Professional Documents

Culture Documents

Piping System Inspection

Uploaded by

Adi Kurnia0 ratings0% found this document useful (0 votes)

87 views3 pagespiping inspection

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentpiping inspection

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

87 views3 pagesPiping System Inspection

Uploaded by

Adi Kurniapiping inspection

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

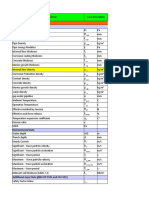

Document No TM ITP-M-004

PT. TRISTAR MARINE

Revision 0

INSPECTION AND TEST PLAN Effective Date 22.04.2013

PIPING SYSTEM Page 1 of 3

Procedure No.: Ship Name : SURYA PUTRA JAYA

TM PRO-M-004 Owner Name : CAKRA BAHANA

N SAN

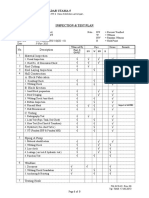

Items Inspection Item TM CCD TKA CLASS RMKS

o TOS

Pipe line visual check and necessary

thickness gauging ( on suspect high √ √ √ √

corrosive area)

Dresser coupling checking and

necessary refurbishment √ √ √ √

Flanges connection check (bolt‐nut,

√ √ √ √

gaskets)

Cargo isolation valves inspection and

1 Cargo system √ √ √ √

tightness testing

Supports and Clamps visual check √ √ √ √

Suction end visual checking and

√ √ √ √

cleaning

Leak test √ √ √ √ √

Hydro test √ √ √ √ √

Corrosive protection and pipe mark

√ √ √ √

inspection and repair

Pipe line visual check and necessary

thickness gauging (on suspect high √ √ √ √

corrosive area)

Flanges connection check (bolt‐nut,

√ √ √ √

gaskets)

Isolation valves checking and tightness

√ √ √ √

(open/close) testing

Fire & Foam Fire monitor & Hydrants visual

2

System inspection, open/close and rotary √ √ √ √

testing

Supports and Clamps visual check √ √ √ √

Leak test √ √ √ √ √

Hydro test √ √ √ √ √

Corrosive protection and pipe mark

√ √ √ √

inspection and repair

Pipe line visual check and necessary

thickness gauging (on suspect high √ √ √ √

corrosive area)

Flanges connection check (bolt‐nut,

√ √ √ √

gaskets)

Isolation valves checking and tightness

√ √ √ √

(open/close) testing

Ballast Over board & safety valves checking

3

System √ √ √ √

and testing

Suction points inspection and cleaning √ √ √ √

Supports and Clamps visual check √ √ √ √

Leak test √ √ √ √ √

Hydro test √ √ √ √ √

Corrosive protection and line mark

√ √ √ √

inspection and repair

FSO SURYA PUTRA JAYA

Document No TM ITP-M-004

PT. TRISTAR MARINE

Revision 0

INSPECTION AND TEST PLAN Effective Date 22.04.2013

PIPING SYSTEM Page 2 of 3

Pipe line visual check and necessary

thickness gauging (on suspect high √ √ √ √

corrosive area)

Flanges connection check (bolt‐nut,

√ √ √ √

gaskets)

Isolation valves checking and tightness

√ √ √ √

(open/close) testing

Fresh water Distribution valves on each lavatory √ √ √ √

4 and Sanitary Suction points inspection √ √ √ √

System

Supports and Clamps visual check √ √ √ √

Leak test √ √ √ √ √

Hydro test √ √ √ √ √

Corrosive protection and line mark

√ √ √ √

inspection and repair

Flushing line and deliver water quality

√ √ √ √

checking

Pipe line visual check and necessary

thickness gauging (on suspect high √ √ √ √

corrosive area)

Flanges connection check (bolt‐nut,

√ √ √ √

gaskets)

Isolation valves checking and tightness

√ √ √ √

(open/close) testing

5

Sewage Overboard valves inspection √ √ √ √

System Suction points inspection √ √ √ √

Supports and Clamps visual check √ √ √ √

Leak test √ √ √ √ √

Hydro test √ √ √ √ √

Corrosive protection and line mark

√ √ √ √

inspection and repair

Flushing line √ √ √ √

Pipe line visual check and necessary

thickness gauging (on suspect high √ √ √ √

corrosive area)

Flanges connection check (bolt‐nut,

√ √ √ √

gaskets)

Isolation valves checking and tightness

√ √ √ √

Fuel & (open/close) testing

Filter inspection and necessary

6 Lubrication √ √ √ √

System refurbishment

Suction points inspection √ √ √ √

Supports and Clamps visual check √ √ √ √

Leak test √ √ √ √ √

Hydro test √ √ √ √ √

Corrosive protection and line mark

√ √ √ √

inspection and repair

Utility Air Pipe line visual check and necessary

7

System thickness gauging (on suspect high √ √ √ √

corrosive area)

FSO SURYA PUTRA JAYA

Document No TM ITP-M-004

PT. TRISTAR MARINE

Revision 0

INSPECTION AND TEST PLAN Effective Date 22.04.2013

PIPING SYSTEM Page 3 of 3

Flanges connection check (bolt‐nut,

√ √ √ √

gaskets)

Isolation valves checking and tightness

√ √ √ √

(open/close) testing

Suction points inspection √ √ √ √

Supports and Clamps visual check √ √ √ √

Leak test √ √ √ √ √

Hydro test √ √ √ √ √

Corrosive protection and line mark

√ √ √ √

inspection and repair

Pipe line visual check and necessary

thickness gauging (on suspect high √ √ √ √

corrosive area)

Flanges connection check (bolt‐nut,

√ √ √ √

O‐ring)

Hydraulic

Control valves checking and tightness

System √ √ √ √

(winches testing

8

hydraulic & Supports and Clamps visual check √ √ √ √

Cargo Control Leak test √ √ √ √ √

valves system) Hydro test √ √ √ √ √

Flushing line and renewal hydraulic oil √ √ √ √

Performance testing √ √ √ √

Corrosive protection and line mark

√ √ √ √

inspection and repair

Pipe line visual check and necessary

thickness gauging (on suspect high √ √ √ √

corrosive area)

Flanges connection check (bolt‐nut,

√ √ √ √

gaskets)

Isolation valves checking and tightness

√ √ √ √

(open/close) testing

9 Steam System Heat isolation inspection √ √ √ √

Supports and Clamps visual check √ √ √ √

Leak test √ √ √ √ √

Hydro test √ √ √ √ √

Corrosive protection and line mark

√ √ √ √

inspection and repair

Performance testing √ √ √ √ √

FSO SURYA PUTRA JAYA

You might also like

- Curso Leak DetectionDocument21 pagesCurso Leak DetectionDurgamadhaba Mishra100% (1)

- Metering SystemDocument21 pagesMetering Systemaadianvi0% (1)

- 2018 Uk Cswip Exam FeeDocument7 pages2018 Uk Cswip Exam FeeMostafaRockNo ratings yet

- Hydrant ValvesDocument4 pagesHydrant ValvesoscarninanNo ratings yet

- Flowlines and Well Gas Lift LinesDocument4 pagesFlowlines and Well Gas Lift LinesDaniel Dambo100% (1)

- Technology - Magnetic Eddy Current MEC Inspection TechniqueDocument12 pagesTechnology - Magnetic Eddy Current MEC Inspection TechniqueCepi Sindang KamulanNo ratings yet

- Hose Test MethodsDocument5 pagesHose Test MethodstriagusmanNo ratings yet

- Bolier Inspection ReportDocument4 pagesBolier Inspection ReportHadi AlloucheNo ratings yet

- ABS Rule Part4 Chapter6 Section1Document8 pagesABS Rule Part4 Chapter6 Section1Kamil AdliNo ratings yet

- Boiler Inspection PDFDocument2 pagesBoiler Inspection PDFsajuhereNo ratings yet

- LL Seminar Romania WE Are GEDocument62 pagesLL Seminar Romania WE Are GEbrctlnNo ratings yet

- LAPESADocument16 pagesLAPESAmusewejamesoumaNo ratings yet

- Data Input Flowline Properties: Pipe Pipe Pipe 3Document12 pagesData Input Flowline Properties: Pipe Pipe Pipe 3Septian FirdausNo ratings yet

- Pressure Vessel Inspection 01Document9 pagesPressure Vessel Inspection 01Bhavani PrasadNo ratings yet

- Pipescan MFL Pipe InspectionDocument4 pagesPipescan MFL Pipe InspectionRICARDO3454No ratings yet

- Welding Inspection: Course Reference WIS 5Document31 pagesWelding Inspection: Course Reference WIS 5venkyNo ratings yet

- Telebrineller System BrochureDocument15 pagesTelebrineller System BrochureITTSA S.A DE C.VNo ratings yet

- Ultrasonic or MFL InspectionDocument4 pagesUltrasonic or MFL InspectionArjun Pratap Singh100% (3)

- Petrofac Piping Inspection Handbook PDFDocument25 pagesPetrofac Piping Inspection Handbook PDFramesh100% (1)

- SEIP For 089-WHB-001: Claus Waste Heat BoilerDocument6 pagesSEIP For 089-WHB-001: Claus Waste Heat BoilerThinh NguyenNo ratings yet

- Drill String DesignDocument3 pagesDrill String Designjefpri simanjuntakNo ratings yet

- API 570 Awareness Course PDFDocument63 pagesAPI 570 Awareness Course PDFRajesh Manoharan50% (4)

- Pig LaunchingDocument5 pagesPig Launchingdabir123No ratings yet

- Melaka Refineary Vib ProposalDocument6 pagesMelaka Refineary Vib ProposalZul Hilmi LihinNo ratings yet

- Pressure Vessel Inspection ReportDocument34 pagesPressure Vessel Inspection ReportJinlong SuNo ratings yet

- Electrical Junction Box ITP (Elektrik Bağlantı Kutusu Muayene Test Planı) PDFDocument1 pageElectrical Junction Box ITP (Elektrik Bağlantı Kutusu Muayene Test Planı) PDFUtku Can KılıçNo ratings yet

- PACIFIC Marine Loading ArmDocument4 pagesPACIFIC Marine Loading ArmGilang Nusantara Bening100% (1)

- G8s-5034-02-Bubble Leak TestDocument4 pagesG8s-5034-02-Bubble Leak TestmaheshNo ratings yet

- New SSIV InstallationDocument12 pagesNew SSIV InstallationDidiNo ratings yet

- Storage Tank API 650Document20 pagesStorage Tank API 650jalison07xNo ratings yet

- 3590 - Marine Piping Systems - VALVES On Shipbuilding ApplicationDocument14 pages3590 - Marine Piping Systems - VALVES On Shipbuilding ApplicationZhafira OspNo ratings yet

- KROHNE - Leak Detection and LocalisationDocument8 pagesKROHNE - Leak Detection and Localisationdaniel_afpNo ratings yet

- General Metal LossDocument4 pagesGeneral Metal LossTony_Black99No ratings yet

- Vertical Storage Tank Calibration by Eodr MethodologyDocument5 pagesVertical Storage Tank Calibration by Eodr MethodologyJahidul Islam100% (1)

- P P NG Abbrev at Ons: AFC A F CDocument11 pagesP P NG Abbrev at Ons: AFC A F COlajide AkekeNo ratings yet

- Introduction To Fiscal MeteringDocument24 pagesIntroduction To Fiscal MeteringAliNo ratings yet

- Sample ReportDocument8 pagesSample ReportRonel John CustodioNo ratings yet

- Resume of Qaqc Mech InspectorDocument5 pagesResume of Qaqc Mech InspectorMohammed IlliasuddinNo ratings yet

- Maintenance, Inspection and Testing of Pressure VesselsDocument13 pagesMaintenance, Inspection and Testing of Pressure Vesselsmshrconsultant100% (1)

- Mechanical Boiler Inspection ReportDocument1 pageMechanical Boiler Inspection ReportAfzal pathanNo ratings yet

- T11 Coriolis PDFDocument19 pagesT11 Coriolis PDFMalouk Cheniouni100% (1)

- 2018 Sea Cswip Course Exam FeeDocument4 pages2018 Sea Cswip Course Exam FeeAmar MohammedNo ratings yet

- Magnescann Pipetronics Trap DimensionsDocument20 pagesMagnescann Pipetronics Trap DimensionsChike NwachukwuNo ratings yet

- API 5L-2007 Specification For Line PipeDocument153 pagesAPI 5L-2007 Specification For Line Pipetom787485100% (1)

- Dacon MFL PresentationDocument30 pagesDacon MFL PresentationCepi Sindang KamulanNo ratings yet

- Nuflo Mc-III Exp DatasheetDocument4 pagesNuflo Mc-III Exp DatasheetJerrydawangNo ratings yet

- Hydrostatic Test ProcedureDocument7 pagesHydrostatic Test Procedurelaleye_olumideNo ratings yet

- Inline Inspection of Pipeline: Intelligent PiggingDocument10 pagesInline Inspection of Pipeline: Intelligent PiggingMitesh JuikarNo ratings yet

- Calculate Flow Rate From Differential PressureDocument27 pagesCalculate Flow Rate From Differential PressureThang Hoang Anh100% (1)

- Tube Inspection A4Document2 pagesTube Inspection A4Cepi Sindang KamulanNo ratings yet

- Inspection Manual For PipingDocument183 pagesInspection Manual For PipingMartin Zaballa100% (3)

- Lampiran Sop Pemeliharaan PendantDocument1 pageLampiran Sop Pemeliharaan PendantDuana ZulqaNo ratings yet

- Tiremaster Maintenance PlanDocument1 pageTiremaster Maintenance PlanShylen SadienNo ratings yet

- Itp H.366.aDocument3 pagesItp H.366.ataufikrendikisserahNo ratings yet

- 3.0 Aceptación Del Carro Encofrador Modelo - Debe Ser Llenado Por El Responsable Chino.Document13 pages3.0 Aceptación Del Carro Encofrador Modelo - Debe Ser Llenado Por El Responsable Chino.juanNo ratings yet

- Verif Epi Protraxion Procedure enDocument4 pagesVerif Epi Protraxion Procedure eninternetNo ratings yet

- Mechanical Checksheet Day1Document1 pageMechanical Checksheet Day1Nazim MirzaNo ratings yet

- API 510 PV Inspection ChecklistDocument9 pagesAPI 510 PV Inspection ChecklistSreekumar SNo ratings yet

- Technical Maintain ScheduleDocument7 pagesTechnical Maintain ScheduleHENRYMARINGANNo ratings yet

- VDR Butterfly ValveDocument1 pageVDR Butterfly ValveIndra SUdirmanNo ratings yet

- Table of ContentsDocument4 pagesTable of ContentsAdi KurniaNo ratings yet

- Fpso PDFDocument12 pagesFpso PDFAdi KurniaNo ratings yet

- Plastic Pipe Fittings DC-DWVDocument68 pagesPlastic Pipe Fittings DC-DWVAdi KurniaNo ratings yet

- Tm-Pro-M-004 Piping System Inspection Procedure 00Document9 pagesTm-Pro-M-004 Piping System Inspection Procedure 00Adi KurniaNo ratings yet

- Well Cost Optimisation PDFDocument7 pagesWell Cost Optimisation PDFAdi KurniaNo ratings yet

- Rocket BottleDocument4 pagesRocket BottleVaggelis DouvaletellisNo ratings yet

- Engineering Piping Design Guide Fiberglass Reinforced Piping SystemsDocument36 pagesEngineering Piping Design Guide Fiberglass Reinforced Piping Systemsoscarhdef100% (1)

- Design of FRP Piping SystemsDocument16 pagesDesign of FRP Piping SystemskapilsontakkeNo ratings yet

- Lahendong 324Document1 pageLahendong 324Adi KurniaNo ratings yet

- Personal Master Plumbing NotesDocument59 pagesPersonal Master Plumbing NotesMichael Vincent Naces AlmueteNo ratings yet

- Brake Kits, Valves and Brass Fittings Section 3Document28 pagesBrake Kits, Valves and Brass Fittings Section 3Eduardo Arnold Martinez100% (1)

- Maintenance and Service Handbook: Equipment:water Tank L. 10000 On IVECO AD190T31Document39 pagesMaintenance and Service Handbook: Equipment:water Tank L. 10000 On IVECO AD190T31Tomislav JovanovicNo ratings yet

- D11R - 7PZDocument58 pagesD11R - 7PZJose A. Basanta H.No ratings yet

- Pumping Stations Design Lecture 5Document60 pagesPumping Stations Design Lecture 5Nestor Augusto Oyarce100% (2)

- F1 - Flare ReliefDocument11 pagesF1 - Flare ReliefJorge Luis HernándezNo ratings yet

- New Design in PlumberDocument10 pagesNew Design in PlumberMartin john loveNo ratings yet

- Section 4Document5 pagesSection 4Eslam HusseinNo ratings yet

- Effects of Subsurface Pump Size and Setting Depth On Performance of Sucker Rod Artificial LiftDocument12 pagesEffects of Subsurface Pump Size and Setting Depth On Performance of Sucker Rod Artificial LiftCF0804No ratings yet

- Esquema Hidráulico 160lcDocument12 pagesEsquema Hidráulico 160lcrodineiNo ratings yet

- Addis Ababa Science and Technology UniversityDocument6 pagesAddis Ababa Science and Technology UniversitydemiseNo ratings yet

- Water Mist Test Report PDFDocument5 pagesWater Mist Test Report PDFMomed MdNo ratings yet

- EH750-3 Rigid Hauler Hydraulic Training 1 ST PartDocument15 pagesEH750-3 Rigid Hauler Hydraulic Training 1 ST Partthan zaw win100% (1)

- 3888.1 Gaborone Building Services Drawing SM 2019-03-20-A0Document1 page3888.1 Gaborone Building Services Drawing SM 2019-03-20-A0Lovemore Makora MukondomiNo ratings yet

- Sectional DrawingsDocument8 pagesSectional DrawingsjulianNo ratings yet

- Juni Now2022Document479 pagesJuni Now2022Hello yusiNo ratings yet

- Construction and Performance Testing of The Hydraulic Ram PumpDocument7 pagesConstruction and Performance Testing of The Hydraulic Ram PumpGreen Action Sustainable Technology Group0% (1)

- Sizing, Specifying and Selecting Centrifugal Pumps (CE) PDFDocument5 pagesSizing, Specifying and Selecting Centrifugal Pumps (CE) PDFjdgh1986100% (1)

- The New ANSI-HI Centrifugal Slurry Pump Standard 2005Document4 pagesThe New ANSI-HI Centrifugal Slurry Pump Standard 2005Ashraf Gomah Mohamed ElshamandyNo ratings yet

- Katalog Hidrolik PDFDocument18 pagesKatalog Hidrolik PDFagustinus arisNo ratings yet

- Koomey AccumulatorDocument7 pagesKoomey AccumulatorQadriNo ratings yet

- Pipe Size Schedule Wall Thickness ID Threadolet LG Max Length CL LengthDocument2 pagesPipe Size Schedule Wall Thickness ID Threadolet LG Max Length CL LengthapgoslingNo ratings yet

- SCHWING TrainingManualDocument303 pagesSCHWING TrainingManualHarlinton descalzi86% (100)

- Technical Datasheet Combination ValveDocument5 pagesTechnical Datasheet Combination ValveNorman GarduñoNo ratings yet

- NU - Lecture 12 (WATER HAMMER) PDFDocument1 pageNU - Lecture 12 (WATER HAMMER) PDFMr. Mark B.No ratings yet

- 181-1-2 Water Motor GongDocument2 pages181-1-2 Water Motor GongCkaal74No ratings yet

- 10 Inch SS 50 HZ CatalogueDocument15 pages10 Inch SS 50 HZ Catalogueالمشتاقة للأقصىNo ratings yet

- KPM Sanki J C PDFDocument24 pagesKPM Sanki J C PDFbrunosamaeianNo ratings yet

- 70Dbg Mud Tank 泥浆罐及流程: Parts List 9-A)Document34 pages70Dbg Mud Tank 泥浆罐及流程: Parts List 9-A)waleedNo ratings yet

- Basic Pump FundamentalDocument99 pagesBasic Pump FundamentalJimit Shah100% (1)