Professional Documents

Culture Documents

Charlie Craig Catfish

Uploaded by

Joe ClarkeCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Charlie Craig Catfish

Uploaded by

Joe ClarkeCopyright:

Available Formats

APPENDIX A

Charlie Craig Hatchery, Arkansas HACCP Plan for Channel Catfish

Revision Date: October 21, 2003

1) Species Description

2) Past Stocking History

3) Flow Diagram

4) Potential Hazards

5) Hazard Analysis Worksheet

6) HACCP Plan Form

7) HACCP Step Summary

1. Species Description

Hatchery Name: Charlie Craig State Fish Hatchery, Arkansas

Hatchery Address: 977 West Fish Hatchery Road

P.O. Box 58

Centerton, AR 72719

Species of fish imported: Channel Catfish (Ictalurus punctatus) Species Code CCF

Cultured, wild harvested, or both: Cultured

Harvest method: Earthen ponds drained into kettle and catfish seined

Method of distribution: Wyoming Game and Fish Department fish distribution unit

Intended use: Importation into the state of Wyoming for public fisheries

management

Risk Level Prior to HACCP: Level 4, Low Risk – NTS Present in Source (APPENDIX D).

Risk Level After HACCP: Level 1 – 3, Low Risk—depended if NTS present prior to

loading and type of NTS present (APPENDIX D).

2. Past Stocking History

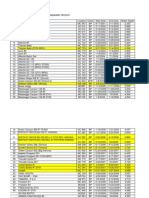

Number Lbs ANS/NTS

Water Name Species Stocked Stocked No/Lb Stocking Date Present

N Platte R Glen-Ppl CCF 8,253 917 9.00 10/02/1997 Unknown

N Platte R Guer-Glen CCF 1,503 167 9.00 10/02/1997 Unknown

Beck Lake CCF 1,494 166 9.00 10/02/1997 Unknown

N Platte R Coli-Mill CCF 8,280 920 9.00 10/02/1997 Unknown

1997 19,530 2,170 Unknown

Packers Lake CCF 2,508 228 11.00 05/07/1998 Unknown

Springer Res CCF 2,508 228 11.00 05/07/1998 Unknown

Charlie Craig State Hatchery, Arkansas Fish Importation Assessment

October 21, 2003

5

2. Past Stocking History (Continued)

Number Lbs ANS/NTS

Water Name Species Stocked Stocked No/Lb Stocking Date Present

Boysen Reservoir CCF 20,011 1,516 132.00 05/07/1998 Unknown

Hawk Springs Res CCF 600 546 1.10 05/07/1998 Unknown

Wheatland Res 1 CCF 5,005 455 11.00 05/07/1998 Unknown

Rock Lake CCF 2,508 228 11.00 05/07/1998 Unknown

Glendo Reservoir CCF 25,106 1,902 13.20 05/07/1998 Unknown

Festo Lake CCF 2,508 228 11.00 05/07/1998 Unknown

Grayrocks Res CCF 13,000 1,182 11.00 05/07/1998 Unknown

Flaming Gorge Res CCF 5,005 455 11.00 05/07/1998 Unknown

1998 78,759 6,968

Festo Lake CCF 2,502 278 9.00 05/05/1999 Unknown

Grayrocks Res CCF 7,506 830 9.00 05/05/1999 Unknown

Rock Lake CCF 2,502 278 9.00 05/05/1999 Unknown

Wheatland Res 1 CCF 3,066 334 9.00 05/05/1999 Unknown

N Platte R Coli-Mill CCF 6,003 667 9.00 05/06/1999 Unknown

Bump Sullivan Res CCF 5,004 556 9.00 05/06/1999 Unknown

Packers Lake CCF 2,502 278 9.00 05/06/1999 Unknown

Hawk Springs Res CCF 6,003 667 9.00 05/06/1999 Unknown

Springer Res CCF 2,502 278 9.00 05/06/1999 Unknown

N Platte R Glen-Ppl CCF 14,103 1,567 9.00 05/06/1999 Unknown

Bryan Stock Trail Res CCF 1,503 167 9.00 05/07/1999 Unknown

Guernsey Slough CCF 1,008 112 9.00 05/07/1999 Unknown

N Platte R Neb-Co Li CCF 1,008 112 9.00 05/07/1999 Unknown

1999 55,212 6,124 Spring

Boysen Reservoir CCF 19,947 932 21.40 10/28/1999 Unknown

Sand Mesa #2 CCF 901 42 21.40 10/28/1999 Unknown

Beck Lake CCF 1,506 70 21.40 10/28/1999 Unknown

Kinnear Lake CCF 700 33 21.40 10/28/1999 Unknown

1999 23,054 1,077 Fall

Rock Lake CCF 2,502 55 45.50 10/05/2000 Unknown

N Platte R Neb-Co Li CCF 1,001 22 45.50 10/05/2000 Unknown

Flaming Gorge Res CCF 6,643 146 45.50 10/05/2000 Unknown

Festo Lake CCF 2,502 55 45.50 10/05/2000 Unknown

Charlie Craig State Hatchery, Arkansas Fish Importation Assessment

October 21, 2003

6

2. Past Stocking History (Continued)

Number Lbs ANS/NTS

Water Name Species Stocked Stocked No/Lb Stocking Date Present

Guernsey Slough CCF 500 11 45.50 10/05/2000 Unknown

Hawk Springs Res CCF 3,003 66 45.50 10/05/2000 Unknown

Grayrocks Res CCF 6,506 143 45.50 10/05/2000 Unknown

Packers Lake CCF 2,502 55 45.50 10/05/2000 Unknown

N Platte R Guer-Glen CCF 1,001 22 45.50 10/05/2000 Unknown

Kleenburn Pond 2 CCF 1,001 22 45.50 10/05/2000 Unknown

Kleenburn Pond 1 CCF 200 4 45.50 10/05/2000 Unknown

Boysen Reservoir CCF 23,196 510 45.50 10/06/2000 Unknown

Beck Lake CCF 1,502 33 45.50 10/06/2000 Unknown

N Platte R Coli-Mill CCF 18,000 1,800 10.00 10/26/2000 Unknown

N Platte R Glen-Ppl CCF 32,410 2,315 14.00 10/26/2000 Unknown

2000 102,469 5,259

Hawk Springs Res CCF 5,825 233 25.00 07/13/2001 Unknown

Bryan Stock Trail Res CCF 500 20 25.00 07/13/2001 Unknown

Guernsey Slough CCF 500 20 25.00 07/13/2001 Unknown

Festo Lake CCF 2,000 80 25.00 07/13/2001 Unknown

Kleenburn Pond 1 CCF 200 8 25.00 07/13/2001 Unknown

Bump Sullivan Res CCF 3,500 140 25.00 07/13/2001 Unknown

Packers Lake CCF 2,000 80 25.00 07/13/2001 Unknown

Kinnear Lake CCF 700 28 25.00 07/13/2001 Unknown

Boysen Reservoir CCF 20,900 836 25.00 07/13/2001 Unknown

Grayrocks Res CCF 6,500 260 25.00 07/13/2001 Unknown

Beck Lake CCF 1,500 60 25.00 07/13/2001 Unknown

Flaming Gorge Res CCF 6,000 240 25.00 07/13/2001 Unknown

Kleenburn Pond 2 CCF 1,000 40 25.00 07/13/2001 Unknown

2002 51,125 2,045

Charlie Craig State Hatchery, Arkansas Fish Importation Assessment

October 21, 2003

7

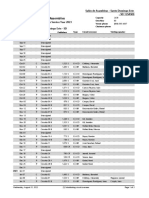

3. Flow Diagram

Step 1 Adult channel catfish spawn in hatchery ponds from June 1- June 15.

⇓

Step 2 Eggs are removed from milk cans and incubate in hatching building for 5-7 days.

⇓

Step 3 Production ponds are filled with spring water approximately 1 month before

stocking.

⇓

Step 4 CCF fry transported to ponds after hatching.

⇓

Step 5 After 1-2 months, channel catfish fingerlings are thinned into new ponds (collected in

seines).

⇓

Step 6 Ponds are partially drained for CCF harvest after 5-6 months in production.

⇓

Step 7 CCF captured with seine, netted into a fish basket and loaded onto CCFH fish

distribution truck with a boom loader.

⇓

Step 8 CCF transported and stocked into fish building holding tanks.

⇓

Step 9 WGFD fish distribution truck arrives and fills with artesian spring water.

⇓

Step 10 CCF are netted out of the holding tank, loaded in bucket of spring water and

weighed.

⇓

Step 11 Buckets of CCF are then transferred to WGFD distribution truck.

⇓

Step 12 CCF poured from bucket into WGFD distribution tank.

Charlie Craig State Hatchery, Arkansas Fish Importation Assessment

October 21, 2003

8

Step 13 During transportation, tank checked periodically for water quality and CCF health.

⇓

Step 14 CCF are transported to Wyoming, then either transferred to another distribution unit

or retained on main distribution unit for stocking. Fish are netted and weighed onto

any receiving distribution units.

⇓

Step 15 Driver nets and weighs CCF from tank into a bucket for stocking in receiving water.

⇓

Step 16 Receiving individual stocks CCF directly into stocking site by either bucket or boat

live car.

⇓

Step 17 Remaining CCF stocked at final stocking site with water released from stocking

truck.

4. Potential Hazards (List relevant species)

A. Aquatic Nuisance Species (ANS) Plants. None identified in immediate drainage

(CONTACT FREQUENCY – NONE).

B. Aquatic Nuisance Species (ANS) Fish and Other Vertebrates. None identified in

immediate drainage (CONTACT FREQUENCY – NONE).

C. Aquatic Nuisance Species (ANS) Invertebrates. None identified in immediate drainage

(CONTACT FREQUENCY – NONE).

D. Non-Target Species (NTS) Plants. Filamentous algae, not an issue (CONTACT

FREQUENCY – VERY LOW).

E. Non-Target Species (NTS) Fish. Occasionally capture mosquitofish (Gambusia affinis)

in ponds (CONTACT FREQUENCY – VERY LOW).

F. Non-Target Species (NTS) Amphibians. Tadpoles (American Bullfrog) occasionally

captured when harvesting ponds. (CONTACT FREQUENCY – VERY LOW).

G. Non-Target Species (NTS) Invertebrates. None captured when harvesting ponds

(CONTACT FREQUENCY –NONE).

Charlie Craig State Hatchery, Arkansas Fish Importation Assessment

October 21, 2003

9

H. Specific Pathogen of Concern and/or Other Health Concerns: Annual fish health

assessments are conducted on channel catfish reared at the CCFH. Channel catfish at

CCFH have experienced mild disease outbreaks in the past including, ESC (Edwarsiella

ictaluri), columnaris (Flexibacter columnaris), and winter fungus (CONTACT

FREQUENCY – VERY LOW).

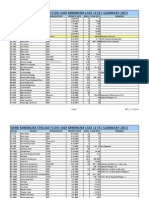

5. Hazard Analysis Worksheet

A. ANS Hazard Analysis Worksheet

(1) (2) (3) (4) (5) (6)

Harvest or Identify potential Are any Justify your What control Is this step a

Aquaculture ANS hazards potential ANS decisions for measures can be critical

Step introduced or hazards column 3. applied to prevent control point?

(from flow diagram) controlled at this significant? the significant (Yes/No)

step (1) (Yes/No) hazards?

Fish/Other Vertebrate

No None Present

All Steps Invertebrate

No None Present

Plant

No None Present

B. NTS Hazard Analysis Worksheet

(1) (2) (3) (4) (5) (6)

Harvest or Identify Are any Justify your What control Is this

Aquaculture Step potential NTS potential decisions for measures can be step a

(from flow diagram) hazards NTS column 3. applied to prevent critical

introduced or hazards the significant control

controlled at this significant? hazards? point?

step (1) (Yes/No) (Yes/No)

Fish/Other Vertebrate

Step 1 Adult channel No None Present

catfish spawn in hatchery Invertebrate

ponds from June 1- June No None Present

15. Plant

No None Present

Parasites and Pathogens

No None Present

Step 2. Eggs are removed Fish/Other Vertebrate

No None Present

from milk cans and Invertebrate

incubate in hatching No None Present

building for 5-7 days. Plant

No None Present

Parasites and Pathogens

No None Present

Step 3. Ponds filled with Fish/Other Vertebrate

No None Present

spring water approximately Invertebrate

1 month before stocking. No None Present

Plant

No None Present

Parasites and Pathogens

No None Present

Charlie Craig State Hatchery, Arkansas Fish Importation Assessment

October 21, 2003

10

B. NTS Hazard Analysis Worksheet (Continued)

(1) (2) (3) (4) (5) (6)

Harvest or Identify Are any Justify your What control Is this

Aquaculture Step potential NTS potential decisions for measures can be step a

(from flow diagram) hazards NTS column 3. applied to prevent critical

introduced or hazards the significant control

controlled at this significant? hazards? point?

step (1) (Yes/No) (Yes/No)

Step 4. Fry transported to Fish/Other Vertebrate

No None Present

ponds after hatching. Invertebrate

No None Present

Plant

No None Present

Parasites and Pathogens

No None Present

Step 5. After 1-2 months, Fish/Other Vertebrate

ID & Remove any

channel catfish fingerlings Gambusia affinis Remote Possibilty

are thinned into new ponds

No NTS Vertebrates No

of NTS Present

(collected in seines).

American Bullfrog From Seine

Invertebrate

No None Present

Plant

No None Present

Parasites and Pathogens

No None Present

Step 6. Ponds are partially Fish/Other Vertebrate

No None Present

drained for CCF harvest Invertebrate

after 5-6 months in No None Present

production. Plant

No None Present

Parasites and Pathogens

No None Present

Step 7. CCF captured with Fish/Other Vertebrate

ID and Remove

seine, netted into a fish Gambusia affinis Remote Possibility

basket and loaded onto

No any NTS Yes

of Introduction

CCFH fish distribution

American Bullfrog Vertebrates

truck with a boom loader. Invertebrate

No None Present

Plant

No None Present

Parasites and Pathogens

No None Present

Step 8. CCF transported Fish/Other Vertebrate

No None Present

and stocked into fish Invertebrate

building holding tanks. No None Present

Plant

No None Present

Parasites and Pathogens

No None Present

Step 9. WGFD fish Fish/Other Vertebrate

No None Present

distribution truck arrives Invertebrate

and filled with artesian No None Present

spring water. Plant

No None Present

Parasites and Pathogens

No None Present

Charlie Craig State Hatchery, Arkansas Fish Importation Assessment

October 21, 2003

11

B. NTS Hazard Analysis Worksheet (Continued)

(1) (2) (3) (4) (5) (6)

Harvest or Identify Are any Justify your What control Is this

Aquaculture Step potential NTS potential decisions for measures can be step a

(from flow diagram) hazards NTS column 3. applied to prevent critical

introduced or hazards the significant control

controlled at this significant? hazards? point?

step (1) (Yes/No) (Yes/No)

Fish/Other Vertebrate

Step 10. CCF are netted If Present, ID &

out of the holding tank, Gambusia affinis Remove Any NTS

loaded in bucket of spring NTS Fish May Be

No Vertebrates From No

water and weighed. American Bullfrog Present in Buckets

Buckets If

Possible

Invertebrate

No None Present

Plant

No None Present

Parasites and Pathogens

No None Present

Step 11. Buckets of CCF Fish/Other Vertebrate

are then transferred to NTS Present

Gambusia affinis NTS Fish May Be

WGFD distribution truck. No Controlled at No

Present in Buckets

American Bullfrog Subsequent Step

Invertebrate

No None Present

Plant

No None Present

Parasites and Pathogens

No None Present

Step 12. CCF poured from Fish/Other Vertebrate

If NTS Present,

bucket into WGFD Gambusia affinis NTS Fish May Be Run Bucket Over

distribution tank. Yes Yes

Present in Buckets Sort Board

American Bullfrog

Before Loading

Invertebrate

No None Present

Plant

No None Present

Parasites and Pathogens

No None Present

Step 13. During Fish/Other Vertebrate

transportation, tank If NTS Present,

Gambusia affinis NTS Fish May Be

checked periodically for No Try to Remove If No

Present in Tank

water quality and CCF American Bullfrog Possible

health.

Invertebrate

No None Present

Plant

No None Present

Parasites and Pathogens

No None Present

Fish/Other Vertebrate

Step 14. CCF are NTS Fish May Be Visual Inspection

transported to Wyoming, Gambusia affinis Present in Net Of Sampled Fish,

then either transferred to No No

Sort Board Fish

another distribution unit or American Bullfrog

If NTS Present

retained on main

Invertebrate

distribution unit for No None Present

stocking. Fish are netted Plant

and weighed onto any No None Present

receiving distribution units. Parasites and Pathogens

No None Present

Charlie Craig State Hatchery, Arkansas Fish Importation Assessment

October 21, 2003

12

B. NTS Hazard Analysis Worksheet (Continued)

(1) (2) (3) (4) (5) (6)

Harvest or Identify Are any Justify your What control Is this

Aquaculture Step potential NTS potential decisions for measures can be step a

(from flow diagram) hazards NTS column 3. applied to prevent critical

introduced or hazards the significant control

controlled at this significant? hazards? point?

step (1) (Yes/No) (Yes/No)

Fish/Other Vertebrate

Step 15. Driver nets and If NTS ID’d By Visual Inspection

weighs CCF from tank into Gambusia affinis Step 12, NTS May Of Bucket, Sort If

a bucket for stocking in Yes Yes

Be Present In NTS Identified

receiving water. American Bullfrog

Bucket

Invertebrate

No None Present

Plant

No None Present

Parasites and Pathogens

No None Present

Fish/Other Vertebrate

Step 16. Receiving NTS Fish May Be If NTS ID’d At

individual stocks CCF Gambusia affinis Present In Bucket Steps 7 & 15,

directly into stocking site Yes Visual Review Of No

by either bucket or boat American Bullfrog

Bucket Before

live car.

Stocking

Invertebrate

No None Present

Plant

No None Present

Parasites and Pathogens

No None Present

Fish/Other Vertebrate

Step 17. Remaining CCF NTS Fish May Still If NTS ID’d At

stocked at final stocking Gambusia affinis Be Present in Step 14 Or 15,

site with water released Distribution Tank Empty Tank Into

from stocking truck. American Bullfrog

Net And Run

Yes Yes

Remaining CCF

Over Sort Board

If NTS Is Of

Concern

Invertebrate

No None Present

Plant

No None Present

Parasites and Pathogens

No None Present

Charlie Craig State Hatchery, Arkansas Fish Importation Assessment

October 21, 2003

13

6. ANS-HACCP Plan Form – Preventative Measures

(1) Critical Control Point: Step 7. CCF captured with seine, netted into a fish basket and loaded

onto CCFH fish distribution truck with a boom loader.

(2) Significant Hazard(s): First opportunity to examine CCF for NTS vertebrates or plant introduction.

If no NTS present, risk level reduced significantly.

(3) Limits for Each Control Measure: Identify any NTS vertebrate present. WGFD representatives

informed of NTS prior to their arrival for loading.

(4) What: If NTS identified, requires focused HACCP due to increased risk level.

Identified NTS may be acceptable for destination and considered lower risk

level after review of WGFD NTS Acceptance List (APPENDIX C,

“Stocking Guide for Non-Target Species Management”).

(5) How: If NTS is identified and a concern, additional examination of fish loaded to

the hatchery is required to determine extent of NTS presence. Sorting and

removal may be required in subsequent steps if NTS not acceptable for

Monitoring destination; or confirm load not accepted for importation.

(6) Frequency: Depended on NTS concern. NTS species may be acceptable for

destination, if so, subsequent monitoring required reaffirming

identified species only NTS present. If NTS species not acceptable,

load not imported to Wyoming if subsequent steps cannot effectively

remove NTS by bucket and sorting board.

(7) Who: Charlie Craig State Fish Hatchery personnel upon sampling, assisted by

WGFD personnel if NTS removal is warranted by Step 12.

(8) Corrective Actions: Upon identifying NTS, Charlie Craig hatchery personnel contact WGFD

representative for NTS acceptance verification. WGFD representative contacts

Assistant Fish Culture Supervisor (307-473-3416) for NTS verification and

final decision. Apply removal procedures if feasible or lot not accepted.

(9) Verification: Communication with WGFD representative to confirm NTS present. WGFD

importation procedures enacted if NTS load accepted.

(10) Records: AGFC stocking record and WGFD stocking slip – identify any NTS under “Remarks” if

load accepted.

>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>><<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<

(1) Critical Control Point: Step 12. CCF poured from bucket into WGFD distribution tank.

(2) Significant Hazard(s): A. If acceptable NTS identified in Step 7, load bucket directly into

distribution unit, monitoring each bucket through Steps 10-11 to

assure no other NTS species are present.

B. If NTS not acceptable, but the load is accepted, continue monitoring

at Step 10 and remove NTS by sorting board during Step 12 before

fish are loaded.

(3) Limits for Each Control Measure: Running each bucket over sort board and complete inventory

sorting provides opportunity to identify and remove

unacceptable NTS if present.

Charlie Craig State Hatchery, Arkansas Fish Importation Assessment

October 21, 2003

14

6. ANS-HACCP Plan Form – Preventative Measures (Continued)

(4) What: Exposure during netting and individual inspection/removal of NTS during

Steps 10-12.

(5) How: Identification and removal of NTS during each step. Sorting board employed

Monitoring before fish are loaded on distribution unit if NTS not acceptable, but load is.

(6) Frequency: Each bucket examined or sorted over board, depending on NTS type.

(7) Who: Charlie Craig State Hatchery personnel and WGFD distribution personnel.

(8) Corrective Actions: Removal of any NTS of concern during each step and by sorting board during

Step 12.

(9) Verification: Visual inspection of fish during Step 12 to verify NTS of concern not loaded into

distribution unit.

(10) Records: AGFC stocking record, WGFD stocking slip “Remarks” if load accepted.

>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>><<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<

(1) Critical Control Point: Step 15. Driver nets and weighs CCF from tank into a bucket for

stocking in receiving water.

(2) Significant Hazard(s): Unacceptable NTS may be introduced into stocking site.

(3) Limits for Each Control Measure: Visual identification for any remaining NTS during handling

and running over a sorting board if unacceptable NTS present.

(4) What: Each net load examined for NTS. If unacceptable NTS possible, run all nets

over sorting board to remove.

Monitoring (5) How: Sorting board and examine each net

(6) Frequency: Each net load.

(7) Who: All personnel available.

(8) Corrective Actions: Each net carefully examined and run across sorting board.

(9) Verification: Identify and total all unacceptable NTS.

(10) Records: Identify NTS species and total(s) removed on WGFD stocking slip under “Remarks”.

>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>><<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<

(1) Critical Control Point: Step 17. Remaining CCF stocked at final stocking site with water

released from stocking truck.

(2) Significant Hazard(s): Probable release of unacceptable NTS if identified during Step 15.

(3) Limits for Each Control Measure: Unloading nets may identify unacceptable NTS present in Step

15 for final removal.

(4) What: Park truck away from direct contact with receiving water and run remaining

fish over sorting board.

Monitoring (5) How: Drain water until remaining fish can be removed and sorted before stocking.

(6) Frequency: During complete draining of distribution unit and subsequent sorting.

(7) Who: All available personnel.

(8) Corrective Actions: All remaining fish carefully examined and run across sorting board.

(9) Verification: Identify and total all unacceptable NTS.

(10) Records: Identify NTS species and total(s) removed on WGFD stocking slip under “Remarks”.

Inform Charlie Craig State Fish Hatchery personnel of final numbers and species.

Charlie Craig State Hatchery, Arkansas Fish Importation Assessment

October 21, 2003

15

7. HACCP Step Summary

NTS occurrences in ponds are extremely rare and in very low incidence levels. If mosquitofish

(Gambusia affinis) and/or American bullfrog tadpoles are present, they can be easily identified

and removed during fish harvest and loading (Steps 5, 7 and 12). Step 8 to hold harvested fish in

the fish building holding tanks increases the opportunity for further NTS assessment under a

controlled environment that greatly enhances the ability to confirm the load NTS free.

ANS/NTS introduction with channel catfish from Charlie Craig Fish Hatchery is considered a

“very low” concern due to drainage location and water source (underground spring) of the

hatchery. The steps throughout this HACCP identifying vertebrate NTS are provided as a

precautionary process on the rare occasion NTS are encountered.

Charlie Craig State Hatchery, Arkansas Fish Importation Assessment

October 21, 2003

16

You might also like

- Foragers on America's Western Edge: The Archaeology of California's Pecho CoastFrom EverandForagers on America's Western Edge: The Archaeology of California's Pecho CoastNo ratings yet

- StockingReport02 06 09Document1 pageStockingReport02 06 09DavidNo ratings yet

- Operating History of The Deepwater HorizonDocument6 pagesOperating History of The Deepwater HorizonOSDocs2012No ratings yet

- StockingReport02 27 09Document1 pageStockingReport02 27 09DavidNo ratings yet

- StockingReport01 23 09Document1 pageStockingReport01 23 09DavidNo ratings yet

- StockingReport04 10 09Document1 pageStockingReport04 10 09DavidNo ratings yet

- Oil Mexico DiscoveriesDocument4 pagesOil Mexico DiscoveriesNGT56No ratings yet

- StockingReport03 13 09Document1 pageStockingReport03 13 09DavidNo ratings yet

- Joe - Reservoir Surveillance W Ofm - Fall 2011Document48 pagesJoe - Reservoir Surveillance W Ofm - Fall 2011Diego TenorioNo ratings yet

- Puyullup Tribe Salmon, Trout Char Report 2005-06 12 Appendix F&G Through End CoverDocument5 pagesPuyullup Tribe Salmon, Trout Char Report 2005-06 12 Appendix F&G Through End CoveremmettoconnellNo ratings yet

- Carsoe Smartline Fishing-Grounds-ReportDocument1 pageCarsoe Smartline Fishing-Grounds-Reportfadelrifqi8No ratings yet

- Final ROE For NB Centennial Well Water RightDocument51 pagesFinal ROE For NB Centennial Well Water RightAaron KunklerNo ratings yet

- GMPE Shallow Crustal EQ-paper (Sadigh Chang Egan 1997) PDFDocument10 pagesGMPE Shallow Crustal EQ-paper (Sadigh Chang Egan 1997) PDFZens Irving Huamani RodriguezNo ratings yet

- Okaloosa ReefDocument5 pagesOkaloosa ReefJosiah JohnsonNo ratings yet

- FDA 1994 P 0127 0005 - Attachment - 1Document4 pagesFDA 1994 P 0127 0005 - Attachment - 1Josh AndersonNo ratings yet

- 2014 Impaired Waters - 303 (D) List: Category 5 - Waters Needing Total Maximum Daily Load StudyDocument6 pages2014 Impaired Waters - 303 (D) List: Category 5 - Waters Needing Total Maximum Daily Load StudySouthside DailyNo ratings yet

- StockingReport02 13 09Document1 pageStockingReport02 13 09DavidNo ratings yet

- Snyder County TIP 2021 04 20Document2 pagesSnyder County TIP 2021 04 20Fred KellerNo ratings yet

- Produced Water - ExxonMobilDocument3 pagesProduced Water - ExxonMobilVijay RajaindranNo ratings yet

- StockingReport01 09 09Document1 pageStockingReport01 09 09DavidNo ratings yet

- 8 Sample ExampleDocument1 page8 Sample ExampleKamalNo ratings yet

- Bakken Shale MontanaDocument21 pagesBakken Shale MontanacarlodolciNo ratings yet

- Foundation DrawingsDocument71 pagesFoundation DrawingsGurumoorthy Dhandayudapani100% (8)

- List Stock Erw Pipe FPH & Inv CM-2 2017Document10 pagesList Stock Erw Pipe FPH & Inv CM-2 2017Sigit PrasetyoNo ratings yet

- United States Department of The Interior: Mr. J.E. WardDocument20 pagesUnited States Department of The Interior: Mr. J.E. WardGrishworld ShanNo ratings yet

- DoublesDocument8 pagesDoublesapi-374652244No ratings yet

- 2008 Worldwide EOR Survey OGJDocument13 pages2008 Worldwide EOR Survey OGJOrlando Casiano FloresNo ratings yet

- A Prospecting: The Discovery ClaimsDocument39 pagesA Prospecting: The Discovery ClaimsAssyifaKurniandaNo ratings yet

- 188: Land To The Rear of Prospect House, Cross Street, Caerleon, Newport. Watching BriefDocument54 pages188: Land To The Rear of Prospect House, Cross Street, Caerleon, Newport. Watching BriefAPAC LtdNo ratings yet

- Additional Geologic Site Characterization Studies West Hackberry Salt DomeDocument110 pagesAdditional Geologic Site Characterization Studies West Hackberry Salt DomeetchplainNo ratings yet

- Flash Report 10 16june10Document2 pagesFlash Report 10 16june10Michael AllenNo ratings yet

- Attachment H To Declaration by Alice C. Newton United States v. Bundy, No. 2:12-cv-804-LDG-GWFDocument34 pagesAttachment H To Declaration by Alice C. Newton United States v. Bundy, No. 2:12-cv-804-LDG-GWFShelley PowersNo ratings yet

- Cimarron Basin 2010 303 (D) List of Waters Formerly Listed As ImpairedDocument25 pagesCimarron Basin 2010 303 (D) List of Waters Formerly Listed As ImpairedAlison ReberNo ratings yet

- PSM 내용 수정본Document6 pagesPSM 내용 수정본호No ratings yet

- Fuerza Hipica: WoodbineDocument11 pagesFuerza Hipica: WoodbineYoshue LeyzeagaNo ratings yet

- List Stock Erw Pipe FPH & Inv CM-2 2017Document11 pagesList Stock Erw Pipe FPH & Inv CM-2 2017Sigit PrasetyoNo ratings yet

- Bfar Approved Fishing Vessels and Boats: Fiqd-FisDocument25 pagesBfar Approved Fishing Vessels and Boats: Fiqd-FisLenlen Ledesma LagranaNo ratings yet

- Ca14422 Jul10Document4 pagesCa14422 Jul10dudmanlakeNo ratings yet

- DGS - Real Estate Inventory 2011-04-08-06-00-31Document553 pagesDGS - Real Estate Inventory 2011-04-08-06-00-31Tim A TellerNo ratings yet

- Wrecks in Gulf of MexicoDocument233 pagesWrecks in Gulf of MexicoEmmanuelleLizéNo ratings yet

- DeedRestrictions 202010201321543258Document52 pagesDeedRestrictions 202010201321543258Deepanshu TanejaNo ratings yet

- Wqls Stage 1 Status Report - 2001 - Complete - Website 0Document94 pagesWqls Stage 1 Status Report - 2001 - Complete - Website 0Santosh K SatiNo ratings yet

- 03.7.17 SJMNDocument22 pages03.7.17 SJMNBayAreaNewsGroupNo ratings yet

- Kelseyville Skate Park Final PlansDocument21 pagesKelseyville Skate Park Final PlansLakeCoNewsNo ratings yet

- Iwrb Minimum Stream Flow and Minimum Lake Level Summary 2013Document11 pagesIwrb Minimum Stream Flow and Minimum Lake Level Summary 2013Mark ReinhardtNo ratings yet

- AssembliesSASD 2023Document3 pagesAssembliesSASD 2023LaurentEuniceNo ratings yet

- BuildingreportmountolympusnurseryDocument15 pagesBuildingreportmountolympusnurseryapi-385626757No ratings yet

- StockingReport01 16 09Document1 pageStockingReport01 16 09DavidNo ratings yet

- Chart Availability List Correct To: Week 43/10: N/A N/ADocument59 pagesChart Availability List Correct To: Week 43/10: N/A N/ATaleb HoballahNo ratings yet

- Global Navigation Satellite System Positions, Horizontal Datums and Position ShiftsDocument3 pagesGlobal Navigation Satellite System Positions, Horizontal Datums and Position ShiftsasdfNo ratings yet

- Memorandum: Date: Company: Attention: Copy: From: Subject: Lord Byron Scoping EstimateDocument6 pagesMemorandum: Date: Company: Attention: Copy: From: Subject: Lord Byron Scoping EstimateJoseph MofatNo ratings yet

- 109 PowerStationsDataDocument700 pages109 PowerStationsDataShruthi DilipNo ratings yet

- Producing CO2, Other Gas, and Chemical EOR in USDocument3 pagesProducing CO2, Other Gas, and Chemical EOR in USMuhammad AL HafizhNo ratings yet

- 10.09.18 - Contra Costa CountyDocument18 pages10.09.18 - Contra Costa CountyBayAreaNewsGroupNo ratings yet

- Smcra Noi FinalDocument23 pagesSmcra Noi FinalgwynethdNo ratings yet

- Oil ZanzibarDocument19 pagesOil ZanzibarMZALENDO.NETNo ratings yet

- Cash Book RusbelPerezDocument2 pagesCash Book RusbelPerezRusbel PerezNo ratings yet

- Patent Us6681853 PDFDocument15 pagesPatent Us6681853 PDFBryan GómezNo ratings yet

- Ml20303a139 PDFDocument136 pagesMl20303a139 PDFNathan BlockNo ratings yet

- Pressure Test Sample Form R2Document1 pagePressure Test Sample Form R2Joe ClarkeNo ratings yet

- Metra Rail Vendor RegDocument2 pagesMetra Rail Vendor RegJoe ClarkeNo ratings yet

- General Knowledge Trivia - Side Games - Silent AuctionDocument1 pageGeneral Knowledge Trivia - Side Games - Silent AuctionJoe ClarkeNo ratings yet

- Keokuk Steel Castings Job Description: General InformationDocument2 pagesKeokuk Steel Castings Job Description: General InformationJoe ClarkeNo ratings yet

- Pressure Test Sample Form R2Document1 pagePressure Test Sample Form R2Joe ClarkeNo ratings yet

- ProQC ExampleReport TS16949 Audit PDFDocument39 pagesProQC ExampleReport TS16949 Audit PDFJoe Clarke100% (3)

- Haz An WKSHTDocument2 pagesHaz An WKSHTJoe ClarkeNo ratings yet

- Mills KSC Capabilities Statement Rev 0Document7 pagesMills KSC Capabilities Statement Rev 0Joe ClarkeNo ratings yet

- Request For Information Jan 2017Document3 pagesRequest For Information Jan 2017Joe ClarkeNo ratings yet

- Mills KSC Capabilities Statement Rev 0Document1 pageMills KSC Capabilities Statement Rev 0Joe ClarkeNo ratings yet

- Mills KSC Capabilities Statement Rev 0Document1 pageMills KSC Capabilities Statement Rev 0Joe ClarkeNo ratings yet

- PAA - 001 Open Sample Status ReportDocument1 pagePAA - 001 Open Sample Status ReportJoe ClarkeNo ratings yet

- Keokuk Steel Castings Presentation - GenericDocument23 pagesKeokuk Steel Castings Presentation - GenericJoe ClarkeNo ratings yet

- Fire Prevention - PolicyDocument16 pagesFire Prevention - PolicyJoe ClarkeNo ratings yet

- Fish Haccp Model 2 - enDocument14 pagesFish Haccp Model 2 - enTRANDAFNo ratings yet

- App D SuppliersDocument4 pagesApp D SuppliersJoe ClarkeNo ratings yet

- PRP 5.7 StorageDocument2 pagesPRP 5.7 StorageJoe ClarkeNo ratings yet

- Glass Policy Verification RecordDocument2 pagesGlass Policy Verification RecordJoe ClarkeNo ratings yet

- Haccp Bear Lake EggtakeDocument8 pagesHaccp Bear Lake EggtakeJoe ClarkeNo ratings yet

- Haccp Bear Lake EggtakeDocument8 pagesHaccp Bear Lake EggtakeJoe ClarkeNo ratings yet

- QCI Services PricelistDocument15 pagesQCI Services PricelistJoe ClarkeNo ratings yet

- ProQC ExampleReport TS16949 Audit PDFDocument39 pagesProQC ExampleReport TS16949 Audit PDFJoe Clarke100% (3)

- ThesisDocument248 pagesThesisJoe ClarkeNo ratings yet

- HM 7 HACCP Flowchart Verification PDFDocument1 pageHM 7 HACCP Flowchart Verification PDFJoe ClarkeNo ratings yet

- Kpfsteel 2009 CPDocument13 pagesKpfsteel 2009 CPJoe ClarkeNo ratings yet

- University of Maine Maple SyrupDocument12 pagesUniversity of Maine Maple SyrupJoe ClarkeNo ratings yet

- PO Terms and ConditionsDocument1 pagePO Terms and ConditionsJoe Clarke0% (1)

- GX5CrNi19-10 - 1Document2 pagesGX5CrNi19-10 - 1Joe ClarkeNo ratings yet

- Invitation To Bid and Instructions To BiddersDocument16 pagesInvitation To Bid and Instructions To BiddersJoe ClarkeNo ratings yet

- Our Survival of SoulDocument463 pagesOur Survival of SoulAnonymous Mq8EkiAyhM100% (2)

- Validated HPTLC Method For Assay of Prednisolone in Tablets and Comparison With Pharmacopeial MethodsDocument4 pagesValidated HPTLC Method For Assay of Prednisolone in Tablets and Comparison With Pharmacopeial MethodsSyifa KhairunnisaNo ratings yet

- Pts 1 Klas XI 2022 (Print)Document11 pagesPts 1 Klas XI 2022 (Print)WoldiaNo ratings yet

- Process Safety and Environmental Protection 2009 Volume 87, Number 1Document2 pagesProcess Safety and Environmental Protection 2009 Volume 87, Number 1jenanboyzNo ratings yet

- LAS10 Week 4 7 2nd QuarterDocument4 pagesLAS10 Week 4 7 2nd QuarterGleamor DaagNo ratings yet

- With Conviction: Moving AheadDocument155 pagesWith Conviction: Moving Aheadkapadia krunalNo ratings yet

- Water Pollution Is The Contamination ofDocument36 pagesWater Pollution Is The Contamination ofsuradotNo ratings yet

- Notice, Caution, Warning Evaluation I Ix Graders: Acces For Residents OnlyDocument2 pagesNotice, Caution, Warning Evaluation I Ix Graders: Acces For Residents OnlyRizqiyah SakinahNo ratings yet

- Waste ManagementDocument34 pagesWaste ManagementSivaRamanNo ratings yet

- Civil Engineering & Its BranchesDocument37 pagesCivil Engineering & Its BranchesMohammad JavedNo ratings yet

- Qi - Magazine Nº48Document41 pagesQi - Magazine Nº48Carvalho100% (4)

- Biology Questions CholeraDocument12 pagesBiology Questions CholeraLucas100% (1)

- Gastro-Intestinal Tract: Entamoeba HistolyticaDocument25 pagesGastro-Intestinal Tract: Entamoeba Histolyticanh2411No ratings yet

- United States Patent (19) 11 Patent Number: 5,676,977: Antelman 45 Date of Patent: Oct. 14, 1997Document4 pagesUnited States Patent (19) 11 Patent Number: 5,676,977: Antelman 45 Date of Patent: Oct. 14, 1997Sunita MarturNo ratings yet

- Segmentos Ica 2022 PDFDocument9 pagesSegmentos Ica 2022 PDFRoberto RodríguezNo ratings yet

- Msds Material Safety Data Sheet For #2 Diesel: of TermsDocument7 pagesMsds Material Safety Data Sheet For #2 Diesel: of TermsAndrew PaulNo ratings yet

- BingggDocument12 pagesBingggZulham YahyaNo ratings yet

- MSDS STA Neoplastine CI PlusDocument8 pagesMSDS STA Neoplastine CI Plusasmaul husnahNo ratings yet

- Risk Management in Military AviationDocument16 pagesRisk Management in Military AviationSp AndaNo ratings yet

- 3 Ways To Prune RhododendronDocument4 pages3 Ways To Prune RhododendronAndreNo ratings yet

- 2 BiotechnologyDocument5 pages2 BiotechnologyJannah BuenavistaNo ratings yet

- Miranda Miracell NewDocument2 pagesMiranda Miracell NewPablo FaldutiNo ratings yet

- IISFM Schemes PDFDocument1 pageIISFM Schemes PDFSurendrasinghNo ratings yet

- 9c5a4module 2 Self EsteemDocument14 pages9c5a4module 2 Self EsteemHarshita Jakhodia100% (1)

- Literature Review On Voluntary Blood DonationDocument7 pagesLiterature Review On Voluntary Blood Donationakjnbowgf100% (1)

- MIP17 - HSE - PP - 001 Environment Management Plan (EMP) 2021 REV 3Document40 pagesMIP17 - HSE - PP - 001 Environment Management Plan (EMP) 2021 REV 3AmeerHamzaWarraichNo ratings yet

- IntralipidDocument3 pagesIntralipidGwyn RosalesNo ratings yet

- 2017-02-23 Calvert County TimesDocument24 pages2017-02-23 Calvert County TimesSouthern Maryland OnlineNo ratings yet

- Addis Ababa Science and Technology University (AASTU)Document24 pagesAddis Ababa Science and Technology University (AASTU)Wasihun DanielNo ratings yet

- Aliens & Asteroids - Expansion 02 - More Faces and FactionsDocument42 pagesAliens & Asteroids - Expansion 02 - More Faces and FactionsJean Dupont100% (1)