Professional Documents

Culture Documents

DigiShot Plus Brochure PDF

Uploaded by

Jennifer GordonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DigiShot Plus Brochure PDF

Uploaded by

Jennifer GordonCopyright:

Available Formats

electronic initiation system

D igiShot Plus is an electronic initiation system

designed for large blasts in surface and underground

UNIQUE DIGISHOT PLUS COMPONENTS

Precision Timing Detonator—The DigiShot Plus

Detonator is designed for better control over large blasts.

mining. It integrates with ViewShot® blast design It is a two wire programmable precision initiation device.

software to generate sophisticated blast designs and The detonator has an electronic circuit board encased in

a water resistant copper shell. The accuracy of electronic

timing analysis. The DigiShot Plus system increases

delay timing helps you achieve better blast control, so

safety, provides accurate timing and is easy to use. you get the best results from each shot.

Rugged Over-extruded Downline Wire—The DigiShot

Plus Wire has been designed and tested to be abrasion

and cut resistant to increase communication reliability

between the detonator and the bench box helping to

ensure detonation. The wire comes in an easy to deploy

coil configuration with a heavy-walled, copper detonator

on one end and a clip-on tester and connector on the

other. All components on the wire are water, ESD and

stray current resistant.

Blaster Friendly Tagger—The DigiShot Plus Tagger is a

light-weight, hand-held tool used to assign the blast hole/

detonator location with minimum keystrokes. The Tagger

can be used to test individual detonators, individual rows

or the entire circuit while on the bench ensuring reliable

communication. The Tagger also has easy-to-follow,

step-by-step screen menus that lead the blaster through

on-bench operations.

Easy to use Bench Box and Base Station—The

DigiShot Plus Bench Box and Base Station are used

in conjunction with one another. The Base Station

provides the Arm and Fire commands to the Bench Box

in order to fire the blast. For flexibility, the delay timing

can be entered into the Bench Box at any time, the

day of the blast or any day before. The blasting boxes

have the capability for remote firing with a maximum

capacity of 7,200 detonators, with up to 15 detonators

per hole. The maximum line-of-sight distance between

the Bench Box and Base Station is 3.5 kilometers

(11,483 feet). Communication with the Bench Box is

maintained through a secure and encrypted signal. With

safety always in mind, the box requires a smart key and

Tagger password to fire the blast.

DIGISHOT PLUS SYSTEM BENEFITS

Easy-to-Use

• Minimal components on the bench

• Simple clip-on detonators to the busline

• Auto tagging and testing

• User friendly software

• Easy to follow menus on Tagger

Robust Over-extruded Downline Wire

• Cable is abrasion and cut resistant

• Passed CEN TS 13763-27 test, the European Standard of

Compliance

Bench Box • Water, ESD and stray current resistant

Detonator Clipped to Buswire

More Control

• Improved: vibration, wall stability, crusher throughput and

operational efficiency

• Precise and accurate timing—electronic microchip

• Programmable blast patterns that can be done in advance

or at the site

• Reduction in user error

• Compatible with ViewShot blast design and timing

analysis software

Improved Safety and Security

• Smart key and password required

• Remote firing capability

• Encrypted signal to fire the blast

DigiShot Plus Carton digishot® plus and viewshot® are registered trademarks of DetNet® South Africa (Proprietary) Ltd.

800-732-7534

w ww.dynonobe l.c om

8/25/2016

You might also like

- DigiShot BrochureDocument4 pagesDigiShot BrochureBaoussou KanoutéNo ratings yet

- C17-Pro Vertical Digital Inclinometer SystemDocument4 pagesC17-Pro Vertical Digital Inclinometer Systemalejandro gambettaNo ratings yet

- Ael Intelligent Blasting Differentitated Products Electronic Delay Detonators PDFDocument21 pagesAel Intelligent Blasting Differentitated Products Electronic Delay Detonators PDFpaoahhoNo ratings yet

- Li4278 Spec Sheet en UsDocument2 pagesLi4278 Spec Sheet en UsErwin RamadhanNo ratings yet

- C17 Vertical Digital Inclinometer SystemDocument4 pagesC17 Vertical Digital Inclinometer Systemmike DonNo ratings yet

- Datum Electronics: Series 460 Bolt-On Strain Gauge SensorsDocument7 pagesDatum Electronics: Series 460 Bolt-On Strain Gauge Sensorsmuhammad taufik rahmanNo ratings yet

- Visonic MCS-730 Data SheetDocument2 pagesVisonic MCS-730 Data SheetJMAC SupplyNo ratings yet

- EAN 26M Digital Inclinometer 1212 11 R04Document4 pagesEAN 26M Digital Inclinometer 1212 11 R04Mriganabh ChoudhuryNo ratings yet

- ds36x8 Er Battlecard A4Document5 pagesds36x8 Er Battlecard A4LeandroGoulartNo ratings yet

- Rightrax System: Sensing & Inspection TechnologiesDocument5 pagesRightrax System: Sensing & Inspection TechnologiesTechnical A-Star Testing & Inspection MalaysiaNo ratings yet

- PS53027 Nicolet IS20 Spec SheetDocument4 pagesPS53027 Nicolet IS20 Spec SheetAnh Quoc LeNo ratings yet

- BCP 2 - Surface Initiation SystemsDocument16 pagesBCP 2 - Surface Initiation SystemsMaurit Francius SimanjuntakNo ratings yet

- ls2208 Spec Sheet en GBDocument2 pagesls2208 Spec Sheet en GBRanaIfteeNo ratings yet

- Gem Mentorutbrochure Web v2 0Document8 pagesGem Mentorutbrochure Web v2 0MarioNo ratings yet

- Gem Mentorutbrochure r1v10Document8 pagesGem Mentorutbrochure r1v10DylkanWingsNo ratings yet

- Brochure Ceta S 1Document2 pagesBrochure Ceta S 1Enrique AntonioNo ratings yet

- CTG-2 Product FlyerDocument2 pagesCTG-2 Product FlyerMohammad Abdul SameerNo ratings yet

- ST4 Vibrating Wire Embedment Strain GaugeDocument4 pagesST4 Vibrating Wire Embedment Strain GaugeNurul BaizuraNo ratings yet

- The SMART Cable Bolt InstallationDocument2 pagesThe SMART Cable Bolt InstallationBrandon Meza FelixNo ratings yet

- IndexDocument2 pagesIndexRavi BabuNo ratings yet

- SurveyorDocument2 pagesSurveyortech kickNo ratings yet

- Secu Gen Hamster PlusDocument2 pagesSecu Gen Hamster PlusNitinNo ratings yet

- Ultrasonic Wall Thickness GaugeDocument4 pagesUltrasonic Wall Thickness GaugeYud YudNo ratings yet

- P P H H D D: Rocessor en Anced EtectionDocument4 pagesP P H H D D: Rocessor en Anced EtectionRomly FerlandoNo ratings yet

- Hilti PS 50 (1 - 1) Concrete Scanning Goes Deeper PDFDocument3 pagesHilti PS 50 (1 - 1) Concrete Scanning Goes Deeper PDFMark VillarosaNo ratings yet

- Toughsonic 3 30mm Data SheetDocument2 pagesToughsonic 3 30mm Data SheetCARLOS XNo ratings yet

- Posit Ector Ut GDocument3 pagesPosit Ector Ut GGeorge ManuelNo ratings yet

- Air-Pak X3 Pro 2018 BrochureDocument8 pagesAir-Pak X3 Pro 2018 BrochureJonathanNo ratings yet

- Katalog TicknessDocument12 pagesKatalog TicknessAbdul AzizNo ratings yet

- DriftShot Presentation - DNADocument14 pagesDriftShot Presentation - DNAyanromulo@gmail.comNo ratings yet

- 7 - 8 at InclinometerDocument2 pages7 - 8 at InclinometerYanuar ChristyawanNo ratings yet

- Noise Noisechek Fly mp2009Document2 pagesNoise Noisechek Fly mp2009eduardo paivaNo ratings yet

- NextGuard BrochureDocument4 pagesNextGuard BrochurefitrahNo ratings yet

- Toughsonic 12 30mm Data SheetDocument2 pagesToughsonic 12 30mm Data SheetCARLOS XNo ratings yet

- Compu CutterDocument2 pagesCompu CutterM YasinNo ratings yet

- Magnum IEC - Product Specific InformationDocument16 pagesMagnum IEC - Product Specific Informationjehad azoozNo ratings yet

- IR US DT Quattro US Oneway Hallway DCS PDFDocument63 pagesIR US DT Quattro US Oneway Hallway DCS PDFmial01No ratings yet

- Digitilt at System DatasheetDocument2 pagesDigitilt at System DatasheetRafael OtrantoNo ratings yet

- DS-90 Sonar Ultrasonic MeasurementDocument2 pagesDS-90 Sonar Ultrasonic MeasurementTanNo ratings yet

- Micromate Specification Sheet PDFDocument2 pagesMicromate Specification Sheet PDFDorji TsheringNo ratings yet

- PatentDocument7 pagesPatentvamsiyadavNo ratings yet

- Waygate Technologies Mentor Visual Iq Video Borescope en Brochure bhcs33632 PDFDocument8 pagesWaygate Technologies Mentor Visual Iq Video Borescope en Brochure bhcs33632 PDFwertyyyNo ratings yet

- Scanning System: Incredibly Fast, Accurate and Easy-To-UseDocument14 pagesScanning System: Incredibly Fast, Accurate and Easy-To-UseRajesh ThorweNo ratings yet

- Weather Station DAVIS 6152 Vantage VueDocument1 pageWeather Station DAVIS 6152 Vantage VueTantan Teknik IndonesiaNo ratings yet

- Profometer 5brochureDocument2 pagesProfometer 5brochureLKBB Fakultas TeknikNo ratings yet

- Electronic DetonatersDocument20 pagesElectronic Detonatersnikhil kumarNo ratings yet

- Smart ShotDocument1 pageSmart ShotAlexander OpazoNo ratings yet

- P 0349 GB Fixturlaser Exo - Low Res 200130Document4 pagesP 0349 GB Fixturlaser Exo - Low Res 200130nino16041973No ratings yet

- Full-Featured, Advanced Vibration and Overpressure MonitorDocument2 pagesFull-Featured, Advanced Vibration and Overpressure MonitorBella PuraNo ratings yet

- Hamster Pro 20 Hamster Pro: The Highest Quality in Fingerprint Biometrics at Affordable PricesDocument2 pagesHamster Pro 20 Hamster Pro: The Highest Quality in Fingerprint Biometrics at Affordable PricesNeznanog Junaka Sest VranjeNo ratings yet

- SIPROTEC 7SA82 ProfileDocument2 pagesSIPROTEC 7SA82 ProfilezainNo ratings yet

- Cam-bien-an-toan-OMRON-F3SG-RA-series-catalogue 18012020091658 PDFDocument80 pagesCam-bien-an-toan-OMRON-F3SG-RA-series-catalogue 18012020091658 PDFbao binhNo ratings yet

- Servo-Pneumatic Drive Solution For Welding Guns: Sturdy and Precise!Document6 pagesServo-Pneumatic Drive Solution For Welding Guns: Sturdy and Precise!Irappa HosamaniNo ratings yet

- Hamster Pro 20: The Highest Quality in Fingerprint Biometrics at Affordable PricesDocument2 pagesHamster Pro 20: The Highest Quality in Fingerprint Biometrics at Affordable PricesAgmatel IndiaNo ratings yet

- Itemiser DX: Explosives and Narcotics Detection in A Desktop SystemDocument2 pagesItemiser DX: Explosives and Narcotics Detection in A Desktop SystemMoath BtooshNo ratings yet

- Checker 3 GDocument4 pagesChecker 3 GGA VaskezNo ratings yet

- Bus Insulation and Wildlife Protection Products: Bushing Connection Animal CoverDocument1 pageBus Insulation and Wildlife Protection Products: Bushing Connection Animal Coverjorge_moralesmNo ratings yet

- ds36x8 SR Specification Sheet A4Document2 pagesds36x8 SR Specification Sheet A4Irpal GiraseNo ratings yet

- DCS LowresDocument2 pagesDCS LowresLittle BigdoeuNo ratings yet

- 7 Lic Thesis Victoria SvahnDocument135 pages7 Lic Thesis Victoria SvahnJennifer GordonNo ratings yet

- International Journal of Surface Mining, Reclamation and EnvironmentDocument8 pagesInternational Journal of Surface Mining, Reclamation and EnvironmentJennifer GordonNo ratings yet

- AirdeckingDocument81 pagesAirdeckingJennifer GordonNo ratings yet

- International Journal of Mining Science and Technology: Zhendong Leng, Yong Fan, Qidong Gao, Yingguo HuDocument8 pagesInternational Journal of Mining Science and Technology: Zhendong Leng, Yong Fan, Qidong Gao, Yingguo HuJennifer GordonNo ratings yet

- Estimation of Fines Generated by Blasting - ApplicDocument12 pagesEstimation of Fines Generated by Blasting - ApplicJennifer GordonNo ratings yet

- MT Salt AdditionDocument6 pagesMT Salt AdditionJennifer GordonNo ratings yet

- SWEBRECDocument16 pagesSWEBRECCapo Dei KapiNo ratings yet

- BMC Post Blast Fume Management Plan PDFDocument16 pagesBMC Post Blast Fume Management Plan PDFJennifer GordonNo ratings yet

- A Comparative Study On The Application of Various PDFDocument8 pagesA Comparative Study On The Application of Various PDFJennifer GordonNo ratings yet

- New Blasting Technique To Eliminate Subgrade Drilling, Improve Fragmentation, Reduce Explosive Consumption and Lower Ground VibrationsDocument16 pagesNew Blasting Technique To Eliminate Subgrade Drilling, Improve Fragmentation, Reduce Explosive Consumption and Lower Ground VibrationsAnonymous KbM6WrPzNo ratings yet

- Evaluating The Fragmentation Data From Copper and Gold Mines Sedat Esen, Esen Mining Consulting, AustraliaDocument13 pagesEvaluating The Fragmentation Data From Copper and Gold Mines Sedat Esen, Esen Mining Consulting, AustraliaJennifer GordonNo ratings yet

- Prediction of Flyrock in Boulder Blastin PDFDocument11 pagesPrediction of Flyrock in Boulder Blastin PDFJennifer GordonNo ratings yet

- Salt Paper PDFDocument7 pagesSalt Paper PDFJennifer GordonNo ratings yet

- Fines and Dust Generation and Control in Rock Fragmentation by BlastingDocument17 pagesFines and Dust Generation and Control in Rock Fragmentation by BlastingJennifer GordonNo ratings yet

- New Blasting Technique To Eliminate Subgrade Drilling, Improve Fragmentation, Reduce Explosive Consumption and Lower Ground VibrationsDocument16 pagesNew Blasting Technique To Eliminate Subgrade Drilling, Improve Fragmentation, Reduce Explosive Consumption and Lower Ground VibrationsAnonymous KbM6WrPzNo ratings yet

- Evaluating The Fragmentation Data From Copper and Gold Mines Sedat Esen, Esen Mining Consulting, AustraliaDocument13 pagesEvaluating The Fragmentation Data From Copper and Gold Mines Sedat Esen, Esen Mining Consulting, AustraliaJennifer GordonNo ratings yet

- Salt Paper PDFDocument7 pagesSalt Paper PDFJennifer GordonNo ratings yet

- BMC Post Blast Fume Management Plan PDFDocument16 pagesBMC Post Blast Fume Management Plan PDFJennifer GordonNo ratings yet

- SWEBRECDocument16 pagesSWEBRECCapo Dei KapiNo ratings yet

- New Blasting Technique To Eliminate Subgrade Drilling, Improve Fragmentation, Reduce Explosive Consumption and Lower Ground VibrationsDocument16 pagesNew Blasting Technique To Eliminate Subgrade Drilling, Improve Fragmentation, Reduce Explosive Consumption and Lower Ground VibrationsAnonymous KbM6WrPzNo ratings yet

- Chia Petta 15945Document148 pagesChia Petta 15945Jennifer GordonNo ratings yet

- 716U3401 Rev 01 - Series III USB To Serial CableDocument9 pages716U3401 Rev 01 - Series III USB To Serial CableJennifer GordonNo ratings yet

- 720u2301 Rev 08 - Minimate Pro Operator ManualDocument129 pages720u2301 Rev 08 - Minimate Pro Operator ManualJennifer GordonNo ratings yet

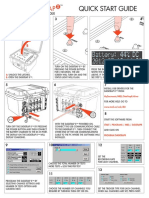

- DataTrapII QuickStartGuideDocument2 pagesDataTrapII QuickStartGuideJennifer GordonNo ratings yet

- 720u2301 Rev 08 - Minimate Pro Operator ManualDocument129 pages720u2301 Rev 08 - Minimate Pro Operator ManualJennifer GordonNo ratings yet

- Sampling and Analysis GuideDocument40 pagesSampling and Analysis GuideJennifer GordonNo ratings yet

- 720U2301 Rev 07 - Minimate Pro Operator ManualDocument126 pages720U2301 Rev 07 - Minimate Pro Operator ManualJennifer GordonNo ratings yet

- Cloud Computing Question Bank Unit IV and Unit V UpdatedDocument25 pagesCloud Computing Question Bank Unit IV and Unit V UpdatedramyaNo ratings yet

- Foiler BrochureDocument4 pagesFoiler BrochureTracy Schortmann GawronNo ratings yet

- Candidate Hall TicketDocument1 pageCandidate Hall TicketKesava KalepuNo ratings yet

- 1-Booklist For CCIEDocument3 pages1-Booklist For CCIEmailsanjayhere8362No ratings yet

- MegaMatcher SDK Brochure 2019-10-03Document65 pagesMegaMatcher SDK Brochure 2019-10-03Eduardo Arrieta EspinozaNo ratings yet

- VMX ServiceDocument344 pagesVMX ServiceRko Orton100% (1)

- CSI Group CapabilitiesDocument51 pagesCSI Group Capabilitiessidwhiz100% (2)

- AbstractDocument42 pagesAbstractMukul Bisht100% (1)

- Fabian Fischer - Forensic Challenge 2011 - Challenge 10Document49 pagesFabian Fischer - Forensic Challenge 2011 - Challenge 10Tertelie Vasile IonNo ratings yet

- 8 BP WEEK 5 - Flowchart - MagnoDocument6 pages8 BP WEEK 5 - Flowchart - MagnoKathrine CadalsoNo ratings yet

- Mutant & Machinegun v3 (Draft)Document28 pagesMutant & Machinegun v3 (Draft)gantherogueNo ratings yet

- Grails AclDocument25 pagesGrails AclXerus AnatasNo ratings yet

- Ethics Paper 1Document9 pagesEthics Paper 1api-314968337No ratings yet

- FKSM 71-8 Brigade Combat Teams December 2009Document173 pagesFKSM 71-8 Brigade Combat Teams December 2009Michele Mookie Mazzetti100% (1)

- Transport Layer SecurityDocument5 pagesTransport Layer Securitysvinoth1981No ratings yet

- NCVT MIS SisuDocument1 pageNCVT MIS SisuAriyan KumarNo ratings yet

- Know Your Client (KYC) Application Form: Middle Name Last Name First Name PrefixDocument2 pagesKnow Your Client (KYC) Application Form: Middle Name Last Name First Name Prefixdr dasNo ratings yet

- Octoplant Broschuere enDocument16 pagesOctoplant Broschuere enRituparna ChowdhuryNo ratings yet

- X98 AllCardsLostDocument6 pagesX98 AllCardsLosthichem allouiNo ratings yet

- PDF 0090 Fcra 609eDocument2 pagesPDF 0090 Fcra 609eNotarys To GoNo ratings yet

- MOXA Industrial Secure Router Installation GuideDocument18 pagesMOXA Industrial Secure Router Installation GuideguguNo ratings yet

- 690V Is A Good Alternative in The Process Industry PDFDocument5 pages690V Is A Good Alternative in The Process Industry PDFAnonymous 1AAjd0No ratings yet

- Advantech Wireless AMT 30 Modem Data SheetDocument2 pagesAdvantech Wireless AMT 30 Modem Data SheetarzeszutNo ratings yet

- TupDocument4 pagesTupRhea Daphne Alaya-ay DanielNo ratings yet

- All Access WiFi Around CEATDocument29 pagesAll Access WiFi Around CEATShayne GaloNo ratings yet

- AdmitCard 190320017423Document1 pageAdmitCard 190320017423Sìñgh Sãåb SinghSardarNo ratings yet

- Smart Focus WebView 7.x BELDEN 090226Document98 pagesSmart Focus WebView 7.x BELDEN 090226Leonardo Da VinciNo ratings yet

- Pce Merz EnglDocument8 pagesPce Merz EnglAxoben BastidasNo ratings yet

- Lessoon 04 Config BuDocument13 pagesLessoon 04 Config BuMohamed_Zubair_403No ratings yet