUIRED

PLAN

SCALE 1:10

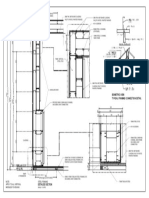

ENDS SQUARED BY ENDS SQUARED BY

BENDING AS SHOWN BENDING AS SHOWN

CUT AFTER APPROVAL SCABBLE SURFACE

OF EXTENSIONS BY ENGINEER PRIOR TO GROUTING

SLAB

DEPTH

LAY BOTTOM REINFORCEMENT MAINTAIN MINIMUM COVER AT ALL PANS REFER TO

COVER

AS NOTED ABOVE GENERAL ARRANGEMENT DRAWINGS.

IN BOTTOM OF CONCRETE FOR WATERTIGHT AREAS APPLY FOSROC

SECTION IN NITROBOND EP OR APPROVED EQUIVALENT EPOXY

3 4

WHICH THE PAN LIES BONDING AGENT. 2 COATS PRIOR TO GROUTING.

- -

SECTION 1a

SCALE = 1:10 -

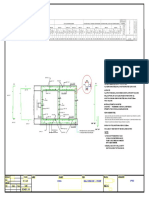

INTERNAL STRESSING POCKET - SLAB 50

CUT AFTER APPROVAL

OF EXTENSIONS BY ENGINEER

TYPICAL PLAN TYPICAL PLAN

TIES 1ST AND 4TH SCABBLE (1-N12) TIES 1ST AND 4TH

2N12 LAY SURFACE LAY U/3RD LIVE END DEAD END

U/3RD PRIOR TO BEAM REINFORCEMENT

GROUTING LAYED 3RD

BEAM DEPTH

N10 HELIX OF 5 TURNS AT 60 N10 HELIX OF 5 TURNS AT 60

100

100

PITCH FOR UP TO AND PITCH FOR UP TO AND

INCLUDING 5x12.7 dia. 260 INCLUDING 5x12.7 dia. 260

OR OR

110

110

100 50 N10 HELIX OF 7 TURNS AT 60 300 N10 HELIX OF 7 TURNS AT 60 300

1-N12 PROVIDE 2N12 1-N12 LAY BOTTOM REINFORCEMENT

COVER

PITCH FOR 3x15.2 dia. & 4x15.2 dia. PITCH FOR 3x15.2 dia. & 4x15.2 dia.

U-BARS FULL AS NOTED ABOVE IN BOTTOM

DEPTH WHEN NO OF CONCRETE SECTION

BEAM TIES PROVIDED IN WHICH THE PAN LIES

SECTION 1b

SCALE = 1:10 -

INTERNAL STRESSING POCKET - BEAM 2N12 TOP & BTM. CONT. LAP 350 2N12 TOP & BTM. CONT.

WHERE REQUIRED. 1000 MIN. LAP 350, 1000 MIN. LONG

LONG FOR SINGLE DUCT FOR SINGLE DUCT

LOCATIONS LOCATIONS

SECTION 3 SECTION 4

SCALE = 1:10 - SCALE = 1:10 -

TO PLAN

REFER

STEP

120

4N12-50 (*)

O.D. 400 400 TENDON

HOLD DOWN

BARS TIED TYPICAL SLAB EDGE SUPPORTED TYPICAL SLAB EDGE SUPPORTED

TO DUCT

BY BEAMS OR THICKENING BY BEAMS OR THICKENING

1-N12 (*) IN 1-N12 (*) IN

GREATER THAN 350mm GREATER THAN 350mm

200

200

CORNERS CORNERS

x1000LG x1000LG

4N12-50 (*) 120

400 400 HOLD DOWN O.D.

BARS TIED TO DUCT

HOLD DOWN BARS (*)

AT STEP LOCATIONS

FRONT ELEVATION TYPICAL SECTION THROUGH STEP N10 HELIX OF 5 TURNS AT 60

100

PITCH FOR UP TO AND

SCALE 1:10 (HOLD DOWN BAR LOCATION) INCLUDING 5x12.7 dia. 260

SCALE 1:10

OR

110

100 50 N10 HELIX OF 7 TURNS AT 60 300

PITCH FOR 3x15.2 dia. & 4x15.2 dia.

2N12 TOP & BTM. CONT.

LAP 350, 1000 MIN. LONG

FOR SINGLE DUCT

LOCATIONS

SECTION 3

SCALE = 1:10 -

TYPICAL UNSUPPORTED

SLAB EDGE

You might also like

- The Vanishing Present: Wisconsin's Changing Lands, Waters, and WildlifeFrom EverandThe Vanishing Present: Wisconsin's Changing Lands, Waters, and WildlifeDonald M. WallerRating: 4 out of 5 stars4/5 (1)

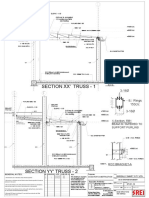

- Truss Details 2: 50mm X 75mm PURLINS W/ 50mm X 75mm STOP BLOCKDocument1 pageTruss Details 2: 50mm X 75mm PURLINS W/ 50mm X 75mm STOP BLOCKJohn And ThenaNo ratings yet

- Kitchen Setail: Section Thru ADocument1 pageKitchen Setail: Section Thru ASha NikzNo ratings yet

- Tanque Vu 570 m3 DSN-RCT275-50Document2 pagesTanque Vu 570 m3 DSN-RCT275-50Comercial FirenoNo ratings yet

- Ar 302 Acoustic Door NewDocument1 pageAr 302 Acoustic Door NewAnshal NaushadNo ratings yet

- Cross CROSS SECTION ETO TALAGA YUNDocument1 pageCross CROSS SECTION ETO TALAGA YUNFermin NaragNo ratings yet

- Lot - 44, 1140 Richmond Road, Marsden Park: NorthDocument1 pageLot - 44, 1140 Richmond Road, Marsden Park: NorthVinay RaoNo ratings yet

- 3rd Triple Sharing-FurnitureDocument1 page3rd Triple Sharing-FurnitureIpsita RoyNo ratings yet

- S-106 Concrete LayoutDocument1 pageS-106 Concrete Layoutarno assassinNo ratings yet

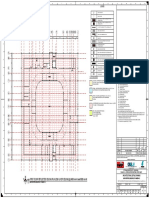

- Swimming Pool Structural DrawingDocument1 pageSwimming Pool Structural DrawingFrederick Quinto100% (1)

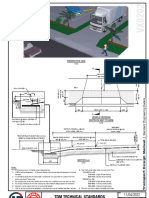

- STD - S0066-Footpath Up To Kerb Line Greater Than 2400mm wideRevFDocument1 pageSTD - S0066-Footpath Up To Kerb Line Greater Than 2400mm wideRevFdarren dmuscat1hotmail.comNo ratings yet

- Section Thru X-X & Y-YDocument1 pageSection Thru X-X & Y-Yvanissamontilla21No ratings yet

- Working Drawing Isa4Document1 pageWorking Drawing Isa4Aakash ReddyNo ratings yet

- 222 BayDocument1 page222 Bayanshalnaushad7No ratings yet

- 12.5-310-100 High Mast Lighting SystemDocument1 page12.5-310-100 High Mast Lighting SystemrituNo ratings yet

- Basic Class Room ElevationDocument1 pageBasic Class Room ElevationSandman MondragonNo ratings yet

- Mock Up-4Document1 pageMock Up-4Shifas E Abdul SalamNo ratings yet

- COMPOUND WALL-ModelDocument1 pageCOMPOUND WALL-ModelEr Mansoor HussainNo ratings yet

- X-Power End Mills EM877 EM876: Carbide, 2 Flute Short Length Ball NoseDocument2 pagesX-Power End Mills EM877 EM876: Carbide, 2 Flute Short Length Ball NosesahNo ratings yet

- Orca Share Media1675682266956 7028320835023463925Document6 pagesOrca Share Media1675682266956 7028320835023463925Lorenz Carlo Robedillo GonzalesNo ratings yet

- Orca Share Media1675682266956 7028320835023463925Document1 pageOrca Share Media1675682266956 7028320835023463925Lorenz Carlo Robedillo GonzalesNo ratings yet

- Berri-Nsh2023-Cvl-159 Relocation of Cable Tray 1Document2 pagesBerri-Nsh2023-Cvl-159 Relocation of Cable Tray 1Ramil LazaroNo ratings yet

- Detail Pondasi: KontractorDocument1 pageDetail Pondasi: KontractorElgi Permana PutraNo ratings yet

- Dolce Gabanna Layout2Document1 pageDolce Gabanna Layout2Nelson M. Malicdem Jr.No ratings yet

- Sheet 4Document1 pageSheet 4Nipun ChoudharyNo ratings yet

- Cb-007 Ground Floor Sanitary (28!6!21) - ModelDocument1 pageCb-007 Ground Floor Sanitary (28!6!21) - ModelSrikrishan singhNo ratings yet

- First Floor Reflected Ceiling Plan (2Nd Layer Ceiling) at 4500 MM HT and 9000 MM HTDocument1 pageFirst Floor Reflected Ceiling Plan (2Nd Layer Ceiling) at 4500 MM HT and 9000 MM HTgilbert850507No ratings yet

- Light Box 1Document1 pageLight Box 1Mohammad Fadhil EmamdhullyNo ratings yet

- vx0202 C Commercial Vehicle CrossingDocument1 pagevx0202 C Commercial Vehicle Crossingshelvin.swamyNo ratings yet

- Mild Steel With Wooden-Layout1Document1 pageMild Steel With Wooden-Layout1subhash0% (1)

- SEPL-1087-CV-FD-007-R1 (1) - ObservationDocument1 pageSEPL-1087-CV-FD-007-R1 (1) - ObservationSumanNo ratings yet

- Third Floor Detail Plan Detail Section Thru "1": Stair 3 (Main Stair) Stair 3 (Main Stair)Document1 pageThird Floor Detail Plan Detail Section Thru "1": Stair 3 (Main Stair) Stair 3 (Main Stair)erico bartoloNo ratings yet

- First Floor Reflected Ceiling Plan (1St Layer Ceiling) at 3000 MM HT and 5700 MM HTDocument1 pageFirst Floor Reflected Ceiling Plan (1St Layer Ceiling) at 3000 MM HT and 5700 MM HTgilbert850507No ratings yet

- MCC #1 Elevation: District of Sicamous Mara Lake WTP UpgradeDocument1 pageMCC #1 Elevation: District of Sicamous Mara Lake WTP UpgradeFaten YASERNo ratings yet

- 2 StoreyDocument19 pages2 Storeyarkitravel onthego100% (5)

- Gd. MI RKBDocument15 pagesGd. MI RKBerik indra islamiNo ratings yet

- BSC - RGOrtigas - WD-AI 2.0Document1 pageBSC - RGOrtigas - WD-AI 2.0Ramon AngNo ratings yet

- Pertamina PertashopDocument4 pagesPertamina Pertashopikeuchi_ogawa79% (19)

- Construction Specialties, Inc.: Screens FinishesDocument1 pageConstruction Specialties, Inc.: Screens FinishesKat PetillaNo ratings yet

- Welded Lap Splice Detail: Tue Mar 07 08:17:00 2017Document1 pageWelded Lap Splice Detail: Tue Mar 07 08:17:00 2017mintu PatelNo ratings yet

- Besada BT05 Sheet3 SectionandplotdetailsDocument1 pageBesada BT05 Sheet3 SectionandplotdetailsBesada BryanNo ratings yet

- Manhole and Concrete Cover Details Scale: 1:100Document1 pageManhole and Concrete Cover Details Scale: 1:100jonathan chandaNo ratings yet

- BC2-Double 2m X 2mDocument1 pageBC2-Double 2m X 2moseni momoduNo ratings yet

- Cardiology - Burwood - Issue 12Document1 pageCardiology - Burwood - Issue 12greedygutzNo ratings yet

- Notes:: Iranian Petroleum StandardsDocument1 pageNotes:: Iranian Petroleum Standardsbabakfun2000No ratings yet

- Elevation: Rib Type Color Roofing Ga. 24 X 8ft of Approved ColorDocument1 pageElevation: Rib Type Color Roofing Ga. 24 X 8ft of Approved ColorJayson FernandezNo ratings yet

- External Street Lighting LayoutDocument1 pageExternal Street Lighting LayoutHarwinder MattuNo ratings yet

- CPHM-80-32 + 75 KW 2 (250M) RB - ModelDocument1 pageCPHM-80-32 + 75 KW 2 (250M) RB - ModelRamesh KumarNo ratings yet

- PARTITIONDocument1 pagePARTITIONKanak YadavNo ratings yet

- Rpop - Canopy Panadura e City - Option - 02Document1 pageRpop - Canopy Panadura e City - Option - 02Kalum ChandraNo ratings yet

- A2-504 Wall SectionDocument1 pageA2-504 Wall SectionPappu Kishore KumarNo ratings yet

- Ex1 Arch 3F SabelloDocument4 pagesEx1 Arch 3F SabelloMaresa Namocot SabellanoNo ratings yet

- Cardiology - Burwood - Issue 8Document1 pageCardiology - Burwood - Issue 8greedygutzNo ratings yet

- Stair ExampleDocument1 pageStair ExampleWinata WinataNo ratings yet

- BSD - Plate 9-Rear ElevationDocument1 pageBSD - Plate 9-Rear ElevationMichael SilvestreNo ratings yet

- Unified Workplace and May Not Be Copied in Part or in WholeDocument1 pageUnified Workplace and May Not Be Copied in Part or in Wholegunjan barejaNo ratings yet

- Panel Distribusi - InnobizDocument3 pagesPanel Distribusi - InnobizRahmat HidayatNo ratings yet

- Structural Steel Layout & Slab Detail DrawingDocument2 pagesStructural Steel Layout & Slab Detail Drawingdjati_No ratings yet

- Lawrenz Exam CadDocument1 pageLawrenz Exam CadAQUINO, LAWRENZ DAVE B.No ratings yet

- Drawing of Truss Shed 2Document2 pagesDrawing of Truss Shed 2Rohit SinghNo ratings yet

- How Much Does An Industrial Water Treatment System Cost?: Chapter FiveDocument13 pagesHow Much Does An Industrial Water Treatment System Cost?: Chapter FiveDuy Linh NguyễnNo ratings yet

- NotesDocument3 pagesNotesDuy Linh NguyễnNo ratings yet

- 19Document1 page19Duy Linh NguyễnNo ratings yet

- Underpinning MethodsDocument14 pagesUnderpinning MethodsDuy Linh NguyễnNo ratings yet

- Hotel LevelsDocument1 pageHotel LevelsDuy Linh NguyễnNo ratings yet

- AEC Collection Industry Presentation - ArchitectureDocument6 pagesAEC Collection Industry Presentation - ArchitectureDuy Linh NguyễnNo ratings yet

- Mall - Etabs Model StatusDocument5 pagesMall - Etabs Model StatusDuy Linh NguyễnNo ratings yet

- Block-9 Etab Check List-R1Document1 pageBlock-9 Etab Check List-R1Duy Linh NguyễnNo ratings yet

- Table of Contents Pti 6thDocument5 pagesTable of Contents Pti 6thDuy Linh NguyễnNo ratings yet

- Pile CapDocument8 pagesPile CapDuy Linh NguyễnNo ratings yet

- Bang Bao Gia - EromedDocument30 pagesBang Bao Gia - EromedDuy Linh NguyễnNo ratings yet

- Thuyet Minh Be Tong 1Document88 pagesThuyet Minh Be Tong 1Duy Linh NguyễnNo ratings yet

- 3 Star Hotel Furniture For BedroomsDocument3 pages3 Star Hotel Furniture For BedroomsDuy Linh NguyễnNo ratings yet

- Curriculum Vitae Đã Dịch SơDocument3 pagesCurriculum Vitae Đã Dịch SơDuy Linh NguyễnNo ratings yet

- 1193 EbooksDocument38 pages1193 EbooksDuy Linh NguyễnNo ratings yet

- Ma Lenh wp7Document3 pagesMa Lenh wp7Duy Linh NguyễnNo ratings yet

- Bao Cao Thang 11-2013Document3 pagesBao Cao Thang 11-2013Duy Linh NguyễnNo ratings yet

- FilmTec ManualDocument205 pagesFilmTec ManualSarmad HameedNo ratings yet

- Automotive After Market Information MEA PDFDocument60 pagesAutomotive After Market Information MEA PDFjose03No ratings yet

- D6372-15-Design, Testing, and Construction of Micro SurfacingDocument8 pagesD6372-15-Design, Testing, and Construction of Micro SurfacingEveling Vanegas NarváezNo ratings yet

- Gu01 2009 Standard ReferenceDocument7 pagesGu01 2009 Standard ReferenceFrancis BoeyNo ratings yet

- Connector SectionDocument28 pagesConnector SectionRamesh ShindeNo ratings yet

- Magnum X5, X7, ProX7 & ProX9 Airless Paint Sprayer Instruction ManualDocument34 pagesMagnum X5, X7, ProX7 & ProX9 Airless Paint Sprayer Instruction Manualwhitewolf777100% (1)

- LA 825 RC Liquid Adhesive Dispensing Electric ApplicatorsDocument2 pagesLA 825 RC Liquid Adhesive Dispensing Electric ApplicatorsNordson Adhesive Dispensing SystemsNo ratings yet

- E 9018 Sika Permac 2330Document4 pagesE 9018 Sika Permac 2330Mark InnesNo ratings yet

- 3Ph Horiz Sep 2010 Weir VerA SIDocument5 pages3Ph Horiz Sep 2010 Weir VerA SIBrenda DavisNo ratings yet

- Legrand Cable Lighting & Data Trunking Technical PDFDocument35 pagesLegrand Cable Lighting & Data Trunking Technical PDFHarshith KunjathurNo ratings yet

- Leather Technology I PDFDocument19 pagesLeather Technology I PDFSundarapandiyan Sundaramoorthy100% (1)

- 303-W1-Rb-0632-1-Rdl-Num Det of Sup STR PDFDocument1 page303-W1-Rb-0632-1-Rdl-Num Det of Sup STR PDFJkkhyhNo ratings yet

- Plant Commissioning & Start Up ProcedureDocument18 pagesPlant Commissioning & Start Up Procedureaamirapi100% (7)

- MOS For Bituminous Protective Coating Water ProofingDocument5 pagesMOS For Bituminous Protective Coating Water ProofingHussam WaleedNo ratings yet

- Biodegradable and Non Bio-Degradable SubstancesDocument12 pagesBiodegradable and Non Bio-Degradable SubstancessdfkjklsdfNo ratings yet

- Visit ReportDocument13 pagesVisit ReportAlankrutha DevuNo ratings yet

- PACCON18 ProceedingBK FullpaperDocument1,486 pagesPACCON18 ProceedingBK FullpaperDo Ngoc Tram67% (3)

- FH Double-Grip Packer Technical DatasheetDocument5 pagesFH Double-Grip Packer Technical DatasheetEvolution Oil ToolsNo ratings yet

- InsulatorDocument6 pagesInsulatorMuhammad AftabuzzamanNo ratings yet

- Optimization of Component of Excavator BucketDocument3 pagesOptimization of Component of Excavator BucketijsretNo ratings yet

- CE155 Estimating Lecture 3 PDFDocument71 pagesCE155 Estimating Lecture 3 PDFArly Tolentino100% (1)

- Composites enDocument20 pagesComposites enpolymer_foam100% (1)

- Dge 169Document6 pagesDge 169Krittika ChandranNo ratings yet

- Datasheet Ni1000SOT 07Document5 pagesDatasheet Ni1000SOT 07Joe SatrianiNo ratings yet

- FBHVN 1117 DDocument6 pagesFBHVN 1117 DkhairolNo ratings yet

- C592 13Document9 pagesC592 13Ichwan Ciptadi100% (1)

- Service Bulletin DDDocument5 pagesService Bulletin DDjohn wrightNo ratings yet

- Caterpillar Motor GradersDocument32 pagesCaterpillar Motor GradersAshraf m aliNo ratings yet

- Unbrick Seagate HDDDocument58 pagesUnbrick Seagate HDDFly KuNo ratings yet

- What Is The Role of Zinc Oxide in Rubber Formulations - Nanjing Union Rubber ChemicalsDocument3 pagesWhat Is The Role of Zinc Oxide in Rubber Formulations - Nanjing Union Rubber ChemicalsShukri FaezNo ratings yet