Professional Documents

Culture Documents

National Fire Alarm and Signaling Code.: Water Spray Fixed Systems For Fire Protection

Uploaded by

Alaa M. GhazalahOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

National Fire Alarm and Signaling Code.: Water Spray Fixed Systems For Fire Protection

Uploaded by

Alaa M. GhazalahCopyright:

Available Formats

15–20 WATER SPRAY FIXED SYSTEMS FOR FIRE PROTECTION

7.4.4.3.2 The water shall be applied at a net rate of not less 7.5.8 Notification of Personnel. Personnel shall be notified

than 0.15 gpm/ft2 [6.1(L/min)/m2] on the expected nonab- upon receipt of any detection signal in accordance with NFPA 72,

sorbing ground surface area of exposure. National Fire Alarm and Signaling Code.

7.4.4.3.3 Water spray application as specified in 7.4.4.3.1 and 7.5.9 Fire Risk Analysis. A fire risk analysis shall be conducted

7.4.4.3.2 shall be provided for special configurations, conser- that considers the following additional items in the design of

vator tanks, pumps, and so forth. the water spray system for vapor mitigation:

7.4.4.3.4 Where transformer components create spaces (1) Importance to continuity of operation

greater than 12 in. (305 mm) in width, the surfaces shall be (2) Size, type, location, and construction of equipment

individually protected. (3) Physical properties of the chemicals involved

7.4.4.3.5 Where there is insufficient clearance to achieve di- (4) Water supply

rect impingement,

p g p

it shall be permitted p

to protect the surfaces (5) Value of equipment

underneath the transformer byy horizontal projection

p j or byy (6) Climate

nozzles directed to cool the area below the transformer pro- (7) Water delivery time

jections. (8) Environment

(9) Access for fire fighting

7.4.4.3.6 The water supply shall be capable of supplying both

(10) Projected flammable liquid or material spill pattern

the design flow rate and 250 gpm (946 L/min) for hose streams

(11) Potential for flammable vapor release

for a minimum duration of 1 hour.

(12) Proximity of personnel to hazard area

7.4.4.4 Water spray piping shall not be routed across the top (13) Protection of system actuation valve from fire and ex-

of the transformer tank or across the face of the transformer plosion

cabinet. (14) Blast containment and pressure relief

7.4.4.5 Piping shall be permitted to be routed across the top (15) Protection of electrical circuits, including explosion-

of the transformer tank or across the face of the transformer proof equipment

cabinet, where impingement cannot be accomplished with (16) Potential for fire spread beyond hazard area

any other configuration and the required distance from live (17) Required replacement time for process equipment

electrical components is maintained. (See 6.1.2.) (18) Potential for business interruption

(19) Notification of personnel upon vapor detection

7.4.4.6 Nozzles shall be positioned such that the water spray

does not envelop energized bushings or lightning arresters by 7.6 Combined Systems.

direct impingement. 7.6.1* General.

7.4.4.7 Direct impingement of water spray on energized bush-

7.6.1.1 The sprinkler system portion of combined systems

ings and/or lightning arresters shall be permitted only when au-

shall be designed and installed in accordance with NFPA 13,

thorized by the manufacturer or manufacturer’s literature and

Standard for the Installation of Sprinkler Systems.

the owner.

7.5* Flammable Vapor Mitigation. 7.6.1.2 The water spray portion of any combined system shall

be designed and installed in accordance with this standard.

7.5.1* Design for Vapor Mitigation.

7.6.2* Design.

7.5.2 The water spray system shall be designed to operate within

the necessary time and shall discharge water for the duration 7.6.2.1 The system demand shall include the simultaneous hy-

needed to dissolve, dilute, disperse, or cool the flammable va- draulic demand from all sprinklers and water spray nozzles on

pors, gases, or hazardous materials. the system.

7.5.3 The duration of the release of the flammable materials 7.6.2.2 The water spray component of the combined demand

shall be included in the determination of the water spray du- shall not reduce the minimum required sprinkler discharge

ration time. density.

7.5.4 The minimum net rate of application shall be based on 7.7 Automatic Detection Equipment.

field experience with the product or on actual test data.

7.7.1* General. Detection systems providing an actuation signal

7.5.5 The design area of the water spray system shall cover to fixed water spray systems shall be designed in accordance with

the entire area of any potential spill anticipated, such as the NFPA 72, National Fire Alarm and Signaling Code.

area of a containment dike, pit, and so forth.

7.7.2 The spacing, location, and position of detectors shall be

7.5.6 Nozzles of the water spray system shall be located to in accordance with 6.5.2.

cover all potential leak points, such as fill and discharge con-

nections, relief valves, flexible connections, flanges, pumps, 7.7.3* The following shall be evaluated when selecting and

valves, vessels, and so forth. adjusting detection equipment:

7.5.7 The water spray system shall be activated automatically (1) Normally changing conditions

by gas/vapor detection in accordance with 6.5.2.7 and manu- (2) Non-fire temperature changes

ally from both the system area and remotely, such as from a 7.7.4* Response Time.

control room.

7.7.4.1 The detection system shall be designed to cause ac-

7.5.7.1* It shall be permitted to have the vapor mitigation sys-

tuation of the system actuation valve to operate without delay.

tem activated by both gas/vapor detection and another detec-

tion system, such as flame or heat detection, but the gas/vapor 7.7.4.2 Where ambient conditions exist that cause false sys-

detection system shall be capable of activating the water spray tem operations, detection systems shall be permitted to in-

system alone. clude delays that would override these conditions.

2012 Edition

You might also like

- Industrial Piping and Equipment Estimating ManualFrom EverandIndustrial Piping and Equipment Estimating ManualRating: 5 out of 5 stars5/5 (7)

- O & M Manual - Foam SystemDocument12 pagesO & M Manual - Foam SystemahsanNo ratings yet

- Storch Flight Manual - Eng Version 28 - 04 - 05 PDFDocument51 pagesStorch Flight Manual - Eng Version 28 - 04 - 05 PDFandre_jvcNo ratings yet

- As 4487 AerosolsDocument6 pagesAs 4487 AerosolsaristobulosNo ratings yet

- Imo 913Document9 pagesImo 913Anonymous 8RFzObvNo ratings yet

- NFPA 14, 2019 Edition - Sprinkler AgeDocument6 pagesNFPA 14, 2019 Edition - Sprinkler AgeJhoNo ratings yet

- Travelling Tripper CalculationDocument5 pagesTravelling Tripper CalculationHarshGuptaNo ratings yet

- Spur Gear DesignDocument15 pagesSpur Gear DesignMaharaja KanthasamyNo ratings yet

- Theory of Elasticity and Plasticity. (CVL 622) M.Tech. CE Term-2 (2017-18)Document2 pagesTheory of Elasticity and Plasticity. (CVL 622) M.Tech. CE Term-2 (2017-18)er.praveenraj30No ratings yet

- Quality Control Handbook Street LightingDocument36 pagesQuality Control Handbook Street LightingbalaafconsNo ratings yet

- Aashto T350Document89 pagesAashto T350werku koshe0% (1)

- Chapter 5 Plans and Hydraulic CalculationsDocument1 pageChapter 5 Plans and Hydraulic CalculationsAlaa M. GhazalahNo ratings yet

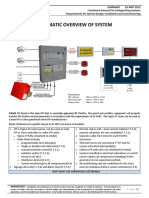

- Deluge Systems False OperationsDocument82 pagesDeluge Systems False OperationsYapKJNo ratings yet

- Nfpa 850 Recommended Practice For Fire Protection For Electric Generating Plants and HighDocument3 pagesNfpa 850 Recommended Practice For Fire Protection For Electric Generating Plants and HighSofiqNo ratings yet

- 6011 - Deluge SystemDocument4 pages6011 - Deluge SystemBhupatiNo ratings yet

- Door Fan Test - NFPA2001Document2 pagesDoor Fan Test - NFPA2001twobruinsNo ratings yet

- 002 - 30 - 20 - 03 ChecklistDocument1 page002 - 30 - 20 - 03 Checklistnasrulsalman9883No ratings yet

- Plans and Hydraulic Calculations: 2017 EditionDocument1 pagePlans and Hydraulic Calculations: 2017 EditionsamNo ratings yet

- MSC.1-Circ.1387 - Revised Guidelines For The Approval of Fixed Water-Based Local Application Fire-Fighting S... (Secretariat)Document13 pagesMSC.1-Circ.1387 - Revised Guidelines For The Approval of Fixed Water-Based Local Application Fire-Fighting S... (Secretariat)mlevNo ratings yet

- Design Manual For Fire Protection: 1. Acts & RegulationsDocument12 pagesDesign Manual For Fire Protection: 1. Acts & RegulationsgugueNo ratings yet

- Cheatsheet For Sprinkler Standpipes Hyd. Calc. GBDocument5 pagesCheatsheet For Sprinkler Standpipes Hyd. Calc. GBfazil yoosufNo ratings yet

- NFPA 14 2013 UpdateDocument4 pagesNFPA 14 2013 UpdateAnonymous qabSVjzrANo ratings yet

- Fire Protection Philosophy (D 15)Document16 pagesFire Protection Philosophy (D 15)Elias EliasNo ratings yet

- Well Testing Systems: Norsok StandardDocument40 pagesWell Testing Systems: Norsok StandardBoris Zaslichko100% (1)

- Training Requirements - Rig Inspection ChecklistDocument4 pagesTraining Requirements - Rig Inspection ChecklistNeyaz MD ArFinNo ratings yet

- AS 4487-2013 - Aerosols PDFDocument6 pagesAS 4487-2013 - Aerosols PDFĐức Huấn ĐỗNo ratings yet

- Ref N° 23 - DIESEL SYSTEM PHILOSOPHYDocument7 pagesRef N° 23 - DIESEL SYSTEM PHILOSOPHYlxz861020No ratings yet

- Method Statement For Pipe Flushing and Internal Cleaning (SAMPLE)Document7 pagesMethod Statement For Pipe Flushing and Internal Cleaning (SAMPLE)Hasann MaawiaNo ratings yet

- Well Testing Recommended PracticesDocument40 pagesWell Testing Recommended Practicessajithv78100% (1)

- 9 15 Design Waterspray&Pilot LineDocument29 pages9 15 Design Waterspray&Pilot Linekhalidwy6342No ratings yet

- MR Num5-EnDocument13 pagesMR Num5-EnaminardakaniNo ratings yet

- FIXED Fire FightingDocument17 pagesFIXED Fire FightingvamsiarangiNo ratings yet

- 2.0 Annexure-III Detailed Technical Specifications of RO Water MakerDocument10 pages2.0 Annexure-III Detailed Technical Specifications of RO Water MakerjrladduNo ratings yet

- Section 2.5 Water SupplyDocument31 pagesSection 2.5 Water SupplyDaryl BadajosNo ratings yet

- Catalyst Loading by Dense Method (SingleBed) in Inert AtmosphereDocument5 pagesCatalyst Loading by Dense Method (SingleBed) in Inert Atmospherevishal bailurNo ratings yet

- Method Statement For CW INTAKE SCREEN WASH WATER SYSTEM FLUSHING BL.1 5 PDFDocument8 pagesMethod Statement For CW INTAKE SCREEN WASH WATER SYSTEM FLUSHING BL.1 5 PDFFredie UnabiaNo ratings yet

- The Criteria To Be Applied in The Process and Other Facilities Design AreDocument5 pagesThe Criteria To Be Applied in The Process and Other Facilities Design AreMohamed KamelNo ratings yet

- Pre-Commissioning Procedure - Air Blowing of Fuel Gas System 1Document3 pagesPre-Commissioning Procedure - Air Blowing of Fuel Gas System 1AdelNo ratings yet

- Ref N° 24 - PRODUCED WATER HANDLING - PHILOSOPHYDocument11 pagesRef N° 24 - PRODUCED WATER HANDLING - PHILOSOPHYlxz861020No ratings yet

- Section 10 Specs For Cooling TowerDocument13 pagesSection 10 Specs For Cooling Towermjmehta81No ratings yet

- F09fire MonitorDocument14 pagesF09fire Monitorummi azzuhraNo ratings yet

- Epirb DocsDocument4 pagesEpirb DocsmiguelNo ratings yet

- MSC Circ 0913Document11 pagesMSC Circ 0913jarbas.otoniNo ratings yet

- NFPA 13-2019 Handbook 28Document1 pageNFPA 13-2019 Handbook 28sundarayya.giscoestimationNo ratings yet

- NF13HBCHS4Document10 pagesNF13HBCHS4olivares91No ratings yet

- FgsDocument6 pagesFgs312818203016 KAMARAJ J III CMENo ratings yet

- (Nisp-Standard Maintenance Procedure) : (Earth Pit Maintainence) Document Code.-PPDSDocument4 pages(Nisp-Standard Maintenance Procedure) : (Earth Pit Maintainence) Document Code.-PPDSPrabagaran PrtNo ratings yet

- Well Ops Template SCR 2015 Schedule 9 Well Notification Inspection July 2015Document13 pagesWell Ops Template SCR 2015 Schedule 9 Well Notification Inspection July 2015MartahanManurungNo ratings yet

- Astm D6634 - 1 (En)Document14 pagesAstm D6634 - 1 (En)JOHONo ratings yet

- Kitchen Hood Suppression Assembly Plan Review NewDocument4 pagesKitchen Hood Suppression Assembly Plan Review NewAlicerp CabanaNo ratings yet

- Api RP 53Document25 pagesApi RP 53jairaso2950No ratings yet

- Working and Control Philosophy - Aircraft Hanger Foam SystemDocument7 pagesWorking and Control Philosophy - Aircraft Hanger Foam SystemAbhishek SinghalNo ratings yet

- AS4775 Checklist AVIDocument3 pagesAS4775 Checklist AVIDiego Fernandes de Oliveira100% (1)

- Fire Protection Water Mist SystemDocument18 pagesFire Protection Water Mist SystemAhmed MahmoudNo ratings yet

- Chapter 5 Design Guidelines Section 5.4 Mechanical Subsection 5.4.2 PlumbingDocument4 pagesChapter 5 Design Guidelines Section 5.4 Mechanical Subsection 5.4.2 PlumbingkapsarcNo ratings yet

- Method Statement For Cooling Tower Frame Sump Screen and Stop LogDocument7 pagesMethod Statement For Cooling Tower Frame Sump Screen and Stop LogYurizal firmansyahNo ratings yet

- REferat GMDSS - EPIRBDocument6 pagesREferat GMDSS - EPIRBAntonio FlorinNo ratings yet

- DIS 8.6.2 Bag StopDocument20 pagesDIS 8.6.2 Bag StopAshraf Ismail HassenNo ratings yet

- Chapter 5 Design Guidelines Section 5.7 Utilities Subsection 5.7.9 Pipeline CorridorsDocument1 pageChapter 5 Design Guidelines Section 5.7 Utilities Subsection 5.7.9 Pipeline CorridorskapsarcNo ratings yet

- Dry Pipe SystemDocument4 pagesDry Pipe SystemAbdalraheemAlqamatiNo ratings yet

- Condenser Flood Test 8 of 11Document14 pagesCondenser Flood Test 8 of 11Sara LopezNo ratings yet

- Regulatory Guides 3.49 Design of An ISFSI (Water-Basin Type) - R0 - 1981Document4 pagesRegulatory Guides 3.49 Design of An ISFSI (Water-Basin Type) - R0 - 1981廖庭億No ratings yet

- API 570 6년차 갱신 퀴즈-1Document4 pagesAPI 570 6년차 갱신 퀴즈-1Seung Woo LeighNo ratings yet

- Sewers For Adoption 7th Edition - WW Amendments Oct 2013Document15 pagesSewers For Adoption 7th Edition - WW Amendments Oct 2013Roger Andres Ordoñez100% (1)

- Fire Fighting Pumping Systems at Industrial FacilitiesFrom EverandFire Fighting Pumping Systems at Industrial FacilitiesRating: 4.5 out of 5 stars4.5/5 (3)

- Mechanical Vibration and Shock Analysis, Specification DevelopmentFrom EverandMechanical Vibration and Shock Analysis, Specification DevelopmentNo ratings yet

- Installation and Maintenance Manual For Electric Fire Pump Controllers With Automatic Transfer Switch Model GPX + GPG or GpuDocument43 pagesInstallation and Maintenance Manual For Electric Fire Pump Controllers With Automatic Transfer Switch Model GPX + GPG or GpusimonsecurityNo ratings yet

- Pages From F4632 - SRI - Catalogue 2019 - OP - Low ResDocument1 pagePages From F4632 - SRI - Catalogue 2019 - OP - Low ResAlaa M. GhazalahNo ratings yet

- Pages From F4632 - SRI - Catalogue 2019 - OP - Low ResDocument1 pagePages From F4632 - SRI - Catalogue 2019 - OP - Low ResAlaa M. GhazalahNo ratings yet

- Archivetempfirst VdS-Approval For Installer of Extinguishing Systems Outside EuropeDocument1 pageArchivetempfirst VdS-Approval For Installer of Extinguishing Systems Outside EuropeAlaa M. GhazalahNo ratings yet

- Air Blowing Sketchr1Document1 pageAir Blowing Sketchr1Alaa M. GhazalahNo ratings yet

- 17-020-Ms-002 Welding For Fuel Gas r2Document53 pages17-020-Ms-002 Welding For Fuel Gas r2Alaa M. GhazalahNo ratings yet

- Binder 1Document23 pagesBinder 1Alaa M. GhazalahNo ratings yet

- BS336 PDFDocument9 pagesBS336 PDFSatish KumarNo ratings yet

- 17 020 Ms 001 Excavation r2Document19 pages17 020 Ms 001 Excavation r2Alaa M. GhazalahNo ratings yet

- Weld Fitting Specs PDFDocument24 pagesWeld Fitting Specs PDFSalmanNo ratings yet

- 1PH7 MotorDocument244 pages1PH7 MotorgetNo ratings yet

- Application of Mecanum WheelsDocument12 pagesApplication of Mecanum WheelsMithun JohnNo ratings yet

- Mollier Diagram BeginDocument3 pagesMollier Diagram BeginKalu BhaiNo ratings yet

- Power Generation by Using Piezoelectric Transducer With Bending Mechanism SupportDocument6 pagesPower Generation by Using Piezoelectric Transducer With Bending Mechanism SupportIAES IJPEDSNo ratings yet

- Appendix 27 Alternative Requirements For Glass-Lined VesselsDocument2 pagesAppendix 27 Alternative Requirements For Glass-Lined VesselsBinay K SrivastawaNo ratings yet

- Chapter 1 Smith and Van NessDocument41 pagesChapter 1 Smith and Van NessJohn Raymart RaferNo ratings yet

- Journal of Natural Gas Science and Engineering 26 (2015) 587-594 PDFDocument8 pagesJournal of Natural Gas Science and Engineering 26 (2015) 587-594 PDFRafael CeccattoNo ratings yet

- Wind Loads Calculation Eurocode1Document1 pageWind Loads Calculation Eurocode1Karthik KrishNo ratings yet

- Preparation of Silver Nanoparticles in Cellulose Acetate Polymer and The Reaction Chemistry of Silver Complexes in The PolymerDocument4 pagesPreparation of Silver Nanoparticles in Cellulose Acetate Polymer and The Reaction Chemistry of Silver Complexes in The Polymer1No ratings yet

- Bio Analytical SopDocument17 pagesBio Analytical SopalexpharmNo ratings yet

- Electricity and MagnetismDocument84 pagesElectricity and Magnetismamalina rohaizanNo ratings yet

- 1697 Dzyan Kitabi Qedim Qutsal Oghreti Bilim Arashdirma Qurupu 1971 61sDocument67 pages1697 Dzyan Kitabi Qedim Qutsal Oghreti Bilim Arashdirma Qurupu 1971 61strametesa100% (1)

- The Key To Super Consciousness Chapter 1Document6 pagesThe Key To Super Consciousness Chapter 1Will FortuneNo ratings yet

- TDS 10562100 EN EN Activator-RK-1300-RK-1500 PDFDocument1 pageTDS 10562100 EN EN Activator-RK-1300-RK-1500 PDFKJ SupplyNo ratings yet

- HCLDocument8 pagesHCLlalit shakhaNo ratings yet

- Fatigue Crack Growth Analysis of A FilletDocument7 pagesFatigue Crack Growth Analysis of A FilletPhilip IannaNo ratings yet

- States of Matter Lesson PlanDocument8 pagesStates of Matter Lesson Planapi-383721875No ratings yet

- D 6988 - 03 Medicion de CalibreDocument7 pagesD 6988 - 03 Medicion de CalibreMiguelAngelPerezEsparzaNo ratings yet

- 05 PDFDocument1 page05 PDFdruwid6No ratings yet

- Assignment N1Document9 pagesAssignment N1Rania ChNo ratings yet

- Tutorial Sheet (ME324) 2018-19Document1 pageTutorial Sheet (ME324) 2018-19Asif SadarNo ratings yet

- Physics ExerciseDocument6 pagesPhysics ExerciseLaw Jing SeeNo ratings yet

- Penetration Tests According To The ISO 11140Document41 pagesPenetration Tests According To The ISO 11140masthan6yNo ratings yet

- Zhang 2007 J. Electrochem. Soc. 154 A910 PDFDocument8 pagesZhang 2007 J. Electrochem. Soc. 154 A910 PDFPeterNo ratings yet