Professional Documents

Culture Documents

Top Drive PB169 - Blower - Motor - U-Bolt - Support

Uploaded by

JoseMi Vacaflor IllanesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Top Drive PB169 - Blower - Motor - U-Bolt - Support

Uploaded by

JoseMi Vacaflor IllanesCopyright:

Available Formats

Model: 1250AC/1275AC

Jul. 27, 2017

Serial #: N/A

Product Bulletin # TDS-169

Blower Motor U-Bolt Support

Issue

During periods of rough drilling, the feet on the E01-1016-030 motor used on the P10576 blower

could fatigue and crack. This could leave the motor unsecured to the blower baseplate and/or

cause damage to the impeller.

Affected Blower

Blower Part No. Blower Motor Part No.

P10576 E01-1016-030

Note: Contact RIGLINE 24/7™ Support to order the U-bolt upgrade kit for blowers other than the

one listed.

Recommendation

Canrig offers a kit that contains additional support to secure the motor to the baseplate and

reduce the stress on the motor feet, see Table 1 below. This consists of (2) U-bolts which harness

around the motor to secure to the blower baseplate. Install this kit on rigs that perform rough

drilling.

Canrig also recommends the following:

• Regular inspection of the blower motor for loose or broken components as well as for loose or

broken fasteners. Inspect weekly under regular drilling conditions. Inspect daily when

operating in rough drilling conditions.

• Replace the blower motor if feet are broken or damaged. Replace broken or damaged

fasteners.

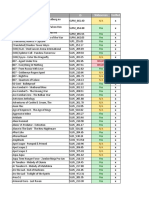

Table 1: (AY23152) Blower Motor Support U-Bolt Assembly Components

Item Qty. Part No. Description

1 1 DT33137 U-BOLT, 1/2-13UNC x 13.38 H x 10.25 ID

2 1 DT33138 U-BOLT, 1/2-13UNC x 14.38 H x 12.75 ID

3 4 LN-0500NC-SS LOCKNUT, 1/2-13UNC, GR8, STOVER

4 10FT M21-2000-010 WIRE ROPE, 1/16 IN, DIA

5 10 M19-3006-010 FERRULE, 1/16, OVAL, ALUMINUM

6 2 M15437 CLAMP, SPRING, 1/2 IN OD HOSE, 17-7SS

RIGLINE 24/7™ Support: 866.433.4345 | International: +1 281.774.5649 | E-mail: support@rigline247.com

Document ID 17-032 v 1.0 | Copyright © 2017 Canrig Drilling Technology Ltd. All rights reserved.

1 of 6

Model: 1250AC/1275AC

Jul. 27, 2017

Serial #: N/A

U-bolt Addition Procedure

Preliminary Fabrication

The blower motor mount will require four (4) drilled holes at locations indicated on Figure 1 for

installation of the U-bolts.

13.25 [336.6]

Drilled Holes 6.63 [168.3]

10.75 [273.1]

2X 11.00 [279.4]

5.38 [136.5]

4X Ø 0.56 [14.3]

2X 1.75 [44.5]

ԩ

Drilled Holes

Figure 1: Four holes required to mount U-bolts.

RIGLINE 24/7™ Support: 866.433.4345 | International: +1 281.774.5649 | E-mail: support@rigline247.com

Document ID 17-032 v 1.0 | Copyright © 2017 Canrig Drilling Technology Ltd. All rights reserved.

2 of 6

Model: 1250AC/1275AC

Jul. 27, 2017

Serial #: N/A

Installing U-bolts

1. Install spring clamps (M15437) on the U-bolts by squeezing the legs with the tool (for example,

pliers) and position toward the bottom of the U-bolt as shown on Figure 2.

Spring clamps

Figure 2: Spring clamps on U-bolts

RIGLINE 24/7™ Support: 866.433.4345 | International: +1 281.774.5649 | E-mail: support@rigline247.com

Document ID 17-032 v 1.0 | Copyright © 2017 Canrig Drilling Technology Ltd. All rights reserved.

3 of 6

Model: 1250AC/1275AC

Jul. 27, 2017

Serial #: N/A

2. Clamp the front of the blower motor by installing DT33137 U-bolt firmly around the bottom of

the blower motor and through holes drilled in blower support mount as shown on Figure 3.

3. Install LN-0500NC-SS locknuts on DT33137, torque to 43 ft-lbs.

4. Clamp the rear of the blower motor by installing DT33138 U-bolt firmly around the bottom of

the blower motor and through holes drilled in blower support mount as shown on Figure 3.

5. Install LN-0500NC-SS locknuts on DT33138, torque to 43 ft-lbs.

DT33137

4X LN-0500NC-SS

DT33138

Figure 3: Installing and Clamping the Motor U-Bolts

RIGLINE 24/7™ Support: 866.433.4345 | International: +1 281.774.5649 | E-mail: support@rigline247.com

Document ID 17-032 v 1.0 | Copyright © 2017 Canrig Drilling Technology Ltd. All rights reserved.

4 of 6

Model: 1250AC/1275AC

Jul. 27, 2017

Serial #: N/A

6. Add safety restraint to U-bolts by adding safety wire (M21-2000-010) through drilled holes in

threaded end of U-bolts DT33137 and DT33138 as shown on Figure 4. Crimp with ferrules

(M19-3006-010). Ensure minimal slack is in safety wire.

See Table 1 on page 1 for items.

4 5

Figure 4: Safety Wire Restraint on the U-bolts

RIGLINE 24/7™ Support: 866.433.4345 | International: +1 281.774.5649 | E-mail: support@rigline247.com

Document ID 17-032 v 1.0 | Copyright © 2017 Canrig Drilling Technology Ltd. All rights reserved.

5 of 6

Model: 1250AC/1275AC

Jul. 27, 2017

Serial #: N/A

7. Use tool (for example, pliers) to squeeze the legs and relieve tension on spring clamp on the

U-bolt.

8. Connect safety restraint around spring clamp and secure with ferrule, see detail on Figure 5.

9. Anchor safety restraint to the blower motor mount cut-outs as shown on Figure 5. Ensure

minimal slack is in safety wire.

Spring clamp

Ferrule

Safety

Wire

Spring clamp with safety

restraint and ferrule

Figure 5: Safety restraint for U-bolts

RIGLINE 24/7™ Support: 866.433.4345 | International: +1 281.774.5649 | E-mail: support@rigline247.com

Document ID 17-032 v 1.0 | Copyright © 2017 Canrig Drilling Technology Ltd. All rights reserved.

6 of 6

You might also like

- 10745350-Pib Sola 24v电源故障Document4 pages10745350-Pib Sola 24v电源故障xlzyydf2015No ratings yet

- Safety Spinning Wrench SSW 40Document88 pagesSafety Spinning Wrench SSW 40Beitsaeed SinaNo ratings yet

- TDM 100 Mechanical Systems Manual Revision March 2010Document63 pagesTDM 100 Mechanical Systems Manual Revision March 2010Chaouki BoukhamlaNo ratings yet

- Gripper Die Block: Removal and InstallationDocument5 pagesGripper Die Block: Removal and InstallationJuan Pablo Villazon RichterNo ratings yet

- Data Migration Good DocumentDocument16 pagesData Migration Good Documentsambit76No ratings yet

- 250T EMI 400HP 50Hz - Install PDFDocument106 pages250T EMI 400HP 50Hz - Install PDFdaniel nunezNo ratings yet

- Top Drive: "Helping Our Customers Achieve Superior Results"Document6 pagesTop Drive: "Helping Our Customers Achieve Superior Results"Mr. Hein Htet Soe100% (1)

- IADC Safety Alert Mud Pumps GDDocument1 pageIADC Safety Alert Mud Pumps GDlucas ronaldo coronel mendozaNo ratings yet

- Automatic Control ExercisesDocument183 pagesAutomatic Control ExercisesFrancesco Vasturzo100% (1)

- Re-Certified TDS-8S Top Drive SystemDocument2 pagesRe-Certified TDS-8S Top Drive Systemahmed farhNo ratings yet

- Century 21 South Western Accounting Answer Key Free PDF Ebook Download Century 21 South Western Accounting Answer Key Download or Read Online Ebook Century 21 SouthDocument8 pagesCentury 21 South Western Accounting Answer Key Free PDF Ebook Download Century 21 South Western Accounting Answer Key Download or Read Online Ebook Century 21 SouthJohn0% (4)

- Item 1 - Ficha Tecnica IBOP Upper Canrig 1250 ACDocument6 pagesItem 1 - Ficha Tecnica IBOP Upper Canrig 1250 ACanghelo marquezNo ratings yet

- Candoc - Es 120 Top Drive Electrical System 1Document160 pagesCandoc - Es 120 Top Drive Electrical System 1JHON JAIRO VALENCIA NIÑONo ratings yet

- Product Information Bulletin: Handling ToolsDocument7 pagesProduct Information Bulletin: Handling ToolsghanNo ratings yet

- Top Drive pb175 - Alert - Block Guide Pin Inspection PDFDocument4 pagesTop Drive pb175 - Alert - Block Guide Pin Inspection PDFFranco SotoNo ratings yet

- Procedura de Inspectie Utilaje BentecDocument192 pagesProcedura de Inspectie Utilaje BentecadrianNo ratings yet

- The Aerodynamics of ParachutesDocument78 pagesThe Aerodynamics of Parachutesstevehuppert50% (2)

- Cameron ValvesDocument44 pagesCameron Valvesadrian villaNo ratings yet

- Technical Manual: Power Limit & Monitor Board P/N: C09G0000Document14 pagesTechnical Manual: Power Limit & Monitor Board P/N: C09G0000Santiago IpialesNo ratings yet

- Fuses f150Document7 pagesFuses f150ORLANDONo ratings yet

- 4197 Emsco 602 DWR SignedDocument11 pages4197 Emsco 602 DWR SignedMohammed Ali YoussefNo ratings yet

- 1 - Hydra Jar - Technical DataDocument3 pages1 - Hydra Jar - Technical DataJoseMi Vacaflor IllanesNo ratings yet

- Shear and Diagonal Tension in BeamDocument16 pagesShear and Diagonal Tension in BeamMouy PhonThornNo ratings yet

- 10×8 CarrierDocument37 pages10×8 CarriernobodymagdesignNo ratings yet

- Hse Manual: VIKING 01-01Document168 pagesHse Manual: VIKING 01-01AF Dowell MirinNo ratings yet

- Top Drive PB169 - Blower - Motor - U-Bolt - SupportDocument6 pagesTop Drive PB169 - Blower - Motor - U-Bolt - SupportJoseMi Vacaflor Illanes100% (1)

- WebpdfDocument276 pagesWebpdfprateekvNo ratings yet

- Centralized PurchasingDocument2 pagesCentralized PurchasingbiyyamobulreddyNo ratings yet

- Perm DRV PDFDocument72 pagesPerm DRV PDFRizki Fajar NovantoNo ratings yet

- Electric Top Drive ETD 500Document76 pagesElectric Top Drive ETD 500SMEETNo ratings yet

- Soft Torque Plugin For Precise PsDocument1 pageSoft Torque Plugin For Precise PsJulio Alejandro Rojas BarbaNo ratings yet

- Welldata/Real Time (RT) 18: Operator ManualDocument140 pagesWelldata/Real Time (RT) 18: Operator ManualMaulik MakwanaNo ratings yet

- Mud Pump Bearing Life 11338 1Document12 pagesMud Pump Bearing Life 11338 1Hassan KhattabNo ratings yet

- RevisionHistory APFIFF33 To V219Document12 pagesRevisionHistory APFIFF33 To V219younesNo ratings yet

- 3500b IntroductionDocument36 pages3500b IntroductionNader abobakrNo ratings yet

- Dive MateDocument2 pagesDive MateAdrian RayosNo ratings yet

- Data Book #Eest-Po-18-004479 Wetorq 100Document237 pagesData Book #Eest-Po-18-004479 Wetorq 100Mai KawayapanikNo ratings yet

- Caterpillar Drilling Rig Repower Brochure PDFDocument10 pagesCaterpillar Drilling Rig Repower Brochure PDFAhmed EzzeddineNo ratings yet

- l3070 e 0 0 PDFDocument128 pagesl3070 e 0 0 PDFAdhita MeryantoNo ratings yet

- CalemEAM Functionality AjaxDocument8 pagesCalemEAM Functionality Ajaxเกียรติศักดิ์ ภูมิลาNo ratings yet

- Safety Alert: Driller Inattention Results in Dropped BlocksDocument1 pageSafety Alert: Driller Inattention Results in Dropped Blockscase013No ratings yet

- TITAN Neumáticos MineríaDocument20 pagesTITAN Neumáticos MineríaFranco Rojas BozaNo ratings yet

- Safety Alert: Tong Incident Results in A FatalityDocument1 pageSafety Alert: Tong Incident Results in A FatalityVimal SinghNo ratings yet

- Safety For Hydraulics: Compac Type Proportional Valves Series CVDocument32 pagesSafety For Hydraulics: Compac Type Proportional Valves Series CVthierrylindoNo ratings yet

- Nsiw em CatalogueDocument68 pagesNsiw em Cataloguejavier06.678061No ratings yet

- TM 80 Daily and Weekly Inspection and Maintenance TasksDocument25 pagesTM 80 Daily and Weekly Inspection and Maintenance TasksAlejandra Noguera GiraldoNo ratings yet

- Winches ChinosDocument3 pagesWinches Chinosfelixriosl100% (1)

- Ton Torque ManometrosDocument16 pagesTon Torque ManometrosEliecer DiazNo ratings yet

- Commander Manual TitanDocument40 pagesCommander Manual TitanjohnfcortesNo ratings yet

- Zj704500drigcomponentsspecificationagreement PDF FreeDocument102 pagesZj704500drigcomponentsspecificationagreement PDF FreeH 8CNo ratings yet

- D392004720 MKT 001 PDFDocument28 pagesD392004720 MKT 001 PDFsorangel_123No ratings yet

- g312 ManualDocument14 pagesg312 Manualflasher_for_nokiaNo ratings yet

- ! CEB Over Centre Cartridge ValveDocument75 pages! CEB Over Centre Cartridge ValvekmstamimNo ratings yet

- RBC Cat SPBDocument68 pagesRBC Cat SPBAl ArdhiNo ratings yet

- WashpipeInst and RemovalFlyerDocument1 pageWashpipeInst and RemovalFlyerBabi LakhdariNo ratings yet

- Wearlimitgauge PDFDocument1 pageWearlimitgauge PDFAbrar HussainNo ratings yet

- 750 Ton Top Drive Course Description FlyerDocument2 pages750 Ton Top Drive Course Description Flyercarlosorizaba0% (1)

- Arabian Drilling Company Rig Specific Procedure AD - 32 Manriding OperationDocument5 pagesArabian Drilling Company Rig Specific Procedure AD - 32 Manriding OperationinfonexusNo ratings yet

- Safety Alert: From The International Association of Drilling ContractorsDocument1 pageSafety Alert: From The International Association of Drilling ContractorsJohnHynesNo ratings yet

- Canrig Tops DrivesDocument4 pagesCanrig Tops DrivesAlejandro GomezNo ratings yet

- P20658 - Proto Torque WrenchesDocument2 pagesP20658 - Proto Torque Wrenchesdionisio emilio reyes jimenezNo ratings yet

- Back PoshtDocument2 pagesBack Poshtmhn yNo ratings yet

- Pages From PS 21 NOVDocument1 pagePages From PS 21 NOVHanyNo ratings yet

- Injector Cut-Out Test ProcedureDocument9 pagesInjector Cut-Out Test ProcedureEd CalheNo ratings yet

- Encoder: Technical Manual 222115-001 40223723-SeriesDocument34 pagesEncoder: Technical Manual 222115-001 40223723-SeriesAndres NavarroNo ratings yet

- 9.4 Dynamic BrakingDocument22 pages9.4 Dynamic BrakingCarlos Alberto RuedaNo ratings yet

- Crosby ShacklesDocument6 pagesCrosby Shacklessabah8800No ratings yet

- KingpinDocument2 pagesKingpinNguyễn Hoài NamNo ratings yet

- 3127 PDFDocument68 pages3127 PDFAseem Vivek MasihNo ratings yet

- 750 Ton Top Drive Guide Runner Shim Modification: AlertDocument4 pages750 Ton Top Drive Guide Runner Shim Modification: AlertMohammed AdelNo ratings yet

- 2 - Hydra Jar - Brochure SLBDocument4 pages2 - Hydra Jar - Brochure SLBJoseMi Vacaflor IllanesNo ratings yet

- 5 - Hydra Jar - Pump Open ForceDocument1 page5 - Hydra Jar - Pump Open ForceJoseMi Vacaflor IllanesNo ratings yet

- G2W0142006 3.5 PUP DP 5FT 中英文质证书Document11 pagesG2W0142006 3.5 PUP DP 5FT 中英文质证书JoseMi Vacaflor IllanesNo ratings yet

- DP HW DC ConexionDocument1 pageDP HW DC ConexionJoseMi Vacaflor IllanesNo ratings yet

- 3 GeodeticsDocument34 pages3 GeodeticsJoseMi Vacaflor IllanesNo ratings yet

- WWC Technical Data BookDocument73 pagesWWC Technical Data BookMario BertoneriNo ratings yet

- 2 Well Design ProcessDocument38 pages2 Well Design ProcessJoseMi Vacaflor IllanesNo ratings yet

- Empowerment TechnologyDocument15 pagesEmpowerment Technologysxhan gwenNo ratings yet

- Om en A: F in Ite D Iffe Ren Ce-B Ase DN Um Eri Ca L M Eth Od SDocument426 pagesOm en A: F in Ite D Iffe Ren Ce-B Ase DN Um Eri Ca L M Eth Od SPrateek Kumar PandeyNo ratings yet

- Pradeep Kshetrapal - Genius Physics (Class 12) - For IIT-JEE and CBSE 2 - Libgen - LiDocument338 pagesPradeep Kshetrapal - Genius Physics (Class 12) - For IIT-JEE and CBSE 2 - Libgen - Lisujan subediNo ratings yet

- Entrepreneurship: Presented By: Marlon N. Tabanao JR., LPTDocument14 pagesEntrepreneurship: Presented By: Marlon N. Tabanao JR., LPTRoj LaguinanNo ratings yet

- Studi Tentang Pelayanan Terhadap Kapal Perikanan Di Pelabuhan Perikanan Pantai (PPP) Tumumpa Kota ManadoDocument9 pagesStudi Tentang Pelayanan Terhadap Kapal Perikanan Di Pelabuhan Perikanan Pantai (PPP) Tumumpa Kota ManadoAri WibowoNo ratings yet

- Making Women's Medicine Masculine: OxpordDocument17 pagesMaking Women's Medicine Masculine: OxpordAdolfo Baqueiro100% (1)

- Dimensions and Methodology of Business Studies Dec 2018Document2 pagesDimensions and Methodology of Business Studies Dec 2018Nallavenaaya Unni100% (1)

- Conceptualizing On Structure Functionalism and Its Applications On Patriotism Study During Covid-19 Pandemic in MalaysiaDocument7 pagesConceptualizing On Structure Functionalism and Its Applications On Patriotism Study During Covid-19 Pandemic in MalaysiaMuhammadSyaqirAimanNo ratings yet

- 07 Endodontic RetreatmentDocument64 pages07 Endodontic RetreatmentGayathriNo ratings yet

- PCBDocument5 pagesPCBarampandey100% (4)

- Capital Budgeting and Capital Budgeting and Risk Analysis Risk AnalysisDocument16 pagesCapital Budgeting and Capital Budgeting and Risk Analysis Risk AnalysisHaris FendiarNo ratings yet

- Sem06 Gca InsoDocument2 pagesSem06 Gca InsoBogdan PistolNo ratings yet

- WideScreen Code For PS2 GamesDocument78 pagesWideScreen Code For PS2 Gamesmarcus viniciusNo ratings yet

- INT PL 2020 Web 01-20 PDFDocument320 pagesINT PL 2020 Web 01-20 PDFAndriana Vilijencova100% (1)

- Cambridge International AS & A Level: Biology 9700/21Document18 pagesCambridge International AS & A Level: Biology 9700/21Lavanya EaswarNo ratings yet

- (English (Auto-Generated) ) Intraday Trading On Nifty (2nd September, 2021) 8 Lakhs Profit Shreyas Bandi Trade Ideas Live (DownSub - Com)Document41 pages(English (Auto-Generated) ) Intraday Trading On Nifty (2nd September, 2021) 8 Lakhs Profit Shreyas Bandi Trade Ideas Live (DownSub - Com)YaaroNo ratings yet

- Lubricants - McMaster-CarrDocument8 pagesLubricants - McMaster-CarrjeanyoperNo ratings yet

- Mecanica MD - AZG-UDocument29 pagesMecanica MD - AZG-UStefanoViganóNo ratings yet

- Da Insem AllDocument217 pagesDa Insem AllTECOA136TejasJadhavNo ratings yet

- Instruction Manual: Slit Lamp Bon SL-EDocument20 pagesInstruction Manual: Slit Lamp Bon SL-EVladimir LevchenkoNo ratings yet

- Python - Data EngineeringDocument34 pagesPython - Data EngineeringChetan PatilNo ratings yet

- 2021 3 AbstractsDocument168 pages2021 3 AbstractsLong An ĐỗNo ratings yet