Professional Documents

Culture Documents

Econ Check Valves Tilting Disc Type ANSI Class 150: Application

Uploaded by

ChristianGuerreroOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Econ Check Valves Tilting Disc Type ANSI Class 150: Application

Uploaded by

ChristianGuerreroCopyright:

Available Formats

contents

section 17 | valves to ANSI standard 309

econ check valves

tilting disc type

ANSI Class 150

suitable for horizontal and vertical pipelines.

the valves should be installed with

the pressure under the disc.

cast steel

ANSI Class 150: fig. 2220

with auxiliary spring: fig. 2221

stainless steel

ANSI Class 150: fig. 2228

with auxiliary spring: fig. 2229

DN ≤ 16”: face to face according to API 594

application: These check valves can be used for steam, gases and liquids.

They are very fast acting, nevertheless, where liquid flows can be expected to

reverse direction very rapidly an auxiliary spring should be used.

pressure/temperature rating: cast steel stainless steel

DN 2” to DN16” 15.8 bar - 150 °C 14.8 bar - 150 °C

(acc. to ANSI class 150) 8.6 0 bar - 350 °C 8.6 bar - 350 °C

materials: cast steel

body 2” to 8” - stainless steel ASTM A351 CF8M

10” to 24” - cast steel ASTM A216 WCC

body seat ≤ 8” - stainless steel ASTM A351 CF8M

body seat ≥ 10” - stainless steel hard faced

disc - stainless steel ASTM A487 CA6NM

hing pin - stainless steel ASTM A276 Type 410

spring- stainless steel ASTM A638 Type 660

stainless steel

body - stainless steel ASTM A351 CF8M

disc and

hing pin - stainless steel ASTM A240 Type 329

spring- stainless steel ASTM A638 Type 660

other types available: PN 16, 25 and 40 see section 3 in this catalogue

on request: ● ANSI Class 300, 600 and 900

● other materials

dimensions (mm): DN 50 80 100 150 200 250 300 350 400 450 500 600

d ANSI class 150 2” 3” 4” 6” 8” 10” 12” 14” 16” 18” 20” 24”

A ANSI class 150 105 137 175 222 279 340 410 451 514 549 606 718

d1 ANSI class 150 37 64 90 140 185 234 286 328 376 420 466 564

L ANSI class 150 60 73 73 98 127 146 181 184 191 152 158 178

L1 ANSI class 150 56 85 95 137 179 222 270 330 362 340 380 460

wt (kg) ANSI class 150 3.4 4.3 6.8 11.9 22 36 62 64 85 96 117 195

You might also like

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Tube FittingsDocument12 pagesTube FittingsspiritveluNo ratings yet

- 12.5 Collision Theory - ChemistryDocument15 pages12.5 Collision Theory - ChemistryAri CleciusNo ratings yet

- Trunnion Ball ValveDocument16 pagesTrunnion Ball ValveDavid ZhuangNo ratings yet

- PerarEC-EB 0 PDFDocument21 pagesPerarEC-EB 0 PDFadrianioantomaNo ratings yet

- Dawn of Solar PV CookingDocument5 pagesDawn of Solar PV CookingAbhinav AgrawalNo ratings yet

- Machining of Stainless Steels and Super Alloys: Traditional and Nontraditional TechniquesFrom EverandMachining of Stainless Steels and Super Alloys: Traditional and Nontraditional TechniquesNo ratings yet

- From Input To Affordance: Social-Interactive Learning From An Ecological Perspective Leo Van Lier Monterey Institute Oflntemational StudiesDocument15 pagesFrom Input To Affordance: Social-Interactive Learning From An Ecological Perspective Leo Van Lier Monterey Institute Oflntemational StudiesKayra MoslemNo ratings yet

- Butterfly ValvesDocument27 pagesButterfly ValvesИгорьNo ratings yet

- Hydrodynamic Calculation Butterfly Valve (Double Disc)Document31 pagesHydrodynamic Calculation Butterfly Valve (Double Disc)met-calcNo ratings yet

- Inferring The Speaker's Tone, ModeDocument31 pagesInferring The Speaker's Tone, Modeblessilda.delaramaNo ratings yet

- 5G Transport Slice Control in End-To-End 5G NetworksDocument19 pages5G Transport Slice Control in End-To-End 5G NetworksmorganNo ratings yet

- Cast Steel Bolted Bonnet Gates: Styles: CB2, CB3, & CB4/2 Class: 1500 - Sizes: 2" Thru 12"Document1 pageCast Steel Bolted Bonnet Gates: Styles: CB2, CB3, & CB4/2 Class: 1500 - Sizes: 2" Thru 12"OceanexNo ratings yet

- Perar WCWB Trunnion Welded BodyDocument19 pagesPerar WCWB Trunnion Welded BodyAlexandra HarperNo ratings yet

- CLASS 150: AWWA C504 Double Flanged Butterfly ValveDocument1 pageCLASS 150: AWWA C504 Double Flanged Butterfly ValveAnnie De WildeNo ratings yet

- BAC NP Ball Valves Carbon Steel, Stainless Steel Full Bore ANSI Class 150, 300Document1 pageBAC NP Ball Valves Carbon Steel, Stainless Steel Full Bore ANSI Class 150, 300ChristianNo ratings yet

- Wafer Check Valve 1Document10 pagesWafer Check Valve 1Roly AnggaraNo ratings yet

- XMZ 210Document3 pagesXMZ 210Carlos GutierrezNo ratings yet

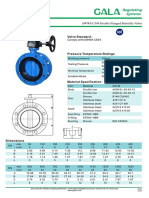

- 2309+QT04 - Gala-Motorized Butterfly ValveDocument4 pages2309+QT04 - Gala-Motorized Butterfly ValveNam Đỗ100% (1)

- m8089 pp66s14l71 Spec SheetDocument2 pagesm8089 pp66s14l71 Spec SheetcaomandanteNo ratings yet

- Econ Ball Valves Carbon Steel Stainless Steel 3 Way Port: Full Bore Blow-Out Proof StemDocument1 pageEcon Ball Valves Carbon Steel Stainless Steel 3 Way Port: Full Bore Blow-Out Proof StemChristianGuerreroNo ratings yet

- AWWA C-504: Model 3900F & Model 3900MDocument2 pagesAWWA C-504: Model 3900F & Model 3900MPriyanka rajpurohitNo ratings yet

- Ke BS 150utdzm PDFDocument2 pagesKe BS 150utdzm PDFFahmi HaidiNo ratings yet

- Check Valve ANSI 300 Swing Check Valve, Cast Steel, Flanged End ANSI 300Document1 pageCheck Valve ANSI 300 Swing Check Valve, Cast Steel, Flanged End ANSI 300Tiara PrasetyoNo ratings yet

- Tozen Valve CatalogueDocument45 pagesTozen Valve CatalogueMyo Kyaw Kyaw100% (1)

- Cast Steel Gate Valve: ANSI Class 150 & 300 ANSI Class 150 & 300Document5 pagesCast Steel Gate Valve: ANSI Class 150 & 300 ANSI Class 150 & 300Andri AjaNo ratings yet

- Cast Iron Rising Stem Gate ValveDocument1 pageCast Iron Rising Stem Gate ValveIj OooNo ratings yet

- Maverick Valves CatalogueDocument84 pagesMaverick Valves Cataloguer4mms3sNo ratings yet

- Cast Iron Regulating Globe Valves PN 16Document3 pagesCast Iron Regulating Globe Valves PN 16Mohamed RaafatNo ratings yet

- Accessories BOQ For HP, MP, LP Steam+CondensateDocument14 pagesAccessories BOQ For HP, MP, LP Steam+Condensatefakir mohammadNo ratings yet

- Valv. Comp. 150v CNMDocument11 pagesValv. Comp. 150v CNMJim SmithNo ratings yet

- Standards MaterialDocument1 pageStandards MaterialFarzad MirzavandNo ratings yet

- Fitting - ASTM A 197Document4 pagesFitting - ASTM A 197yajuNo ratings yet

- Vanessa Basic Datasheet-Valves PDFDocument10 pagesVanessa Basic Datasheet-Valves PDFGogyNo ratings yet

- Specification - 9110 - 201510 at Globe (Rev.03)Document10 pagesSpecification - 9110 - 201510 at Globe (Rev.03)Công PhạmNo ratings yet

- Carbon Steel Strainer Fig 34 HP-Technical InformationDocument3 pagesCarbon Steel Strainer Fig 34 HP-Technical InformationSouljah KhifferNo ratings yet

- CI Wafer / DI Lug Butterfly Valves: Series 0160Document2 pagesCI Wafer / DI Lug Butterfly Valves: Series 0160Vignesh NadimuthuNo ratings yet

- SMZ 210Document2 pagesSMZ 210Carlos GutierrezNo ratings yet

- Kirloskar Romak Pump - RMK: ISO 2858 / DIN EN 22858 / ISO 5199Document8 pagesKirloskar Romak Pump - RMK: ISO 2858 / DIN EN 22858 / ISO 5199Amit pumpXpertzNo ratings yet

- KG Ball Valve PresentationDocument21 pagesKG Ball Valve PresentationmmmlormamNo ratings yet

- Construction of Petroleum Storage Depot at Pali, Rajasthan: Doc No.: NAYA-PALI-SP-80 Rev: 00 Date: 25-04-2019Document4 pagesConstruction of Petroleum Storage Depot at Pali, Rajasthan: Doc No.: NAYA-PALI-SP-80 Rev: 00 Date: 25-04-2019chintanNo ratings yet

- Hidrante Seco Mod F0733Document1 pageHidrante Seco Mod F0733Julio FloresNo ratings yet

- Butterfly ValvesDocument28 pagesButterfly ValvesLAWRENCENo ratings yet

- BAC LD Butterfly Valves Lugged Type Carbon Steel/stainless Steel ANSI Class 150 and 300Document1 pageBAC LD Butterfly Valves Lugged Type Carbon Steel/stainless Steel ANSI Class 150 and 300ChristianNo ratings yet

- Tosaca-Valvula AlivioDocument2 pagesTosaca-Valvula AlivioAntony BonillaNo ratings yet

- Fitting ASTM A 197 PDFDocument4 pagesFitting ASTM A 197 PDFSusan Sue Berrospi Merino100% (1)

- Filtro y Eco-FyDocument1 pageFiltro y Eco-FydgarciabNo ratings yet

- Malleable Cast Iron Forged Steel and Nipple Standards and SpecificationsDocument4 pagesMalleable Cast Iron Forged Steel and Nipple Standards and SpecificationspdiconpNo ratings yet

- SY Rubber Disc Check ValveDocument2 pagesSY Rubber Disc Check ValvePhú Song LongNo ratings yet

- Foot Valve Cataloque IFCDocument2 pagesFoot Valve Cataloque IFCPuntanata SiagianNo ratings yet

- Valves AccessoriesDocument14 pagesValves AccessoriesnajiruddinshaikNo ratings yet

- 3 Way Valve - BallDocument2 pages3 Way Valve - BallchintanNo ratings yet

- 1 Gala CI Y-Strainer Cast Iron Fig 7101Document1 page1 Gala CI Y-Strainer Cast Iron Fig 7101Non Etabas GadnatamNo ratings yet

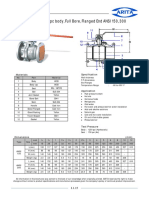

- Ball Valve AritaDocument1 pageBall Valve AritaTiara PrasetyoNo ratings yet

- Catalog Ball Valve ARITADocument1 pageCatalog Ball Valve ARITAAdi Kira YamatoNo ratings yet

- Cast Iron Sluice Specs 2017Document8 pagesCast Iron Sluice Specs 2017Osama MohammedNo ratings yet

- Class 600: Apollo Flange Valves Deliver FeaturesDocument2 pagesClass 600: Apollo Flange Valves Deliver FeaturesAniket AngreNo ratings yet

- Arita Gate ValveDocument8 pagesArita Gate Valvemr_fahmiNo ratings yet

- Filtro DuplexDocument8 pagesFiltro DuplexGuillermo ArandaNo ratings yet

- Valvulas Mariposas DorotDocument4 pagesValvulas Mariposas DorotVicenteRojasLeonNo ratings yet

- DPCVDocument4 pagesDPCVjamil voraNo ratings yet

- Gala 333FF-300Document1 pageGala 333FF-300Adriano BispoNo ratings yet

- Lit RD10 ENDocument6 pagesLit RD10 ENlesonspkNo ratings yet

- (S-11.12-00) 2019 Gala Butterfly Valve Wafer Type 16 Bar SUS 304 Disc ANSI 150 Fig 2302Document3 pages(S-11.12-00) 2019 Gala Butterfly Valve Wafer Type 16 Bar SUS 304 Disc ANSI 150 Fig 2302Bernard Bonnin CervantesNo ratings yet

- Wafer Style Twin Disc Ductile Iron Check ValveDocument1 pageWafer Style Twin Disc Ductile Iron Check ValveAlbeiro LeivaNo ratings yet

- EP1 Materials ListDocument2 pagesEP1 Materials ListGrover Miranda VallejosNo ratings yet

- Econ Globe Valves Forged Steel Stainless Steel Trim ANSI Class 800Document1 pageEcon Globe Valves Forged Steel Stainless Steel Trim ANSI Class 800ChristianGuerrero0% (1)

- Econ Gate Valve Cast Iron Bronze Trim ANSI Class 125 Fig. 1800Document1 pageEcon Gate Valve Cast Iron Bronze Trim ANSI Class 125 Fig. 1800ChristianGuerreroNo ratings yet

- Econ Y-Pattern Globe and Check Valves Forged Steel Stainless Steel TrimDocument1 pageEcon Y-Pattern Globe and Check Valves Forged Steel Stainless Steel TrimChristianGuerreroNo ratings yet

- BAC SR8 Ball Valves Forged Steel Stainless Steel Full Bore ANSI Class 800Document1 pageBAC SR8 Ball Valves Forged Steel Stainless Steel Full Bore ANSI Class 800ChristianGuerreroNo ratings yet

- Econ Globe Valves Carbon Steel Stainless Steel Trim ANSI Class 150 and 300Document1 pageEcon Globe Valves Carbon Steel Stainless Steel Trim ANSI Class 150 and 300ChristianGuerreroNo ratings yet

- Econ Gate Valve For Oil Tankers Cast Iron Bronze Trim Class 125 Fig. 339Document1 pageEcon Gate Valve For Oil Tankers Cast Iron Bronze Trim Class 125 Fig. 339ChristianGuerreroNo ratings yet

- Linear Conversion Table Inches - Millimetres: (1 Inch 25.4 Millimeter)Document1 pageLinear Conversion Table Inches - Millimetres: (1 Inch 25.4 Millimeter)ChristianGuerreroNo ratings yet

- Flow of Water at Several Velocities Through Pipelines DN 10 To DN 300Document1 pageFlow of Water at Several Velocities Through Pipelines DN 10 To DN 300ChristianGuerreroNo ratings yet

- Econ Check Valves Bronze Class 150 Fig. 1425: Pressure/temperature RatingDocument1 pageEcon Check Valves Bronze Class 150 Fig. 1425: Pressure/temperature RatingChristianGuerreroNo ratings yet

- Sizing of Pipelines For Saturated Steam: Section 21 Technical DataDocument1 pageSizing of Pipelines For Saturated Steam: Section 21 Technical DataChristianGuerreroNo ratings yet

- Flange Dimensions and Drilling To DIN 2501: Section 21 Technical DataDocument1 pageFlange Dimensions and Drilling To DIN 2501: Section 21 Technical DataChristianGuerreroNo ratings yet

- Econ Sight Glasses With Indicator: Valves & FittingsDocument1 pageEcon Sight Glasses With Indicator: Valves & FittingsChristianGuerreroNo ratings yet

- Steam Table For Saturated Steam: (Continued)Document1 pageSteam Table For Saturated Steam: (Continued)ChristianGuerreroNo ratings yet

- Steam Table For Saturated SteamDocument1 pageSteam Table For Saturated SteamChristianGuerreroNo ratings yet

- Steam Table For Specific Volume of Superheated Steam From 1 To 50 Bar Absolute. (100 - 320 °C)Document1 pageSteam Table For Specific Volume of Superheated Steam From 1 To 50 Bar Absolute. (100 - 320 °C)ChristianGuerreroNo ratings yet

- Flange Dimensions and Drilling To JIS B 2210 (1984)Document1 pageFlange Dimensions and Drilling To JIS B 2210 (1984)ChristianGuerreroNo ratings yet

- 239 PDFDocument1 page239 PDFChristianGuerreroNo ratings yet

- Econ Level Gauges Forged Brass and Steel PN 25: Safety: Max. Working PressureDocument1 pageEcon Level Gauges Forged Brass and Steel PN 25: Safety: Max. Working PressureChristianGuerreroNo ratings yet

- Econ Level Gauges Bronze: Max. Working Pressure: On Request: Dimensions (MM)Document1 pageEcon Level Gauges Bronze: Max. Working Pressure: On Request: Dimensions (MM)ChristianGuerreroNo ratings yet

- Econ Level Gauges For Steam Boilers Forged Steel Reflex/transparentDocument1 pageEcon Level Gauges For Steam Boilers Forged Steel Reflex/transparentChristianGuerreroNo ratings yet

- Econ Level Gauges For Chemical Applications: Fig. 577: Knee Type Arms of Stainless Steel, Ws - No. 1.4571 (AISI - 316)Document1 pageEcon Level Gauges For Chemical Applications: Fig. 577: Knee Type Arms of Stainless Steel, Ws - No. 1.4571 (AISI - 316)ChristianGuerreroNo ratings yet

- Econ Level Gauges Forged Steel PN 40: MaterialsDocument1 pageEcon Level Gauges Forged Steel PN 40: MaterialsChristianGuerreroNo ratings yet

- Cambridge IGCSE Paper 2Document4 pagesCambridge IGCSE Paper 2irajooo epik zizterNo ratings yet

- Main Girders: CrossDocument3 pagesMain Girders: Crossmn4webNo ratings yet

- Cisco 2500 Series RoutersDocument16 pagesCisco 2500 Series RoutersJull Quintero DazaNo ratings yet

- Goliath 90 v129 eDocument129 pagesGoliath 90 v129 eerkanNo ratings yet

- Ali Erdemir: Professional ExperienceDocument3 pagesAli Erdemir: Professional ExperienceDunkMeNo ratings yet

- 123 09-Printable Menu VORDocument2 pages123 09-Printable Menu VORArmstrong TowerNo ratings yet

- Amnaya Sutra (English)Document458 pagesAmnaya Sutra (English)Assam Bhakti SagarNo ratings yet

- Nissan Copper LTDDocument11 pagesNissan Copper LTDankit_shahNo ratings yet

- Rail Vehicle DynamicsDocument55 pagesRail Vehicle DynamicsdfNo ratings yet

- 08 Activity 1 (10) (LM)Document2 pages08 Activity 1 (10) (LM)Jhanine Mae Oriola FortintoNo ratings yet

- Lecture Planner - Inorganic Chemistry (Legend) - Yakeen NEET 2.0 2024Document1 pageLecture Planner - Inorganic Chemistry (Legend) - Yakeen NEET 2.0 2024Dipendra KumarNo ratings yet

- Shawal 1431 AH Prayer ScheduleDocument2 pagesShawal 1431 AH Prayer SchedulemasjidibrahimNo ratings yet

- Emw 2007 FP 02093Document390 pagesEmw 2007 FP 02093boj87No ratings yet

- Worlds Apart: A Story of Three Possible Warmer WorldsDocument1 pageWorlds Apart: A Story of Three Possible Warmer WorldsJuan Jose SossaNo ratings yet

- Midterm Exam Gor Grade 11Document2 pagesMidterm Exam Gor Grade 11Algelle AbrantesNo ratings yet

- Dusta ManaDocument16 pagesDusta ManamahaphalaNo ratings yet

- Rekomendasi AnimeDocument11 pagesRekomendasi Animeosvaldo manurungNo ratings yet

- Lesson 1 Chapter 9 ErosiondepositionDocument1 pageLesson 1 Chapter 9 Erosiondepositionapi-249320969No ratings yet

- AssessmentDocument9 pagesAssessmentJuan Miguel Sapad AlpañoNo ratings yet

- TM-8000 HD Manual PDFDocument37 pagesTM-8000 HD Manual PDFRoxana BirtumNo ratings yet

- Chapter 7 - Muscular SystemDocument29 pagesChapter 7 - Muscular SystemlNo ratings yet

- Straight LineDocument15 pagesStraight LineAyanNo ratings yet

- Syllabus Unit Iv Unit Commitment and Economic DispatchDocument23 pagesSyllabus Unit Iv Unit Commitment and Economic DispatchBALAKRISHNANNo ratings yet

- Lecture 12Document8 pagesLecture 12Mechanical ZombieNo ratings yet