Professional Documents

Culture Documents

Cigre 400 K

Uploaded by

erson1981Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cigre 400 K

Uploaded by

erson1981Copyright:

Available Formats

Two Years of Experience with

Reprint

a Mobile Resonant Test System for

Testing of Installed Medium- and

High Voltage Power Cables

P. Schikarski

M. Gamlin

J. Rickmann

P. Peeters

P. v.d. Nieuwendijk

R. Koning

ISH 99

E 1-89 HIGH VOLTAGE TEST

TWO YEARS OF EXPERIENCE WITH A MOBILE RESONANT TEST SYSTEM FOR TESTING

OF INSTALLED MEDIUM- AND HIGH VOLTAGE POWER CABLES

P. Schikarski, M. Gamlin, J. Rickmann P. Peeters, P. v.d. Nieuwendijk, R. Koning

Haefely Trench AG NKF Kabel

Basel, Switzerland Delft, Netherlands

Abstract

Since October 1996 one of the largest series resonant good results can be achieved. Installed cables several

test system with variable frequency has been in kilometer in lengths represent a large capacitive load

operation. More than 270 installed medium- and high for the test equipment. (E.g. for a 13 km long 150 kV

voltage cables have been tested using this equipment in XLPE-insulated cable, test voltage 220 kV, 50 Hz a test

the Netherlands, Germany, Belgium and in the United power of up to 40 MVA is needed). On-site testing with

Kingdom. The tested cable lines consist of either a conventional test transformer, due to the heavy weight

XLPE, oil-paper or a combination of both insulating and the high power supply requirement, is not practical.

materials. The principle of testing is briefly described Considering reasonable size and weight DC and 0.1 Hz

and the results of these tests, depending on the voltage test systems seems to be the most convenient solution.

level, the age and construction of the cable, are But especially for DC tests on extruded polymeric

statistically evaluated. The experience in on-site testing insulated cables (XLPE), there are doubts about the

of power cables is summarized and future testing trends adequacy of the test method due to the difference in

and recommendations are discussed. stress distribution of DC and AC voltages. DC tests can

even be dangerous for the cable under test because of

1. Introduction weak points inside the cable insulation caused by

electrostatic space charges. This effect could lead to

Testing on installed cable systems is gaining breakdowns during the tests or could decrease the

importance. After laying tests on new cables prove that lifetime of the cable system dramatically [1].

the cable laying and the accessories installation were The very low frequency test system (0.1 Hz) is

carried out correctly. The after laying test fills the normally used for medium voltage cables. For high

“quality assurance gap“ between the routine test of the voltage cable testing this equipment is not available on

cable drum at manufacturer site and the commissioning the market as a commercial product. Furthermore the

of the complete cable system on-site (Fig. 1). Tests on sensitivity to detect failures with test voltage is only

old installed cables should establish that the quality of half as compared to the AC voltage test systems [2].

the cable, the cable joints and cable end terminations is To have, on one hand, the advantage of testing with

sufficient to allow further operation of the cable system. frequencies close to power frequency and on the other

For on-site tests on installed medium- and high voltage hand a test system which can be handled easily on-site,

cables several test methods like withstand tests with resonant test systems with variable frequency were

DC, 0.1 Hz, AC or impulse voltages are known. developed. This paper describes the more than two

Depending on the specific test application more or less years of experience made by a well-known cable

manufacturer using this kind of on-site test system.

Life-Cycle / Test Cycles of an Eletrical H.V. Equipment

Manufacturer On-site

Shipping End of

Manufacturing Running time Running time Life-time

Assembling

On-line Monitoring On-line Monitoring

Special Type Sample Routine Commissioning Off-line

Test Test Test Test Test Monitoring

Figure 1: Life-cycle / test cycles of a cable system

2. Design of the on-site AC test system The ratio between weight and testing power of this

resonant test system is only a quarter of a comparable

The resonant test system with variable frequency conventional test transformer.

mainly consists of the frequency converter, the exciting The power supply has only to deliver 1 to 3 % of the

transformer, the coupling capacitors and two high required testing power. The technical data and the

voltage reactors with fixed inductance (Fig. 2). To be test capabilities of the resonant test system are shown in

independent from a stationary power supply a motor- Table 1.

generator set is used. The frequency converter

generates a variable voltage and frequency output

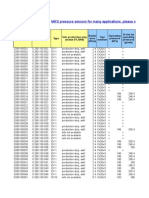

1 reactor 2 reactors 2 reactors in

which is applied to the exciter transformer. The exciter (1S1P) parallel (1S2P) series (2S1P)

transformer excites the series resonant circuit consisting

of the reactor’s inductance L and the cable capacitance Nominal voltage 220 kV 220 kV 440 kV

C. Even though the frequency converter creates Nominal power 14.5 MVA 29 MVA 29 MVA

harmonics the output voltage shows a pure sine wave Max. test load 1.6 µF 3.2 µF 0.8 µF

[3]. The resonance is adjusted by tuning the frequency Frequency range 30 Hz - 200 Hz

of the frequency converter according the formula: Tuning - range 1 : 44.44

Load duty cycle 1 h ON / 2 h OFF, 6 x in 48 h

1

f= Weight including trailer 40 t

2π ⋅ ( L ⋅ C) Length 13.6 m

Width 2.5 m

The tuning range of the test system is determined by the

Height 4m

converter’s frequency range:

2

C max fmax Table 1: Technical data of described resonant test

=

C min f min system

Depending on the voltage level and the capacitance of

the cable the test system can be extended by a second

reactor. For longer power cables up to 150 kV and

more than 10 km, the second reactor is connected in

parallel. For test voltages up to 440 kV a series

connection of the two reactors has to be realized

(Fig. 3).

The quality factor “Q“ of the resonant system

determines the relation between testing power and the

required power supply [4]. For the XLPE cable testing

a system quality factor in the range of 100 - 150 and for

paper-insulated cables 50 - 90 were achieved. The high

quality factor of the high voltage reactors leads to a

compact and lightweight system design.

Figure 3: Test set-up to reactors in series ( 2S1P)

2 x Reactors with 2 x Coupling Capacitors

fixed Inductance 220 kV, 10 nF

220 kV, 66 A

Primary

Power Secondary Test Load

Breaker Contactor 220 KV, 3.2 µF

440 kV, 0.8 µF

U

M G f

Diesel Generator Frequency Exciter

Drive Converter Transformer

30 - 200 Hz 400 V - 0.4 / 1.5 / 3 / 6 kV

30 - 400 V 400 kVA

630 kVA, 3 phases

364 kVA, 2 phases

Figure 2: Electrical diagram of the described resonant test system

3. Operating experience

Since October 1996 the 440 kV, 29 MVA resonant test

system has been in operation. More than 270 installed 250

medium- and high voltage power cables with a total 30 / 50 kV Cable

110 kV Cable

200

length of approx. 1'600 km has been tested. The

Tested cable length [km]

150 kV Cable

220 kV Cable

demand for on-site testing on cables is increasing 150

400 kV Cable

rapidly. E.g. between 1997 and 1998 the growth rate

was 70 % (Fig. 4)! 100

To operate an on-site test system economically a short

set up time has to be considered. Due to the easy 50

operation and the fast connection of the test system to

0

the cable under test the typical installation time is 1996 1997 1998

Year

approx. an hour.

Most of the tested circuits consist of polymeric (XLPE) Figure 4: Tested cable length by NKF Kabel from

cables. Also fluid filled (FF) and fluid filled mixed with 4.10.96 till 14.12.98 with the 440 kV

polymeric (XLPE&FF) has been tested (Fig. 5). resonant test system

The performed on-site tests have been made on new

laid cables (38 %) as well as on old installed cables

(68 %) (Fig. 6).

Depending on the voltage level, type and age of the 374 km

XLPE&FF

cable system different test procedures have been used. 23%

Often the customer defines his own special test

procedure. Most tests have been performed according

the Dutch Standard NEN 3630 [5]:

166 km

New XLPE-insulated cable systems FF Cable

11%

845 km

Cable Class Test Voltage Test duration XLPE Cable

66%

[kV] [min]

50 2.5 U0 10

110 2.5 U0 10 Figure 5: Statistic of tested cables depending on the

150 2.5 U0 10 cable type

Old XLPE-insulated cable systems

Cable Class Test Voltage Test duration

[kV] [min]

50 2.5 U0 x 80 % 10 544 km

After-laying test

110 2.5 U0 x 80 % 10 on new cables

38%

150 2.5 U0 x 80 % 10

Old paper-insulated cable systems

Cable Class Test Voltage Test duration 862 km

Test on old

[kV] [min] installed cables

62%

50 2.5 U0 x 80 % 15

110 2.5 U0 x 80 % 15

150 2.5 U0 x 80 % 15 Figure 6: Statistic of tested cables depending on the

380 2.5 U0 x 80 % 15 cable age

mixed cable systems

Cable Class Test Voltage Test duration

[kV] [min]

50 2.5 U0 x 80 % 10

110 2.5 U0 x 80 % 10

150 2.5 U0 x 80 % 10

In some cases the circuit capacitance had to be ment of the conventional PD measurement has to be

increased by additional load capacitors to fulfill the done. This might be realized by using digital filters to

customers specification of a test frequency e.g. less than suppress interfering noise [7].

100 Hz.

Some test arrangements due to limited space on-site or

because of cable terminations installed within a Reference

building required an additional 200 m feeding cable

connecting the test system to the cable under test. This [1] CIGRE WG 21.09

feeding cable has also been used as an additional load After laying tests on high voltage extruded

capacitance for testing short cable length to lower the insulation cable systems

test frequency. ELECTRA, No. 173, August 1997

Of 230 cable systems tested, two failed in the cable

insulation and four in the accessories. Three installed [2] Dipl.-Ing. Gundolf Schiller

accessories broke down after 5 to 20 min of applied test Breakdown behavior of cross linked polyethylene

voltage. Only one accessory and two cable insulation depending on voltage wave form and pre-stress

failed during the voltage rise of the test voltage. Dissertation Universität Hannover

Five of the six failed cable circuits were in operation February 1996

several years. The only new cable circuit which failed

during the after-laying test was due to an accessory. [3] P. Mohaupt, M. Gamlin, R. Gleyvod, J. Kraus,

From the tested cable circuits which fulfilled the test G, Voigt

requirements no failure has occurred during service High voltage testing using series resonance with

until now. variable frequency

10th ISH Montreal, 1997

4. Conclusion

[4] A. Jenni, M. Pasquier, R. Gleyvod, P. Thommen

More than 270 cable circuits has been tested with the Testing of high voltage power cables with series

variable frequency series resonant test system. Due to resonant systems and water terminations

the easy handling, low specific weight and high 7th ISH Dresden, 1991

reliability of resonant systems with variable frequency

and the achieved test experiences the AC high voltage [5] Dutch Standards NEN 3630

on-site testing is a useful tool to prove the quality of the Cables with insulation of cross-linked

commissioning work of a new laid cable system and to polyethylene for voltages of 50 kV up to and

verify the reliability of an old installed cable system. including 220 kV

Therefore a further increase of AC high voltage on-site June 1996

tests on high voltage cables could be expected.

When on-site testing becomes a subject of standardi- [6] A. Miyazaki, M. Yagi, S. Kobayashi, C. Min, K.

zation different test procedures and test levels for after- Hirotsu, H. Nishima

laying tests on new cable system and tests on old Development of partial discharge automated

installed cable circuits should be taken into locating system for power cable

consideration. The testing experience documents shows CEIDP Annual Report 1998, Volume II

that the CIGRE recommendations „After laying tests on

high voltage extruded insulation cable systems“ [1] [7] K. Feser, E. Grossmann, M. Lauersdorf, T. Grun

have not been applied. The tests showed that the Improvement of sensitivity in online PD-

breakdown voltage of the failed accessories were in any measurement on transformers by digital filtering

cases higher than the test levels given in the CIGRE Submitted as paper for 11th ISH London, 1999

recommendations. E.g. for the 150 kV equipment the

breakdown voltage of the accessories were ≥ 2 U0

(CIGRE recommendation 1.7 U0) and for the 220 kV

equipment ≥ 1.7 U0. (CIGRE recommen-dation 1.4 U0).

If a sensitive partial discharge locating system is used a

reduction of the above described test levels could be

expected. For operating of this PD measuring system

pairs of sensors have to be installed in the joints of the

laid cable. Based on the time differences of the PD

signal measured by each sensors the PD in cable joints

can be located and verified [6].

To reduce the test level for installed old cable systems

the quality of the cable insulation as well as the quality

of the accessories has to be tested by a sensitive partial

discharge measurement. Therefore a further improve-

Haefely Test AG

High Voltage Test Division

CH-4028 Basel/Switzerland

Phone +41.61.373 41 11

Fax +41.61.373 49 12

www.haefely.com

e-mail: sales@haefely.com HIGH VOLTAGE TEST

You might also like

- 11LE 968 SampleDocument16 pages11LE 968 Samplefarooqs21No ratings yet

- @practical Guide To Electrical Grounding, 1st Edition, 1999Document131 pages@practical Guide To Electrical Grounding, 1st Edition, 1999cyong7788100% (15)

- Box Fill CalculationsDocument10 pagesBox Fill Calculationserson1981No ratings yet

- An Example of Calculation Transformer Size and Voltage Drop Due Starting of Large MotorDocument15 pagesAn Example of Calculation Transformer Size and Voltage Drop Due Starting of Large Motorerson1981No ratings yet

- Guide Exterior LightingDocument2 pagesGuide Exterior Lightingerson1981No ratings yet

- Nec GuideDocument2 pagesNec Guideerson1981No ratings yet

- Alfanar Low Voltage Power Cables Catalog PDFDocument106 pagesAlfanar Low Voltage Power Cables Catalog PDFerson1981No ratings yet

- Yum e 0718 PDFDocument7 pagesYum e 0718 PDFerson1981No ratings yet

- Nec GuideDocument2 pagesNec Guideerson1981No ratings yet

- EarthGround TutorialDocument16 pagesEarthGround TutorialMohammed Maher100% (1)

- MainDocument1 pageMainerson1981No ratings yet

- Conductor Sizing Part 2 of 2: Mike HoltDocument9 pagesConductor Sizing Part 2 of 2: Mike Holterson1981No ratings yet

- General 8 26Document15 pagesGeneral 8 26jayathri pasanNo ratings yet

- Guide Exterior LightingDocument2 pagesGuide Exterior Lightingerson1981No ratings yet

- @practical Guide To Electrical Grounding, 1st Edition, 1999Document131 pages@practical Guide To Electrical Grounding, 1st Edition, 1999cyong7788100% (15)

- Guide 30-60-90 Min Fire RatedDocument1 pageGuide 30-60-90 Min Fire Ratederson1981No ratings yet

- Calculate Size of Cable For Motor (As NEC)Document2 pagesCalculate Size of Cable For Motor (As NEC)erson1981No ratings yet

- 250.122 (B) Size of Equipment Grounding Conductors. Increased in SizeDocument3 pages250.122 (B) Size of Equipment Grounding Conductors. Increased in Sizeerson1981No ratings yet

- Electrical Notes & Articles: Calculate No of Street Light PolesDocument4 pagesElectrical Notes & Articles: Calculate No of Street Light Poleserson1981No ratings yet

- Calculate Size of Circuit Breaker or Fuse For Transformer (As Per NEC)Document4 pagesCalculate Size of Circuit Breaker or Fuse For Transformer (As Per NEC)erson1981No ratings yet

- Electrical Notes & Articles: Calculate No of Lighting Fixtures / Lumen For Indoor LightingDocument10 pagesElectrical Notes & Articles: Calculate No of Lighting Fixtures / Lumen For Indoor Lightingerson1981No ratings yet

- Calculate Size of Cable For Motor (As NEC)Document2 pagesCalculate Size of Cable For Motor (As NEC)erson1981No ratings yet

- Calculate Size of Circuit Breaker or Fuse For Transformer (As Per NEC)Document4 pagesCalculate Size of Circuit Breaker or Fuse For Transformer (As Per NEC)erson1981No ratings yet

- 5 key factors for selecting cablesDocument11 pages5 key factors for selecting cableserson1981No ratings yet

- 5 key factors for selecting cablesDocument11 pages5 key factors for selecting cableserson1981No ratings yet

- 5 key factors for selecting cablesDocument11 pages5 key factors for selecting cableserson1981No ratings yet

- Basic Conductor Sizing Part 2Document11 pagesBasic Conductor Sizing Part 2erson1981No ratings yet

- How To Design Efficient Street Lighting - (Part-3)Document8 pagesHow To Design Efficient Street Lighting - (Part-3)erson1981No ratings yet

- Calculate Size of Contactor, Fuse, C.B, Over Load Relay of DOL StarterDocument5 pagesCalculate Size of Contactor, Fuse, C.B, Over Load Relay of DOL Startererson1981No ratings yet

- Transformer InstallationDocument24 pagesTransformer Installationerson1981No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Nseallcompanies 31122020Document78 pagesNseallcompanies 31122020guy fawkesNo ratings yet

- Bosch Injector Data SheetDocument124 pagesBosch Injector Data SheetThibaut Lrt56% (9)

- MERCEDES MEDIC ACROYNMS GUIDEDocument6 pagesMERCEDES MEDIC ACROYNMS GUIDEDProkhorov100% (1)

- Solar Electric Tiffin Box (1) - 2Document36 pagesSolar Electric Tiffin Box (1) - 2imrashi18kNo ratings yet

- Water Wash Procedure For EconomizerDocument3 pagesWater Wash Procedure For EconomizerRajendra100% (1)

- 10 STD Specifications - Building - 2018 (A1)Document902 pages10 STD Specifications - Building - 2018 (A1)Logan LiNo ratings yet

- Gas Turbine Heat Rejection and Refrigeration Cycle CalculationsDocument8 pagesGas Turbine Heat Rejection and Refrigeration Cycle CalculationsRENE JOSHUA PECASONo ratings yet

- Alternating Current TechnologyDocument118 pagesAlternating Current TechnologyMadhav DeshpandeNo ratings yet

- FCRR19 (6) Kirkwood Matura-ShepherdDocument5 pagesFCRR19 (6) Kirkwood Matura-ShepherdRuslan ZakirovNo ratings yet

- Xenon Short Arc Lamps: Light Source XE150 (650-0091)Document2 pagesXenon Short Arc Lamps: Light Source XE150 (650-0091)Abhishek GuddadNo ratings yet

- Chemical Kinetics: Practice ExamplesDocument31 pagesChemical Kinetics: Practice ExamplesJudith Del Valle MorejonNo ratings yet

- 33 11KV Substation SLDDocument3 pages33 11KV Substation SLDRajeshYadav100% (1)

- Siemens SSA31.04 PDFDocument6 pagesSiemens SSA31.04 PDFJohn DunbarNo ratings yet

- Chapter 5 (2nd Law of ... )Document64 pagesChapter 5 (2nd Law of ... )yohannes lemiNo ratings yet

- Rotational Motion Engineering Mechanics IIT KanpurDocument67 pagesRotational Motion Engineering Mechanics IIT KanpurNitin SharmaNo ratings yet

- J300, J4ATS, J7ATS Transfer Switches 260, 400, and 600 Amp SizesDocument6 pagesJ300, J4ATS, J7ATS Transfer Switches 260, 400, and 600 Amp SizesMatt PittmanNo ratings yet

- VCO Based ADCDocument3 pagesVCO Based ADCBlake PayriceNo ratings yet

- Condensate Treatment AQUAMAT Series: For Compressor Flow Rates Up To 100 M /minDocument5 pagesCondensate Treatment AQUAMAT Series: For Compressor Flow Rates Up To 100 M /minBui Hoang DucNo ratings yet

- Hydraulic Turbines: Turbines and That Con Vert Mechanical Energy IntoDocument22 pagesHydraulic Turbines: Turbines and That Con Vert Mechanical Energy IntosaitejaNo ratings yet

- Chemistry 3202 Reaction Rates and Equilibrium NotesDocument4 pagesChemistry 3202 Reaction Rates and Equilibrium NotesMorgan SearsNo ratings yet

- Vietnamese Olympiad English exam passageDocument6 pagesVietnamese Olympiad English exam passageLê Thanh ThảoNo ratings yet

- Ventilation of The Industrial Environment PDFDocument7 pagesVentilation of The Industrial Environment PDFnelson escuderoNo ratings yet

- Rwu90 SpecsDocument2 pagesRwu90 SpecsEduardo LuboNo ratings yet

- LevyDocument4 pagesLevyRamon FerreiraNo ratings yet

- Practice HSC Papers General 2Document47 pagesPractice HSC Papers General 2DarrenPurtillWrightNo ratings yet

- Daewoo 4603Document42 pagesDaewoo 4603David LovatoNo ratings yet

- Aplicaciones Con El Ne - 558Document5 pagesAplicaciones Con El Ne - 558julio_m_pNo ratings yet

- Enigma Motors: Mobility Company That Sticks To GrassrootsDocument14 pagesEnigma Motors: Mobility Company That Sticks To GrassrootsUmangNo ratings yet

- YVAA0490 - DataSheetSpec. - Rev01pdfDocument2 pagesYVAA0490 - DataSheetSpec. - Rev01pdfMohamed AskarNo ratings yet

- Egypowpd Module3Document52 pagesEgypowpd Module3Jas PayaNo ratings yet