Professional Documents

Culture Documents

Dog Bone Connection PDF

Uploaded by

Chinnaraja GandhiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dog Bone Connection PDF

Uploaded by

Chinnaraja GandhiCopyright:

Available Formats

THE DOGBONE

CONNECTION: PART II

Selectively trimming a portion of a beam allows

connection strength to exceed beam strength without

the need to develop a stronger connection

By Michael D. Engelhardt, case, however, the connection is

Ted Winneberger, Andrew J. made stronger than the beam

Zekany and Timothy J. not by increasing the strength of

Potyraj the connection, but rather by

decreasing the strength of the

S

INCE THE 1994 NORTHRIDGE beam. The dogbone can be

EARTHQUAKE, INTENSIVE viewed as a ductile fuse. It forces

RESEARCH AND TESTING yielding to occur within the

EFFORTS have been underway to reduced section of the beam, an

find better methods to design area that can sustain large

and construct seismic resistant inelastic strains. At the same

steel moment connections. A Figure 1: Typical “dogbones” time, the dogbone acts as a fuse,

wide variety of solutions have limiting stress at the less ductile

been proposed over the last two region near the face of the col-

years, many of which have ated states of triaxial tension, umn. Previous work has been

shown greatly improved perfor- etc. The reinforcement reduces conducted on the constant cut

mance in the laboratory com- stress levels within this vulnera- and tapered cut dogbone shapes

pared to the previous “Pre- ble region near the column face, shown in Figure 1. In the case of

Northridge” connection. The and forces the large stresses and the tapered cut, the taper is

overall goal in the development inelastic strains further into the intended to follow the moment

of new connections is to provide beam. Reinforcing the connec- diagram in order to promote uni-

highly ductile response, reliable tion, however, increases its cost. form yielding over the full length

performance, and economy. Further, if excessive reinforce- of the dogbone.

Many of the new moment con- ment is used, new problems can At first glance, it may seem

nections combine improvements be created resulting from the counterintuitive that removing a

in welding with some type of need for very large welds with portion of a structure actually

reinforcement at the connection high shrinkage, and higher improves the performance of the

(cover plates, ribs, haunches, degrees of restraint and triaxial structure. In the case of the dog-

side plates, etc.). The purpose of tension. bone, however, this is exactly the

the reinforcement, in the most An alternative to reinforcing a case! The dogbone results in only

general terms, is to provide a moment connection that provides a small reduction in lateral

connection that is stronger than benefits similar to reinforce- strength and stiffness of a frame

the beam. A strong earthquake ment, but may avoid some of the but can provide a large increase

would be expected to develop disadvantages, is the “dogbone” in ductility, the key to survival of

plastic hinges at the beam ends moment connection. A distin- a structure in a strong earth-

in a traditional fully restrained guishing feature of the dogbone, quake. Trading a small amount

(FR) moment frame. The rein- also known as the Reduced of strength in return for a large

forcement is intended to force Beam Section (RBS) connection, amount of ductility represents

the plastic hinge away from the is that portions of the beam an excellent bargain for earth-

face of the column, where prema- flange are trimmed away in the quake resistant design.

ture fractures can occur due to region adjacent to the beam-to- The size of moment frame

potential weld defects, stress column connection (Figure 1). beams is normally controlled by

concentrations at weld access Various shape cutouts are possi- code-mandated drift limitations

holes, stress concentrations due ble. The result is similar to rein- rather than by code strength

to column flange bending, high forcement, i.e., the connection is requirements. The dogbone gen-

levels of restraint and the associ- stronger than the beam. In this erally results in only a slight

Modern Steel Construction / August 1996

E I N

S M C DE S

I S I G

decrease in frame stiffness.

Consequently, in many practical

cases, the use of the dogbone will

likely not necessitate a change of

beam size in order to meet code

strength and stiffness require-

ments.

A significant amount of

research and full scale testing

has already been done on the

dogbone concept. An article by

Nestor R. Iwankiw, P.E., and

Charles J. Carter in the April

1996 Modern Steel Construction

summarized some of the recent

testing. Early work was conduct-

ed by S.J. Chen and C.H. Yeh in

Taiwan, and by A. Plumier in

Figure 2 (above): Typical floor

Belgium. More recently, addi-

framing plan

tional work has been conducted

by AISC at Smith-Emery

Figure 3 (left): 3D view of lateral

Company in Los Angeles, and by

framing members

Ove-Arup & Partners working

with the University of California

at San Diego. This previous

research, conducted on either

constant cut or tapered cut dog-

bones (Figure 1) has shown very

promising performance. Typ-

ically, large plastic rotations

have been obtained. In a few

cases, fractures developed during

testing, either at the beam

flange to column connection or

within the dogbone, but only

after large levels of plastic rota-

tion were achieved.

Based on the earlier laborato-

ry successes of the dogbone, this

concept was recently applied to a steel moment frames as its pri- and typical office space. The

25-story steel office building in mary lateral force resisting sys- office space is designed for maxi-

Salt Lake City. In applying this tem. W&W Steel Company of mum flexibility and is pro-

concept, some further refine- Oklahoma City was responsible grammed to be an open space

ments were made to the dogbone for detailing, fabricating and plan layout, requiring 43-ft.-4-in.

approach and verified by full erecting the building’s 7,900 tons spans for the floor framing.

scale laboratory testing. The of structural steel. The floor framing was

remainder of this article The typical floor of the build- designed using composite steel

describes this building project, ing is triangular shaped in plan beams with 3 1/4-in. lightweight

and the associated connection (Figure 2). The plan measures concrete slabs over 3-in. compos-

testing program 302-ft. along the long face and ite deck. The AISC Load and

121-ft. along the width. A promi- Resistance Factor Design

AMERICAN STORES COMPANY nent feature of the plan is an Specification (LRFD) was uti-

HEADQUARTERS enclosed atrium on the west side lized in the design of the beams

When the American Stores of the building. The atrium con- and columns. ASTM A572 Gr. 50

Company and Howa sists of a series of individual steel was used for all members.

Construction Company decided four-story and two-story open The primary frames are locat-

to build the new American spaces that stack above each ed around the building perimeter

Stores Headquarters Building in other throughout the height of and around the elevator cores. A

Salt Lake City, HKS Inc. of the building. Surrounding the three dimensional perspective

Dallas designed a 25 story, atriums are the elevator cores illustration of the lateral fram-

650,000-sq.-ft. structure with and lobbies, conference rooms ing members is shown in Figure

Modern Steel Construction / August 1996

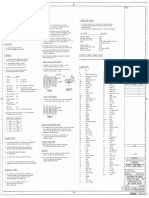

A test program with five

Table 1: Description of Test Specimens & Results large-scale specimens was

Spec. Column Beam Dogbone Plastic Comments undertaken to evaluate suitabili-

Type Rotation ty of the dogbone for use in the

DB1 W14x426 W36x160 Constant Cut 0.020 rad. Fracture at dogbone 2,000 moment connections of the

DB2 W14x426 W36x150 Radius Cut 0.030 rad. No conn. failure

American Stores Company

headquarters building. The spec-

DB3 W14x426 W36x170 Radius Cut 0.038 rad. No conn. failure

imens, designated DB1 to DB5

DB4 W14x426 W36x194 Radius Cut 0.037 rad. No. conn. failure are outlined in Table 1. The con-

DB5 W14x257 W30x148 Radius Cut 0.040 rad. No conn. failure; cept adopted for these specimens

signif. column panel was to combine the dogbone cut

zone participation in the beam, together with a

high quality welded beam-to-col-

umn connection at the face of the

Table 2: Beam Tensile Properties column. Both welding and design

improvements were incorporated

Spec. Beam Yield Stress (ksi) Tensile Strength (ksi)

into the beam-to-column connec-

Flange Web Flange Web tion to provide significantly

DB1 W36x160 54.7 53.5 75.6 79.2 improved capabilities compared

DB2 W36x150 41.4 47.1 58.7 61.8 to the Pre-Northridge type con-

DB3 W36x170 58.0 58.5 73.0 76.7 nection. With these improved

DB4 W36x194 38.5 43.6 58.6 59.8 connection capabilities, together

DB5 W30x148 46.6 48.5 64.5 65.4 with a reduced demand on the

connection due to the presence of

3. W36 and W40 frame column umn. This, in turn, increases the dogbone, the hope was for a

sizes were utilized to control stress levels at the face of the seismic resistant moment con-

drift. The building design called column, and negates some the nection system capable of devel-

for 1,000 moment resisting beneficial effects of forcing the oping large plastic rotations

frame beams, ranging in size plastic hinge away from the col- under severe cyclic loading con-

from W27x114 to W36x210. umn. ditions.

Located in UBC Seismic Zone Considering the options, the For the beam-to-column con-

3, earthquake safety was an dogbone emerged as the most nection at the face of the column,

important design concern for this cost effective solution for this each of the five specimens used

building. The design and con- project. Although the dogbone essentially the same detail. A

struction team was faced with already had a good track record typical detail is illustrated in

the challenge of developing a in earlier testing, Andy Zekany Figure 4. An all-welded connec-

moment resisting connection of HKS requested additional tion was used, in which the beam

that would perform as intended testing using representative W36 flanges and beam web were con-

by the UBC for a Special beams. These tests would permit nected to the column flange

Moment Resisting Frame. evaluation of details specific to using complete joint penetration

Working together with The this project, and help build confi- groove welds. It was believed

University of Texas at Austin, dence in the connection. that the welded web connection,

HKS and W&W Steel explored Remarkably, the decision was although somewhat more costly

several options, including rein- made to embark upon this test than a more conventional bolted

forced connections, bolted con- program after construction on web connection, would provide a

nections, and the dogbone con- the American Stores Company higher level of ductility. The

nection. Connection design was Headquarters had already begun welded web connection can

somewhat complicated by the on an extremely fast track sched- transfer significant moment

very short 17-ft. clear spans on ule. Stuart King with American from the beam to the column,

many of the building’s moment Stores and Rick Howa of Howa thereby reducing demands on

frame girders since connection Construction required the most the beam flange welds. The rela-

concepts that move the plastic effective and economical moment tively thin shear tab provided at

hinge away from the face of the connection available for seismic- the beam web connection serves

column are more difficult to resistant steel framing. Their to support the beam during erec-

implement on short spans. The consistent direction in meeting tion and also acts as backing for

high moment gradients associat- this goal and their support of the the beam web groove weld.

ed with short spans cause a large engineers’ recommendations led Testing done since the

amplification of moment from to the test program. Northridge Earthquake has

the point of plastic hinge forma- raised questions on previous

tion back to the face of the col- TEST PROGRAM design criteria for continuity

plates in seismic resistant

Modern Steel Construction / August 1996

E I N

S M C DE S

I S I G

moment connections. For this based on AWS D1.1-94, Specimen DB1 showed excellent

project, the decision was made to Structural Welding Code - Steel. performance in the initial inelas-

provide continuity plates at all Items emphasized for in process tic cycles. However, a fracture

connections, with the thickness inspection included checking the developed within the dogbone at

chosen to be comparable to the joint fit-up, preheat, and enforc- the end of the flat portion of the

beam flange thickness. For the ing the Welding Procedure cutout that was closest to the

test specimens, beam flange Specification (WPS) for the pro- face of the column. A stress con-

thickness ranged from 0.94 to ject. Ultrasonic testing was done centration resulting from the

1.26 in. One-in. thick continuity for the complete joint penetra- change of cross-section at this

plates were used for all speci- tion groove welds, with accep- point apparently contributed to

mens. tance criteria based on Table 8.2 this fracture. Despite this frac-

Welding at the beam-to-col- of AWS D1.1-94. ture, the specimen still sus-

umn connection was accom- The member sizes used for the tained 0.02 radian of plastic

plished by self-shielded flux- test specimens are listed in rotation. Further, there were no

cored arc welding process using Table 1. Each of the test speci- signs of distress anywhere with-

an electrode with a minimum men columns were A572 Gr. 50 in the beam-to-column connec-

specified Charpy V-Notch tough- steel. Four of the specimens used tion at the face of the column.

ness of 20 ft.-lbs. at -20 degrees W14x426 columns, taken from Although the first test did not

F. For the beam flange groove three different heats of steel. For meet full performance expecta-

welds, properly oriented weld the beam sections used in the tions, the results were still

runoff tabs were used, and then tests, mill certificates were not encouraging. It appeared that

removed after completion of the available. Tensile coupon tests achievement of the higher per-

weld. At the bottom flange were run on the beam sections, formance goal might be possible

groove weld, the backing bar was and the results are shown in by changing the shape or dimen-

removed, and a reinforcing fillet Table 2. Actual beam flange sions of the dogbone cutout to

weld was placed at the root of yield stresses varied from 38.5 reduce stress concentrations

the weld joint. Removing the ksi to 58 ksi. Consequently, a within this region. In order to

backing bar permits visual wide range of beam strengths provide a cutout region with

inspection of the weld root, mini- were represented in the test minimum stress concentrations

mizing the chance of undetected specimens. Member sizes in and one that would still be eco-

root defects, and eliminating any Specimens DB1 to DB4 were nomical to fabricate, the concept

possible notch effects of the selected to force virtually all of of a circular radius-cut dogbone

backing bar. the inelastic deformations into was suggested by Ted

The top flange backing bar the beam. Specimen DB5 was Winneberger of W&W Steel Co.

was left in place. There were sev- sized to encourage shear yielding This ultimately proved success-

eral reasons for this. First, root of the column panel zone, in ful in the testing program.

defects are less likely at the top order to evaluate its effects on The remaining four test speci-

flange since neither the groove the dogbone connection. mens were all constructed with a

weld nor the ultrasonic testing of radius-cut dogbone. Figure 5

the groove weld is interrupted by TEST RESULTS shows the shape and dimensions.

the beam web, as they are at the Testing was conducted at The The same all-welded beam-to-

bottom flange. Further, removal University of Texas Ferguson column connection described ear-

of the top flange backing bar is Laboratory. All tests were con- lier was used. A typical speci-

more difficult and costly than at ducted on single cantilever type men, DB4, is shown in Figure 4.

the bottom flange, since the arc- specimens, with cyclic loads Each of the four radius-cut

gouging must be done through applied to the tip of the beam fol- dogbone specimens (DB2 to DB5)

the weld access hole. lowing the loading protocol of showed excellent performance.

Consequently, for this project ATC-24. The goal of the test pro- The plastic rotations developed

the top backing bar was left in gram was to develop plastic rota- by each specimen at the end of

place. However, a continuous fil- tions of at least 0.03 radian, as the test are listed in Table 1. In

let weld was provided between suggested by the SAC Interim each case, testing was stopped as

the backing bar and the column Guidelines. a result of limitations in the test

flange (see Figure 4). From a The first specimen, DB1, com- equipment, rather than because

theoretical perspective, this fillet bined the all-welded connection of specimen failure. Conse-

weld reduces the potential notch described above with a constant quently, the specimens would

effect of a left in place backing cut dogbone (Figure 1(a)). have likely developed larger

bar. Previous successful tests had plastic rotations had the testing

For welding quality control, been run on both constant cut been continued.

both in-process inspection and and tapered cut dogbones. The At large plastic rotations, the

ultrasonic testing were specified. constant cut was elected for this beams of the test specimens typi-

Inspection and testing were first test. During testing, cally exhibited considerable

Modern Steel Construction / August 1996

twist that accompanied local

flange and web buckling in the

beam. This resulted in a gradual

reduction in flexural strength.

Testing was stopped in each case

to avoid damage to the test

equipment from this twisting. It

should be noted however that

the twisting experienced by

these dogbone specimens was no

more severe, and perhaps some-

what less severe, than reinforced

connections previously tested at

The University of Texas.

At the point at which testing

was stopped, no fractures had

developed within the dogbone

region for any of the radius-cut

specimens. Further no failures

occurred at the beam-to-column

connections. The connection on

Specimen DB3 showed small

cracks near the weld access holes

that developed during the cycles

at 0.02 radian. These small

cracks, however, did not grow

during the remainder of the test

and had no impact on the

response of the specimen. For

the remaining specimens, the

weld access holes were enlarged

and were provided with a

smoother transition to the beam

flange. The small cracks

observed in DB3 were not

observed in the remaining speci-

mens.

Figure 6 shows photos of

Specimen DB4 during testing.

Figure 6(a) is a view looking

down at the top beam flange at a

plastic rotation of 0.012 radian.

The darkened regions are areas

where the whitewash coating

has flaked off, providing a quali-

tative indication of where yield-

ing has occurred. This photo

Figure 4 (top): Test specimen DB4 shows yielding concentrated

within the dogbone region of the

Figure 5 (above): Radius cut dogbones beam, and indicates the connec-

tion was performing as intended.

Figure 6(b) shows the specimen

at plastic rotation of 0.022 radi-

an. Finally, Figure 6(c) shows

the specimen at a plastic rota-

tion of 0.037 radian, the point at

which testing was stopped.

As noted earlier, at large plas-

tic rotations the specimens

exhibited flange and web local

buckling within the plastic hinge

Modern Steel Construction / August 1996

E I N

S M C DE S

I S I G

Table 3: Cost Comparisons

Connection Type Relative

Cost

Pre-Northridge welded

flange-bolted web 1.00

Radius-cut dogbone 1.71

Constant or tapered

cut dogbone 2.18

Cover plate 2.50

Flange ribs 2.91

Bottom haunch 3.01

Proprietary side plates 3.76

Side plates 3.96

Top & bottom haunch 4.00

Column tree 6.38

region. Flange buckling is visible

in Figure 6(c). Such local buck-

ling has been observed in many

tests on reinforced or other modi-

fied connection concepts.

However, this severe local buck-

ling typically occurs at very large

plastic rotations. Figure 6(b)

shows Specimen DB4 at a plastic

rotation of 0.022 radian. At this

level of demand, the degree of

local buckling is still very slight,

and in fact, is hardly noticeable. Figure 6a (above): View of beam

Analytical studies of steel flange of specimen DB4 at 0.012

moment frame buildings affected rad. plastic rotation (column is at

by the Northridge Earthquake left)

suggest that most buildings

experienced maximum plastic Figure 6b (left): Specimen at

joint rotations on the order of 0.022 rad. plastic rotation

0.005 to 0.00 radian. Under this

level of demand, these test speci- Figure 6c (top): Specimen at end

mens had no visible damage, of test; plastic rotation equals

other than yielding patterns 0.037 rad.

indicated by whitewash flaking.

Such connections would likely

require no repair after experi- deformations of the panel zone number of moment connections

encing this level of demand. had no apparent detrimental in this building, the cost of the

For all test specimens, with effect on the connection, and con- dogbone connection relative to

the exception of DB5, plastic tributed to the ductility of the other options was also a critical

rotations were developed by test specimen. concern.

inelastic deformations in the Based on the successful To address the issue of cost,

beams. Specimen DB5 was results of this testing program, W&W Steel developed cost esti-

designed to permit significant the overall cyclic loading perfor- mates for a number of moment

shear yielding of the column mance of the radius-cut dogbone connection options for this pro-

panel zone. During testing, a connection was judged as excel- ject. The results are shown in

great deal of yielding was in fact lent. Table 3. Relative costs are pro-

observed in the panel zone. vided with respect to the Pre-

Analysis of test data indicates COST COMPARISONS Northridge welded flange-bolted

that of the total plastic rotation The test program indicated web moment connection. Cost

of 0.040 radian developed by that the radius-cut dogbone con- comparisons were based on a

DB5, approximately 25% was nection was capable of providing W36x194 girder of A572 Gr. 50

contributed by the column panel a high level of performance. steel with weld metal toughness

zone. For this specimen, inelastic However, because of the large requirements for all cases except

Modern Steel Construction / August 1996

dimensions as small as possible,

in order to minimize the amplifi-

cation of moment from the hinge

location in the dogbone to the

face of the column. The dimen-

sion “a” must be large enough,

however, to permit stress in the

reduced beam flange to spread

uniformly over the flange width

at the face of the column.

Similarly, dimension “b” should

be large enough to avoid exces-

sive inelastic strains in the dog-

bone. Consequently, the suggest-

ed dimensions above are a

compromise between different

requirements.

The depth of the cut, dimen-

sion “c” in Figure 5 is a critical

dimension for the dogbone. The

following approach was used to

determine this dimension. First,

it was assumed that the maxi-

mum moment that can develop

at midlength of the dogbone was

equal to the plastic moment of

Figure 7: this reduced section, increased

Mechanized by 10 to 15 percent to allow for

plasma arc strain hardening. This moment

cutting of was then projected to the face of

dogbones in the column using a moment gra-

fabrication shop dient based on an assumed point

of inflection at midspan of the

beam. The maximum moment at

the face of the column was then

limited to approximately 90 to

the Pre-Northridge connection. DESIGN AND FABRICATION 100 percent of the plastic

The various connection types CONSIDERATIONS moment of the full cross section

listed in Table 3, other than the In designing the radius-cut of the beam. It was believed that

radius-cut dogbone, are connec- dogbone test specimens, it was the all-welded connection com-

tion options illustrated in the necessary to establish dimen- bined with the welding details

SAC Interim Guidelines. The sions of the dogbone. Key dimen- used in these tests was capable

cost data presented in Table 3 sions are shown in Figure 5, and of sustaining such levels of bend-

were developed for this project, were established based on the ing moment. The reduced beam

and will vary for other projects judgment of the writers. This sections were also checked for

depending upon location, labor judgment relied on these test conformance with flexural

factors, and connection design results, results of previous dog- strength requirements of the

variations. bone tests, and experience with LRFD Specification for all fac-

The cost comparisons for this other connection test programs tored gravity and lateral load

project indicated that the radius- over the last several years. combinations. Following this

cut dogbone was the most eco- Based on this judgment, the dis- basic approach, the depth of cut,

nomical alternative of all the tance “a” from the face of the col- “c,” was chosen. For all of the

options considered. Based on the umn to the start of the dogbone radius-cut specimens, the depth

successful testing program, com- cut was chosen to be approxi- of cut resulted in removing

bined with the favorable econom- mately 50 to 75 percent of the approximately 40 percent of the

ics, the radius-cut dogbone beam flange width. The length of beam flange width.

moment connection was accepted the cut, dimension “b” in Figure The maximum moment devel-

for use on the American Stores 5, was chosen in the range of oped at the face of the column

Company Headquarters about 65 to 85 percent of the can be reduced by increasing the

Building. beam depth. In general, it is depth of cut in the dogbone. The

preferable to keep the “a” and “b” writers view removal of about 50

Modern Steel Construction / August 1996

E I N

S M C DE S

I S I G

percent of the beam flange width

as a maximum practical cut.

Note that for a given depth of

cut, a greater reduction in

moment at the face of the col-

umn is possible in longer span

beams with smaller moment gra-

dients. If further reduction of

stress at the face of the column

is desired, some reinforcement

could be added to the connection,

for example, thin cover plates or

ribs. In these tests, the actual

maximum moments developed at

the face of the column ranged

from 92 percent to 113 percent of

the actual plastic moment of the

beam. These moments were sus-

tained without connection fail-

ure. Consequently, no additional

reinforcement was provided at

the connection. It was felt that

such additional reinforcement

would largely negate the econo-

my of this connection and was

unnecessary.

Once the length of the dog-

bone “b” and depth of cut “c”

have been chosen, the radius of

the cut follows simply from the

geometry of a circular arc, as

indicated by the formula in

Figure 5.

Once the radius-cut dogbone

was accepted for use on the

American Stores Company build-

ing, W&W Steel was faced with

the task of cutting dogbones into

both flanges of both ends of

1,000 moment frame girders.

This required making 8,000 cuts. Figures 8a & 8b: Moment frame during erection

In order to make these cuts as

economically as possible, W&W

devised a mechanized process ing is expected to be completed nection concepts that have

employing plasma arc cutting. in November of 1996. shown good performance in labo-

Figure 7 shows two cuts being ratory cyclic loading tests.

made simultaneously in the fab- CONCLUSIONS Engineers must carefully consid-

rication shop. The mechanized The test program conducted er currently available test data

plasma arc cut left a very high on the radius-cut dogbone con- combined with the economics of

quality surface. The cutting was nection showed excellent perfor- a project when choosing the most

followed by the use of a 3M pad- mance. Together with a number appropriate moment connection

dle wheel grinder. Grinding was of other connection types devised detail. This represents a rapidly

done parallel to the beam flange and tested since the Northridge changing picture in the current

to minimize stress concentra- Earthquake, the dogbone connec- environment of intensive

tions due to grinding marks. tion promises to deliver a much research and testing. Based on

Figure 8 shows views of higher level of ductility and safe- the experiences from this project,

moment frame girders with ty as compared to the “Pre- however, the dogbone connection

radius-cut dogbone moment con- Northridge” moment connection. appears to be one of the more

nections during erection at the Structural engineers can now promising moment connection

construction site in Salt Lake choose from a fairly wide variety concepts capable of delivering

City. The structural steel fram- of seismic resistant moment con- both performance and economy.

Modern Steel Construction / August 1996

Michael D. Engelhardt, is an

Associate Professor of Civil

Engineering, The University of

Texas at Austin, Ted Winne-

berger, is Senior Vice President,

Engineering, W&W Steel

Company, Oklahoma City, OK,

Andrew J. Zekany, is Vice

President, Structural Eng-

ineering, HKS Inc., Dallas, and

Timothy J. Potyraj, is a

Graduate Research Assistant,

The University of Texas at

Austin. The testing program was

financially sponsored by W&W

Steel Co. and the American

Institute of Steel Construction,

Inc. Additional support was pro-

vided through National Science

Foundation Grant Nos. CMS-

9358186 and CMS-9416287. The

writers thank Nestor Iwankiw

and Charlie Carter of AISC, Inc.

Modern Steel Construction / August 1996

You might also like

- Castellated Beam PPT GatDocument33 pagesCastellated Beam PPT GatChittan Mac Maisnam50% (2)

- Pile Cap For 4 PilesDocument4 pagesPile Cap For 4 Pileshemantkle2u100% (2)

- The Dogbone Connection: Part IIDocument9 pagesThe Dogbone Connection: Part IIAndreea CrisanNo ratings yet

- Reinforcedconcrete Beam-Column Jointsfor Seismic Loading P A R T II - Experimental ResultsDocument12 pagesReinforcedconcrete Beam-Column Jointsfor Seismic Loading P A R T II - Experimental Resultssaikat mondalNo ratings yet

- Seismic Performance of Repaired Hollow-Bridge PiersDocument13 pagesSeismic Performance of Repaired Hollow-Bridge PiersSom SasithornNo ratings yet

- The Effect of Infill Steel Plate Thickness On The Cycle Behavior of Steel Plate Shear WallsDocument7 pagesThe Effect of Infill Steel Plate Thickness On The Cycle Behavior of Steel Plate Shear WallsGogyNo ratings yet

- Behavior of Interior Beam-to-Column Connections UnderDocument7 pagesBehavior of Interior Beam-to-Column Connections UnderMarimuthu KaliyamoorthyNo ratings yet

- Powell (1983) - Ductile Anchor Bolts For Tall ChimneysDocument11 pagesPowell (1983) - Ductile Anchor Bolts For Tall Chimneystimur sibaevNo ratings yet

- Kim, T., 2020Document16 pagesKim, T., 2020primasukmayuanaNo ratings yet

- 5 - Paulay Equilibrium Criteria For Reinforced ConcreteDocument9 pages5 - Paulay Equilibrium Criteria For Reinforced ConcreteMarimuthu KaliyamoorthyNo ratings yet

- "Retrofitting of Reinforced Concrete Beam Column Joints": Presented by Miss. Mule Disha PradipDocument48 pages"Retrofitting of Reinforced Concrete Beam Column Joints": Presented by Miss. Mule Disha PradipBara' alsayedNo ratings yet

- Development of A New Steel Moment Connection: March 2016Document9 pagesDevelopment of A New Steel Moment Connection: March 2016Veerabhadrayya KatapurmathNo ratings yet

- Lateral Load Response of Strengthened and Repaired Reinforced Concrete ColumnsDocument10 pagesLateral Load Response of Strengthened and Repaired Reinforced Concrete ColumnsCiro AscioneNo ratings yet

- 2002 12 TaipeiDocument4 pages2002 12 TaipeiElvis GrayNo ratings yet

- JCSR Krawinkler Mohasseb 1987Document18 pagesJCSR Krawinkler Mohasseb 1987faisaladeNo ratings yet

- Seismic Enhancement of Circular RC Bridge Piers With Fiber CompositesDocument9 pagesSeismic Enhancement of Circular RC Bridge Piers With Fiber CompositesGerardoSosaDavilaNo ratings yet

- Strengthening of Bridge Beams and Similar Structures byDocument4 pagesStrengthening of Bridge Beams and Similar Structures byArun KumarNo ratings yet

- Development of Box-Shaped Steel Slit Dampers For Seismic Retrofit of Building StructuresDocument13 pagesDevelopment of Box-Shaped Steel Slit Dampers For Seismic Retrofit of Building StructuresZyrah Anne Victoria DoyolaNo ratings yet

- Thin-Walled Structures: Zonghua Zhang, Shutian Liu, Zhiliang TangDocument11 pagesThin-Walled Structures: Zonghua Zhang, Shutian Liu, Zhiliang TangNguyễn Văn Ngọc LinhNo ratings yet

- Short Proposal Finite ElementDocument9 pagesShort Proposal Finite ElementMuhammad Ilham ZulkipllyNo ratings yet

- Earthquake Resilient Steel Braced Frames With Controlled Rocking and Energy Dissipating FusesDocument5 pagesEarthquake Resilient Steel Braced Frames With Controlled Rocking and Energy Dissipating Fusesehsan_civil_62No ratings yet

- Correspondence: 3 The Structural Engineer Online 88 (6) 16 March 2010Document1 pageCorrespondence: 3 The Structural Engineer Online 88 (6) 16 March 2010oundhakarNo ratings yet

- Wang-Salhab2009 Article StructuralBehaviourAndDesignOfDocument11 pagesWang-Salhab2009 Article StructuralBehaviourAndDesignOfRodyShineNo ratings yet

- Quasi-Static Test of Assembled Steel Shear Panel Dampers With Optimized ShapesDocument12 pagesQuasi-Static Test of Assembled Steel Shear Panel Dampers With Optimized ShapesMohsen MNo ratings yet

- Composite Beams: P. AnsourianDocument27 pagesComposite Beams: P. AnsourianLeonardoMadeira11No ratings yet

- Cyclic Tests of Steel Moment Connections Rehabilitated With RBS or Welded Haunch - Uang Et Al - ASCEDocument12 pagesCyclic Tests of Steel Moment Connections Rehabilitated With RBS or Welded Haunch - Uang Et Al - ASCEkostas formulagrNo ratings yet

- Thin-Walled Structures: Kim J.R. Rasmussen, Mani Khezri, Benjamin W. Schafer, Hao ZhangDocument42 pagesThin-Walled Structures: Kim J.R. Rasmussen, Mani Khezri, Benjamin W. Schafer, Hao ZhangJavedNo ratings yet

- One-Way Shear Strength of Thick Slabs and Wide BeamsDocument9 pagesOne-Way Shear Strength of Thick Slabs and Wide BeamsWasin WaiyasusriNo ratings yet

- Behavior and Strength of RC Column-To-Steel Beam Connections Subjected To Seismic LoadingDocument8 pagesBehavior and Strength of RC Column-To-Steel Beam Connections Subjected To Seismic Loadingbravo deltafoxNo ratings yet

- Strength and Behavior of Reinforced Concrete Obtuse Corners Under Opening Bending MomentsDocument6 pagesStrength and Behavior of Reinforced Concrete Obtuse Corners Under Opening Bending MomentspaulkohanNo ratings yet

- "Retrofitting of Reinforced Concrete Beam Column Joints": Presented by Miss. Mule Disha PradipDocument48 pages"Retrofitting of Reinforced Concrete Beam Column Joints": Presented by Miss. Mule Disha PradipBara' alsayedNo ratings yet

- Performance of Reduced Beam Section in Castellated Beam Subjected To Cyclic LoadingDocument11 pagesPerformance of Reduced Beam Section in Castellated Beam Subjected To Cyclic LoadingniniNo ratings yet

- Anbarasu 2021Document11 pagesAnbarasu 2021Suhail BabaNo ratings yet

- Design Procedure For BRBsDocument17 pagesDesign Procedure For BRBsPremalatha JeyaramNo ratings yet

- Analytical Model For Predicting Shear Strengths of Exterior Reinforced Concrete Beam-Column Joints For Seismic ResistanceDocument14 pagesAnalytical Model For Predicting Shear Strengths of Exterior Reinforced Concrete Beam-Column Joints For Seismic ResistanceAndres NaranjoNo ratings yet

- Analytical Model For Predicting Shear Strengths of Exterior Reinforced Concrete Beam-Column Joints For Seismic ResistanceDocument14 pagesAnalytical Model For Predicting Shear Strengths of Exterior Reinforced Concrete Beam-Column Joints For Seismic ResistanceAndres NaranjoNo ratings yet

- Structural Behaviour of Three-Pile Caps Subjected To Axial Compressive LoadingDocument14 pagesStructural Behaviour of Three-Pile Caps Subjected To Axial Compressive LoadingNitin shepurNo ratings yet

- Reinforced Concrete Eccentric Beam-Column Connections Subjected To Earthquake-Type LoadingDocument11 pagesReinforced Concrete Eccentric Beam-Column Connections Subjected To Earthquake-Type LoadingUcok DedyNo ratings yet

- AWD D1.8 Seismic Supplement - 2Document4 pagesAWD D1.8 Seismic Supplement - 2mrezaiNo ratings yet

- Comparative Study On Behaviour of Reinforced Beam-Column Joints With Reference To Anchorage DetailingDocument6 pagesComparative Study On Behaviour of Reinforced Beam-Column Joints With Reference To Anchorage DetailingMohd parvezNo ratings yet

- Push Over Analysis of Unstiffened Steel Plate Shear Wall: Abhishek Verma, P. R. MaitiDocument9 pagesPush Over Analysis of Unstiffened Steel Plate Shear Wall: Abhishek Verma, P. R. MaitiIJERDNo ratings yet

- ContentServer AspDocument11 pagesContentServer AspSantiago GonzalezNo ratings yet

- ACI STRUCTURAL JOURNAL-Shear Strength of Steel Fiber ReinforcedDocument9 pagesACI STRUCTURAL JOURNAL-Shear Strength of Steel Fiber ReinforcedMuchtar SufaatNo ratings yet

- Membrane Analysis of Flat Plate Slabs: Aci Structural Journal Technical PaperDocument10 pagesMembrane Analysis of Flat Plate Slabs: Aci Structural Journal Technical PaperpicottNo ratings yet

- An Experimental Study On Steel Encased Buckling Restrained Brace Hysteretic Dampers PDFDocument21 pagesAn Experimental Study On Steel Encased Buckling Restrained Brace Hysteretic Dampers PDFM. Murat ErginNo ratings yet

- Beam - Column Joint EC2Document11 pagesBeam - Column Joint EC2undf25No ratings yet

- Industrial Fiber Concrete FlooDocument5 pagesIndustrial Fiber Concrete FlooMarial MbzNo ratings yet

- 01 4 132Document5 pages01 4 132cmkohNo ratings yet

- Hancock Et Al 1994 DB Curves PaperDocument18 pagesHancock Et Al 1994 DB Curves Paperclam2014No ratings yet

- Development of Crawler Steel Damper For BridgesDocument11 pagesDevelopment of Crawler Steel Damper For BridgesXL YinNo ratings yet

- Cantilever SlabDocument7 pagesCantilever Slabyuva_86No ratings yet

- A Parametric Study of R.C. Slab in Beam-Column Connection Under Cyclic LoadingDocument9 pagesA Parametric Study of R.C. Slab in Beam-Column Connection Under Cyclic Loadingمحمد تانزيم ابراهيمNo ratings yet

- Asce1 As PublishedDocument11 pagesAsce1 As PublishedWendell Ariel LanzasNo ratings yet

- Seismic Behavior of Nonseismically Detailed Interior Beam-Wide Column Joints-Part I: Experimental Results and Observed BehaviorDocument12 pagesSeismic Behavior of Nonseismically Detailed Interior Beam-Wide Column Joints-Part I: Experimental Results and Observed BehaviorpaulkohanNo ratings yet

- Bar Pullout Tests and Seismic Tests of Small-Headed Barsin Beam-Column JointsDocument11 pagesBar Pullout Tests and Seismic Tests of Small-Headed Barsin Beam-Column JointsProfessor Dr. Nabeel Al-Bayati-Consultant EngineerNo ratings yet

- Moment RedistributionDocument13 pagesMoment Redistributionprakashcg123No ratings yet

- Influence of Column Straightening Protocol On Connection PerformanceDocument11 pagesInfluence of Column Straightening Protocol On Connection PerformancekvrgmsNo ratings yet

- The Performance of Epoxy-Coated Shear Reinforcement: Aci Structural Journal Technical PaperDocument7 pagesThe Performance of Epoxy-Coated Shear Reinforcement: Aci Structural Journal Technical PaperpicottNo ratings yet

- Some Mooted Questions in Reinforced Concrete Design American Society of Civil Engineers, Transactions, Paper No. 1169, Volume LXX, Dec. 1910From EverandSome Mooted Questions in Reinforced Concrete Design American Society of Civil Engineers, Transactions, Paper No. 1169, Volume LXX, Dec. 1910No ratings yet

- Instructions on Modern American Bridge BuildingFrom EverandInstructions on Modern American Bridge BuildingNo ratings yet

- UntitledDocument1 pageUntitledChinnaraja GandhiNo ratings yet

- PassportDocument1 pagePassportChinnaraja GandhiNo ratings yet

- Youtube ChannelDocument1 pageYoutube ChannelChinnaraja GandhiNo ratings yet

- The Personal Mastery Journal - DailyDocument85 pagesThe Personal Mastery Journal - DailyChinnaraja GandhiNo ratings yet

- PassportDocument1 pagePassportChinnaraja GandhiNo ratings yet

- Wiac - Info PDF Learn Telugu Through Tamil PRDocument3 pagesWiac - Info PDF Learn Telugu Through Tamil PRChinnaraja GandhiNo ratings yet

- Metals and Non - MetalsDocument3 pagesMetals and Non - MetalsChinnaraja GandhiNo ratings yet

- General NotesDocument12 pagesGeneral NotesChinnaraja GandhiNo ratings yet

- Grandma ThoughtDocument3 pagesGrandma ThoughtChinnaraja GandhiNo ratings yet

- Dunes International SchoolDocument4 pagesDunes International SchoolChinnaraja GandhiNo ratings yet

- Dunes International SchoolDocument3 pagesDunes International SchoolChinnaraja GandhiNo ratings yet

- Famous Person (Autosaved)Document5 pagesFamous Person (Autosaved)Chinnaraja GandhiNo ratings yet

- Dunes International School: L.15-Knowledge Is PowerDocument3 pagesDunes International School: L.15-Knowledge Is PowerChinnaraja GandhiNo ratings yet

- Dunes International School: Worksheet Answer Key Subject: SST Class: 5 Section: NameDocument4 pagesDunes International School: Worksheet Answer Key Subject: SST Class: 5 Section: NameChinnaraja GandhiNo ratings yet

- Loadout AnalysisDocument23 pagesLoadout AnalysisChinnaraja GandhiNo ratings yet

- HKTS 9/16: Home Theater Speaker SystemDocument14 pagesHKTS 9/16: Home Theater Speaker SystemChinnaraja GandhiNo ratings yet

- 2021 Calendar: January 2021 February 2021Document1 page2021 Calendar: January 2021 February 2021Chinnaraja GandhiNo ratings yet

- ZDM BrochureDocument24 pagesZDM BrochureChinnaraja GandhiNo ratings yet

- Palker Food Forest Model: Land Area: 16'x16' Model-6Document1 pagePalker Food Forest Model: Land Area: 16'x16' Model-6Chinnaraja GandhiNo ratings yet

- NEROLAMDocument56 pagesNEROLAMChinnaraja GandhiNo ratings yet

- Spectral Fatigue Flow Chart PDFDocument1 pageSpectral Fatigue Flow Chart PDFChinnaraja GandhiNo ratings yet

- Blue Footed BoobyDocument4 pagesBlue Footed BoobyChinnaraja GandhiNo ratings yet

- Juniors Cricket Coaching GuideDocument78 pagesJuniors Cricket Coaching GuideChinnaraja GandhiNo ratings yet

- Natwest Inter Cricket Session PlansDocument30 pagesNatwest Inter Cricket Session PlansChinnaraja GandhiNo ratings yet

- Water Tank DesignDocument1 pageWater Tank DesignChinnaraja GandhiNo ratings yet

- SingingDocument3 pagesSingingChinnaraja GandhiNo ratings yet

- Agitation and MixingDocument26 pagesAgitation and MixingMehran Rasheed Goraya100% (2)

- Fracture MechanicsDocument39 pagesFracture MechanicsDEEPAKNo ratings yet

- Simple Stresses and Strains: ThereforeDocument4 pagesSimple Stresses and Strains: ThereforeSuraj KumarNo ratings yet

- Direct Displacement Based Seismic Design of Concrete StructuresDocument25 pagesDirect Displacement Based Seismic Design of Concrete StructuresGerardo MendozaNo ratings yet

- 17505-2019-Winter-Model-Answer-Paper (Msbte Study Resources)Document28 pages17505-2019-Winter-Model-Answer-Paper (Msbte Study Resources)Jose Javier JulioNo ratings yet

- 2015 - Zingoni - Liquid-Containment Shells of Revolution A Review of Recent Studies On Strength Stability and Dynamics PDFDocument13 pages2015 - Zingoni - Liquid-Containment Shells of Revolution A Review of Recent Studies On Strength Stability and Dynamics PDFpouyaNo ratings yet

- Evacuated TubeDocument12 pagesEvacuated Tubeحسن كميت hassankomeit lNo ratings yet

- HVAC & Water SystemDocument153 pagesHVAC & Water SystemSujan Bose100% (1)

- Problems On Rao's Book (Free Vibration For Damped SystemDocument6 pagesProblems On Rao's Book (Free Vibration For Damped SystemNavarro, Jherwin F.No ratings yet

- Answer Before P612 LT1Document5 pagesAnswer Before P612 LT1ina17_eaglerNo ratings yet

- Unit 4B - Design of Pressur VesselDocument3 pagesUnit 4B - Design of Pressur VesselVikas RathodNo ratings yet

- ViscosityDocument4 pagesViscosityManP13No ratings yet

- CVNG 1001 Orifice Lab 2015Document3 pagesCVNG 1001 Orifice Lab 2015Harrington HaynesNo ratings yet

- Chapter - 7 - External Flow-ZoomDocument54 pagesChapter - 7 - External Flow-ZoomAhmad Alifian LirajabiNo ratings yet

- 3D FEM of Welding Process Using Element Birth & Element Movement TechniquesDocument7 pages3D FEM of Welding Process Using Element Birth & Element Movement TechniquesDebabrata PodderNo ratings yet

- CES522 A 04 - Topic 2b - 2. RC Beam Design - Examples234 PDFDocument38 pagesCES522 A 04 - Topic 2b - 2. RC Beam Design - Examples234 PDFAizuddinNo ratings yet

- 260.equipment For Decentralized Cold Pressing of Oil SeedsDocument40 pages260.equipment For Decentralized Cold Pressing of Oil SeedsJhon SyalfiandyNo ratings yet

- Crip LingDocument24 pagesCrip LingMohamed NkNo ratings yet

- 06 0625 31 2015 94500.inddDocument2 pages06 0625 31 2015 94500.inddRana SlimNo ratings yet

- USS Physics-Pages-491-493Document3 pagesUSS Physics-Pages-491-493Arnav PatilNo ratings yet

- Temperature and Kinetic TheoryDocument48 pagesTemperature and Kinetic TheoryTimofejs MaksimovsNo ratings yet

- Steam ExcelDocument12 pagesSteam Excelsid sNo ratings yet

- Article Review: "Density Estimation For Ionic Liquids"Document26 pagesArticle Review: "Density Estimation For Ionic Liquids"Gie AndalNo ratings yet

- General Types of Cooling Tower IllustrationsDocument10 pagesGeneral Types of Cooling Tower IllustrationsanisalyaaNo ratings yet

- Prediction of Swelling Rocks Strain in Tunneling: D. Parsapour and A. FahimifarDocument11 pagesPrediction of Swelling Rocks Strain in Tunneling: D. Parsapour and A. FahimifarpabulumzengNo ratings yet

- IC EngineDocument52 pagesIC EngineShreepal ChilaNo ratings yet

- Day 2 Part 2 PDFDocument3 pagesDay 2 Part 2 PDF5ChEA DriveNo ratings yet

- DEFORM 2D TutorialDocument31 pagesDEFORM 2D Tutorialdarwin_huaNo ratings yet