Professional Documents

Culture Documents

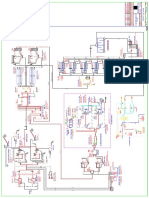

Electrical STP

Uploaded by

كرم عمروOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Electrical STP

Uploaded by

كرم عمروCopyright:

Available Formats

ELECTRICAL WORKS

LIST AS PER BOQ

Item Area Earthing Lighting Panels Equipments Instrumentation Cables

Parshal Flume (2 pc)

pH (1 pc)

1 Inlet Works Y N MCC-3 Sand Classifier (2 pc) Conductivity (1 pc) 4x10+10mm2 (310m)

D.O. (1 pc)

NTU (1 pc)

Ultrasonic Level (1 pc)

2 CL2 Contact & Return Sludge Y N (3x10+6)+10mm2 (75m)

Magflow (2 pc)

3 Aeration Tank Y N D.O. (6 pc) 2x(3x50+25)+25mm2 (850m)

4 Clarrifier Tanks Y N - 4x6+10mm2 (185m)

Backwash Pump Ultrasonic Flow (1 pc)

5 Tertiary Station Y N MCC-4 4x10+10mm2 (105m)

Secondary Excess Pump Residual CL2 (1 pc)

MCC-2

6 Final Treated Water Y N Magflow (4x10+6)+10mm2

LCP

Magflow

7 Sludge Holding Tank N N

Chart Recorder

Control Panel

8 Belt Press N N 3x10+10mm2

Control Panel

MCC-1 4x6+10mm2 (45m)

9 Chlorine Room Y N

Control Panel (3x10+6)+10mm2 (15m)

10 Waste Return - to - Inlet Work Y N LCP (3x10+6)+10mm2 (42m)

Disbo 4x6+10mm2 (45m)

11 CCR Y Y PLC (3x16+10)+10mm2 (35m)

Wonderware (3x50+25)+16mm2 (28m)

pH Meter (1 pc)

BOD5 (2 pc)

COD (2 pc)

Kjaldhal Nitrogen (2 pc)

TSS (1 pc)

Turbidity (1 pc)

Conductivity (1 pc)

Electronic Balance (1 pc)

12 Lab Equipments N N N N Spectro Photometer (1 pc) N

Oven 250DegC (1 pc)

Furnace 1200 DegC (1 pc)

Incubator (1 pc)

Distiller (1 pc)

Flame photometer (1 pc)

DO meter (2 pc)

Wet Analysis (1 pc)

Titriametric Analysis (1 pc)

MCC Load

MCC-1

Service: Chlorination Building

Item Description Operation KW

1 Sample Pump 1Duty

2 Booster Pump 1Duty/1Standby

3 Automatic Chlorination Panel

4 Ejector

5 Automatic Changeover Unit

MCC-2

Service: Treated Effluent Pumping Station

Item Description Operation KW

1 Treated water pump 2Duty/1Standby

MCC-3

Service: Screen Channel, Grit Removal

Item Description Operation KW

1 Screen 2Duty 3

2 Belt Conveyor 1Duty 0.75

3 Air Blower 1Duty/1Standby 15

4 Bridge 2Duty 0.37

5 Air Lift pumps 2Duty

6 Grease Pumps 2Duty 4.1

7 Sand Classifier 2Duty 1.3

MCC-4

Service: Tertiary Sand Filter, Filter/BKP and Drainage System

Item Description Operation KW

1 Filter Feed Pump 2Duty/1Standby 24

2 Air Blower 1Duty/1Stanby 55

3 Backwash Pump 2Duty 110

4 Drainage Pump 2Duty/1Standby

5 Backwash spent/return pump 1Duty/1Stanby

MCC-5

Service: RAS/WAS, Secondary Settling Tank

Item Description Operation KW

1 WAS pump 1Duty/1Stanby 15

2 RAS pump 2Duty/1Standby 18

3 Scrapper 1Duty/1Stanby

4 Submerged Aerator

MCC-6

Service: Sludge Dewatering, Sludge Thickner

Item Description Operation KW

1 Polymer Panel Feeder

2 Belt Press Panel Feeder

3 Scrapper

4 Sludge Feed Pump

5 Air compressor

MCC-7

Service: Oxidation Ditch

Item Description Operation KW

1 Aerators 6Duty 90

BAHA STP

Instrumentation List

Item Area Description Pipe DN Pipe Material More Specifications

Parshal Flume

pH Meter

Conductivity Meter

1 Inlet Works D.O. Meter

Turbidity Meter

Diff. Level Transmitter

Diff. Level Sensor

2 Chlorine Contact Ultrasonic Level

3 Aeration Tank D.O. Meter

Ultrasonic Level

4 Tertiary Station

Residual Chlorine

Ultrasonic Level

5 Final Treated Tank

Magflow

Magflow

6 Sludge Holding Tank

Chart Recorder

7 Waste return-to- Inlet Works Ultrasonic Level

MLSS

8 Selector Tank

Magflow

9 RAS/WAS Magflow

10 Sand Filters Level XMTR

Where is the autosampler's location?

Qty

1

1

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Capacitor Bank Calculation MSMDocument1 pageCapacitor Bank Calculation MSMكرم عمروNo ratings yet

- Albaha Project BerkefeldDocument2 pagesAlbaha Project Berkefeldكرم عمروNo ratings yet

- خرسانة مسلحة لمبنى المضخاتDocument8 pagesخرسانة مسلحة لمبنى المضخاتكرم عمروNo ratings yet

- حصر حديد مبنى المضخاتDocument26 pagesحصر حديد مبنى المضخاتكرم عمروNo ratings yet

- Mcc-1 Electrical LoadDocument1 pageMcc-1 Electrical Loadكرم عمروNo ratings yet

- الاعمال الصحيةDocument9 pagesالاعمال الصحيةكرم عمروNo ratings yet

- كهرباء مجمع معاهد فتيات ميت حبيشDocument9 pagesكهرباء مجمع معاهد فتيات ميت حبيشكرم عمروNo ratings yet

- حريقDocument21 pagesحريقكرم عمرو50% (2)

- Awwa - D100-96 Welded Steel Tanks For Water Storage - Awwa PDFDocument140 pagesAwwa - D100-96 Welded Steel Tanks For Water Storage - Awwa PDFكرم عمروNo ratings yet

- جدول اوزان الالواح المقاومة للصدDocument1 pageجدول اوزان الالواح المقاومة للصدكرم عمروNo ratings yet

- Coker Loan Amortization ScheduleDocument8 pagesCoker Loan Amortization Scheduleكرم عمروNo ratings yet

- تكييفDocument18 pagesتكييفكرم عمرو100% (1)

- Tanques API MCDocument46 pagesTanques API MCكرم عمروNo ratings yet

- Pre11cf06000003 3500 55 MC 041Document5 pagesPre11cf06000003 3500 55 MC 041كرم عمروNo ratings yet

- Electrical STPDocument5 pagesElectrical STPكرم عمروNo ratings yet

- Strengths: Mixers - AeratorsDocument2 pagesStrengths: Mixers - Aeratorsكرم عمروNo ratings yet

- Cable TrenchDocument1 pageCable Trenchكرم عمروNo ratings yet

- Oreja de Izaje Model PDFDocument1 pageOreja de Izaje Model PDFكرم عمروNo ratings yet

- P&ID Sep08Document1 pageP&ID Sep08كرم عمروNo ratings yet

- Baha STP CablesDocument1 pageBaha STP Cablesكرم عمروNo ratings yet

- Coker Loan Amortization ScheduleDocument8 pagesCoker Loan Amortization Scheduleكرم عمروNo ratings yet

- حريقDocument21 pagesحريقكرم عمرو50% (2)

- Sludge DisposalDocument62 pagesSludge Disposalblumunchie100% (2)

- Foam Calculation: Page 1 of 3Document3 pagesFoam Calculation: Page 1 of 3كرم عمروNo ratings yet

- رسوم العمالة الوافدة في السعودية شهرياDocument2 pagesرسوم العمالة الوافدة في السعودية شهرياكرم عمروNo ratings yet

- Arabic-WT Level IIbDocument42 pagesArabic-WT Level IIbكرم عمروNo ratings yet

- Dewatering TechnologiesDocument31 pagesDewatering TechnologiesChokri ChakiirNo ratings yet

- SapcoDocument16 pagesSapcoكرم عمروNo ratings yet

- Labor SystemDocument83 pagesLabor Systemكرم عمروNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)