Professional Documents

Culture Documents

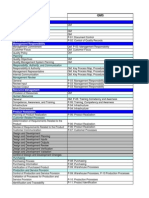

Lear-75-GM Quality System Basics Audit Form

Uploaded by

sebastian lureCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lear-75-GM Quality System Basics Audit Form

Uploaded by

sebastian lureCopyright:

Available Formats

General Motors

QUALITY SYSTEMS BASICS AUDIT

SUPPLIER: DATE:

SUPPLIER DUNS NO:

SUPPLIER LOCATION: AUDITOR:

SUPPLIER CONTACT:

CONTACT EMAIL: EMAIL:

This audit corresponds to the current Quality Systems Basics requirements as defined in the QSB presentation

revised in March, 2009. This audit applies to all suppliers regardless of which revision of the QSB presentation was

used for training. The new presentation contains several new requirements which are included in this audit. This

audit supersedes any previous audit and presentation revisions. If a QSB audit was conducted using the audit form

approved for use at that time and prior to this revision date, it is should not be necessary to repeat the entire audit

unless it has been longer than 2 years.

AUDIT SUMMARY

POTENTIAL AUDIT

KEY STRATEGIES STATUS IS CORRECTIVE ACTION REQUIRED

SCORE SCORE

1.0 FAST RESPONSE NR

0 0

CONTROL OF

2.0 NR

NONCONFORMING PRODUCT 0 0

3.0 VERIFICATION STATIONS NR

0 0

4.0 STANDARDIZED OPERATIONS NR

0 0

5.0 OPERATOR TRAINING NR

0 0

ERROR PROOFING

6.0 NR

VERIFICATION 0 0

7.0 LAYERED PROCESS AUDITS NR

0 0

8.0 RISK REDUCTION NR

0 0

9.0 CONTAMINATION CONTROL NR

0 0

10.0 SUPPLY CHAIN MANAGEMENT NR

0 0

11.0 MANAGING CHANGE NR

0 0

TOTAL SCORE 0 0

Audit status is equal to

AUDIT STATUS the lowest color status of NR

the above strategies.

Note: YELLOW and RED status on any question requires corrective actions.

Follow-up may be done on site or via E-mail; at the auditor's discretion.

Application of this audit's requirements, including requirements added after

December 31, 2008, and the results to the supplier's status is at Supplier Quality's discretion.

STATUS FOR INDIVIDUAL QUESTIONS

R 0 - No implementation: Corrective Action Required

R 1 - Written implementation plan: Corrective Action Required, or

R 2 - In place, not followed: Corrective Action Required.

Y 3 - YELLOW: requirement partially implemented

G 4 - GREEN: requirement met

Note: Potential & Audit Scores are entered automatically from audit sheet..

QSB Audit form 07.04 Rev 20090213

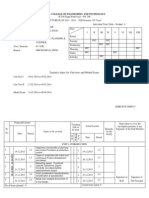

QUALITY SYSTEMS BASICS AUDIT

# EVIDENCE REQUIRED LOOK FOR… COMMENTS SCORE R/Y/G

1.0 FAST RESPONSE: PROBLEM SOLVING, COMMUNICATION and LESSONS LEARNED

Is there a system in place to immediately respond to significant internal and external quality failures?

Daily leadership meeting ON THE SHOP FLOOR:

Addresses significant Quality concerns. 1) Prior to the meeting review the board:

Owned by Manufacturing - for report out dates and statusing to see if any are past due,

Designates owners. statused appropriately with detail explaining missed dates.

Assigns report out dates. - Ask if there are any new issues.

Cross-functional, multilevel attendees. 2) Observe the report out process and verify that the Problem Solving

report format is used to document & communicate the status of the

issue.

3) Sign-in Sheet identifying cross-functional & plant wide support is in

1.1 attendance daily. NR

4) Natural owners are assigned to problems

5) Internal issues are included and addressed to the same Fast

Response criteria.(e.g. LPA findings, Verification Station or Dock

Audit issues, Supplier Issues)

6) Who leads the meeting & is there a designated back up person.

Exit Criteria Follows the problems steps ON THE SHOP FLOOR:

including Lessons Learned, LPA, Error 1) Exit criteria represents the 6 "Core" steps of problem solving plus

proofing and updates to Work tracking for LPA, Error proofing, updates to Work Instructions,

Instructions, PFMEA & Control Plan. PFMEA & Control Plan.

2) Method of communicating problems to all Key Stake holders (e.g.

Timing for each of the criteria Quality Alert, Temporary Work Instructions, By-Pass Procedure)

established, A guideline for timing for each of the exit criteria.

3) Red items have a planned date to go green, some detail

1.2 Problems are communicated to the 4) explaining why and the next step. NR

appropriate employees. Problems are not closed until all criteria is met.

5) Follow an issue from Fast Response Tracking Board through the

Overall status represents the worst 6) exit criteria confirming corrective action is in place & all

condition or overall planned timing has documentation has been updated.

been exceeded

The concerns are communicated to the ON THE SHOP FLOOR

appropriate employees & Fast Response 1) Quality Q or other method to track FR performance is tracked,

Process performance is tracked posted and up to date.

1.3 Quality status is posted. 2) Compare Quality "Q" to Fast Response Tracking Form for

NR

correlation. Do the metrics show improvement?

Is there a defined process for Problem Solving leading to root cause identification and elimination?

A defined process for Problem Solving 1) Completed Problem Solving forms used across the plant for

including a standard for documenting the internal, customer and supplier issues.

tools used for root cause identification. 2) Standard forms (PPSR or equivalent) used with a format that

follows the core '6 Steps' of problem solving

(Define, Contain, Root Cause, Correct, Validate, Institutionalize)

3) Forms identifying root cause( Drill Deep, 5 Why, Fishbone, Cause

& Effect, etc...)

4) Changes to PFMEA and Control Plan indicating root cause

elimination.

5) Evidence of cross-functional team approach.

1.4

ON THE SHOP FLOOR ASK:

NR

6) Supervisors/Team or Group Leaders and OPERATORS about their

role in Problem Solving

BEST PRACTICES:

- Forms completed on shop floor by Supervisors/Team or Group

Leaders (non-engineering staff) with team input.

- A standard training method for all Team Members/Leaders

Is there a system in place to capture information that supports continuous improvements to all operations/processes?

A system to capture and institutionalize 1) Review Lessons Learned procedure & forms.

lessons learned. 2) Documented sources that capture lessons learned such as Fast

Response, Problem Solving Documents, Continuous Improvement

Process, APQP, Risk Reduction team checklist, Read-Across,

1.5 Customer re-allocations (tool moves). NR

3) Completed Lessons Learned information which is easily

retrievable by all who need the information. (e.g. Master FMEA,

Read Across, Electronic forms or database).

A disciplined approach to problem 1) APQP Program check list reviews lessons learned.

prevention using lessons learned. 2) Continuous improvement team notes and agendas

3) Method which assures implementation supported by evidence of

1.6 review dates, distribution lists, or posted Lessons Learned. NR

(e.g. Active Drill Wide, Read-Across tracking)

QSB Audit form 07.04 2 of 12 Rev 20090213

QUALITY SYSTEMS BASICS AUDIT

# EVIDENCE REQUIRED LOOK FOR… COMMENTS SCORE R/Y/G

Leadership reviews Lessons Learned 1) Leadership notes or agenda indicating Lesson Learned system is

process to assure implementation. reviewed such as through a LPA or internal systems audit.

1.7 2) Regularly scheduled reviews documenting steps of NR

institutionalizing lessons learned. (e.g. Read-Across)

SCORE / POTENTIAL 0 0

QSB Audit form 07.04 3 of 12 Rev 20090213

QUALITY SYSTEMS BASICS AUDIT

# EVIDENCE REQUIRED LOOK FOR… COMMENTS SCORE R/Y/G

2.0 CONTROL OF NONCONFORMING MATERIAL

Is there a system in place to ensure products that do not conform to specified requirements are prevented from unintended use?

A consistent tagging system is used to ON THE SHOP FLOOR

identify suspect and nonconforming 1) Color coding of scrap containers, hold tags, scrap labels, in-

product. process tags, travelers, routers, etc…

2) If red tags are used for both scrap and suspect material, tag must

have disposition.

3) Suspect tags should have last operation performed.

2.1

BEST PRACTICE:

NR

System is Stoplight visual management where red indicates scrap

or and yellow indicates suspect product/material. Green or any

other color (except yellow or red) indicates acceptable product.

Nonconforming and suspect material are ON THE SHOP FLOOR:

segregated in properly identified areas. 1) Segregation areas are identified and/or foot printed,

2.2 2) Scrap bins, rework tables, hold areas, etc…are identified/foot NR

printed

Containment form or nonconforming 1) Containment worksheet or equivalent,

material form identifies expected quantity

and locations of suspect material. ON THE SHOP FLOOR:

Product in containment properly 2) There are standards in place for Color coding of scrap containers

identified. for containment issues.

Red = Non-conforming Product

2.3 Yellow = Suspect Product NR

Green = After Breakpoint, Conforming Product

3) Std Containers for W.I.P. and Finished good are not used for

sorting and placement of defective material.

4) Nonconforming material area and associated documents.

Is there a nonconformance quality alert and notification procedure that meets customer requirements?

The organization’s nonconformance alert Documents to ensure communication and follow-up activities occur

notification and containment process as required such as:

includes communication and action for 1) An Alert document that is used:

all stakeholders: - For external and internal issues

- Customer(s) - To establish tasks, time line,& communications

- Tier-2s, etc. necessary to meet customer requirements.

2.4 - Internal stakeholders - Defines the problem & the standard NR

2) Internal/external distribution and notification

3) Customer contact list

4) Certified shipment log

5) Tiered supplier contacts and certified shipment documents.

Product removed from the approved ON THE SHOP FLOOR: (if live example is available)

process flow for repair or rework: 1) Look for evidence of reintroduction, at or prior to point of removal.

- Has Approved Work Instructions 2) Verify that reintroduction includes all downstream checks such as

- Is reintroduced into the process at or error proofing. (All control plan inspections & tests to be performed)

prior to the point of removal If it cannot be reintroduced into the process, verify that an

- Is traceable through an identifier 3) approved (Quality Manager) documented rework and inspection

- Is released using a defined process procedure is followed.

and authority. Look for an identifier such as serial number or special marking that

2.5 4) can be traced back to the supplier record to show what was done NR

and when.

Form to release product with authorized signature and approved

5) inspection of product

BEST PRACTICE: The limit for the number of times repaired is

not more than 2 times with a tracking method.

Scrap is prevented from unintended use, 1) Procedure and method for materials/parts designated as scrap to

tracked and reduced through on-going ensure it is properly identified and kept from being reintroduced

continuous improvement. back into the normal material flow. (e.g. destruction, paint, locked

2.6 container) NR

2) Performance metrics and goals established to reduce scrap at all

levels of the operation.

Leadership involvement in internal and 1) Periodic summary reports

2.7 external spill, containment and 2) Material Review Board information and signatures NR

communication activities

SCORE / POTENTIAL 0 0

QSB Audit form 07.04 4 of 12 Rev 20090213

QUALITY SYSTEMS BASICS AUDIT

# EVIDENCE REQUIRED LOOK FOR… COMMENTS SCORE R/Y/G

3.0 VERIFICATION STATIONS

Is there at least one Verification Station in the process? (If a GMPT supplier, C.A.R.E. must be implemented.)

A procedure, operator instructions or ON THE SHOP FLOOR

other documentation which focuses on 1) How process information is monitored and information is relayed

Building Quality in Station through upstream to those that need to know and react:

Feedback from the process. - Station staffed for 100% inspection with a defect tally sheet

listing defects to look for.

- Automated testing and list of part characteristic/defect

checks being verified. (fault codes, defect description)

- Control chart noting reaction to out-of-control conditions.

2) When C.A.R.E. is in place, documentation requires identification

3.1 and inspection of customer satisfaction items: warranty issues, NR

pass-through items, PR/R issues, past Quality problems, high RPN

items, etc...

BEST PRACTICE:

- Look for a minimum of 1 at the end of each product assembly

line, or between departments such as molding, paint, assembly,

which provides feedback to upstream operations.

Procedure or instructions that require ON THE SHOP FLOOR:

immediate reaction when alarm limit is Look for evidence in the documentation stating:

reached. (Past Customer defects shall 1) When and who to call,

always have an Alarm limit of '1'. All 2) Who responded and when

C.A.R.E. items must be '1). 3) The immediate fix, corrective action taken and breakpoint.

4) Document that describes when a problem is to be escalated.

3.2 Responses to alarms are documented. 5) Escalation identifies who is the next person to be called and their NR

contact information?

Escalation procedure is followed for BEST PRACTICE:

repeat defects or no response. - Alarm & Escalation is applied at each step of the operation where

defect detection exists.

Corrective actions implemented as a ON THE SHOP FLOOR

result of Verification Station activities. 1) Assignment of problem solving activities related to station data

2) Tracking sheet displayed in the area on the shop floor.

3.3 Team reports out weekly and the status 3) Problem solving documentation NR

is reviewed during the 4) Problem Report out Schedule

leadership/support staff walk through.

Feed Back data from downstream ON THE SHOP FLOOR

customers is documented and 1) Performance Graphic or report card showing (i.e. calendar days-

performance is tracked at the inspection red/green) feedback from downstream customers and details.

point. 2) Graphic or report card showing findings at the station for

3.4 communication to upstream processes/suppliers. NR

3) FTQ or scrap analysis showing improvement trend, reduction of

events/defects over time.

Leadership reviews Verification Stations ON THE SHOP FLOOR

activities and results. 1) Sign-in sheet, and meeting assignment log.

Daily management walk through or 2) Evidence the station operator reports results and responses to

3.5 meetings at selected stations. calls NR

3) At the meeting, a review of the current findings and the previous

shift to determine if the escalation process is effective.

SCORE / POTENTIAL 0 0

QSB Audit form 07.04 5 of 12 Rev 20090213

QUALITY SYSTEMS BASICS AUDIT

# EVIDENCE REQUIRED LOOK FOR… COMMENTS SCORE R/Y/G

4.0 STANDARDIZED OPERATIONS

WORKPLACE ORGANIZATION

Is there a systematic approach to utilize and maintain Workplace Organization?

Procedures or operator instructions for ON THE SHOP FLOOR:

cleaning and maintaining organized 1) Ask a Team Member to explain the 5S process.

areas. Procedures or instructions or 2) Does the 5S process focus on waste elimination?

other documentation that support a 3) Documentation that defines:

systematic approach to standardization - what is to be in a work cell,

of workplace organization. - how it is to be labeled and guides for label location.

4) Standards that display placement and identification of material,

equipment, tools, aisles, hazards, including storage of personal

belongings.

4.1 5) Start-up/Shut down task list, 5S or TPM Check List, identifying NR

frequency, time, and tools required.

6) FIFO - Material is staged with oldest material to be used first and

newest to be used last.

7) Visual aids used to assist in the process flow.

8) A process for updating workplace organization standards at some

frequency.

Clean, organized work areas. Items in ON THE SHOP FLOOR:

areas labeled, foot printed or otherwise 1) Ask if the Production, Maintenance, Quality, Material and office

identified. areas have documented workplace organization standards.

2) Look for evidence of an established audit frequency and that it is

4.2 followed. NR

3) A countermeasure sheet or equivalent includes issue found, owner,

action, and date for correction.

STANDARDIZED WORK INSTRUCTIONS

Is there a system in place to develop standardized work instruction (methods and sequence) for all operations?

Standardized Work Instructions are ON THE SHOP FLOOR

posted at or near all operations where 1) Ask the Team Member where their standardized Work instructions

there are human operators. are located.

2) Instructions are located for quick and easy reference. (close to the

workstation)

3) Documentation of required PPE, availability and use at the

4.3 workstation. NR

4) Instructions include Work Elements & Times (element-walk-wait),

Work Flow Sequence (operator path), Standard in-process stock,

Operation Cycle Time, Takt Time (Customer and Actual).

5) Visuals accurately represent the workstation layout and work

sequence.

All affected operators are trained in the 1) Evidence that operators are trained in the use of Standardized

use of Standardized Work Instructions Work Instructions.

4.4 ON THE SHOP FLOOR: NR

2) Ask team member how the Standardized Work Instructions are

used.

Procedure requires cross-functional teams ON THE SHOP FLOOR

and continuous improvement. 1) Ask the Team Member/Leader their level of involvement in

developing their standardized work.

2) Verify Team Leaders, Team Members, Group Leader original

signature is on the document.

3) Ask if the Group Leader understands their role in the support of

4.5 standardized work by acting as a liaison to the support NR

organizations.

4) Ask the Team Leader if there is a process (formal or informal) for

teams to seek agreement for job element sequence within the team

and across all shifts and crews.

QSB Audit form 07.04 6 of 12 Rev 20090213

QUALITY SYSTEMS BASICS AUDIT

# EVIDENCE REQUIRED LOOK FOR… COMMENTS SCORE R/Y/G

OPERATOR INSTRUCTIONS

Is there a systematic approach to develop Operator Instructions for all work.

Procedure, instructions or other ON THE SHOP FLOOR:

documentation that requires 1) Operator instructions in or near work areas that are accessible to

development of operator instructions for operators.

all work. 2) Compare instructions to work performed by operators.

OBSERVE 3 full cycles of the job in station &Verify:

- That the Major Steps (What), Key Points (HOW),

and Reason (WHY) are followed.

- (All key points shall have a reason Why)

3) Ask the Team Member how they know they have made good part.

Quality checks are included.

4.6 4) Specific tool requirements are listed at the operation. NR

5) Verify critical items such as torque or Customer Safety

6) requirements are specified in the document.

BEST PRACTICE:

Major Steps (What), Key Points (HOW), and Reason (WHY) are

properly explained. (What is the outcome if the step is not

performed as described)

Verify, maintain and update operator instructions as processes/products change.

Procedure, instructions or other ON THE SHOP FLOOR:

documentation that requires 1) Review revision history of operator instructions.

implementation and revision of operator 2) Compare revision levels of operator instructions with PFMEA or

instructions. Control Plan revision levels.

4.7 3) Check to see if it is marked up, signed, and dated around the NR

timing of a recent customer problem or CI action item.

4) Evidence of appropriate operator training records when revisions

were made.

Is there a system in place for Gage control.

Procedure and forms to document 1) Documented procedure and gage/fixture use instructions.

process. 2) Calibration sticker.

Compliance to customer requirements 3) Operator gage training to the current gage instruction.

(GM 1925) for both internal & external 4) Gage master device.

gage providers. 5) Gage certification frequency.

6) Gage R@R.

4.8 Gage instructions updated to current BEST PRACTICE: NR

product and process level. Last Part Checked should be held for confirmation of last known

good part at a frequency of at minimum of 1 per shift. Best practice

would be to retain hourly samples for each inspection, retained for

the entire shift or previous 8 hours.

SCORE / POTENTIAL 0 0

QSB Audit form 07.04 7 of 12 Rev 20090213

QUALITY SYSTEMS BASICS AUDIT

# EVIDENCE REQUIRED LOOK FOR… COMMENTS SCORE R/Y/G

5.0 STANDARD OPERATOR TRAINING

Is there a system to define a standard training method, minimum content and tracking for all operators new to an

operation and/or those in need of refresher training?

A standard method that defines the 1) Evidence of a graduating step approach such as the 4 Step (Job

steps trainers are trained and certified to, Instruction Training) process and are provided the opportunity to

in order to properly train operators on practice the new skill or knowledge.

their job. - Prepare, Demonstrate, Try-out performance, Follow-Up.

2) Documentation to show who is certified to train.

5.1 NR

ON THE SHOP FLOOR:

3) Ask operators how they are trained.

Standard operator training records 1) Training record that documents training of procedures and overall

document specific areas of training such job knowledge to:

as safety, quality record keeping, gaging, - Work safely (guards, start-up shut down, lock out)

workplace organization responsibilities. - Perform proper record keeping (production/quality)

5.2 - Understand work place organization responsibility NR

- Quality requirements (containment, red-bins, andon, etc)

2) Records are available and easily retrieved.

Specific Job instruction training is 1) Individual Job training record with dates and trainer signoff for each

documented for each operator showing job.

all jobs trained on, skill or knowledge 2) Record indicates the steps in training & skill/knowledge level

level of the job, who trained them and achieved for each job:

when. 3) Follow-up includes the trainer audits employee to standard work

instructions, verifies quality & productivity within shift and again

approximately one day later.

5.3 NR

ON THE SHOP FLOOR:

4) Verify a new operator is following Standardized Work Instructions &

know the quality and productivity requirements.

5) Training for the job is documented on their individual record.

Records reflecting training status of all ON THE SHOP FLOOR:

operators posted at the operation 1) Operator Tracking Sheets or equivalent posted at all operations or

indicating they are trained to the current work area.

work instruction change level. 2) All operators listed including supplemental employees.

3) Review training dates and tracking sheet revision dates.

BEST PRACTICE:

- Chart showing cross training/certification level in a cell such as a

flexibility chart.

5.4 - Look for a job rotation plan or log. How often does team rotate? NR

- The number of Team Members certified per station should support

the Job Rotation Plan.

- If it does not, look for a plan such as a Flexibility Chart 2x2 or 4x4

matrix, that shows the status, actual vs planned number certified

per station that is being used to maintain job rotation.

Training records for supplemental or 1) Documentation, scheduling, and tracking forms for supplemental

temporary employees that document operator refresher training.

5.5 refresher training if they have not NR

performed that job within the last three

months.

SCORE / POTENTIAL 0 0

QSB Audit form 07.04 8 of 12 Rev 20090213

QUALITY SYSTEMS BASICS AUDIT

# EVIDENCE REQUIRED LOOK FOR… COMMENTS SCORE R/Y/G

6.0 ERROR PROOFING VERIFICATION

Is there a system in place to verify that error proofing/ detection devices used in manufacturing and assembly are functioning properly?

Documentation and evidence that ON THE SHOP FLOOR:

indicates devices are verified at least 1) Documentation (verification logs) of device verification at a

once per day. minimum of once per day & are easily accessible.

6.1 2) Reaction plan includes who is notified and actions to be taken. NR

Reaction to failures and corrective 3) Containment and corrective action documentation for failures.

actions are documented.

Error Proofing device locations shall be 1) Master list of all devices that prevent/detect the manufacture or

6.2 documented. assembly of nonconforming product. NR

Management periodically reviews results 1) Verification failures on Fast Response Tracking Sheets, Layered

6.3 of verification. Audit, Management Review agenda, Verification tracking forms NR

available.

SCORE / POTENTIAL 0 0

7.0 LAYERED PROCESS AUDITS

Is there a system in place to verify the documented manufacturing/assembly process through layered audits?

A defined Layered Process Audit 1) Written Procedure

procedure that is owned by 2) Audit & work instructions

7.1 manufacturing. 3) Counter measure process NR

4) Owned by Manufacturing

All levels of the organization participate 1) Audit Schedule showing level of participation and frequency.

in Layered Process Audits at established 2) Evidence that ALL layers of the organization perform regularly

frequencies. scheduled standardized audits. Plant Manager should be monthly,

Shift Leaders and Management Support Staff - Weekly, Group

7.2 Leader-Team Leaders-Daily.

NR

3) Tracking to ensure every work station is evaluated on regular

basis.

Audit Check sheet includes: 1) Quality Focused checks for past customer failures. (i.e. Assigned at

Workstation, Quality (Customer Focus), Fast Response, for PRR or Liaison Report issues, error-proofing

and System high risk items. verification, etc...)

2) Workstation Specific check items (Review of actual work performed

by Team Members to standardized work instructions, 5S-WPO,

7.3 Rotation Log, Training, etc..) NR

3) Work Station and Quality Focused items are checked by all

auditors.

4) System Specific items (Preventative Maintenance, Business Plan

reviews, Shop Floor Management standards, etc..)

Process specific audits are performed 1) Verification in the Layered Process Audit under system specific

7.4 (CQI 9, 11, 12, Weld Audit, Chrome items that, where applicable, Audits for special processes are NR

Audit, Paint Process Audit etc.) performed.

System to review and document the 1) Results reviewed with team members & area supervisors

results of the audit. 2) Evidence and documentation of immediate corrective action for

nonconformance. (Items corrected immediately)

All deviations are recorded on the check 3) Countermeasure list with responsibility and dates for items that

sheet. could not be corrected immediately.

7.5 4) Review of counter measure process at least once per week. NR

5) When appropriate nonconformance is added to Fast Response or

C.A.R.E.

BEST PRACTICE:

Check that the Audits are verified by the next level Supervisor.

Addition of Layered Process Audit issues 1) Lessons Learned system, documentation.

7.6 to the Lessons Learned system. NR

Audit results are summarized and 1) Reports or graphics that are reviewed by management.

7.7 reviewed by manufacturing site NR

leadership.

SCORE / POTENTIAL 0 0

QSB Audit form 07.04 9 of 12 Rev 20090213

QUALITY SYSTEMS BASICS AUDIT

# EVIDENCE REQUIRED LOOK FOR… COMMENTS SCORE R/Y/G

8.0 RISK REDUCTION

Is there a system in place for reducing the risk of all production processes by reducing the highest RPN values?

PFMEA’s shall be developed and 1) PFMEA available for all part numbers and all operations, especially

maintained by cross-functional teams high risk such as labeling and rework.

for all manufacturing processes and 2) Accurate Severity/Occurrence/Detection Ratings with Valid RPN

8.1 support functions as required by the numbers and revision dates with some correlation to known NR

AIAG manual. problems (PRRs, etc…).

3) Are updated on a regular basis (living documents).

Cross-functional teams have periodic 1) Cross-functional team agenda or other evidence of RPN reduction

reviews of PFMEA and coordinate RPN activities.

reduction activities? 2) Documentation that frequency and prioritization of reviews is based

on customer input, process capability, process changes, AIAG

guidelines, etc…

3) Review checklists, agendas or equivalent that assure adequate

PFMEA review (all operations/processes (paint, heat treat,

material handling, labeling, rework/repair, etc…) are included and

8.2 accurate. NR

- All process controls are included.

- Detection ratings are accurate.

- Occurrence ratings are analyzed using data (SPC, FTQ,

Quality Gate, C.A.R.E.*, Scrap, Layered Process

Audits* results)

Proactive approach to reduction of 1) Top RPN list,

highest RPN values has been 2) Tracking charts

8.3 implemented. Top RPN list with action 3) Cross-functional team minutes noting improvement actions and NR

plans. completion details.

There is a Reverse PFMEA (Pro-active 1) Cross-functional team conducts a process walk through audit .

Error Proofing) process in place. 2) Action Plan.

3) Does this cover all High Risk Parts.

4) Are the findings driven back into Process Flow, PFMEA, Control

8.4 Plan, Work Instructions as applicable. NR

5) Have Occurrence/Detection numbers been revised.

Evidence of past quality issues and 1) Revision date of PFMEA to address error proofing and verification

corrective actions that have been of past failures.

implemented. 2) Action plans with target completion dates

8.5 3) Team validates the new Occurrence and Detection rankings and NR

resultant RPN.

4) Error proofing is verified per the Error Proofing Verification*

process.

Management review of the RPN 1) Management review agenda/minutes

reduction process, training requirements, 2) Cross-functional team training and individual qualifications

8.6 and tracking of RPN reduction results. reviewed and verified annually. NR

3) Evidence of documentation to track improvements. (Trend Chart,

Process change validation, Layered Process Audit)

SCORE / POTENTIAL 0 0

QSB Audit form 07.04 10 of 12 Rev 20090213

QUALITY SYSTEMS BASICS AUDIT

# EVIDENCE REQUIRED LOOK FOR… COMMENTS SCORE R/Y/G

9.0 CONTAMINATION CONTROL

Is there a system in place to control contamination when appropriate?

Sediment: Procedures for the 1) Procedure to include:

measurement and monitoring - Methods defining sediment collection

- System to measure to a standard

9.1 - Application using statistical method to monitor and control NR

2) Site leadership review of results for compliance and continuous

improvement

Sediment: Procedure for maintaining the 1) Process controls to maintain:

processes to control the affect of Parts Washers, Deburrs, metal working fluid systems, dunnage

9.2 sediment and part storage, air and fluid probes NR

2) If there is a clean room, standards are established and adhered to.

Extra Parts: Procedure for controlling 1) Method to prevent extra parts or materials that may fall into or stick

extra parts. to products which are not intended as part of the finished product.

such as:

Magnetic tools, Shielding, Fixture Orientation, Rollovers and

9.3 Dump Stations, Magnetic wrench. NR

2) Methods are verified through error proof verification and/or Layered

Process Audits.

Dirt in Paint: Procedure for maintaining 1) Procedure to include:

the processes to control and prevent dirt - Dirt training awareness

contamination. - Post paint handling methods

- Application using statistical method to monitor and control

9.4 2) There is an active dirt reduction team and action plan. NR

3) Site leadership review of results for compliance and continuous

improvement

Retained material in Castings: 1) Procedure to include:

Procedure to measure, monitor, and - Methods to measure retained material (i.e. Tunk test)

improve retained material in castings. - Verification that measurements are taken and results are

documented.

- Any non-conformance to standards are documented and

corrective actions are implemented.

9.5 - Processes/Equipment are verified through error proof NR

verification, preventative/predictive maintenance, and Layered

Process Audits.

2) Site leadership review of results for compliance and continuous

improvement

Corrective actions for customer 1) Review customer complaint history for contamination related

complaints related to contamination. complaints.

2) Verify complaints are reviewed at Fast Response, have

documented problem solving, and corrective actions have been

9.6 implemented. NR

3) Contamination issue and corrective actions are added to Layered

Process Audits.

SCORE / POTENTIAL 0 0

10.0 SUPPLY CHAIN MANAGEMENT

Is there a systematic process in place to control suppliers?

Procedures and work instructions to Procedures that require supplier audits to support sourcing

select and evaluate suppliers. decisions, quality systems, special processes, and product/process

specific evaluations.

1) - Potential supplier assessments

10.1 2) - Quality Systems Basics audit NR

3) - Special Processes such as Heat Treat, Plating, and Coating.

4) - Labeling PFMEA/Control Plan

Procedure for evaluating compliance to 1) Compliance to Customer specific requirements such as GP-9, GP-

customer specifications and 12, etc.

requirements 2) Process Control Plan Audits

10.2 3) Gaging Audits NR

4) Problem Solving with disciplined method for root cause analysis

such as 5-Why.

Measurement and validation system for Methods to determine ranking of Key suppliers with reviews of

key suppliers performance supplier performance to specified goals.

1) Key Supplier list with defined metrics/goals

2) Reviews of supplier performance with a defined procedure and

10.3 actions for poor performing suppliers. NR

3) Method or process in place to communicate problems and track

corrective action.

SCORE / POTENTIAL 0 0

QSB Audit form 07.04 11 of 12 Rev 20090213

QUALITY SYSTEMS BASICS AUDIT

# EVIDENCE REQUIRED LOOK FOR… COMMENTS SCORE R/Y/G

11.0 MANAGING CHANGE

Is there a systematic process in place to control product, process, or source changes?

A documented procedure for monitoring 1) A plant process change form utilized to document all changes.

and controlling all product, process or 2) Change Forms are controlled through a Document Control

source changes. Process. (e.g. tracking log sheet, revision numbering system,

11.1 approval process) NR

3) Both planned and emergency changes covered by the change

procedure.

Procedure to establish a defined 1) A standardized communication procedure and form to control and

Production Trial Run (PTR) process. monitor all Production Trial Runs that documents each step of the

process & records all approvals and results.

2) Build readiness reviews required to authorize the start of the trial

11.2 run production process. NR

3) Quality reviews documented to release product for PTR shipment

and verification process has returned to normal production.

A parts banking strategy/procedure for 1) Defined procedure and responsibility for the execution of long term

identifying, protecting and retrieving long storage of parts or materials?

term storage of parts or materials. 2) Established guidelines for protective packaging for parts and

11.3 material. NR

3) Quality reviews to established inspection criteria for the authorized

release of banked parts and material.

Procedure to authorize bypassing 1) Written procedure to include:

processes How product quality standards are maintained

Method for proper authorization to enter and exit the process

Defines when the process is initiated and returned to normal

Standardized work and operator training are documented

11.4 2) A Worksheet is used to track each process that is in bypass. NR

3) The bypassed process is frequently audited for compliance (Best

Practice is hourly)

4) Bypassed processes are documented in PFMEA and Control Plan

SCORE / POTENTIAL 0 0

SCORING CRITERIA

0 No implementation: Corrective Action Required

1 Written implementation plan: Corrective Action Required

2 In place, not followed: Corrective Action Required

3 YELLOW: Requirement partially implemented

4 GREEN: Requirement met

NR NR: Not Reviewed

Note: Enter appropriate score based on R Y G score criteria and hit enter. Correct color will appear in R/Y/G cell.

Not Reviewed is used when:

1) Immediate focus does not include the strategy. Give future review date in comments box.

2) Plan to review in the future. Give future review date in comments box.

3) Question or strategy does not apply to this supplier. Explain in comments box.

QSB Audit form 07.04 12 of 12 Rev 20090213

You might also like

- Layered Audit System VerificationDocument13 pagesLayered Audit System VerificationcpsinasNo ratings yet

- QA/QC Process DocumentationDocument1 pageQA/QC Process DocumentationChiheb GNo ratings yet

- Quality ToolDocument7 pagesQuality ToolAhmed M. HashimNo ratings yet

- ISO 13485:2016 Quality Systems Manual: Document No. QMD-001Document11 pagesISO 13485:2016 Quality Systems Manual: Document No. QMD-001Roslan.Affandi2351100% (1)

- Bqs Asq Lpa Overview 2 3 2017 Rev 11 PDFDocument48 pagesBqs Asq Lpa Overview 2 3 2017 Rev 11 PDFelyesNo ratings yet

- Mistake ProofingDocument38 pagesMistake ProofingkotharideepNo ratings yet

- Layered Audit Process: 1. PurposeDocument5 pagesLayered Audit Process: 1. PurposeHeart Touching VideosNo ratings yet

- Audit - Visio-Template Process MapDocument1 pageAudit - Visio-Template Process MapPurushothama Nanje GowdaNo ratings yet

- Supplier Assessment (F - 003 - QF-SQ-COM - 002 Rev. 02) .Document50 pagesSupplier Assessment (F - 003 - QF-SQ-COM - 002 Rev. 02) .muthuselvanNo ratings yet

- Performance Review TemplateDocument6 pagesPerformance Review TemplateDrAnand ShankarNo ratings yet

- Error ProofingDocument114 pagesError ProofingDebashishDolonNo ratings yet

- LPA - Layer Process Audit GuidelinesDocument23 pagesLPA - Layer Process Audit GuidelinesR J100% (2)

- Problem SolvingDocument31 pagesProblem SolvingSudhagarNo ratings yet

- Process Map–Internal AuditsDocument1 pageProcess Map–Internal AuditsNikhilesh NaikNo ratings yet

- Barcode Labelling & Part Marking TraceabilityDocument23 pagesBarcode Labelling & Part Marking TraceabilityVaibhav KotnalaNo ratings yet

- Inspection standards for foam packing partsDocument9 pagesInspection standards for foam packing partsBalvinder SinghNo ratings yet

- AME Lean Assessment GuideDocument35 pagesAME Lean Assessment GuideacauaNo ratings yet

- Audit MatrixDocument4 pagesAudit MatrixramschellamNo ratings yet

- ImarqDocument7 pagesImarqashishvaid2005No ratings yet

- BIQS Manual Auditoria 2017 PDFDocument168 pagesBIQS Manual Auditoria 2017 PDFJuan Carlos PadillaNo ratings yet

- Document change request form templateDocument1 pageDocument change request form templatesuresh kumarNo ratings yet

- Continuous Improvement Record SheetDocument1 pageContinuous Improvement Record SheetRambir KaushikNo ratings yet

- Appendix 1 - Quality Objectives: Zanzibar Bureau of StandardsDocument3 pagesAppendix 1 - Quality Objectives: Zanzibar Bureau of StandardsMariel GentilesNo ratings yet

- CSR Matrix - Issue 2Document6 pagesCSR Matrix - Issue 2normalNo ratings yet

- Motorola Quality ManualDocument12 pagesMotorola Quality ManualHaroon MukhtarNo ratings yet

- Error Proofing TechniquesDocument140 pagesError Proofing TechniquesThe Informative Corner हिंदीNo ratings yet

- DS-04-01 R0 Competency Requirements of Internal AuditorsDocument2 pagesDS-04-01 R0 Competency Requirements of Internal AuditorsDhinakaranNo ratings yet

- Internal audit checklist for MR, CIP, training and customer complaintsDocument3 pagesInternal audit checklist for MR, CIP, training and customer complaintsganrashNo ratings yet

- MAstering IATFDocument20 pagesMAstering IATFGyanesh_DBNo ratings yet

- 8D Form InstrucDocument9 pages8D Form InstrucPedro Pi100% (2)

- Gemba Overview - Sheena Butts - IIESHS - WEBINAR v1Document35 pagesGemba Overview - Sheena Butts - IIESHS - WEBINAR v1Bryan OrdialesNo ratings yet

- MARUTI VENDOR QUALITY SYSTEM AUDIT REPORTDocument5 pagesMARUTI VENDOR QUALITY SYSTEM AUDIT REPORTRahul kumarNo ratings yet

- QM-ANN-07 Responsibility and AuthorityDocument6 pagesQM-ANN-07 Responsibility and AuthorityMythri Metallizing Pvt Ltd Projects100% (1)

- Auditoria Por CapasDocument23 pagesAuditoria Por Capasmpedraza-1No ratings yet

- A3 Process Guide for Improving Patient TransportDocument14 pagesA3 Process Guide for Improving Patient TransportJayantRKNo ratings yet

- Calibration Process Audit ExampleDocument1 pageCalibration Process Audit ExampleMuhammad Alief OthmanNo ratings yet

- Special Audit of Key Characteritics in Control Plan FAU-F-PSG-0800-En-4Document1 pageSpecial Audit of Key Characteritics in Control Plan FAU-F-PSG-0800-En-4KarlNo ratings yet

- EEN 11XXXX Audit Results Summary ProposalDocument2 pagesEEN 11XXXX Audit Results Summary ProposalDuane SchumacherNo ratings yet

- KSS Global Standard Supplier Advanced Product Quality Planning (APQP) ProcedureDocument12 pagesKSS Global Standard Supplier Advanced Product Quality Planning (APQP) ProcedureNabeel Arya ZahranNo ratings yet

- The Process Approach QuestionsDocument6 pagesThe Process Approach QuestionsDwinanda SeptiadhiNo ratings yet

- Daimler DPA - Questionnaire 4-0 Nov 2007Document80 pagesDaimler DPA - Questionnaire 4-0 Nov 2007cjscNo ratings yet

- Kaizen Tool Kit: Mistake Proofing - PokayokeDocument8 pagesKaizen Tool Kit: Mistake Proofing - PokayokeJohn P. BandoquilloNo ratings yet

- Instructions: 'No' Answers Are To Be Resolved Immediately and DocumentedDocument1 pageInstructions: 'No' Answers Are To Be Resolved Immediately and Documentedrgrao85No ratings yet

- List of Contents: Process-And Product AuditDocument6 pagesList of Contents: Process-And Product AuditiresendizNo ratings yet

- Daimler-Chrysler Layered Process AuditsDocument27 pagesDaimler-Chrysler Layered Process AuditsR JNo ratings yet

- QMS Management Review ProcedureDocument2 pagesQMS Management Review ProcedureSagar Daund100% (1)

- 5S Visual Workplace HandbookDocument19 pages5S Visual Workplace HandbookDiegoRosso100% (1)

- Layered Audit ChecklistDocument4 pagesLayered Audit ChecklistNavnath TamhaneNo ratings yet

- 1st Team Leader Standard WorkDocument1 page1st Team Leader Standard Workwayneseal1No ratings yet

- Monthly production capacity planning reportDocument3 pagesMonthly production capacity planning reportamolkingNo ratings yet

- 02 - Fast Response - QIP V3Document85 pages02 - Fast Response - QIP V3HOSSIENNo ratings yet

- 3 Zero Quality ControlDocument6 pages3 Zero Quality ControlShreyas KolheNo ratings yet

- Layered Process Audit Checklist (LPA)Document5 pagesLayered Process Audit Checklist (LPA)ALBERTO ALVARADO CARRILLONo ratings yet

- Guide To Auditing The Quality Management SystemDocument23 pagesGuide To Auditing The Quality Management SystemAzrul Akiff Azman100% (1)

- PPApDocument11 pagesPPApBraulio Od100% (1)

- Quality DashboardDocument64 pagesQuality DashboardEkane NgemeNo ratings yet

- Gage R&R DetailsDocument6 pagesGage R&R DetailssahilNo ratings yet

- Auditor Training Content Files CombinedDocument211 pagesAuditor Training Content Files CombinedSaemundrSigfussonNo ratings yet

- AdvertisementsDocument71 pagesAdvertisementsRohanNo ratings yet

- Case study questions distribution and student assignmentsDocument2 pagesCase study questions distribution and student assignmentsTomi -No ratings yet

- K010250 - Actionable Profitability Analytics Article - 0 PDFDocument6 pagesK010250 - Actionable Profitability Analytics Article - 0 PDFnazirkuraNo ratings yet

- 74936bos60526-Cp3 UnlockedDocument70 pages74936bos60526-Cp3 Unlockedhrudaya boysNo ratings yet

- MKT646 Test1 (2019)Document2 pagesMKT646 Test1 (2019)cutespidermonkey061050% (2)

- Vertical Marketing Systems ExplainedDocument9 pagesVertical Marketing Systems ExplainedAkshay Krishnan VNo ratings yet

- NUS EC1301 Mid-Term Exam Multiple Choice QuestionsDocument10 pagesNUS EC1301 Mid-Term Exam Multiple Choice QuestionsLiu XinchengNo ratings yet

- Marketing Management Sample 2024Document32 pagesMarketing Management Sample 2024Vibrant PublishersNo ratings yet

- Framework For A Third Party Risk Management ProgramDocument9 pagesFramework For A Third Party Risk Management ProgrammurugaNo ratings yet

- LA020504 Ass1 BSBMGT517 Ed2Document6 pagesLA020504 Ass1 BSBMGT517 Ed2ghasepNo ratings yet

- Business Model CanvassDocument2 pagesBusiness Model CanvassAbriel BumatayNo ratings yet

- Strategic Management and AnalysisDocument7 pagesStrategic Management and AnalysisLisaNo ratings yet

- The Balanced Scorecard: A Tool To Implement StrategyDocument39 pagesThe Balanced Scorecard: A Tool To Implement StrategyAilene QuintoNo ratings yet

- PPC Lesson PlanDocument6 pagesPPC Lesson PlanSaravanan MathiNo ratings yet

- X (Bss-Oss) BSS - Oss Portfolio Success Why ComarchDocument76 pagesX (Bss-Oss) BSS - Oss Portfolio Success Why Comarchzulhelmy photo100% (2)

- Takt" Is The German Word For The Baton That AnDocument3 pagesTakt" Is The German Word For The Baton That AnmuneerppNo ratings yet

- Lecture 7 - Identify Risks: Project Risk Management Ms (PM)Document50 pagesLecture 7 - Identify Risks: Project Risk Management Ms (PM)javeria zahidNo ratings yet

- AG - The Contract Management Benchmark Report, Sales Contracts - 200604Document26 pagesAG - The Contract Management Benchmark Report, Sales Contracts - 200604Mounir100% (1)

- Business Analyst: Job Location Reports To Travel Role OverviewDocument2 pagesBusiness Analyst: Job Location Reports To Travel Role Overviewsouarbh khemkaNo ratings yet

- Spiral ModelDocument3 pagesSpiral Modelanil100% (3)

- Job Analysis and DesignDocument47 pagesJob Analysis and DesignfayazalamaligNo ratings yet

- Client AcceptanceDocument26 pagesClient AcceptanceSaiful IslamNo ratings yet

- Strategic Cost Management QuizDocument10 pagesStrategic Cost Management QuizMelanie SamsonaNo ratings yet

- KK Pillar PDFDocument91 pagesKK Pillar PDFdiwesh26decNo ratings yet

- Writing A Feasibility Study: de Villa, John Paul D. CDocument13 pagesWriting A Feasibility Study: de Villa, John Paul D. CJohn Paul de VillaNo ratings yet

- CV Project Assistant ZDocument2 pagesCV Project Assistant Zmaha AbdulazizNo ratings yet

- Auditing Reviewer 3 Auditing Reviewer 3Document4 pagesAuditing Reviewer 3 Auditing Reviewer 3Ryan PedroNo ratings yet

- Chapter Seven: Cost-Volume-Profit AnalysisDocument48 pagesChapter Seven: Cost-Volume-Profit AnalysisNoni PcyNo ratings yet

- At MCQ Salogsacol Auditing Theory Multiple ChoiceDocument32 pagesAt MCQ Salogsacol Auditing Theory Multiple Choicealmira garciaNo ratings yet

- TUI Business StrategyDocument20 pagesTUI Business StrategyMuhammad Sajid Saeed86% (7)