Professional Documents

Culture Documents

Sensus 143 PDF

Uploaded by

Vel MuruganOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sensus 143 PDF

Uploaded by

Vel MuruganCopyright:

Available Formats

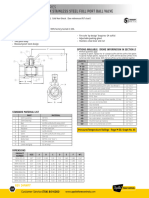

TD-1301

Sensus Metering Systems

Model 143-80 Service Regulator

Models: Valve Body: Cast Iron, 125 psig Working Pressure Straight Body

Technical Data 143-80-1 Spring and Lower Case: Die-Cast Aluminum 3/4" x 3/4"

143-80-2 Orifice: Stainless Steel 3/4" x 1"

Fulcrum Pin: Aluminum or Brass 3/4" x 1-1/4"

143-80-2HP

I N D U S T R Y

Valve Seat/Stem: One piece molded

1" x 1"

Buna-N seat pad and fiberglass reinforced nylon stem

Throat/Support/Stem Guide: Cast Aluminum

1" x 1-1/4"

integral to lower case

Diaphragm Plate: Plated Steel 1-1/4" x 1-1/4"

Diaphragm: Nylon fabric reinforced Buna-N with full 26 in effective area 2

Vent and Valve: Precision-fit polyethylene valve and seat, threaded 3/4" or 1" NPT

Operating Temperature: -20° F to 150° F (-28.9° C to 65.5° C)

Corrosion Protection: Cases dip primed chromate conversion coating, topcoat enamel

Internal Relief Valve: Set to relieve at approximately 7" w.c. above normal outlet pressure setting

Spring Ranges Orifice and Maximum Inlet Pressure

G A S

Outlet Pressure Spring Spring Orifice Part Number Pressure

Ranges Color Part Number 1

⁄8 " aluminum 143-62-023-37 125 psig

3 1⁄2" to 61⁄2" w.c. Red 143-62-021-15 3

⁄16" aluminum 143-63-023-40 125 psig

5" to 81⁄2" w.c. Blue 143-62-021-16 1

⁄4" aluminum 143-62-023-42 60 psig

6" to 14" w.c. Green 143-62-021-17

T H E

5

⁄16" aluminum 143-62-023-43 40 psig

12" to 28" w.c. Orange 143-62-021-18 3

⁄8 " aluminum 143-62-023-44 40 psig

1

⁄2 psi to 2 psi Black & White 143-62-021-22 1

⁄2" aluminum 143-62-023-45 20 psig

1

⁄2 psi to 3 psi Cadmium* 173-62-021-02 5

⁄8 " aluminum 143-62-023-46 10 psig

2 to 6 psi Black* 139-16-021-01

*For high pressure model 143-80-2HP

Relief Valve Performance: Lever blocked with valve disc in the wide open position

7" w.c. Set Point – Blue Spring 7" w.c. Set Point – Blue Spring

3/4" Vent – No Vent Piping 1" Vent – No Vent Piping

1

1

2 ⁄2 2 ⁄2

3/8" 5/16" 1/4" 3/16" 3/8" 5/16" 1/4" 3/16"

Orifice Orifice Orifice Orifice Orifice Orifice Orifice Orifice

2 2

OUTLET PRESSURE – in psi.

OUTLET PRESSURE – in psi.

11⁄2 11⁄2

1/8" 1/8"

Orifice Orifice

1 1

1

1

⁄2 ⁄2

0 0

0 10 20 30 40 50 60 70 80 90 100 0 10 20 30 40 50 60 70 80 90 100

INLET PRESSURE – in psi INLET PRESSURE – in psi

Maximum Emergency Pressure Full Open Capacity

The maximum pressure that the model 143-80-1, 143-80-2 Use the following formula for the full open capacity:

and 143-80-2HP regulator inlets may be subjected under abnormal P

1. Q = K PO(PI – PO) .... (for I less than 1.894)

conditions without causing damage to the regulator is the stated PO

Maximum Inlet Pressure + 50 psi KPI P

2. Q = ...................... (for I greater than 1.894)

2 PO

Note: For the Low Pressure Cut Off version model 143-80-6 it is

Q = maximum capacity of the regulator

Maximum Inlet Pressure + 10 psi. See bulletin TD-1301-L (in SCFH of 0.6 specific gravity natural gas).

The maximum pressure to which the 143-80 diaphragm case may K = the “K” factor, the regulator constant from the table below.

be subjected under abnormal conditions without causing damage PI = absolute inlet pressure (psia).

to the internal parts of the regulator is the set point + 3 psi. PO = absolute outlet pressure (psia).

If the outlet pressure exceeds this pressure, the regulator must

5 1 3 5 1 3 1

be removed from service and carefully inspected. Damaged or Orifice ⁄8" ⁄2" ⁄8" ⁄16 " ⁄4 " ⁄16 " ⁄8"

otherwise unsatisfactory parts must be replaced before returning K 820 520 292 206 132 74 33

the regulator to service. The maximum outlet pressure that can

be safely contained in the 143-80 diaphragm case is 10 psi

(safely means no leakage as well as no bursting).

Model 143-80 Technical Data

Capacities Body Size 3/4" x 3/4"

Flow capacities in SCFH natural gas Inlet Orifice

(0.6 specific gravity – 14.65 psia – 60°F) psig 1/8" 3/16" 1/4" 5/16" 3/8" 1/2" 5/8"

Capacities are based on the following maximum 1/2 – – – – 340 450 510

variations in outlet pressure: 1 – – – 480 500 510 530

Red and Blue Springs – 1" w.c. droop 2 – – 530 560 570 580 600

3 – 420 600 620 630 650 670

Orange Spring – 3" w.c. droop

5 250 560 700 720 730 770 790

Green Spring – 2" w.c. droop 7.5 310 700 840 860 880 900 900

Black Spring – 10% droop 10 370 830 950 970 1000 1020 1020

Note: The 1/2 psig, 1 psig and 2 psig inlet pressures 20 530 1200 1220 1240 1250 1270 –

apply only to Red and Blue springs. 40 860 1570 1330 1340 1450 – –

Note: The last capacity figure in each column 60 1200 1660 1520 – – – –

indicates the maximum capacity for each 80 1500 1710 – – – – –

orifice at recommended pressure within 125 1800 1900 – – – – –

the optimum performance range.

The performance data is based on normal testing at

70°F flowing temperature.

Body Size 3/4" x 1" • 1" x 1"

Changes in performance can occur at extreme low

flowing temperatures. Inlet Orifice

psig 1/8" 3/16" 1/4" 5/16" 3/8" 1/2" 5/8"

Other Gases 1/2 – – – – 350 460 520

1 – – – 480 550 600 650

143-80 Regulators are mainly used on natural gas.

2 – – 530 700 840 880 780

However, they perform equally well on LP gas, nitro-

3 – 420 650 870 1000 920 810

gen, dry CO2, air and others.

5 250 580 890 1120 1160 950 970

Other Gases Correction Factor 7.5 310 700 1140 1340 1270 1140 1060

Air (Specific Gravity 1.0) 0.77 10 370 840 1360 1500 1330 1200 1180

Propane (Specific Gravity 1.53) 0.63 20 530 1230 2000 1600 1480 1400 –

1350 BTU Propane Air Mix (1.20) 0.71 40 860 1700 2000 1640 1900 – –

Nitrogen (Specific Gravity 0.97) 0.79 60 1200 1900 2000 – – – –

Dry Carbon Dioxide 80 1540 2000 – – – –

(Specific Gravity 1.52) 0.63 125 2100 2100 – – – – –

For other non corrosive gases: 0.6

CORRECTION FACTOR = Specific Gravity

of the Gas Body Size 3/4" x 1-1/4" • 1" x 1-1/4" • 1-1/4" x 1-1/4"

Dimensions Inlet Orifice

psig 1/8" 3/16" 1/4" 5/16" 3/8" 1/2" 5/8"

Regulator A B C D E F 1/2 – – – – 350 460 520

143-80 9 3⁄8" 15⁄16" 37⁄16" 67⁄8" 53⁄4" 131⁄32" 1 – – – 480 550 680 760

B

2 – – 530 700 840 1020 1030

C

A 3 – 420 650 870 1030 1200 1050

5 250 580 890 1180 1350 1490 1060

7.5 310 700 1140 1500 1610 1580 1060

10 370 840 1360 1700 1710 1800 1180

E 20 630 1230 1600 1800 1900 1900 –

40 860 1800 2200 1900 2000 – –

60 1200 2100 2400 – – – –

80 1550 2200 – – – – –

F 125 2250 2400 – – – – –

D

Mounting Positions

805 Liberty Boulevard

DuBois, PA 15801

6 – 12 POSITION 6 – 9 POSITION 12 – 12 POSITION 12 – 9 POSITION 800-375-8875

Fax: (814) 375-8460

www.sensus.com

(open “North America Gas”)

© Sensus Metering Systems 2006 Made in USA

6 – 6 POSITION 6 – 3 POSITION 12 – 6 POSITION 12 – 3 POSITION

09-06-Becken 50M

You might also like

- 440T4 4T60 4t60e 4t65eDocument24 pages440T4 4T60 4t60e 4t65eFTompkins73100% (4)

- PR-1078 - Hydrogen Sulphide Management ProcedureDocument22 pagesPR-1078 - Hydrogen Sulphide Management Procedureromedic360% (1)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- An Introduction to Metal-Working (Illustrated)From EverandAn Introduction to Metal-Working (Illustrated)Rating: 2.5 out of 5 stars2.5/5 (2)

- 015 VT PumpsDocument32 pages015 VT PumpsZainul Abdin100% (1)

- Cisco Email Security Customer PresentationDocument38 pagesCisco Email Security Customer Presentationravi199250% (2)

- Tenarishydril-Premium-Connections-Catalog TSH Blue PDFDocument2 pagesTenarishydril-Premium-Connections-Catalog TSH Blue PDFGustavo Pérez100% (1)

- Pragmatic Electrical Engineering: FundamentalsDocument201 pagesPragmatic Electrical Engineering: FundamentalsaminmominNo ratings yet

- Especificaciones Tecnicas Motor 4g54 2.6ltsDocument20 pagesEspecificaciones Tecnicas Motor 4g54 2.6ltsjr50% (2)

- Online Bank SynopsisDocument7 pagesOnline Bank SynopsisPrashant VermaNo ratings yet

- Model 043-B Service Regulator: Technical DataDocument2 pagesModel 043-B Service Regulator: Technical Dataramiro rincon suarezNo ratings yet

- Plastic Modular Belt: Rough Uni CSBDocument4 pagesPlastic Modular Belt: Rough Uni CSBSrinadh ShaikNo ratings yet

- Guardian G1814P Eyewash Station Wall Mounted Plastic Bowl TechdataDocument2 pagesGuardian G1814P Eyewash Station Wall Mounted Plastic Bowl TechdatamwrsbsNo ratings yet

- F-14 Park Jet (Assembly Drawing Non-Tiled)Document1 pageF-14 Park Jet (Assembly Drawing Non-Tiled)pedrods141No ratings yet

- VW-BV 80R (80 Series-RB) - v2021Document4 pagesVW-BV 80R (80 Series-RB) - v2021Mazwan Che MansorNo ratings yet

- P627 High Flow Gas Regulator: ApplicationsDocument10 pagesP627 High Flow Gas Regulator: Applicationsivan8villegas8buschNo ratings yet

- Product Data Sheet: Actuator AssemblyDocument2 pagesProduct Data Sheet: Actuator AssemblylorenzoNo ratings yet

- SHEF30 SalesDocument2 pagesSHEF30 Salesallen_worstNo ratings yet

- SFdetails 1Document1 pageSFdetails 1AlimajNo ratings yet

- T&S Brass and Bronze Works, Inc.: B-0113-ADF12-BDocument2 pagesT&S Brass and Bronze Works, Inc.: B-0113-ADF12-BSheik Abdul NazeerNo ratings yet

- Plastic Y FiltersDocument1 pagePlastic Y FiltersMuhammad UsmanNo ratings yet

- Reotemp RTD Assembly: Part#: BH-1T-PD12524Y DescriptionDocument1 pageReotemp RTD Assembly: Part#: BH-1T-PD12524Y DescriptionJAIME CIFUENTESNo ratings yet

- DV 4650 470Document1 pageDV 4650 470Fernando EspinosaNo ratings yet

- Manometro Winters PDFDocument4 pagesManometro Winters PDFMisshell Tu GatitaNo ratings yet

- Imi PBM - Pb-Af3 - 2022Document2 pagesImi PBM - Pb-Af3 - 2022ariesca.instrumentacionNo ratings yet

- PF3CCE Data SheetDocument3 pagesPF3CCE Data SheetJosé MelchorNo ratings yet

- BelGAS P627 R627 F627Document24 pagesBelGAS P627 R627 F627Prihartono Danan WingusNo ratings yet

- Apollo Valve TS - 70-100Document4 pagesApollo Valve TS - 70-100akashmalayiNo ratings yet

- Gziw 300XDocument2 pagesGziw 300Xrodrigo francoNo ratings yet

- Von Duprin 994 996L L-BE Breakaway Trim For Rim and Vertical Rod Device Installation Instructions 107622Document2 pagesVon Duprin 994 996L L-BE Breakaway Trim For Rim and Vertical Rod Device Installation Instructions 107622edielNo ratings yet

- SRP PUMP ASSEMBLY Parts and Accessories CatalogueDocument52 pagesSRP PUMP ASSEMBLY Parts and Accessories Catalogue000No ratings yet

- Ficha Tecnica de MECH - Conexiones RoscadasDocument9 pagesFicha Tecnica de MECH - Conexiones RoscadasCesar RomeroNo ratings yet

- Mech Conexiones RoscadasDocument12 pagesMech Conexiones RoscadasGuillermo Catter FarroNo ratings yet

- Es WD FD 930 UsaDocument1 pageEs WD FD 930 UsaWattsNo ratings yet

- Backdraft Damper: Standard ConstructionDocument2 pagesBackdraft Damper: Standard ConstructionJOSE ACOSTA RODRIGUEZNo ratings yet

- Flippen Float Valves: Agricultural & IrrigationDocument12 pagesFlippen Float Valves: Agricultural & IrrigationwfjerrNo ratings yet

- Diaphragm PumpDocument1 pageDiaphragm PumpmiorNo ratings yet

- Datasheet Uni Flex ASB 43 Open Radius 1 6Document4 pagesDatasheet Uni Flex ASB 43 Open Radius 1 6Saepul RochmanNo ratings yet

- Federal Signal 151XSTDocument2 pagesFederal Signal 151XSTLogan Marquez AguayoNo ratings yet

- Aakar Facade Solution-1Document1 pageAakar Facade Solution-1Nazeer AhamedNo ratings yet

- Ugly Stick 60 Plans SH2Document1 pageUgly Stick 60 Plans SH2Ria JiotNo ratings yet

- Apollo Super Duplex Stainless Steel Full Port Ball Valve 76FK-100-A TSDocument4 pagesApollo Super Duplex Stainless Steel Full Port Ball Valve 76FK-100-A TSgeneraljomoNo ratings yet

- P627 High Flow Gas Regulator: ApplicationsDocument17 pagesP627 High Flow Gas Regulator: ApplicationsWilmar salgado cañateNo ratings yet

- WellheadDocument4 pagesWellheadseNo ratings yet

- Technical Data: A61 F F A61 G GDocument2 pagesTechnical Data: A61 F F A61 G GAmol GoreNo ratings yet

- Hex Rod CouplingDocument1 pageHex Rod CouplingvirajNo ratings yet

- Fire DamperDocument1 pageFire DamperAbdel Razak Al AsmarNo ratings yet

- Seg-5 Security Grille - Supply or Return: Project LocationDocument1 pageSeg-5 Security Grille - Supply or Return: Project Locationahmedshawky31297No ratings yet

- Series 314Document8 pagesSeries 314Prathamesh GangalNo ratings yet

- Es WD RD 200 CP 85 UsaDocument1 pageEs WD RD 200 CP 85 UsaWattsNo ratings yet

- R1100-Metal Dome Type - Selling Price - 410 QARDocument1 pageR1100-Metal Dome Type - Selling Price - 410 QARabdulrahman elmograbiNo ratings yet

- Hose ReelDocument4 pagesHose ReelDavidNo ratings yet

- Apollo Valves: Technical Data ForDocument48 pagesApollo Valves: Technical Data ForElsad HasanliNo ratings yet

- Metalife Scheda Filtri INGDocument20 pagesMetalife Scheda Filtri INGOrlando RebeloNo ratings yet

- Roller Door Installation Instructions ManualDocument12 pagesRoller Door Installation Instructions ManualJames O'DonnellNo ratings yet

- Gemini T: RGB Glass-Wing Mid-TowerDocument2 pagesGemini T: RGB Glass-Wing Mid-TowerMariano GarciaNo ratings yet

- Gemini S UsermanualDocument2 pagesGemini S UsermanualLuis Alberto HMNo ratings yet

- Technical SummaryDocument2 pagesTechnical SummaryRidhuan RaisNo ratings yet

- Datasheet Uni Flex ASB 43 Open Curved Surface Radius 2 2Document4 pagesDatasheet Uni Flex ASB 43 Open Curved Surface Radius 2 2Saepul RochmanNo ratings yet

- Lista de MaterialesDocument39 pagesLista de MaterialesCristian Ookami CcenchoNo ratings yet

- WYN-X Vibration-Proof (Liquid Filled) Pressure Gauge: An Instrument Company in USADocument4 pagesWYN-X Vibration-Proof (Liquid Filled) Pressure Gauge: An Instrument Company in USAShankar PediredlaNo ratings yet

- G5016 G5016BP: Drench Hose Unit, Wall Mounted Drench Hose Unit, Wall Mounted, With Backflow PreventerDocument2 pagesG5016 G5016BP: Drench Hose Unit, Wall Mounted Drench Hose Unit, Wall Mounted, With Backflow Preventerمحمد اصدNo ratings yet

- Es WD FD 900 UsaDocument1 pageEs WD FD 900 UsaWattsNo ratings yet

- Constant Flow Valves: Standard Features (Sizes 1/2" - 4") Sample SpecificationDocument5 pagesConstant Flow Valves: Standard Features (Sizes 1/2" - 4") Sample SpecificationeandresmarNo ratings yet

- Crosby Hoist RingDocument1 pageCrosby Hoist RingtecanasioNo ratings yet

- Designed and Drawn by Michael Ramsey: Cessna MaterialsDocument1 pageDesigned and Drawn by Michael Ramsey: Cessna MaterialsVeras limaNo ratings yet

- Ban Chang Hardware Co., LTDDocument1 pageBan Chang Hardware Co., LTDolanoshitNo ratings yet

- English-French and French-English dictionary of the motor car, cycle, and boatFrom EverandEnglish-French and French-English dictionary of the motor car, cycle, and boatNo ratings yet

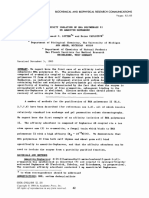

- Vol. 119, No. 1, 1984 Biochemical and Biophysical Research Communications February 29, 1984 Pages 42-48Document7 pagesVol. 119, No. 1, 1984 Biochemical and Biophysical Research Communications February 29, 1984 Pages 42-48Vel MuruganNo ratings yet

- 2011 01 94 PDFDocument6 pages2011 01 94 PDFVel MuruganNo ratings yet

- Dynamic Storage Allocation in The Atlas Computer, Including An Automatic Use of A Backing StoreDocument2 pagesDynamic Storage Allocation in The Atlas Computer, Including An Automatic Use of A Backing StoreVel MuruganNo ratings yet

- Notice To ShareholdersDocument6 pagesNotice To ShareholdersVel MuruganNo ratings yet

- Iaut 05 I 4 P 275Document1 pageIaut 05 I 4 P 275Vel MuruganNo ratings yet

- Olymyxins A Review Focusing On Their NephrotoxicityDocument7 pagesOlymyxins A Review Focusing On Their NephrotoxicityVel MuruganNo ratings yet

- ICI Application Well Built Residential AwardsDocument6 pagesICI Application Well Built Residential AwardsVel MuruganNo ratings yet

- Hakushima Hiroshima Sta. Yokogawa StaDocument1 pageHakushima Hiroshima Sta. Yokogawa StaVel MuruganNo ratings yet

- Steel Placement HandbookDocument56 pagesSteel Placement HandbookVel MuruganNo ratings yet

- 16 1 Stone PDFDocument29 pages16 1 Stone PDFVel MuruganNo ratings yet

- Physicochemical Analysis of Triveni Lake Water of Amravati District in (MS) IndiaDocument3 pagesPhysicochemical Analysis of Triveni Lake Water of Amravati District in (MS) IndiaVel MuruganNo ratings yet

- Reinforcing Steel Placement Handbook: NeitcDocument20 pagesReinforcing Steel Placement Handbook: NeitcVel MuruganNo ratings yet

- Das T. and Teng B. 2001 Trust Control and Risk in Strategic Alliances An Integrated Framework'Document35 pagesDas T. and Teng B. 2001 Trust Control and Risk in Strategic Alliances An Integrated Framework'Vel MuruganNo ratings yet

- Infosecuritystandards 2009 12 FinalDocument20 pagesInfosecuritystandards 2009 12 FinalVel MuruganNo ratings yet

- Ej 047 Pages 025 034Document10 pagesEj 047 Pages 025 034Vel MuruganNo ratings yet

- RMS DPI 2010-1-49-1: Abdallah N, Liegeois J.P., de Waele B., Fezza N. Et Ouabadi A. The Temaguessine FeDocument1 pageRMS DPI 2010-1-49-1: Abdallah N, Liegeois J.P., de Waele B., Fezza N. Et Ouabadi A. The Temaguessine FeVel MuruganNo ratings yet

- Service Manual: Purewatercooler Model Pwc-500/1000/1010/1500Document38 pagesService Manual: Purewatercooler Model Pwc-500/1000/1010/1500Vel MuruganNo ratings yet

- Global Cardiac Catheters - 2012-2018Document4 pagesGlobal Cardiac Catheters - 2012-2018Axis Research MindNo ratings yet

- Dialogues in French and EnglishDocument62 pagesDialogues in French and Englishmiki1222No ratings yet

- Starter MP EecDocument21 pagesStarter MP EecIshan 96No ratings yet

- Operation and Maintenance Manual: Mux-2200E Integrated Service MultiplexerDocument82 pagesOperation and Maintenance Manual: Mux-2200E Integrated Service Multiplexerlee.tetleie1675No ratings yet

- Whirlpool SPIW318A2WF Air ConditionerDocument324 pagesWhirlpool SPIW318A2WF Air ConditionerAxxNo ratings yet

- LennoxDocument32 pagesLennoxCharly ColumbNo ratings yet

- MSS - Manual Bernoulli FilterDocument3 pagesMSS - Manual Bernoulli FilterFLTR PURPLE E.No ratings yet

- BC Ii 800Document38 pagesBC Ii 800Pop Ciprian100% (2)

- VirtualHost Examples - Apache HTTP ServerDocument9 pagesVirtualHost Examples - Apache HTTP ServerSaitejaTallapellyNo ratings yet

- STR Mpa-MpmDocument8 pagesSTR Mpa-MpmBANGGANo ratings yet

- Instalación Sensor RPM TurboDocument13 pagesInstalación Sensor RPM TurboLuis Herrera MarinNo ratings yet

- Sikafloor Morritex Self-Levelling Broadcast SystemDocument4 pagesSikafloor Morritex Self-Levelling Broadcast SystemTPNo ratings yet

- Pds Luxathane 5000 VocDocument2 pagesPds Luxathane 5000 Vocmuthukumar100% (1)

- Principles of Accounting, Volume 2: Managerial AccountingDocument59 pagesPrinciples of Accounting, Volume 2: Managerial AccountingVo VeraNo ratings yet

- The Scientist PDFDocument68 pagesThe Scientist PDFPetcu Adrian100% (1)

- Trial and Error: Failure and Innovation in Criminal Justice ReformDocument5 pagesTrial and Error: Failure and Innovation in Criminal Justice ReformAzim MohammedNo ratings yet

- 100124119Document175 pages100124119mkeiwuaNo ratings yet

- GitHub - Shenwei356 - Datakit - CSV - TSV File Manipulation and More. Please Use My Another Tool - CSVTK, Https - Github - Com - Shenwei356 - CSVTKDocument4 pagesGitHub - Shenwei356 - Datakit - CSV - TSV File Manipulation and More. Please Use My Another Tool - CSVTK, Https - Github - Com - Shenwei356 - CSVTKtabani_shaikNo ratings yet

- IPCR Part 2 2017Document4 pagesIPCR Part 2 2017RommelNo ratings yet

- Ref: Bboneblk - SRM Beaglebone Black System Reference Manual Rev BDocument125 pagesRef: Bboneblk - SRM Beaglebone Black System Reference Manual Rev BhernangycNo ratings yet

- Adopter CategoriesDocument6 pagesAdopter CategoriesCaroline Mputhia100% (1)

- 690 2004Document19 pages690 2004RahilaHammadNo ratings yet