Professional Documents

Culture Documents

23 - Cylinder Block - Inspectionmmm

Uploaded by

mhOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

23 - Cylinder Block - Inspectionmmm

Uploaded by

mhCopyright:

Available Formats

EM–99

ENGINE MECHANICAL – CYLINDER BLOCK

EM164–01

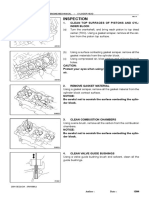

INSPECTION

1. REMOVE GASKET MATERIAL

Using a gasket scraper, remove all the gasket material from the

top surface of the cylinder block.

2. CLEAN CYLINDER BLOCK

Using a soft brush and solvent, thoroughly clean the cylinder

block.

NOTICE:

A01165

If the cylinder is washed at high temperatures, the cylinder

liner sticks out beyond the cylinder block, so always wash

the cylinder block at a temperature of 45°C (133°F) or less.

3. INSPECT TOP SURFACE OF CYLINDER BLOCK FOR

FLATNESS

Using a precision straight edge and feeler gauge, measure the

surface contacting the cylinder head gasket for warpage.

Maximum warpage: 0.05 mm (0.0020 in.)

If warpage is greater than maximum, replace the cylinder block.

A01169

4. INSPECT CYLINDER BORE DIAMETER

Visually check the cylinder for vertical scratches.

If deep scratches are present, replace the cylinder block.

A01167

2000 CELICA (RM744U)

EM–100

ENGINE MECHANICAL – CYLINDER BLOCK

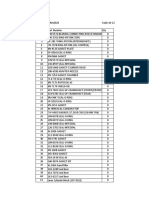

5. INSPECT CYLINDER BORE DIAMETER

Using a cylinder gauge, measure the cylinder bore diameter at

positions A, B and C in the thrust and axial directions.

Standard diameter:

1ZZ–FE 79.000 – 79.013 mm (3.1102 – 3.1107 in.)

2ZZ–GE 82.000 – 82.013 mm (3.2283 – 3.2289 in.)

Maximum diameter:

1ZZ–FE 79.013 mm (3.1107 in.)

2ZZ–GE 82.013 mm (3.2289 in.)

1 Thrust If the diameter is greater than maximum, replace the cylinder

1 Direction block.

Front 2

2 Axial

Direction

10 mm

A (0.39 in.)

B

C 10 mm

A01168

EM2548

(0.39 in.)A01467

6. REMOVE CYLINDER RIDGE

If the wear is less than 0.2 mm (0.008 in.), using a ridge reamer,

grind the top of the cylinder.

A01166

7. INSPECT 12 POINTED HEAD BEARING CAP SUB–AS-

SEMBLY BOLTS

Using vernier calipers, measure the tension portion diameter of

the bolt.

Standard diameter: 7.3 – 7.5 mm (0.287 – 0.295 in.)

Minimum diameter: 7.3 mm (0.287 in.)

If the diameter is less than minimum, replace the bolt.

A01194

8. CLEAN PISTON

(a) Using a gasket scraper, remove the carbon from the pis-

ton top.

A01172

2000 CELICA (RM744U)

EM–101

ENGINE MECHANICAL – CYLINDER BLOCK

(b) Using a groove cleaning tool or broken ring, clean the pis-

ton ring grooves.

A01222

(c) Using solvent and a brush, thoroughly clean the piston.

NOTICE:

Do not use a wire brush.

A01173

9. INSPECT PISTON OIL CLEARANCE

(a) 1ZZ–FE:

Using a micrometer, measure the piston diameter at right

angles to the piston pin center line, 25.6 mm (1.008 in.)

1ZZ–FE: from the piston head.

25.6 mm

(b) 2ZZ–GE:

Using a micrometer, measure the piston diameter at right

2ZZ–GE: angles to the piston pin center line, 12.0 mm (0.048 in.)

12.0 mm A01174 from the piston bottom.

Piston diameter:

1ZZ–FE:

78.925 – 78.935 mm (3.1073 – 3.1077 in.)

2ZZ–GE:

81.975 – 81.993 mm (3.2274 – 3.2281 in.)

(c) Measure the cylinder bore diameter in the thrust direc-

tions (See procedure in step 5).

(d) Subtract the piston diameter measurement from the cylin-

der bore diameter measurement.

Standard oil clearance:

1ZZ–FE:

0.065 – 0.088 mm (0.0026 – 0.0035 in.)

2ZZ–GE:

0.007 – 0.038 mm (0.0003 – 0.0015 in.)

Maximum oil clearance:

0.10 mm (0.0039 in.)

If the oil clearance is greater than maximum, replace all the 4

pistons. If necessary, replace the cylinder block.

2000 CELICA (RM744U)

EM–102

ENGINE MECHANICAL – CYLINDER BLOCK

10. INSPECT PISTON RING END GAP

Using a feeler gauge, measure the clearance between new pis-

ton ring and the wall of the ring groove.

Ring groove clearance:

0.030 – 0.070 mm (0.0012 – 0.0028 in.)

If the clearance is not as specified, replace the piston.

A01171

11. INSPECT PISTON RING END GAP

(a) Insert the piston ring into the cylinder bore.

(b) Using a piston, push the piston ring a little beyond the bot-

tom of the ring travel, 110 mm (4.33 in.) from the top of the

cylinder block.

(c) Using a feeler gauge, measure the end gap.

110

mm Standard end gap:

No.1 0.25 – 0.35 mm (0.0098 – 0.0138 in.)

A01170 No.2 0.35 – 0.50 mm (0.0138 – 0.0197 in.)

Oil (Side rail) 0.15 – 0.40 mm (0.0059 – 0.0157 in.)

Maximum end gap:

No.1 1.05 mm (0.0413 in.)

No.2 1.20 mm (0.0472 in.)

Oil (Side rail) 1.05 mm (0.0413 in.)

If the end gap is greater than maximum, replace the piston ring.

If the end gap is greater than maximum, even with a new piston

ring, replace the cylinder block.

EM7639

12. INSPECT PISTON PIN FIT

At 80 – 90°C (176 – 194°F), you should be able to push the pis-

ton pin into the piston pin hole with your thumb.

A01183

13. INSPECT CONNECTING ROD ALIGNMENT

Using a rod aligner and feeler gauge, check the connecting rod

alignment.

S Check for out–of–alignment

Maximum out–of alignment:

0.05 mm (0.0020 in.) per 100 mm (3.94 in.)

If out–of alignment is greater than maximum, replace the con-

necting rod assembly.

Z00064

2000 CELICA (RM744U)

EM–103

ENGINE MECHANICAL – CYLINDER BLOCK

S Check for twist

Maximum twist:

0.05 mm (0.0020 in.) per 100 mm (3.94 in.)

If twist is greater than maximum, replace the connecting rod as-

sembly.

Z00065

14. INSPECT PISTON PIN OIL CLEARANCE

(a) Using a caliper gauge, measure the inside diameter of the

connecting rod bushing.

Bushing inside diameter:

1ZZ–FE 20.012 – 20.021 mm (0.7879 – 0.7882 in.)

2ZZ–GE 20.011 – 20.023 mm (0.7878 – 0.7883 in.)

A01185

(b) 2ZZ–GE:

Using caliper gauge, measure the inside diameter of the

piston bushing.

Bushing inside diameter:

20.013 – 20.025 mm (0.7879 – 0.7884 in.)

A11414

(c) Using a micrometer, measure the piston pin diameter.

Piston pin diameter:

1ZZ–FE 20.004 – 20.013 mm (0.7876 – 0.7879 in.)

2ZZ–GE 20.004 – 20.016 mm (0.7876 – 0.7880 in.)

(d) Subtract the piston pin diameter measurement from the

bushing inside diameter measurement.

Standard oil clearance:

1ZZ–FE 0.005 – 0.011 mm (0.0002 – 0.0004 in.)

EM0227 2ZZ–GE

Piston x Piston pin

0.005 – 0.013 mm (0.0002 – 0.0005 in.)

Piston pin x Connecting rod

0.005 – 0.009 mm (0.0002 – 0.0004 in.)

Maximum oil clearance:

0.05 mm (0.0020 in.)

If the oil clearance is greater than maximum, replace the bush-

ing. If necessary, replace the piston and piston pin as a set.

2000 CELICA (RM744U)

EM–104

ENGINE MECHANICAL – CYLINDER BLOCK

15. INSPECT CONNECTING ROD BOLTS

Using a vernier calipers, measure the tension portion diameter

of the bolt.

Standard diameter: 6.6 – 6.7 mm (0.260 – 0.264 in.)

Minimum diameter: 6.4 mm (0.252 in.)

If the diameter is less than minimum, replace the bolt.

A01470

16. INSPECT CRANKSHAFT FOR CIRCLE RUNOUT

(a) Place the crankshaft on V–blocks.

(b) Using a dial indicator, measure the circle runout, as

shown in the illustration.

Maximum circle runout: 0.03 mm (0.0012 in.)

If the circle runout is greater than maximum, replace the crank-

shaft.

A01180

17. INSPECT MAIN JOURNALS AND CRANK PINS

(a) Using a micrometer, measure the diameter of each main

journal and crank pin.

Main journal diameter:

47.988 – 48.000 mm (1.8893 – 1.8898 in.)

Crank pin diameter:

1ZZ–FE:

43.992 – 44.000 mm (1.7320 – 1.7323 in.)

2ZZ–GE:

44.992 – 45.000 mm (1.7713 – 1.7717 in.)

If the diameter is not as specified, check the oil clearance (See

page EM–89).

If necessary, replace the crankshaft.

(b) Check each main journal and crank pin for taper and out–

of–round as shown.

Maximum taper and out–of–round:

0.02 mm (0.0008 in.)

If the taper and out–of round is greater than maximum, replace

A01181 the crankshaft.

2000 CELICA (RM744U)

You might also like

- 2012 Audi A4 s4 ManualDocument310 pages2012 Audi A4 s4 ManualNorberto MonárrezNo ratings yet

- Parts List For S4Document3 pagesParts List For S4Alessandro SouzaNo ratings yet

- SSP 181 Audi A3 PresentationDocument32 pagesSSP 181 Audi A3 PresentationMichel FonsecaNo ratings yet

- S - Fa/Rs: Owners ManualDocument18 pagesS - Fa/Rs: Owners ManualbachstradNo ratings yet

- Audi Allroad Owners Manual OCRDocument306 pagesAudi Allroad Owners Manual OCRIvailo Tzenkov100% (1)

- 1.9L ALH Manual TrsDocument13 pages1.9L ALH Manual TrsBecheanu GeorgeNo ratings yet

- SM 68Document189 pagesSM 68Calin KidzorNo ratings yet

- SM 45.cDocument138 pagesSM 45.cKovács EndreNo ratings yet

- Caution! Hot Vapor or Hot Coolant May Escape On Opening Reservoir. Cover Cap With Cloth and Open CarefullyDocument16 pagesCaution! Hot Vapor or Hot Coolant May Escape On Opening Reservoir. Cover Cap With Cloth and Open Carefullyscribd_com1889No ratings yet

- NR 343 The New Audi A4 05Document32 pagesNR 343 The New Audi A4 05Cristian TopalaNo ratings yet

- Ks Si 0014 en WebDocument0 pagesKs Si 0014 en WebMoaed KanbarNo ratings yet

- GTV SpiderDocument149 pagesGTV SpiderRumpel Stiltskin100% (1)

- 55-1 Hood PDFDocument11 pages55-1 Hood PDFmefisto06cNo ratings yet

- 2.0litter DisassemblyDocument46 pages2.0litter DisassemblyAales WeldingNo ratings yet

- LH2.2 & EZ-F User Manual Issue 2bDocument73 pagesLH2.2 & EZ-F User Manual Issue 2bphilro52No ratings yet

- Scott Bonnar 45 Owners Manual S1942892-IDocument12 pagesScott Bonnar 45 Owners Manual S1942892-IAndrew Wilson0% (1)

- 2006 Cclass Clkclass Sclass Clclass SlclassDocument79 pages2006 Cclass Clkclass Sclass Clclass Slclassopenid_nHbxM2cxNo ratings yet

- Service: Wheel and Tire GuideDocument113 pagesService: Wheel and Tire GuidealexNo ratings yet

- Optimization of Double Wishbone Suspension System by Replacing Its Upper Arm by Single Member in Atv IJERTV6IS110006 PDFDocument6 pagesOptimization of Double Wishbone Suspension System by Replacing Its Upper Arm by Single Member in Atv IJERTV6IS110006 PDFMahesh BorateNo ratings yet

- Paradox Digiplex EVO48 EVO192 V1.2Document64 pagesParadox Digiplex EVO48 EVO192 V1.2Ivan CvetkovicNo ratings yet

- VW Passat b6 Heating Air Conditioning System EngDocument174 pagesVW Passat b6 Heating Air Conditioning System EngFadel B ChNo ratings yet

- AUDI A6 c5 4.2 Cyl HD Left RemovingDocument8 pagesAUDI A6 c5 4.2 Cyl HD Left RemovingmotorhNo ratings yet

- ABT Audi RS3 8V07 Sportback 04-2019 542 CDocument14 pagesABT Audi RS3 8V07 Sportback 04-2019 542 CMartin UnknownNo ratings yet

- Air Mass Sensor For VW TDI Engines PDFDocument2 pagesAir Mass Sensor For VW TDI Engines PDFSrđan PavićNo ratings yet

- A5 2011 2.0T CaebDocument329 pagesA5 2011 2.0T CaebjulianNo ratings yet

- 01 LandscapeDocument30 pages01 Landscapenajeebcr9No ratings yet

- Audi 2.7T Coil Pack Conversion - Installation TutorialDocument11 pagesAudi 2.7T Coil Pack Conversion - Installation TutorialJSH100No ratings yet

- Electronic Fuel Injection AssignmentDocument11 pagesElectronic Fuel Injection AssignmentyogapostNo ratings yet

- Timing Cover 190EDocument8 pagesTiming Cover 190ESergio Belmar CrisostoNo ratings yet

- 2012 Nissan Altima 44985 Cruise ControlDocument7 pages2012 Nissan Altima 44985 Cruise ControlPHÁT NGUYỄN THẾNo ratings yet

- Z4 E85 Cruise Control Retrofit Kit InstallationDocument5 pagesZ4 E85 Cruise Control Retrofit Kit InstallationChristian MariNo ratings yet

- A8 - May 06 PDFDocument52 pagesA8 - May 06 PDFSean WilsonNo ratings yet

- SM 9 PDFDocument218 pagesSM 9 PDFVictor CostacheNo ratings yet

- SSP 324 - Audi A6 - 05 Running GearDocument56 pagesSSP 324 - Audi A6 - 05 Running GearMcGiver990100% (1)

- Compare Chevrolet Tavera Vs Toyota InnovaDocument11 pagesCompare Chevrolet Tavera Vs Toyota InnovaBikeportalNo ratings yet

- Formula R1 Racing - Explosionszeichnungen Und Adapter PDFDocument9 pagesFormula R1 Racing - Explosionszeichnungen Und Adapter PDFIBC_TobiNo ratings yet

- Montare Distributie Audi A6 C7 2.0 TdiDocument12 pagesMontare Distributie Audi A6 C7 2.0 TdiEduard ŞtefanNo ratings yet

- 439-2012 A6 Self Study Program Part 2Document36 pages439-2012 A6 Self Study Program Part 2quyềnNo ratings yet

- Cylinder Head, ValvetrainDocument111 pagesCylinder Head, Valvetrainguillermoal539No ratings yet

- Tensioning Issues On Chevrolet/Daewoo 16V Petrol EnginesDocument4 pagesTensioning Issues On Chevrolet/Daewoo 16V Petrol EnginesChristobal EngelbreitNo ratings yet

- C5 Corvette - General InformationDocument15 pagesC5 Corvette - General InformationScott KramerNo ratings yet

- Caddy LHN 130, 140, 200, (Caddy) PDFDocument36 pagesCaddy LHN 130, 140, 200, (Caddy) PDFPE TruNo ratings yet

- 2005 2006 2007 2008 Toyota Tacoma Factory Service ManualDocument12 pages2005 2006 2007 2008 Toyota Tacoma Factory Service ManualmarranNo ratings yet

- 1.9l 4-Cylinder Turbo DieselDocument26 pages1.9l 4-Cylinder Turbo Dieselfloresf5100% (1)

- 19 - Engine - Cooling SystemDocument48 pages19 - Engine - Cooling Systemakmal15No ratings yet

- Your Bentley New Continental GT First Edition: PresentingDocument8 pagesYour Bentley New Continental GT First Edition: PresentingBogdan TeglaNo ratings yet

- Haynes Elschema Volvo 740 760 1987Document11 pagesHaynes Elschema Volvo 740 760 1987Niklas LindhNo ratings yet

- 960 - 1996 Owner's ManualDocument254 pages960 - 1996 Owner's ManualhucnNo ratings yet

- Inspection: - Cylinder BlockDocument6 pagesInspection: - Cylinder Blockdawitmesfin9No ratings yet

- Cylinder Bloc InspectionDocument7 pagesCylinder Bloc InspectionYannick de WalqueNo ratings yet

- Inspection: 1. Clean Cylinder BlockDocument7 pagesInspection: 1. Clean Cylinder Blockdolphi_742078No ratings yet

- Camshaft GearDocument10 pagesCamshaft GearJuan Antonio Ochoa PadronNo ratings yet

- 14 - Cylinder Head - InspectionDocument9 pages14 - Cylinder Head - InspectionNazmul HassanNo ratings yet

- Cyl Head InstallDocument8 pagesCyl Head InstallYannick de WalqueNo ratings yet

- Overhaul: - Vane Pump AssyDocument7 pagesOverhaul: - Vane Pump AssyRomy MNo ratings yet

- Manual de Repararacion Yaris 1NZFEDocument18 pagesManual de Repararacion Yaris 1NZFEVictorNo ratings yet

- Causative Verbs Exercises With Answers MCQ QuizDocument6 pagesCausative Verbs Exercises With Answers MCQ QuizmhNo ratings yet

- Me5adrangy: Final Revision ForDocument7 pagesMe5adrangy: Final Revision FormhNo ratings yet

- كلمة انجليزية الجزء الثانيDocument8 pagesكلمة انجليزية الجزء الثانيmhNo ratings yet

- انجليزي طنطاgggDocument5 pagesانجليزي طنطاgggmhNo ratings yet

- كلمة انجليزيةDocument8 pagesكلمة انجليزيةmhNo ratings yet

- بنك الانجلش 2019Document30 pagesبنك الانجلش 2019mhNo ratings yet

- Basic Level Grammar Exercises With Answers in English - Learn ESLDocument5 pagesBasic Level Grammar Exercises With Answers in English - Learn ESLmhNo ratings yet

- PronounsDocument18 pagesPronounsmhNo ratings yet

- Future II Progressive - Default - English GrammarDocument1 pageFuture II Progressive - Default - English GrammarmhNo ratings yet

- Latest Change Gender Exercises With Answers TDocument6 pagesLatest Change Gender Exercises With Answers TmhNo ratings yet

- English Articles TestDocument7 pagesEnglish Articles TestmhNo ratings yet

- Boxer PDFDocument5 pagesBoxer PDFmhNo ratings yet

- Fill in The Blanks With Suitable Sequence ConnectorsDocument2 pagesFill in The Blanks With Suitable Sequence ConnectorsIndramany Periasamy100% (3)

- English Grammar Articles A An The Quiz 3 With AnswerDocument6 pagesEnglish Grammar Articles A An The Quiz 3 With AnswermhNo ratings yet

- PhonicsDocument31 pagesPhonicsmh0% (1)

- Infografia SMRPDocument1 pageInfografia SMRPFerrel Infante AcuñaNo ratings yet

- 885 - English Tenses Advanced Level Mcqs Test With Answers 2Document8 pages885 - English Tenses Advanced Level Mcqs Test With Answers 2mhNo ratings yet

- المادة العلمية لقسم صحة مجتمعDocument16 pagesالمادة العلمية لقسم صحة مجتمعmhNo ratings yet

- MGMT 1Document8 pagesMGMT 1Lanie Aler Delos SantosNo ratings yet

- Toefl Essay: Types of EssaysDocument6 pagesToefl Essay: Types of Essayshbat saidNo ratings yet

- Infografia SMRPDocument1 pageInfografia SMRPFerrel Infante AcuñaNo ratings yet

- Documentt PDFDocument16 pagesDocumentt PDFmhNo ratings yet

- Part B-9 PDFDocument23 pagesPart B-9 PDFFejs Za ScribdNo ratings yet

- b2 U1 6min Gram Present TensesDocument5 pagesb2 U1 6min Gram Present TensesmhNo ratings yet

- Infografia SMRPDocument1 pageInfografia SMRPFerrel Infante AcuñaNo ratings yet

- Mobil Rarus SHC 1025 PDFDocument2 pagesMobil Rarus SHC 1025 PDFCorina StanculescuNo ratings yet

- 5c3236322d573 PDFDocument4 pages5c3236322d573 PDFmhNo ratings yet

- Upper Transom A3L 30Document1 pageUpper Transom A3L 30mhNo ratings yet

- Non Circular Pipe FrictionDocument3 pagesNon Circular Pipe Frictionravi_radanNo ratings yet

- Upper Transom A2S 20Document1 pageUpper Transom A2S 20mhNo ratings yet

- Repair ListDocument7 pagesRepair Listangga andi ardiansyahNo ratings yet

- Fir Engine TP-542 FMX - 440Document21 pagesFir Engine TP-542 FMX - 440CwsNo ratings yet

- Operating CharacteristicsDocument23 pagesOperating CharacteristicsJeff Hentzen F. SimeneNo ratings yet

- SMC Service 2006-10 EngDocument339 pagesSMC Service 2006-10 EngMitica Popescu100% (4)

- Motor K4100 495 Weychai PDFDocument126 pagesMotor K4100 495 Weychai PDFTerah PioNo ratings yet

- Must Change Item in PohDocument23 pagesMust Change Item in Pohmailbkrao100% (1)

- Lecture 6 Design of The Crankshaft: ResearchDocument22 pagesLecture 6 Design of The Crankshaft: Researchsujay nayak0% (1)

- Connecting Rod Force Analysis and Weight OptimizationDocument18 pagesConnecting Rod Force Analysis and Weight OptimizationSukhamMichaelNo ratings yet

- 5Document253 pages5julian marinNo ratings yet

- Reciprocating Compressor Theory PDFDocument33 pagesReciprocating Compressor Theory PDFyeshig200083% (6)

- Kawaski Service ManualDocument101 pagesKawaski Service ManualJonathan StephensNo ratings yet

- Catalogues$ci LPK 2518HD BS3 Cum PDFDocument322 pagesCatalogues$ci LPK 2518HD BS3 Cum PDFSajan AhmedNo ratings yet

- Quincy QP15Document24 pagesQuincy QP15luis0raul0arriolaNo ratings yet

- Slider Crank Mechanism Term Project ReportDocument15 pagesSlider Crank Mechanism Term Project ReportUsamaNo ratings yet

- General Knowledge About A Power Plant-1Document41 pagesGeneral Knowledge About A Power Plant-1Yasir Arafin TonmoyNo ratings yet

- Engine Mechanical (D6A, D8A)Document168 pagesEngine Mechanical (D6A, D8A)Manuales De Maquinaria JersoncatNo ratings yet

- AB35049U English VersionDocument214 pagesAB35049U English VersionsaifulNo ratings yet

- Catalogo Afa Cummins v504 SeriesDocument59 pagesCatalogo Afa Cummins v504 SeriesAlexis Sanchez100% (2)

- KMP Brand Detroit Catalogo 2012 PDFDocument56 pagesKMP Brand Detroit Catalogo 2012 PDFj_hernandez_ch0% (1)

- PL80 S6D95L-1 22842-Or EG85Document50 pagesPL80 S6D95L-1 22842-Or EG85yosy prastiyo100% (1)

- K90MC-C 01 PDFDocument926 pagesK90MC-C 01 PDFPaul Lucian VentelNo ratings yet

- OM616 Engine Repair ManualDocument223 pagesOM616 Engine Repair ManualBernard Booh67% (3)

- Amm 592-594 1015-1Document1 pageAmm 592-594 1015-123dr0207No ratings yet

- 2019 Winter Model Answer Paper (Msbte Study Resources)Document21 pages2019 Winter Model Answer Paper (Msbte Study Resources)Rakshit IyengarNo ratings yet

- 14.dual Power Generation System For Automobile (Thermoelectric and Exhaust Gas Power Generation)Document107 pages14.dual Power Generation System For Automobile (Thermoelectric and Exhaust Gas Power Generation)WORLD360No ratings yet

- Jac HFC4GB1Document70 pagesJac HFC4GB1Jeifred Espitia AraujoNo ratings yet

- DTE150 (150cc) : Guangzhou Dirtmax Motorsports Co., Ltd. - 1Document18 pagesDTE150 (150cc) : Guangzhou Dirtmax Motorsports Co., Ltd. - 1Юзик лол ChanelNo ratings yet

- Engine Coding: 1988 Mazda 626 1988 Mazda 626Document26 pagesEngine Coding: 1988 Mazda 626 1988 Mazda 626lopezdestructionNo ratings yet

- 22RE Instructions 09012020Document58 pages22RE Instructions 09012020Mohamed ReGaiegNo ratings yet

- DEUTZ TCD2012 Engine Overhaul Part ListDocument21 pagesDEUTZ TCD2012 Engine Overhaul Part ListTong Hai WangNo ratings yet