Professional Documents

Culture Documents

Methods of Inspection For Finding Out Defects in Casting

Uploaded by

Ashok PradhanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Methods of Inspection For Finding Out Defects in Casting

Uploaded by

Ashok PradhanCopyright:

Available Formats

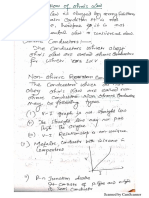

Methods of Inspection for Finding Out Defects in Casting

Different methods of inspection for finding out defects in casting process are discussed below

1. Visual Inspection

2. Hydrostatic Pressure Test

3. Magnetic Particle Inspection

4. Radiographic Examination

5. Ultrasonic inspection

6. Dye Penetrant Inspection

7. Coin Testing

1. Visual Inspection

Common defects such as surface roughness, obvious shifts, the omission of cores and surface cracks can be

detected by a visual inspection of the casting. Cracks may also be detected by hitting the casting with a

mallet and listening to the quality of the tone produced.

2. Hydrostatic Pressure Test

The Hydrostatic pressure test is conducted on a casting to be used as a pressure vessel.

In this test, first, all the flanges and ports are blocked.

Then the casting is filled with water, oil or compressed air, Thereafter, the casting is submerged in a

soap solution when any leak will be evident by the bubbles that come out.

3. Magnetic Particle Inspection

The Magnetic particle test is conducted to check for very small voids and cracks at or just below the surface

of a ferromagnetic material. The test involves inducing a magnetic field through the section inspection. this

done, the powdered ferromagnetic material is spread out onto the surface. The presence of voids or cracks in

the section results in an abrupt change in the permeability of the surface; this, in turn, causes a leakage in the

magnetic field. The powdered particles accumulate on the disrupted magnetic field, outlining the boundary

of a discontinuity.

4. Radiographic Examination

The radiographic method is expensive and is used only for sub surface exploration. In this, both X-rays

and γ-rays are used. With γ-rays, more than one film can be exposed simultaneously; however, x-ray pictures

are more distinct. Various defects, like voids, nonmetallic inclusions, porosity, cracks, and tears, can be

detected by this method. The defects being less dense, the film appears darker in contrast to the surrounding.

5. Ultrasonic Inspection

In the Ultrasonic method, an oscillator is used to send an ultrasonic signal through the casting. such as signal

is readily transmitted through a homogeneous medium. However, on encountering a discontinuity, the signal

is reflected back. This reflected signal is then detected by an ultrasonic detector. The time interval between

sending the signal and receiving its reflection determines the location of the discontinuity. the method is not

very suitable for a material with a high damping capacity (e.g. cast iron) because in such a case the signal

gets considerably weakened over some distance.

6. Dye Penetrant Inspection (DPI)

The dye penetrant inspection method is used to detect invisible surface defects in a non-magnetic casting.

The casting is brushed with, sprayed with, or dipped into a dye containing a fluorescent material. The

surface to be inspected is the wiped, dried and viewed in darkness. The discontinuous in the surface will then

be readily discernible.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Oscillations PDFDocument12 pagesOscillations PDFRaviKumarNo ratings yet

- Form 4 Add Maths Chapter 1Document25 pagesForm 4 Add Maths Chapter 1Azhar GameMaster100% (1)

- 33 ch6Document13 pages33 ch6swccgopalNo ratings yet

- Examples On Mathematical Induction: Trigonometry: Sin Sin 1 SinDocument11 pagesExamples On Mathematical Induction: Trigonometry: Sin Sin 1 SinAshok PradhanNo ratings yet

- M¡ (VH$ (DKMZ (G¡Õmpývh$) : ZmoqDocument37 pagesM¡ (VH$ (DKMZ (G¡Õmpývh$) : ZmoqAshok PradhanNo ratings yet

- COLUMMNDocument2 pagesCOLUMMNAshok PradhanNo ratings yet

- 12 Physics Lyp 2016 Central Outside Delhi Set3Document7 pages12 Physics Lyp 2016 Central Outside Delhi Set3Ashok PradhanNo ratings yet

- (Zym© (Av G Kêq O A (Yh$V A H$Document30 pages(Zym© (Av G Kêq O A (Yh$V A H$Ashok PradhanNo ratings yet

- State Biot Servat Law and Hence Obtain An Expression For The Magnetic Induction Produced by Infinite Long Current Carrying Conductor at Any Point Near ItDocument5 pagesState Biot Servat Law and Hence Obtain An Expression For The Magnetic Induction Produced by Infinite Long Current Carrying Conductor at Any Point Near ItAshok PradhanNo ratings yet

- Strength of Materials: Er. S K MondalDocument3 pagesStrength of Materials: Er. S K MondalAshok PradhanNo ratings yet

- Solution, Success Study CircleDocument4 pagesSolution, Success Study CircleAshok PradhanNo ratings yet

- Curret 2Document2 pagesCurret 2Ashok PradhanNo ratings yet

- Cold Working and AnnealingDocument10 pagesCold Working and AnnealingAshok PradhanNo ratings yet

- Comparison Between Edge and Screw DislocationDocument5 pagesComparison Between Edge and Screw DislocationAshok PradhanNo ratings yet

- Manufacturing Process 1 Question BankDocument6 pagesManufacturing Process 1 Question BankAshok PradhanNo ratings yet

- Weekly Test July MMMMMMMMDocument2 pagesWeekly Test July MMMMMMMMAshok PradhanNo ratings yet

- Cold Working and AnnealingDocument10 pagesCold Working and AnnealingAshok PradhanNo ratings yet

- Cold Working and AnnealingDocument10 pagesCold Working and AnnealingAshok PradhanNo ratings yet

- Cold Working and AnnealingDocument10 pagesCold Working and AnnealingAshok PradhanNo ratings yet

- Comparison Between Edge and Screw DislocationDocument5 pagesComparison Between Edge and Screw DislocationAshok PradhanNo ratings yet

- Cold Working and AnnealingDocument10 pagesCold Working and AnnealingAshok PradhanNo ratings yet

- Reproduction in OrganismsDocument10 pagesReproduction in OrganismsAshok PradhanNo ratings yet

- Surprize TestDocument3 pagesSurprize TestAshok PradhanNo ratings yet

- L No 01Document38 pagesL No 01Annas Equity AnalystNo ratings yet

- Cold Working and AnnealingDocument10 pagesCold Working and AnnealingAshok PradhanNo ratings yet

- Moving Coil GalvanometerDocument5 pagesMoving Coil GalvanometerAshok PradhanNo ratings yet

- Chapter7cor1 2Document19 pagesChapter7cor1 2senthilkumar100No ratings yet

- Ess at 12 CN StuDocument11 pagesEss at 12 CN Stujsmith012xNo ratings yet

- Current ElectricityDocument2 pagesCurrent ElectricityAshok PradhanNo ratings yet

- OpticsDocument6 pagesOpticsAshok PradhanNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Proposed Revisions To Usp Sterile Product - Package Integrity EvaluationDocument56 pagesProposed Revisions To Usp Sterile Product - Package Integrity EvaluationDarla Bala KishorNo ratings yet

- REE0913ra LegazpiDocument6 pagesREE0913ra LegazpiScoopBoyNo ratings yet

- Blender To Google EarthDocument41 pagesBlender To Google Earthrichx7No ratings yet

- ESL Discussion Questions To Practise IdiomsDocument5 pagesESL Discussion Questions To Practise IdiomsElaine Mc AuliffeNo ratings yet

- Tillotson HD & HR Service ManualDocument11 pagesTillotson HD & HR Service ManualBeckyNo ratings yet

- Auto CadDocument24 pagesAuto Cadkanchan Redas RedasNo ratings yet

- Cast Your HoroscopeDocument27 pagesCast Your HoroscopeSunil ShastriNo ratings yet

- Interzinc 2280 Product BrochureDocument4 pagesInterzinc 2280 Product BrochureAshish Raul CIENo ratings yet

- The Symbols Found in TarotDocument17 pagesThe Symbols Found in TarotPEdro100% (1)

- MantrasDocument45 pagesMantrasharibhakta100% (1)

- User Manual For Emvólio: WWW - Blackfrog.InDocument22 pagesUser Manual For Emvólio: WWW - Blackfrog.InmariaNo ratings yet

- DuranDuran OrdinaryWorldDocument1 pageDuranDuran OrdinaryWorldEduardo LuzNo ratings yet

- Systems of Linear Equations With Two VariablesDocument34 pagesSystems of Linear Equations With Two VariablesFatima KausarNo ratings yet

- Designing Hopping Animal PDFDocument3 pagesDesigning Hopping Animal PDFAntonio Francisco Muñoz100% (1)

- Honda Bikes and ScootersDocument6 pagesHonda Bikes and ScootersShamrjit AgrahariNo ratings yet

- Booster Mock Test For NEETDocument15 pagesBooster Mock Test For NEETDrNo ratings yet

- Neurology Condition Assessment Methods: Guillain-Barre Syndrome (GBS) Disability ScoreDocument15 pagesNeurology Condition Assessment Methods: Guillain-Barre Syndrome (GBS) Disability ScoreMrinmayeeDeshmukhNo ratings yet

- Shell Omala S2 GX 150: Performance, Features & Benefits Main ApplicationsDocument2 pagesShell Omala S2 GX 150: Performance, Features & Benefits Main ApplicationsVelibor KaranovicNo ratings yet

- Concrete Tunnel Design and Calculation Spreadsheet Based On AASHTO and ACIDocument3 pagesConcrete Tunnel Design and Calculation Spreadsheet Based On AASHTO and ACIFirat PulatNo ratings yet

- Woodcock 1987Document37 pagesWoodcock 1987Rodrigo MachadoNo ratings yet

- Marine Upholstery SpecsDocument1 pageMarine Upholstery SpecsRezza KurniawanNo ratings yet

- Ketron 1000 PEEK PDS E 30032019 01Document1 pageKetron 1000 PEEK PDS E 30032019 01jorgepradaco1No ratings yet

- ERIC Section4 Hadrian - C. AlbinusDocument83 pagesERIC Section4 Hadrian - C. AlbinusDarko SekulicNo ratings yet

- Sri Vidya College of Engineering & Technology Virudhunagar: Department: Semester: Vi SUBJECT CODE / Name: CE 6602Document34 pagesSri Vidya College of Engineering & Technology Virudhunagar: Department: Semester: Vi SUBJECT CODE / Name: CE 6602JEYA KUMARNo ratings yet

- The Rheological Properties of Ketchup As A Function of Different Hydrocolloids and TemperatureDocument8 pagesThe Rheological Properties of Ketchup As A Function of Different Hydrocolloids and TemperatureVicente WiethNo ratings yet

- Baño - Griferia - KOHLER - K-74013M+0.50GPMDocument3 pagesBaño - Griferia - KOHLER - K-74013M+0.50GPMGiordano Tuanama YapoNo ratings yet

- Quiz13 130630200754 Phpapp02Document10 pagesQuiz13 130630200754 Phpapp02anukrititiwaNo ratings yet

- 0900-9914 I1 201012 PDFDocument132 pages0900-9914 I1 201012 PDFIvan Arjona50% (2)

- Serial Interface RS485 (RS422) Configuration InstructionsDocument20 pagesSerial Interface RS485 (RS422) Configuration Instructionsyana sopian hidayatNo ratings yet

- Installation Instructions: Harley-Davidson Softail Saddlebag Mount Bracket PART# 21946Document4 pagesInstallation Instructions: Harley-Davidson Softail Saddlebag Mount Bracket PART# 21946Justin StewartNo ratings yet