Professional Documents

Culture Documents

Analysis of Box Culvert To Reduce Stress Values

Uploaded by

IJAERS JOURNALOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Analysis of Box Culvert To Reduce Stress Values

Uploaded by

IJAERS JOURNALCopyright:

Available Formats

International Journal of Advanced Engineering Research and Science (IJAERS) [Vol-5, Issue-5, May- 2018]

https://dx.doi.org/10.22161/ijaers.5.5.14 ISSN: 2349-6495(P) | 2456-1908(O)

Analysis of Box Culvert to ReduceStressValues

Vasu Shekhar Tanwar1, Dr. M. P. Verma2, Sagar Jamle3

1

MTech (SE) Scholar, Department Of Civil Engineering, Oriental University, Indore, MP, India

2

Prof. & Head, Department Of Civil Engineering, Oriental University, Indore, MP, India

3

Assistant Professor, Department Of Civil Engineering, Oriental University, Indore, MP, India

Abstract—At the time of construction of roads, highways Case-3:Dead Load and Earth Pressure Acting from

a structure is placed (commonly used) to transfer the Outside, no Water Pressure Acting from Inside.

traffic, rain water, drainage from one side to another of

the road is called a culvert placed beneath the road. Due IV. PARAMETERS USED

to the structural use, multiple loads are placed on the box 1 Plate thickness= 0.30m

causing various types of stress which occurs on it. The 2 Length =10.50m

paper tries to reduce the stress occurred in the box by 3 Width =3.80m

flaring the box partially. 4 Flared width= 1.05m

Keywords—Box culvert, flaredportion,pressure cases, 5 Support= Fixed Type

side walls, staad pro. 6 Live Load on top slab= 6420kg/m2

7 Earth Pressure Load from bottom slab= 7860kg/m2

I. INTRODUCTION 8 Earth Pressure Load on side walls= 1900-

Culvert is an underpass provided beneath the high way 4180kg/m2(case 2)

which under goes various types of loading .It helps to 9 Earth pressure Load on side walls= 400-

facilities the flow of water, provide cross drainage, 2280kg/m2(case 3)

roadways or railways, to take electrical or other cables 10 Water pressure Load on inside side walls= 0-

from one side of road to another side of the road . due 3800kg/m2

construction of these high load bearing components 11 Coefficient of Active Earth pressure = 1/3

various stress and shear gets generated in very high 12 E= 2.17185e+007

values the paper objects to reduce the values of the stress 13 Poisson= 0.17

which have been generated for various cases. 14 Density = 25

15 Damping=0.05

II. TYPES OF CULVERTS 16 Strength FCU = 25000

1 On basis of shape:-

1.1 Pipe culvert

1.2 Pipe Arch culvert

1.3 Box Culvert (single/multiple)

1.4 Arch culvert

1.5 Bridge culvert

2 On basis of material used:-

2.1 Concrete

2.2 Steel

2.3 Plastic

2.4 Aluminum

2.5 High density polyethylene

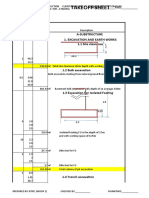

III. CASES TO BE SOLVED Fig.1: 3-D View of Flared Box Culvert

For the purpose of design, culverts are subjected to

following cases:-

Case-1:Dead Load, Live Load and Earth Pressure Acting

from Outside, no Water Pressure Acting from Inside.

Case-2:Dead Load, Live Load and Earth Pressure Acting

from Outside, Water Pressure Acting from Inside.

www.ijaers.com Page | 103

International Journal of Advanced Engineering Research and Science (IJAERS) [Vol-5, Issue-5, May- 2018]

https://dx.doi.org/10.22161/ijaers.5.5.14 ISSN: 2349-6495(P) | 2456-1908(O)

there is an increase of flared portion from 0mm to

70mm

5. TRESCA values declined in case 2 by 37.97% when

there is an increase of flared portion from 0mm to

70mm

6. TRESCA values declined in case 3 by 52.55% when

there is an increase of flared portion from 0mm to

70mm

7. VONMISS values declined in case 1 by 30.62%

when there is an increase of flared portion from

0mm to 70mm

8. VONMISS values declined in case 2 by 40.81%

Fig.2: Case -1 of Box Culvert when there is an increase of flared portion from

0mm to 70mm

9. VONMISS values declined in case 3 by 49.24%

when there is an increase of flared portion from

0mm to 70mm.

Detailed values are described in tables shown below:-

Table.1: For Analysis of Principle Top in Box Culvert

FLARED PRINCIPAL TOP(KN/MMSQ)

PORTION C1 C2 C3

0MM 4.147 4.19 4.243

10MM 2.185 2.185 0.179

20MM 2.171 1.228 0.179

30MM 2.157 1.221 0.178

40MM 2.142 1.215 0.178

Fig.3: Case -2 of Box Culvert

50MM 2.128 1.208 0.178

60MM 2.114 1.201 0.178

70MM 2.1 1.2 0.178

Fig.4: Case-3 of Box Culvert

V. RESULT AND DISCUSSIONS

1. PRINCIPAL TOP values declined in case 1 by Graph 1- Principle Stress Values v/s Flared Thickness

49.36% when there is an increase of flared portion

from 0mm to 70mm. Table.2: For Analysis of Tresca in Box Culvert

2. PRINCIPAL TOPvalues declined in case 2 by FLARED TRESCA IN (KN/MMSQ)

71.36% when there is an increase of flared portion PORTION CASE1 CASE2 CASE3

from 0mm to 70mm. 0MM 6.519 6.125 5.67

3. PRINCIPAL TOPvalues declined in case 3 by

10MM 4.983 4.983 2.738

95.80% when there is an increase of flared portion

20MM 4.959 3.866 2.728

from 0mm to 70mm.

30MM 4.936 3.849 2.719

4. TRESCAvaluesdeclined in case 1 by25.75% when

40MM 4.913 3.832 2.71

www.ijaers.com Page | 104

International Journal of Advanced Engineering Research and Science (IJAERS) [Vol-5, Issue-5, May- 2018]

https://dx.doi.org/10.22161/ijaers.5.5.14 ISSN: 2349-6495(P) | 2456-1908(O)

50MM 4.891 3.816 2.701 4. Principal stress declined and gave a positive response

60MM 4.867 3.8 2.69 for structural change.

70MM 4.84 3.8 2.69 5. Tresca values also dropped.

ACKNOWLEDGEMENTS

I extend my deepest gratitude to Mr. Sagar Jamle, Asst.

Prof., Department of Civil Engineering, Oriental

University, Indore, (M.P.) for providing all the necessary

facilities and feel thankful for his innovative ideas, which

led to successful completion of this work.

REFERENCES

[1] NehaKolate, Molly Mathew, Snehal

Mali(2014),Analysis and Design of RCC Box

Culvert,ISSN2229-5518, Vol.05, Issue 12

[2] A. C. Lande, K. Kamane, A.Mahadik(2015),Finite

Element Analysis of Box Culvert, ISSN2319-

5347,Vol. 04,Issue 01.

Graph.2: Tresca Values v/s Flared Thickness

[3] A. D. Patil, A. Galatage (2016), Analysisof Box

Culvert under Cushion Loading,ISSN(Print) 2394-

Table.3: For Analysis of Von miss in Box Culvert

1588, Vol. 03, Issue 06.

FLARED VONMISS IN (KN/MMSQ)

[4] Ajay R Polra, Prof. S. P. Chandresha, Dr. K. B.

PORTION CASE1 CASE2 CASE3 Parikh(2017),A Review Paper on Analysis and Cost

0MM 6.054 5.689 5.266 Comparison of Box Culvert for Different Aspect

10MM 4.326 4.326 2.717 Ratio of Cell, ISSN: 2231-5381, Vol. 44, Issue 03.

20MM 4.306 3.423 2.709 [5] Mr. AfzalHanif Sharif(2016), IJSDR,Review Paper

30MM 4.286 3.409 2.7 on Analysis and Designof Railway Box Bridge,

40MM 4.266 3.395 2.691 ISSN: 2455-2631,Vol.01, Issue 07.

50MM 4.246 3.381 2.682 [6] Shivan and Tenagi, Shreedhar(2015),Comparative

60MM 4.227 3.367 2.673 Study of Slab Culvert Design Using IRC 112:2011

70MM 4.2 3.367 2.673 and IRC 21:2000,ISSN(Online): 2321-0613, Vol.

03, Issue 05.

[7] Ketan Kishor Sahu, Shraddha Sharma

(2015),Comparison and Study of Different Aspect

Ratio of Box Culvert, ISSN(Online): 2321-0613,

Vol. 03, Issue 07.

[8] Mahesh D. Kakade, Rajkuwar A. Dubal (2017),A

Study of Behavior of RCC Box Culvert under the

Influence of Static and Dynamic Loads in

Accordance with IRC,ISSN: 2395-0056, Vol. 04

Issue: 10.

Graph.3: Von miss Values v/s Flared Thickness

VI. CONCLUSION

1. By usage of Staad pro software analysis of structure

was thoroughly done.

2. Shear values decreased on increment of flared

portion.

3. Vonmiss values decreased very fast and remained

constant on further increment of thickness.

www.ijaers.com Page | 105

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Climatic Rhythms and Prevalence of Malaria in The Municipality of Sinende in Northern BeninDocument8 pagesClimatic Rhythms and Prevalence of Malaria in The Municipality of Sinende in Northern BeninIJAERS JOURNALNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Enhancing Cybersecurity: The Power of Artificial Intelligence in Threat Detection and PreventionDocument6 pagesEnhancing Cybersecurity: The Power of Artificial Intelligence in Threat Detection and PreventionIJAERS JOURNALNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Beef Cattle Farmers' Economic Behavior in The Minahasa Tenggara Regency, IndonesiaDocument7 pagesBeef Cattle Farmers' Economic Behavior in The Minahasa Tenggara Regency, IndonesiaIJAERS JOURNALNo ratings yet

- Analysis of The Thermal Behavior of Masonry Concrete Block With Internal Natural Element CoatingDocument11 pagesAnalysis of The Thermal Behavior of Masonry Concrete Block With Internal Natural Element CoatingIJAERS JOURNALNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Economic Impact of Coronavirus Disease (COVID-19) : A Study On Tourism Indicators in The Kingdom of Saudi ArabiaDocument4 pagesThe Economic Impact of Coronavirus Disease (COVID-19) : A Study On Tourism Indicators in The Kingdom of Saudi ArabiaIJAERS JOURNALNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Facing Dengue and Malaria As A Public Health Challenge in BrazilDocument6 pagesFacing Dengue and Malaria As A Public Health Challenge in BrazilIJAERS JOURNALNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Impacts On The Mental Health of Professionals in A Prisonal System in Alagoas During The Covid-19 PandemicDocument7 pagesImpacts On The Mental Health of Professionals in A Prisonal System in Alagoas During The Covid-19 PandemicIJAERS JOURNALNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Childhood/ Pediatric Cancer: Nursing Care in Oncopediatrics With A Central Focus On HumanizationDocument12 pagesChildhood/ Pediatric Cancer: Nursing Care in Oncopediatrics With A Central Focus On HumanizationIJAERS JOURNALNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Business Logistics and The Relationship With Organizational SuccessDocument4 pagesBusiness Logistics and The Relationship With Organizational SuccessIJAERS JOURNALNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Associativism As Strategy of Reaching Territorial Rights, Programs, Projects and Public Policies of Rural Development: The Case of The São Francisco Do Mainã Community, Manaus, AMDocument9 pagesAssociativism As Strategy of Reaching Territorial Rights, Programs, Projects and Public Policies of Rural Development: The Case of The São Francisco Do Mainã Community, Manaus, AMIJAERS JOURNALNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Water Quality Assessment Using GIS Based Multi-Criteria Evaluation (MCE) and Analytical Hierarchy Process (AHP) Methods in Yenagoa Bayelsa State, NigeriaDocument11 pagesWater Quality Assessment Using GIS Based Multi-Criteria Evaluation (MCE) and Analytical Hierarchy Process (AHP) Methods in Yenagoa Bayelsa State, NigeriaIJAERS JOURNALNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Constructed Wetlands: Technology For Removing Drug Concentration From WaterDocument12 pagesConstructed Wetlands: Technology For Removing Drug Concentration From WaterIJAERS JOURNALNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Breastfeeding and Factors Associated With The Prevention of Childhood Obesity: An Integrative Literature ReviewDocument16 pagesBreastfeeding and Factors Associated With The Prevention of Childhood Obesity: An Integrative Literature ReviewIJAERS JOURNALNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Study of The Extraction Process of The Pleurotus Citrinopileatus Mushroom and Evaluation of The Biological Activity of The ExtractDocument8 pagesStudy of The Extraction Process of The Pleurotus Citrinopileatus Mushroom and Evaluation of The Biological Activity of The ExtractIJAERS JOURNALNo ratings yet

- Multiprofessional Care For A Patient With Gestational DiabetesDocument12 pagesMultiprofessional Care For A Patient With Gestational DiabetesIJAERS JOURNALNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Morphometric Analysis of The Ekole River As A Consequence of Climate Change: A Case Study in Yenagoa, Bayelsa State, NigeriaDocument9 pagesMorphometric Analysis of The Ekole River As A Consequence of Climate Change: A Case Study in Yenagoa, Bayelsa State, NigeriaIJAERS JOURNALNo ratings yet

- Process Sequence Optimization and Structural Analysis of Nanoscale Heterostructure Using Compound Semiconductors AlAsSb/In0.59Ga0.41As/GaAs0.53Sb0.47Document5 pagesProcess Sequence Optimization and Structural Analysis of Nanoscale Heterostructure Using Compound Semiconductors AlAsSb/In0.59Ga0.41As/GaAs0.53Sb0.47IJAERS JOURNALNo ratings yet

- Design and Building of Servo Motor Portable Coconut Peller MachineDocument5 pagesDesign and Building of Servo Motor Portable Coconut Peller MachineIJAERS JOURNALNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Association of Bacterial Vaginosis To Atypia in Squamous Cells of The CervixDocument15 pagesAssociation of Bacterial Vaginosis To Atypia in Squamous Cells of The CervixIJAERS JOURNALNo ratings yet

- Komla Uwolowudu Amegna: International Journal of Advanced Engineering Research and Science (IJAERS)Document9 pagesKomla Uwolowudu Amegna: International Journal of Advanced Engineering Research and Science (IJAERS)IJAERS JOURNALNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Mining and Its Impacts On Environment and Health With Special Reference To Ballari District, Karnataka, IndiaDocument7 pagesMining and Its Impacts On Environment and Health With Special Reference To Ballari District, Karnataka, IndiaIJAERS JOURNALNo ratings yet

- VCO Rancidity Analysis Refers To Fermentation Time That Produced by Gradual Heating MethodDocument6 pagesVCO Rancidity Analysis Refers To Fermentation Time That Produced by Gradual Heating MethodIJAERS JOURNAL100% (1)

- Detection and Control of Bacterial BiofilmsDocument15 pagesDetection and Control of Bacterial BiofilmsIJAERS JOURNALNo ratings yet

- Modeling of Geological and Geophysical Data, Onshore Field of Potiguar Basin, Northeastern BrazilDocument5 pagesModeling of Geological and Geophysical Data, Onshore Field of Potiguar Basin, Northeastern BrazilIJAERS JOURNALNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Does Blended Learning Approach Affect Madrasa Students English Writing Errors? A Comparative StudyDocument12 pagesDoes Blended Learning Approach Affect Madrasa Students English Writing Errors? A Comparative StudyIJAERS JOURNALNo ratings yet

- The Psychologist's Role in The Process of Listening To Children Victims of Sexual Violence in Legal ProceedingsDocument8 pagesThe Psychologist's Role in The Process of Listening To Children Victims of Sexual Violence in Legal ProceedingsIJAERS JOURNALNo ratings yet

- Sociodemographic and Clinical Profile of Women With Uterine Cervical Cancer Attended in An Oncological Hospital in The State of Acre, BrazilDocument9 pagesSociodemographic and Clinical Profile of Women With Uterine Cervical Cancer Attended in An Oncological Hospital in The State of Acre, BrazilIJAERS JOURNALNo ratings yet

- Humanization in Undergraduate Medical Education: The Brazilian Learner's PerspectiveDocument12 pagesHumanization in Undergraduate Medical Education: The Brazilian Learner's PerspectiveIJAERS JOURNALNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Assessment of The Risk of Cardiovascular Diseases and Its Relationship With Heart Rate Variability in Physically Active and Sedentary IndividualsDocument13 pagesAssessment of The Risk of Cardiovascular Diseases and Its Relationship With Heart Rate Variability in Physically Active and Sedentary IndividualsIJAERS JOURNALNo ratings yet

- Study Evaluating The Ability of Fe-BDC-PEG To Carry and Release Active Ingredient 5-FluorouracilDocument5 pagesStudy Evaluating The Ability of Fe-BDC-PEG To Carry and Release Active Ingredient 5-FluorouracilIJAERS JOURNALNo ratings yet

- ABSTrACT OF NEGOTIATION AND DETAILED ESTIMATEDocument61 pagesABSTrACT OF NEGOTIATION AND DETAILED ESTIMATEnathanieldagsaNo ratings yet

- Schedule of Beam and Slab For Ground Floor Top-ModelDocument1 pageSchedule of Beam and Slab For Ground Floor Top-Modeldhiraj patilNo ratings yet

- Financial Markets (Beginner Module)Document98 pagesFinancial Markets (Beginner Module)gauravNo ratings yet

- Transportation SCMDocument34 pagesTransportation SCMsharathNo ratings yet

- 1 PDFDocument3 pages1 PDFFatima Ja'aferNo ratings yet

- Complete Construction Cost of An A+ Category 1 Kanal House 2020Document15 pagesComplete Construction Cost of An A+ Category 1 Kanal House 2020Muhammad Taha JilaniNo ratings yet

- BMX Case Study For OperationsDocument7 pagesBMX Case Study For Operationsfarbwn100% (1)

- Hoja de Calculo para LosasDocument4 pagesHoja de Calculo para LosasRichard GuerreroNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Spread Sheet of Plate Girder-Is800-2007Document3 pagesSpread Sheet of Plate Girder-Is800-2007yedida v r aviswanadhNo ratings yet

- Steel Stud Installation GuideDocument6 pagesSteel Stud Installation GuiderfadeNo ratings yet

- Structural Assignment 2Document21 pagesStructural Assignment 2Praveen FernandoNo ratings yet

- Concrete Concrete Water Cement Aggregate AdmixtureDocument2 pagesConcrete Concrete Water Cement Aggregate AdmixtureRoihans Muhammad IqbalNo ratings yet

- Lecture 6 Design and Detailing of Specia PDFDocument26 pagesLecture 6 Design and Detailing of Specia PDFS. M. Habibul AhsanNo ratings yet

- Elective 3 Modular Activity 2Document7 pagesElective 3 Modular Activity 2Chrisneil DelosreyesNo ratings yet

- Saudi Arabian Oil Company: AbbreviationsDocument1 pageSaudi Arabian Oil Company: AbbreviationsAdel KhalilNo ratings yet

- Manpower RequirementsDocument12 pagesManpower Requirementslinga2014No ratings yet

- Car Chassis Basics and HowDocument11 pagesCar Chassis Basics and HowRafael Elles0% (1)

- Saic B 1002Document3 pagesSaic B 1002jerinNo ratings yet

- Lecture8 Geotechnical InvestigationDocument76 pagesLecture8 Geotechnical Investigationadia kajunaNo ratings yet

- Ar Ged 04 001 0Document1 pageAr Ged 04 001 0Bahaa MohamedNo ratings yet

- Takeoff Sheet: 1. Excavation and Earth Works A-SubstructureDocument48 pagesTakeoff Sheet: 1. Excavation and Earth Works A-Substructuremamuka kassa100% (1)

- E 10 K IN ME SP 001 009 - Transmittal - 20190313Document1 pageE 10 K IN ME SP 001 009 - Transmittal - 20190313Oscar Morato LópezNo ratings yet

- Understanding The PCB Drilling Process For Different Hole Types and Locations - TempoDocument10 pagesUnderstanding The PCB Drilling Process For Different Hole Types and Locations - TempoAldrin AtolleNo ratings yet

- Positioning West Bengal Asakey Logistics Hub: November 2018Document52 pagesPositioning West Bengal Asakey Logistics Hub: November 2018Sandeep ChatterjeeNo ratings yet

- Stuctural JHW Sms 100 CDDocument44 pagesStuctural JHW Sms 100 CDAkmalNo ratings yet

- 1200 - 12.plastering & PointingDocument10 pages1200 - 12.plastering & PointingSivakumar Arul0% (2)

- Mind Map ExampleDocument1 pageMind Map Examplemagiva873No ratings yet

- Above Ground Home ShelterDocument69 pagesAbove Ground Home ShelterwattajeffNo ratings yet

- Charmilles Edm Manual PDFDocument2 pagesCharmilles Edm Manual PDFsravan13% (16)

- Partition WallsDocument25 pagesPartition Wallssaransh yadavNo ratings yet