Professional Documents

Culture Documents

Ashlar

Uploaded by

سامح الجاسم0 ratings0% found this document useful (0 votes)

23 views2 pagesIf applying directly to existing brickwork /blockwork / render surface, the substrate must be brushed down to remove any friable material, algae or lichen and fungicidal.

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentIf applying directly to existing brickwork /blockwork / render surface, the substrate must be brushed down to remove any friable material, algae or lichen and fungicidal.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

23 views2 pagesAshlar

Uploaded by

سامح الجاسمIf applying directly to existing brickwork /blockwork / render surface, the substrate must be brushed down to remove any friable material, algae or lichen and fungicidal.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

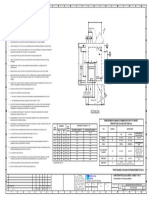

Apsirend - Ashlar Detailing

WBS ASHLAR DETAILING ONTO NEW / EXIST-

ING BLOCKWORK

FOR REFURBISHMENT ONLY APPLICATIONS

If applying directly to existing brickwork /blockwork / render surface, the

substrate must be brushed down to remove any friable material, algae or lichen

and fungicidal wash should then be applied. Any ridges or protrusions should be

removed and hollows filled to provide a smooth surface.

FOR REFURBISHMENT & NEW BUILD

APPLICATIONS

• Stabilising solution may be applied if required to help

improve adhesion and offer uniform suction.

• Install all beads and trims using approved WBS fixings

at a maximum of 300mm centres (depending on the

substrate – please consult WBS technical department

for assistance).

• Mix basecoat to a pliable consistency using

approximately 4-5 litres of clean water per 25kg bag. A

suitable measuring bucket ensures the correct quantity

and accuracy each time. Ensure that the basecoat

is mixed thoroughly – it takes at least 10 minutes to

dissolve the powder additives. Note how the dryish mix

becomes creamy after several minutes. Mix will normally

be slightly sticky.

• Note: Renders with a high polymer content should be

left to stand for 10-15 minutes and be remixed to break

the initial set.

• Do not add anything to the mix other than clean water.

• Trowel apply initial coat to substrate, dubbing out to a

minimum of 8mm (or to architect’s specification) until a

level surface is achieved.

• Bed in alkali resistant reinforcing mesh into top third

of basecoat (if required), ensuring that an overlap of a

minimum of 75mm is achieved.

• When basecoat is dry, apply additional stress patches

and corner reinforcements across all window and door

openings at a 45° angle.

• Tidy up base rails and profiles with a damp paint brush

or similar to ensure a professional finish.

Apsirend - Ashlar Detailing - Page 2

• Lightly scratch basecoat surface with a scratch comb to

provide a key for finishing coat.

• Mix coloured mortar coat with clean water as per

manufacturers instructions.

• Apply render 16-20mm thick ensuring that it is finished

proud of all profiles.

• A darby or straight edged tool may be used to ensure a

relatively uniform thickness, then smoothed out using a

plastic float.

• To achieve a smooth ashlar finish

• When green (set but not fully hardened), form cuts in

the render using an ashlar cutting tool (various types are

available).

• A minimum of 10mm of render should be left between

the recessed ashlar joints and the substrate.

• To achieve an open stone ashlar finish

• Take care to avoid even small hollows, which make a good finish difficult to

achieve. Hollows should not be filled out if a skin has formed, as it will

spoil the finish.

• Scratching should take place when the render is

considered green (i.e. set but not fully hardened). The

exact timing of this operation varies according to weather

conditions and can be anything from 4-48 hours, however

usually the next day is considered adequate.

• When green, remove approximately 1-2mm of the surface

with a nail float, in an even circular motion, to achieve the

scratched texture finish. Render should be dry enough

not to stick to the nail float.

• When dry, brush down with a soft brush to remove any

loose material. This will also highlight any unscraped

areas which must be scraped at the same time to avoid

colour variations.

• If scrape patterns or marks are observed, they should be

softened by gently scraping or brushing. Loose material

that has been scraped from the wall may aslo be used to

repair small blemishes at this stage.

Provided strictly for guidance purposes only. For technical

support please call 08458 382380.

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Wind Turbine MaintenanceV47Document4 pagesWind Turbine MaintenanceV47سامح الجاسمNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Wind Turbine Vestas - V47Document6 pagesWind Turbine Vestas - V47سامح الجاسمNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- VestasOperatingManual 1Document37 pagesVestasOperatingManual 1سامح الجاسمNo ratings yet

- Wbs Brick Effect Render Onto New / Existing BlockworkDocument2 pagesWbs Brick Effect Render Onto New / Existing Blockworkسامح الجاسمNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Carrier Brochure en 2017Document72 pagesCarrier Brochure en 2017سامح الجاسمNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Epsirend FT - Smooth Finish: Epsirend (FT) Render Onto New / Existing Block-WorkDocument1 pageEpsirend FT - Smooth Finish: Epsirend (FT) Render Onto New / Existing Block-Workسامح الجاسمNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Epsitec (SFS, EPS Insulation, Silicone) : Wbs Roughcast Onto New / Existing Block-WorkDocument1 pageEpsitec (SFS, EPS Insulation, Silicone) : Wbs Roughcast Onto New / Existing Block-Workسامح الجاسمNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Humidification and Evaporative Cooling SystemsDocument106 pagesHumidification and Evaporative Cooling Systemsسامح الجاسمNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Wbs Dry Dash Finish Onto New / Exist-Ing BlockworkDocument1 pageWbs Dry Dash Finish Onto New / Exist-Ing Blockworkسامح الجاسمNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Condensing Dehumidifier ManualDocument44 pagesCondensing Dehumidifier Manualسامح الجاسمNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Steam Humidification Systems ManualDocument52 pagesSteam Humidification Systems Manualسامح الجاسمNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Direct Steam Injection HumidifierDocument41 pagesDirect Steam Injection Humidifierسامح الجاسم100% (1)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Rotary Comp PDFDocument44 pagesRotary Comp PDFسامح الجاسمNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Industrial Heat Flux SensorDocument27 pagesIndustrial Heat Flux Sensorسامح الجاسمNo ratings yet

- Needle Type Heat Flux and Temperature SensorDocument31 pagesNeedle Type Heat Flux and Temperature Sensorسامح الجاسمNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Self-Calibrating Heat Flux SensorDocument39 pagesSelf-Calibrating Heat Flux Sensorسامح الجاسمNo ratings yet

- Flare Radiation MonitorDocument27 pagesFlare Radiation Monitorسامح الجاسمNo ratings yet

- User Manual Hf03-Li19: HuksefluxDocument25 pagesUser Manual Hf03-Li19: Huksefluxسامح الجاسمNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Heat Flux SenserDocument35 pagesHeat Flux Senserسامح الجاسمNo ratings yet

- User Manual: RHF SeriesDocument21 pagesUser Manual: RHF Seriesسامح الجاسمNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Rock Valve BrochureDocument8 pagesRock Valve Brochureسامح الجاسمNo ratings yet

- User Manual: HFP01 & HFP03Document43 pagesUser Manual: HFP01 & HFP03سامح الجاسمNo ratings yet

- LoadMatch Temperature Cascade2Document3 pagesLoadMatch Temperature Cascade2سامح الجاسمNo ratings yet

- Heat Flux and Temperature SensorDocument23 pagesHeat Flux and Temperature Sensorسامح الجاسمNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Student Exploration: Inclined Plane - Simple MachineDocument9 pagesStudent Exploration: Inclined Plane - Simple MachineLuka MkrtichyanNo ratings yet

- The Influence of Irish Monks On Merovingian Diocesan Organization-Robbins BittermannDocument15 pagesThe Influence of Irish Monks On Merovingian Diocesan Organization-Robbins BittermanngeorgiescuNo ratings yet

- Canon Powershot S50 Repair Manual (CHAPTER 4. PARTS CATALOG) PDFDocument13 pagesCanon Powershot S50 Repair Manual (CHAPTER 4. PARTS CATALOG) PDFRita CaselliNo ratings yet

- Amount of Casien in Diff Samples of Milk (U)Document15 pagesAmount of Casien in Diff Samples of Milk (U)VijayNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Lecture2 GranulopoiesisDocument9 pagesLecture2 GranulopoiesisAfifa Prima GittaNo ratings yet

- Modlist - Modlist 1.4Document145 pagesModlist - Modlist 1.4Tattorin vemariaNo ratings yet

- Notes:: Reinforcement in Manhole Chamber With Depth To Obvert Greater Than 3.5M and Less Than 6.0MDocument1 pageNotes:: Reinforcement in Manhole Chamber With Depth To Obvert Greater Than 3.5M and Less Than 6.0Mسجى وليدNo ratings yet

- 2014 - A - Levels Actual Grade A Essay by Harvey LeeDocument3 pages2014 - A - Levels Actual Grade A Essay by Harvey Leecherylhzy100% (1)

- Rifle May 2015 USADocument72 pagesRifle May 2015 USAhanshcNo ratings yet

- Week 4 - Theoretical Framework - LectureDocument13 pagesWeek 4 - Theoretical Framework - LectureRayan Al-ShibliNo ratings yet

- Subject Manual Tle 7-8Document11 pagesSubject Manual Tle 7-8Rhayan Dela Cruz DaquizNo ratings yet

- Sept Dec 2018 Darjeeling CoDocument6 pagesSept Dec 2018 Darjeeling Conajihah zakariaNo ratings yet

- Genetics Icar1Document18 pagesGenetics Icar1elanthamizhmaranNo ratings yet

- 1 - 2020-CAP Surveys CatalogDocument356 pages1 - 2020-CAP Surveys CatalogCristiane AokiNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- MCI Approved Medical College in Uzbekistan PDFDocument3 pagesMCI Approved Medical College in Uzbekistan PDFMBBS ABROADNo ratings yet

- Miniature Daisy: Crochet Pattern & InstructionsDocument8 pagesMiniature Daisy: Crochet Pattern & Instructionscaitlyn g100% (1)

- Nadee 3Document1 pageNadee 3api-595436597No ratings yet

- Final Project Strategic ManagementDocument2 pagesFinal Project Strategic ManagementMahrukh RasheedNo ratings yet

- postedcontentadminuploadsFAQs20for20Organization PDFDocument10 pagespostedcontentadminuploadsFAQs20for20Organization PDFMohd Adil AliNo ratings yet

- Sample Monologues PDFDocument5 pagesSample Monologues PDFChristina Cannilla100% (1)

- Sem4 Complete FileDocument42 pagesSem4 Complete Fileghufra baqiNo ratings yet

- CV & Surat Lamaran KerjaDocument2 pagesCV & Surat Lamaran KerjaAci Hiko RickoNo ratings yet

- Pidsdps 2106Document174 pagesPidsdps 2106Steven Claude TanangunanNo ratings yet

- BSC HTM - TourismDocument4 pagesBSC HTM - Tourismjaydaman08No ratings yet

- Export Management EconomicsDocument30 pagesExport Management EconomicsYash SampatNo ratings yet

- B I o G R A P H yDocument17 pagesB I o G R A P H yRizqia FitriNo ratings yet

- Lieh TzuDocument203 pagesLieh TzuBrent Cullen100% (2)

- 2022 Mable Parker Mclean Scholarship ApplicationDocument2 pages2022 Mable Parker Mclean Scholarship Applicationapi-444959661No ratings yet

- Standard Answers For The MSC ProgrammeDocument17 pagesStandard Answers For The MSC ProgrammeTiwiNo ratings yet

- Contents EEMUA Publication 190 Edition1 May 2015Document4 pagesContents EEMUA Publication 190 Edition1 May 2015Aditya JainNo ratings yet

- Edward's Menagerie New Edition: Over 50 easy-to-make soft toy animal crochet patternsFrom EverandEdward's Menagerie New Edition: Over 50 easy-to-make soft toy animal crochet patternsNo ratings yet

- 100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiFrom Everand100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiRating: 5 out of 5 stars5/5 (2)

- House Rules: How to Decorate for Every Home, Style, and BudgetFrom EverandHouse Rules: How to Decorate for Every Home, Style, and BudgetNo ratings yet

- Crochet Southwest Spirit: Over 20 Bohemian Crochet Patterns Inspired by the American SouthwestFrom EverandCrochet Southwest Spirit: Over 20 Bohemian Crochet Patterns Inspired by the American SouthwestRating: 5 out of 5 stars5/5 (2)

- Crochet Creatures of Myth and Legend: 19 Designs Easy Cute Critters to Legendary BeastsFrom EverandCrochet Creatures of Myth and Legend: 19 Designs Easy Cute Critters to Legendary BeastsRating: 4.5 out of 5 stars4.5/5 (10)

- The Martha Manual: How to Do (Almost) EverythingFrom EverandThe Martha Manual: How to Do (Almost) EverythingRating: 4 out of 5 stars4/5 (11)