Professional Documents

Culture Documents

CBT Trolley Man

Uploaded by

JESUSCALVILLO0 ratings0% found this document useful (0 votes)

35 views3 pagesball bearing trolley

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentball bearing trolley

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

35 views3 pagesCBT Trolley Man

Uploaded by

JESUSCALVILLOball bearing trolley

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 3

BALL BEARING TROLLEY

SERVICE INSTRUCTIONS AND PARTS LIST

1/4 THRU 5 TON

MODELS CBTP AND CBTG

This trolley is a relatively simple mechanism requiring

comparatively tle care, maintenance, inspection and

lubrication. The following information is provided to

assist in installing and maintaining this equipment.

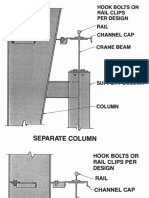

INSTALLATION

Sliding the trolley over the open end of the runway

beam is the simpiest way to install this unit. if an

open beam end is not available, one side plate can be

removed and the unit can be reassembled on the

beam. Always verly the trolley is adjusted property to

fit the beam. See the adjustment instructions below

and the diagram to the right. Always run the unit

along the entire length of the runway beam to verity

proper operation and clearances.

GENERAL MAINTENANCE

Thorough inspection is recommended at regular

intervals. The frequency of inspection must be

determined by the user, since application factors such

as duty cycle and ambient conditions will dictate the

maintenance requirements of the unit. When

inspections are made, the entire trolley should be

inspected for wear, or for damage such as may be

sustained through severe overloading or impact with

other objects. Replace ali damaged parts

immediately. Check trolley motion along the runway

beam, to verity proper operation.

LUBRICATING THE TROLLEY

4/4 thru 5 ton trolleys are built with sealed, life-time

lubricated precision bail bearings that should require

no further lubrication. Periodic lubrication of the

geared trolley drive shaft support block is

recommended. A small amount of medium grade

motor oil should be applied in the oll hote provided in

the top of the rive shaft support block.

‘ADJUSTMENT INSTRUCTIONS

The beam flange width plus approximately 1/16"

running clearance on each side of the flange is the

correct trolley setting with the total beam to wheel

flange clearance not to exceed 3/16". Move the

spacing washers to the inside or outside of the side

plates as required. Aiter adjustment, tighten the

trolley pin nuts and the locking nuts securely.

CAUTIOI

‘THE EQUIPMENT ILLUSTRATED AND DESCRIBED IN

‘THIS BULLETIN IS DESIGNED FOR MANUAL

‘OPERATION ONLY AND IS NOT TO BE POWER DRIVEN,

NOR IS IT SUITABLE FOR TRANSPORTING PERSONS!

ADJUSTMENT ILLUSTRATION

SPACING WASHERS

MAINTAIN CLEVIS

tokp'N CENTER OF TROLLEY

= TO AVOID INJURY —

oor aermre ToT aouMTOWER RANGE EAE

IMPORTANT

1/4 THRU 5 TON CAPACITY TROLLEY PARTS LIST

13

Q

a \

i

ps ®

GA

>

3 U

rac

a] re porto] ton yao | — TeX —]—ron

ne | __vesoneon__[RATRE TET BaRTH' arr PARROT PAR NOL GTY | PaRTHO' [OT

Ties srensy Tse |r { omer fap we | Tome ay co a

7 fea ter foe“ of ose foe omer [oer feomers oe meme fo

+ feos saline ¢-{eosorr (eel suse on Tomseer eet ones Tart

+ eeie te sf onan [gut woe ap [wes fost at

Ea

a

+f ons a

a

ao teem -o tone tne 8

ees Pee fae to omer tte

ere meme ane of

foe ear an —[ Poti fanaa facie | me a

$b Gaomensua [ot 1-6 [rane [e-waste [oe fee ar [ee fo

t[osieane es Bes [ares | ee arses Tooter a [anon fo

$e se entanar| eo [ants [eens [oer reais et fons oe

ir posearees Bee farts [een woes oe [een aeons

ities ahs eT esr {at ese [of wsmeeo at or Tat

72 |Handuhoel Retaining Pia va | 0 | optaa052 | o(1) | oet408e | o(1) | ootaa0se | ot) | 09134052 | om)

13. [Hand Ghein(specty length) | mwa {0 | 04907654 [oqi) | 04907664 | o(1) | 04907654 | oc) | 04907054 | Olt)

44 [Hand Chain Connecting Link a 0 {| o0a04733 | 01) | 00404733 | 0/1) | 00404733 T 0(1) | 0404733 | 0(1)

on was 1 taser ( oaemes [Pee were |

ie fee ne

ie freien —[osuapar|-+-[eornse-{-+-Losnetr | 4-[osnser +f osnie [2

te free barar [otras [tomes -{ a {eotstae | a Tooses [or [esas | oe

3 featioee Sous [wees [-«-[wocsnes {a feonone [avon {2

alas Seon staesss [+ |oeaoe [stoners | +f osm | $

NOTE: QUANTITIES SHOWN FOR PLAIN UNITS. GEARED QUANTITIES ARE SHOWN IN BRACKETS ()-

‘YW TON AND ¥s TON TROLLEY AVAILABLE IN PLAIN STYLE ONLY.

COFFING HOIST, P.O. BOX 449, WADESBORO, NC 28170 PHONE: (800) 477-5003

(CM HOIST, 140 JOHN JAMES AUDUBON PARKWAY, AMHERST, NY 14228 PHONE: (600) 888-0985

YALE/LIFT-TECH , P.O. BOX 769, MUSKEGON, MI 49443 PHONE: (600) 742-9269

w

Trolley Type: STP/STG 1%-5 Metric Ton (

c

Technical Data STP

Metric Capacity fon] 172 1 2 3 5

Beam Width Range |"in. | 20-87 | 25-87 | 23-87 | 30-87 | 35-87

Max. Fig. Thickness | in. |__.75 75: 75 1.0 1.0

Min. Radius Curve | in. | 27 36, 45 55 70

Unit Weight Ib. 19 26 46. 86, 130

Technica Data STG

Metric Capacity [ton] 2 3 5

Beam Width Range | in. ic 2.3-8.7 3.0-8.7 3.5-8.7

Max, Fig. Thickness | in. oh 75 1.0 1.0

Min. Radius Curve in. iat 45 55 70

Unit Weight™ tb] = 55 100 144

* (includes 15 ft of handchain)

Dimensions in inches

wane, | af e fo] o [tole | « LK e] m [ [obe

Metric Ton STG

ve [3.94] 3.54/7.18/77.87 2.36 | 2.83 31 | 7.56 | 71

4.93 | 5.12 |1.38]12.20]9.602.36| 2.83503] 31] 0.84 | 71 [438

1

2 5.12 6.91 | 1.89 12.60|3.56/3.15/ 3.78 [3.86] 47 |11.81| .79 | 4.33,

3 6.18 [7.09 [2.36] 13.39] 4.23| 4.41 | 5.20 | 6.24) 56 [14.57] 1.14|4.33

5 7.09 [8.23 [2.76] 13.78 | 5.89 | 4.92] 5.63 | 5.87] .79 [17.32] 1.26| 4.33

Yale Industrial Products GmbH 26.07.04/Schon

CaDrcaments and SetingslaVoca Setingsempocaryftret FlesOLKGEATechie Data. doe

You might also like

- 900 263 49 CAT. Demag Gearmotor SystemDocument12 pages900 263 49 CAT. Demag Gearmotor SystemJESUSCALVILLONo ratings yet

- Rmproductcode JUNIO 2018Document27 pagesRmproductcode JUNIO 2018JESUSCALVILLONo ratings yet

- CCEZmanDocument14 pagesCCEZmanJESUSCALVILLONo ratings yet

- CCEZplusmanDocument23 pagesCCEZplusmanJESUSCALVILLONo ratings yet

- HPL500 PDFDocument2 pagesHPL500 PDFJESUSCALVILLONo ratings yet

- Manual 83510Document9 pagesManual 83510JESUSCALVILLONo ratings yet

- Relay CatalogueDocument1 pageRelay CatalogueJESUSCALVILLONo ratings yet

- Configure One BB3: CTO Model DefinitionDocument5 pagesConfigure One BB3: CTO Model DefinitionJESUSCALVILLONo ratings yet

- Relay CatalogueDocument1 pageRelay CatalogueJESUSCALVILLONo ratings yet

- Icd Ebdrumbrake CatalogDocument6 pagesIcd Ebdrumbrake CatalogJESUSCALVILLONo ratings yet

- Aluminum Chain Hoists - March 1987 113534-01 PDFDocument14 pagesAluminum Chain Hoists - March 1987 113534-01 PDFJESUSCALVILLONo ratings yet

- Lever Operated Hoists - Nov 1997 113536-18Document24 pagesLever Operated Hoists - Nov 1997 113536-18JESUSCALVILLONo ratings yet

- HiCap Army Type Trolley - Nov 1998 113534-13Document24 pagesHiCap Army Type Trolley - Nov 1998 113534-13JESUSCALVILLONo ratings yet

- SNGL GRDR Crane BRDG Kits Electrical-113533-74Document8 pagesSNGL GRDR Crane BRDG Kits Electrical-113533-74JESUSCALVILLONo ratings yet

- Aluminum Chain Hoists - March 1987 113534-01Document14 pagesAluminum Chain Hoists - March 1987 113534-01JESUSCALVILLONo ratings yet

- Spare Parts List: Lever Hoists & Chain HoistsDocument8 pagesSpare Parts List: Lever Hoists & Chain HoistsJESUSCALVILLONo ratings yet

- Wiring Diagrams FOR Bridge Control Panels: Bridge W/D'sDocument16 pagesWiring Diagrams FOR Bridge Control Panels: Bridge W/D'sJESUSCALVILLONo ratings yet

- Lever Operated Hoist - Oct 1997 113536-14Document16 pagesLever Operated Hoist - Oct 1997 113536-14JESUSCALVILLONo ratings yet

- Lever Operated Hoists - May 1977 113536-10Document16 pagesLever Operated Hoists - May 1977 113536-10JESUSCALVILLONo ratings yet

- 128-Top Running Cross Section PDFDocument3 pages128-Top Running Cross Section PDFJESUSCALVILLONo ratings yet

- Electric Hoist - June 1973 113534-37Document28 pagesElectric Hoist - June 1973 113534-37JESUSCALVILLONo ratings yet

- Electric Hoists - June 1971 17010-37D-71Document28 pagesElectric Hoists - June 1971 17010-37D-71JESUSCALVILLONo ratings yet

- Crane Kits Specifications CSL1003 0206Document28 pagesCrane Kits Specifications CSL1003 0206JESUSCALVILLONo ratings yet

- 06 BrakesDocument31 pages06 BrakesJESUSCALVILLONo ratings yet

- Boletin13 enDocument9 pagesBoletin13 enJESUSCALVILLONo ratings yet

- Electric Wire Rope Winch MachineDocument3 pagesElectric Wire Rope Winch MachineJESUSCALVILLONo ratings yet

- Index:: 1) Gt09 Wheel Diameter 90 MMDocument14 pagesIndex:: 1) Gt09 Wheel Diameter 90 MMJESUSCALVILLONo ratings yet

- Folleto de PolipastosDocument8 pagesFolleto de PolipastosJESUSCALVILLONo ratings yet

- STAHL ST Electric HoistsDocument5 pagesSTAHL ST Electric HoistsJESUSCALVILLONo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)