Professional Documents

Culture Documents

OISD Check List - 1

Uploaded by

Pinjala AnoopOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

OISD Check List - 1

Uploaded by

Pinjala AnoopCopyright:

Available Formats

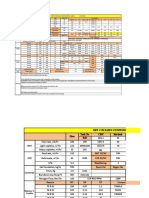

OISD CHECK LIST

S. No REQUIREMENT COMPLIANCE BY

1. Updated Operating Manual (Controlled Copy) with valid Operations

signatures

2. Updated Safety manual / Safety policy Operations

3. Updated Work permit system manual Operations/ Executing depts.

4. Updated ERDMP (Emergency Response & Disaster Common

Management Plan)

5. Updated MSDS manual Operations / Technical

6. Updated P&IDs Operations / Technical

7. Updated Trip registers & safety interlock registers Operations

8. Trips bypass file (more than 72 hrs & more than 7 days) Operations

9. Updated Register for Fire water pumps Auto Cut-in F&S

checking

10. Gas Detector Test record file (including last 3 months) Inst. / F&S

11. EHS policy display in the field rooms with valid signature PS&E

and approval

12. Updated hydrocarbon clamp register Operations

13. Updated gasket register Operations

14. Updated employee training register Operations

15. Compliance of Good Housekeeping (Debris, scrap Operations

material, waste insulations and Oil filled drums)

16. Integrity of dykes TPH/ATP

17. Surrounding area and Surface drain cleaning TPH/ATP

18. Oil Spillage area Cleaning in the units and offsite area TPH/ATP

19. Compliance of Display of Safety boards & Caution Operations

boards

20. Compliance of Display of Noise level boards at high Operations / F&S

noisy area / Noise level surveys

21. Compliance of Healthy Safety Showers Operations

S. No REQUIREMENT COMPLIANCE BY

22. Compliance of Chemical handling area demarcation Operations

with yellow paint

23. Compliance of Availability of all PPE items with proper Operations/F&S

cleaning

24. Compliance of CCTV functioning (*) HR

25. Compliance of Working condition of Wind Socks F&S

26. Statutory approval for EOT, lifts, weigh bridges, chain Rotary

pulley blocks, cranes, tools, valves, pipes, fittings and

tackles and their testing records

27. Tank inspection report, Tank drain and routing, F&S/INSP/TPH

High/low alarms and gauging etc

28. Oil soaked cotton/rags to be removed from tank farm TPH/ATP

area including tank gauge hatch area

29. Covering cable tranches, OWS manholes in unit & tank Operations

farm

30. All licenses (CCOE/PESO, Boilers, APPCB, Factories Act, MES, Inspection, PS&E, HR

Labour commissioner)

31. Inspection records of boilers, compressors, GTGs etc Opns/Insp

32. Copies of ISA, ESA, SSA along with recommendations F&S

status

33. Updated Refinery/ATP Plot plans, lay out plans, Fire Operations, MES, F&S

water system drawings

34. QRA Reports, Hazop study recommendations PS&E

implementation

35. Fire water Adequacy Reports Projects, F&S

36. ISO 14001 Audits PS&E

37. EHS/ RSC meeting Minutes, Accident Investigation F&S

reports, Mock Drill Reports, Mutual Aid schemes,

Offsite mock drills

38. Fire Fighting facilities, Upkeeping Data F&S

39. Sludge and Solid Disposals PS&E

40. Fire Proofing of Cables Elec / Inst

S. No REQUIREMENT COMPLIANCE BY

41. Earthing Checking and records Elec

42. Grass cutting, removal of vegetation inside dykes Operations/Offsite

43. Stack Analysers and CAAMS checking Inst

44. Chemical Hoses Checking F&S, Operations

45. Updated Electrical Single line drawing and earthing, Electrical

Records of earth pits checking

46. Covering of cable trenches / OWS manholes Maintenance

47. Emergency Organogram F&S

48. Electrical Poles Condition / Adequacy of lighting Elec

49. Laboratory – Chemical storage, Cylinder Storage, LAB

Caution boards

50. Warehouse – Chemical storage, Cylinders storage, Warehouse

Caution boards

51. Employee Periodical Medical Checks HR

52. Testing of PSV / TSV / RV/ Rupture Disc records Valve Section

53. Underground Diesel Tanks at ATP MES/F&S

54. Bottom pumps (Short Residue pumps) to have double Operations/Maint

isolation (ROV provision)

55. Implementation of power and steam load shedding PP-1,2/PAD

scheme to avoid total power and steam failure

56. No flame impingement in Heaters, Skin temperatures to Operations

be within limits, Arch pressure within limits

57. List of tanks overdue for Maint and Inspection TPH/ATP/Maint

58. HC detectors at Flare KOD vessel Operations/PAD/Maint

59. ISA audits to be strengthened General

60. Consent for Air/water and handling of hazardous waste PS&E

renewal to be taken up

61. Area / zone wise classification drawings to be updated MES/PAD

62. Safety promotion and safety awareness survey report F&S

63. Process Hazard Analysis of units every 5 years PS&E

64. Offsite disaster drill with district administration F&S

65. Disaster Control rooms Maintenance F&S

66. MOCs generated and P&ID updation reports PS&E

67. Flying of Naval planes above refinery to be addressed General

68. Growing of pupil, banyan and coconut trees to be CIVIL

avoided

69. Hot well off gases not to be routed to Atmosphere Operations

70. Kerb walls to contain oil spills, chemical spills near Operations

storage and pump areas

71. OWS/ CBD lines demarcations Operations

72. LOTO boxes, registers to be in updated condition Operations/F&S

73. First Aid training and names display Operations / HR

S. No REQUIREMENT COMPLIANCE BY

74. Heaters Stack dampers to be in closed condition. Operations

Position of damper to be visible from grade level

75. Fire water sprinkler systems for vessels, pumps (Auto Operations/F&S/PAD

check), columns and Air Fin coolers

76. Tanks WSS, FFS, Foam system, Siren testing, checking F&S

records

77. Working of Fire phones, MCPs, Rim seal systems, HC Inst/ F&S /HR

detectors, Clean agent system and records

78. Steam distribution Network PAD/PP-1/2

79. Pressurized cylinders color codes, chained stacking Lab/warehouse/Other areas

80. Permits checking records / deviations F&Sdrill

81. Flare adequacy report PAD/Merox

82. List of minor/major fires, NLTAs, LTAs, near misses F&S

monitoring and their records

83. Checking of vehicles/trucks with material entry HR

84. SWSU blowdown to be routed to flare All sour water processing units

85. Upkeep of Nearmiss boxes F&S

86. Fire proofing of structures to be ensured Civil

87. Removal of loose material, removed insulation etc Operations/Onsite

88. Adequacy of extinguishers in Control rooms F&S

89. Display of do’s and donts near flame front generator Flare/Merox

90. Availability of PA systems Inst/Opns/Elec

91. Lighting adequacy Elec

92. Facility of Remote Operation of Tank valves PAD/Opns

93. All substations window panes to be checked for broken Elec

condition

94. All inst/elec panels to be in closed condition Inst/Elec

95. Chemicals to be stored under shed in a proper manner Opns

96. Ensure working of HC, H2S , Analysers working at Inst/Opns

cooling towers

97. Industrial hygienist not available HR

98. Authorsation for handling and disposal of biomedical HR

waste

99. Time bound activity to be taken up for IWLs with Onsite/Offsite

priority 0 and 1

100. Ensuring thermal indicative paint on external surface of DHDS

DHDS Reformer furnace bottom tube header

101. Segregation of Alloy steel and carbon steel material Warehouses

102. Pipetracks to be ensured free of oil Opns/Offsite

103. Testing of SPM hoses Wharf/Marine

104. All substations : PPE to be ensured, Insulating mats to Elec

be healthy, fire resistant painting on cables,

pressurization system to be completed, deluge system

readiness, Internal Audit records

S. No REQUIREMENT COMPLIANCE BY

105. Usage of use scaffold/Donot use scaffold / Scaffolding in Maint

progress tags at locations

106. Provision of continuity jumps on LPG/Naphtha lines Opns/Maint

107. All sample point drains to be routed to closed system Opns/PAD

108. Closed sampling system for LPG Opns

109. Furnaces with FO firing facilities should have sand at the Opns

bottom of the furnace for oil spillage and avoiding auto

ignition

110. Surge protector testing records at Mounded Bullets Opns/Elec

111. Emergency lighting provisions in working condition Elect

112. All TSV outlets to be routed to closed systems OPns

113. Log book records and signatures of shift crew Opns

114. Records of JSA/JHA for critical jobs Maint

115. Records of PCSA/PSSR F&S

116. Connection of all vents to flare Opns/PAD

117. Smoke detectors, HC detectors, personal gas detectors Inst/F&S

testing and records

118. All emergency exits free of material/obstruction (All Common

buildings)

119. Emergency preparedness training, Contractors, drivers, F&S

supervisors training records

You might also like

- SOP-015-Testing of H2S, CO2 & H2O in Sales GasDocument9 pagesSOP-015-Testing of H2S, CO2 & H2O in Sales GasAmnaKamranNo ratings yet

- Uran Plantpresentation1Document70 pagesUran Plantpresentation1Hari KCNo ratings yet

- STD 135Document26 pagesSTD 135Mathan Selva Kumar ANo ratings yet

- PSV LPG TankDocument8 pagesPSV LPG TankyosafatedenNo ratings yet

- OISD 225 ROs Oct2010Document17 pagesOISD 225 ROs Oct2010taranakgecNo ratings yet

- A-One Consultant - Methanol & Other LicensesDocument12 pagesA-One Consultant - Methanol & Other LicensesWasim PathanNo ratings yet

- Oisd 182Document46 pagesOisd 182Arvind Bharadwaj100% (1)

- SOP 16 Management of FuellingDocument7 pagesSOP 16 Management of Fuellingshamroz khanNo ratings yet

- Tank TruckDocument80 pagesTank Truckjacobpm2010No ratings yet

- Ocp For Oil Handling-ModiDocument3 pagesOcp For Oil Handling-ModiRaja RamNo ratings yet

- Oisd STD 124Document22 pagesOisd STD 124Nanu PatelNo ratings yet

- Petroleum Rules 2002Document237 pagesPetroleum Rules 2002deeparora188% (8)

- Oisd STD 105Document23 pagesOisd STD 105NarendrasinhNo ratings yet

- Oryx, Salt-MsdsDocument6 pagesOryx, Salt-MsdsMarg ConveyorsNo ratings yet

- C.02 - Gas-Freeing and Cleaning of TanksDocument7 pagesC.02 - Gas-Freeing and Cleaning of TanksmkkamarajNo ratings yet

- GDN 197Document21 pagesGDN 197Arvind BharadwajNo ratings yet

- D.09 - Vehicle Entry Permit FormDocument1 pageD.09 - Vehicle Entry Permit FormBenedito Cossa FelicianoNo ratings yet

- SMPV PDFDocument54 pagesSMPV PDFAnonymous BbZceWkVnNo ratings yet

- OISD StandardsDocument12 pagesOISD StandardsPratiek RaulNo ratings yet

- OISD GDN 182draftDocument60 pagesOISD GDN 182draftramptgdNo ratings yet

- Oisd STD 176Document1 pageOisd STD 176Arun Bhati0% (2)

- Process Safety Day Presentations 2014pptxDocument16 pagesProcess Safety Day Presentations 2014pptximafishNo ratings yet

- Noise MonitoringDocument1 pageNoise MonitoringSAMEER JAVEDNo ratings yet

- 13 Very Important Type Tests of A Low Voltage Switchgear Carried Out by The ManufacturerDocument10 pages13 Very Important Type Tests of A Low Voltage Switchgear Carried Out by The ManufacturerAhmed BoussoffaraNo ratings yet

- CEC-GE-CT-EN-001 - Citadel General EN CatalogueDocument37 pagesCEC-GE-CT-EN-001 - Citadel General EN CatalogueAlmustafa SabeehNo ratings yet

- 1.0 OISD STD 105 Work Permit SystemDocument24 pages1.0 OISD STD 105 Work Permit SystemRavi100% (1)

- 01the Gujarat Factories Rules 1963Document365 pages01the Gujarat Factories Rules 1963Siddhrajsinh Zala100% (1)

- Oisd STD 175Document59 pagesOisd STD 175yandiNo ratings yet

- Petroleum-Loading Unloading Top LoadingDocument4 pagesPetroleum-Loading Unloading Top LoadingLakshmi Bala100% (1)

- Hazop Study For Thermic Fluid Heater (At Industry by Heterogeneous Method)Document11 pagesHazop Study For Thermic Fluid Heater (At Industry by Heterogeneous Method)IJRASETPublicationsNo ratings yet

- Materi Hazard - IdentificationDocument61 pagesMateri Hazard - IdentificationRatna CahyaningtyasNo ratings yet

- National Iranian Oil Company: South Pars Gas Field Development Phase 19 Onshore FacilitiesDocument13 pagesNational Iranian Oil Company: South Pars Gas Field Development Phase 19 Onshore FacilitiesNasim MemarianNo ratings yet

- Intern Report ONGCDocument41 pagesIntern Report ONGCSaptarshi MajiNo ratings yet

- Oisd GDN 165Document30 pagesOisd GDN 165Nayan AhmedNo ratings yet

- CIN: U28909WB1981PTC034204: Head (Works) Head (Q.A.)Document3 pagesCIN: U28909WB1981PTC034204: Head (Works) Head (Q.A.)Nirmal WiresNo ratings yet

- HASAP Lima Husky Refinery 0908Document11 pagesHASAP Lima Husky Refinery 0908Mohamed HadjkacemNo ratings yet

- ERDMP of City Gate Station.Document40 pagesERDMP of City Gate Station.Jinal PathakNo ratings yet

- Assessment Checklist EnvironmentalDocument3 pagesAssessment Checklist EnvironmentalSanket Patil100% (1)

- GDN 227Document31 pagesGDN 227Vasant Kumar Varma100% (2)

- Barite MsdsDocument9 pagesBarite Msdsadvantage025100% (1)

- Safety Audit Format Gs ManmadDocument3 pagesSafety Audit Format Gs ManmadsunilNo ratings yet

- Quiz For TT DriverDocument8 pagesQuiz For TT DriverGulbarga DepotNo ratings yet

- Static and Mobile Pressure Vessels Rules 1981Document40 pagesStatic and Mobile Pressure Vessels Rules 1981mahendran50% (2)

- FM200 KiddeDocument37 pagesFM200 KiddeNguyen Van TuanNo ratings yet

- BIS Standard For IlluminationDocument14 pagesBIS Standard For IlluminationbhaskarNo ratings yet

- Objectives: CareerDocument14 pagesObjectives: CareerHedi Ben MohamedNo ratings yet

- Tank Lorry Filling GantryDocument21 pagesTank Lorry Filling GantrySiddharth BarmanNo ratings yet

- Msds of Argon GasDocument6 pagesMsds of Argon GasQilah KamarudinNo ratings yet

- MB Lal ReportDocument130 pagesMB Lal ReportVasant Kumar VarmaNo ratings yet

- PSC Hands Free Lifting and Hands-Off ToolsDocument28 pagesPSC Hands Free Lifting and Hands-Off ToolsProject Sales CorpNo ratings yet

- 6.10 Exhibit K Rules - and - Regulations - For - ContractorsDocument60 pages6.10 Exhibit K Rules - and - Regulations - For - ContractorsanggaNo ratings yet

- Maharashtra Factories Rules, 1963Document210 pagesMaharashtra Factories Rules, 1963Jatin Shah100% (4)

- Minimum Requirements To Leave Shipyard For Sea TrialDocument3 pagesMinimum Requirements To Leave Shipyard For Sea TrialHUNG NIKKONo ratings yet

- Checklist For TakeoverDocument3 pagesChecklist For TakeoverMariyath Muraleedharan KiranNo ratings yet

- Vetting InspectionsDocument6 pagesVetting InspectionsСергейNo ratings yet

- Vessel Inspection Checklist - Spirit / Endeavor: SRL Fire Prevention and Fighting Yes No N/a CommentsDocument5 pagesVessel Inspection Checklist - Spirit / Endeavor: SRL Fire Prevention and Fighting Yes No N/a CommentsSANDS ENGINEERING DESIGNS & CONSTRUCTION CO. LTD.No ratings yet

- EHS Audit Checklist-NBKDocument112 pagesEHS Audit Checklist-NBKVenkata ReddyNo ratings yet

- FERA-Check List Rev.0Document8 pagesFERA-Check List Rev.0Yaser AhmadNo ratings yet

- Boiler Light Up ChecklistDocument8 pagesBoiler Light Up ChecklistHolly SmithNo ratings yet

- Rig Inspection Check ListDocument4 pagesRig Inspection Check ListEd Calhe100% (1)

- Data Sheet Cylinder Rack & Piping ManifoldDocument1 pageData Sheet Cylinder Rack & Piping ManifoldPinjala Anoop100% (1)

- Data Sheet Directional ValveDocument1 pageData Sheet Directional ValvePinjala AnoopNo ratings yet

- Data Sheet Co2 Cylinder AssemblyDocument2 pagesData Sheet Co2 Cylinder AssemblyPinjala AnoopNo ratings yet

- Data Sheet Discharge NozzleDocument1 pageData Sheet Discharge NozzlePinjala AnoopNo ratings yet

- Preparation of LC and LG ArrangementDocument13 pagesPreparation of LC and LG ArrangementPinjala AnoopNo ratings yet

- Data Sheet Air Foam ChamberDocument1 pageData Sheet Air Foam ChamberPinjala AnoopNo ratings yet

- Inline Mixing JGS 210-120-1-72E: ConfidentialDocument11 pagesInline Mixing JGS 210-120-1-72E: ConfidentialPinjala AnoopNo ratings yet

- Safety Contact - Pipeline Bursted During HydrotestDocument1 pageSafety Contact - Pipeline Bursted During HydrotestPinjala AnoopNo ratings yet

- Process DescriptionDocument7 pagesProcess DescriptionPinjala AnoopNo ratings yet

- Tank Mixing JGS 210-120-1-66E: ConfidentialDocument9 pagesTank Mixing JGS 210-120-1-66E: ConfidentialPinjala AnoopNo ratings yet

- PSA User Meet - JaipurDocument2 pagesPSA User Meet - JaipurPinjala AnoopNo ratings yet

- 201906beaconenglish-Corrosion Under InsulationDocument1 page201906beaconenglish-Corrosion Under InsulationguhadebasisNo ratings yet

- 2 Phase Flow OrificeDocument14 pages2 Phase Flow OrificePinjala AnoopNo ratings yet

- General Considerations: Design PracticesDocument21 pagesGeneral Considerations: Design PracticesPinjala Anoop100% (1)

- Beacon - Corrosion Under InsulationDocument1 pageBeacon - Corrosion Under Insulationkave4923No ratings yet

- Plan 53 BDocument2 pagesPlan 53 BPinjala AnoopNo ratings yet

- Points For Discussion During Training of Distillation Techniques, Operation & TroubleshootingDocument1 pagePoints For Discussion During Training of Distillation Techniques, Operation & TroubleshootingPinjala AnoopNo ratings yet

- Centrifugal Compressor Surge Control Methods PDFDocument1 pageCentrifugal Compressor Surge Control Methods PDFPinjala AnoopNo ratings yet

- t000001864 - Filename2 - Press Tender For NHT - CCR - 24.07.2009-fDocument88 pagest000001864 - Filename2 - Press Tender For NHT - CCR - 24.07.2009-fPinjala AnoopNo ratings yet

- Standard Refinery Fuel TonsDocument2 pagesStandard Refinery Fuel TonsPinjala Anoop100% (4)

- Fccu IiDocument4 pagesFccu IiPinjala AnoopNo ratings yet

- OISD 166 GuidelinesDocument50 pagesOISD 166 GuidelinesPinjala AnoopNo ratings yet

- Standard Refinery Fuel TonsDocument2 pagesStandard Refinery Fuel TonsPinjala AnoopNo ratings yet

- QuizDocument6 pagesQuizPinjala AnoopNo ratings yet

- 3-AAP Analysis ReportDocument11 pages3-AAP Analysis ReportPinjala AnoopNo ratings yet

- Energy ConversionDocument16 pagesEnergy ConversionPinjala AnoopNo ratings yet

- DMS 16-12-2017Document6 pagesDMS 16-12-2017Pinjala AnoopNo ratings yet

- DMS 06-04-2018Document59 pagesDMS 06-04-2018Pinjala AnoopNo ratings yet

- Name: Katakam Sandeep Reddy Mobile: 9704575353: ResumeDocument2 pagesName: Katakam Sandeep Reddy Mobile: 9704575353: ResumePinjala AnoopNo ratings yet

- The Law of CosinesDocument4 pagesThe Law of Cosinesapi-213604106No ratings yet

- Paragraph Completion Material 1Document5 pagesParagraph Completion Material 1d.jyr2xNo ratings yet

- B737 SRM 51 - 40 - 08 Rep - Fiberglass OverlaysDocument6 pagesB737 SRM 51 - 40 - 08 Rep - Fiberglass OverlaysAlex CanizalezNo ratings yet

- Week 1 - Intrduction To Nursing Research - StudentDocument24 pagesWeek 1 - Intrduction To Nursing Research - StudentWani GhootenNo ratings yet

- I O OrganizationDocument26 pagesI O Organization08-Avinash SNo ratings yet

- Music, Arts, Pe & HealthDocument2 pagesMusic, Arts, Pe & HealthEvan Maagad LutchaNo ratings yet

- TUYA ManualDocument2 pagesTUYA ManualMagandang MallNo ratings yet

- NCERT Exemplar Class 7 Maths IntegersDocument661 pagesNCERT Exemplar Class 7 Maths IntegersRohiniNo ratings yet

- Mining EsriDocument30 pagesMining EsriCipta Nur Asa100% (1)

- Research Title Approval FormDocument2 pagesResearch Title Approval FormJames EdlynNo ratings yet

- Frequency Spectrum On XXX OperatorsDocument4 pagesFrequency Spectrum On XXX OperatorsPeng Yuan FengNo ratings yet

- Very High Frequency Omni-Directional Range: Alejandro Patt CarrionDocument21 pagesVery High Frequency Omni-Directional Range: Alejandro Patt CarrionAlejandro PattNo ratings yet

- Aircraft Tyre Maintenance - SKYbrary Aviation SafetyDocument8 pagesAircraft Tyre Maintenance - SKYbrary Aviation Safetynosh1983No ratings yet

- Self-Diagnosis With Advanced Hospital Management-IJRASETDocument5 pagesSelf-Diagnosis With Advanced Hospital Management-IJRASETIJRASETPublicationsNo ratings yet

- Group 2 PBA - ScriptDocument6 pagesGroup 2 PBA - ScriptruciNo ratings yet

- Probability of Event Intersections: Vietnamese-German UniversityDocument17 pagesProbability of Event Intersections: Vietnamese-German UniversityĐặng ThưNo ratings yet

- Vichinsky Et Al.2019Document11 pagesVichinsky Et Al.2019Kuliah Semester 4No ratings yet

- Arguments and FallaciesDocument18 pagesArguments and FallaciesSarah Mae Peñaflor Baldon-IlaganNo ratings yet

- Literature Review 1Document7 pagesLiterature Review 1api-609504422No ratings yet

- Philippine Ecd Checklist Class Summary (Post-Test) SY: 2022-2023Document5 pagesPhilippine Ecd Checklist Class Summary (Post-Test) SY: 2022-2023UltravioletHeartNo ratings yet

- Training Guide: Administering Windows Server 2012Document33 pagesTraining Guide: Administering Windows Server 2012sabastianNo ratings yet

- Learning Activity Sheet in Science-9: Week 7-Quarter 3Document5 pagesLearning Activity Sheet in Science-9: Week 7-Quarter 3theinvaderNo ratings yet

- Problem Set 1Document2 pagesProblem Set 1Lovedeep SinghNo ratings yet

- Sika Decap PDFDocument2 pagesSika Decap PDFthe pilotNo ratings yet

- Soft-Starter: Programming ManualDocument162 pagesSoft-Starter: Programming ManualThaylo PiresNo ratings yet

- Excavation and Trenching Implementation PlanDocument29 pagesExcavation and Trenching Implementation Planracing.phreakNo ratings yet

- Alonex Special Amp Industrial Electronic Equipment PDFDocument342 pagesAlonex Special Amp Industrial Electronic Equipment PDFthanh vanNo ratings yet

- Lesson Plan For C.O. 2Document1 pageLesson Plan For C.O. 2Jubilee BundaNo ratings yet

- Indian Standard: Methods of Test For Aggregates For ConcreteDocument22 pagesIndian Standard: Methods of Test For Aggregates For ConcreteAnuradhaPatraNo ratings yet

- Multidisciplinary Research: EPRA International Journal ofDocument5 pagesMultidisciplinary Research: EPRA International Journal ofMathavan VNo ratings yet