Professional Documents

Culture Documents

Cobalt-Chromium Alloys

Uploaded by

Pinto PintoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cobalt-Chromium Alloys

Uploaded by

Pinto PintoCopyright:

Available Formats

CoCr Alloys

There are basically two types of cobalt-chromium alloys:

1. The castable CoCrMo alloy.

2. The CoNiCrMo alloy (which is usually wrought by (hot) forging).

The castable CoCrMo alloy has been used for many decades in dentistry and, recently, in making artificial

joints.

The wrought CoNiCrMo alloy is relatively new, now used for making the stems of prostheses for heavily

loaded joints such as the knee and hip.

The ASTM lists four types of CoCr alloys which are recommended for surgical implant applications:

(1) cast CoCrMo alloy (F75).

(2) wrought CoCrWNi alloy (F90).

(3) wrought CoNiCrMo alloy (F562).

(4) wrought CoNiCrMoWFe alloy (F563).

At the present time only two of the four alloys are used extensively in implant fabrications, the castable

CoCrMo and the wrought CoNiCrMo alloy.

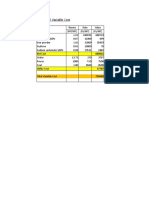

Chemical Compositions of CoCr Alloys [ASTM]

Element CoCrMo(F75) CoCrWNi(F90) CoNiCrMo(F562) CoNiCrMoWFe(F563)

Min. Max Min. Max. Min. Max. Min. Max.

Cr 27.0 30.0 19.0 21.0 19.0 21.0 18.00 22.00

Mo 5.0 7.0 — — 9.0 10.5 3.00 4.00

Ni — 2.5 9.0 11.0 33.0 37.0 15.00 25.00

Fe — 0.75 — 3.0 — 1.0 4.00 6.00

C — 0.35 0.05 0.15 — 0.025 — 0.05

Si — 1.00 — 1.00 — 0.15 — 0.50

Mn — 1.00 — 2.00 — 0.15 — 1.00

W — — 14.0 16.0 — — 3.00 4.00

P — — — — — 0.015 — —

S — — — — — 0.010 — 0.010

Ti — — — — — 1.0 0.50 3.50

Co Balance

*The two basic elements of the CoCr alloys form a solid solution of up to 65% Co.

*The molybdenum is added to produce finer grains which results in higher strengths after casting or forging.

*The chromium enhances corrosion resistance as well as solid solution strengthening of the alloy.

*The CoNiCrMo alloy contains approximately 35% Co and Ni each. The alloy is highly corrosion resistant

to seawater (containing chloride ions) under stress. Cold working can increase the strength of the alloy

considerably .

*There is a considerable difficulty of cold working on this alloy, especially when making large devices such

as hip joint stems. Only hot-forging can be used to fabricate a large implant with the alloy.

*The superior fatigue and ultimate tensile strength of the wrought CoNiCrMo alloy make it suitable for the

applications which require long service life without fracture or stress fatigue. Such is the case for the stems

of the hip joint prostheses. This advantage is better appreciated when the implant has to be replaced, since it

is quite difficult to remove the failed piece of implant embedded deep in the femoral medullary canal.

*Both the cast and wrought alloys have excellent corrosion resistance

The metallic products released from the prosthesis because of wear, corrosion, and fretting may impair

organs and local tissues.

*In vitro studies have indicated that particulate Co is toxic to human, but particulate Cr and CoCr alloys are

no significant toxicity. The toxicity of metal extracts in vitro have indicated that Co and Ni extracts at 50%

concentration appear to be highly toxic since all viability parameters were altered after 24 h. However, Cr

extract seems to be less toxic than Ni and Co.

*The modulus of elasticity for the CoCr alloys does not change with the changes in their ultimate tensile

strength. The values range from 220 to 234 GPa, which are higher than other materials such as stainless

steels. This may have some implications of different load transfer modes to the bone in artificial joint

replacements.

Low wear has been recognized as an advantage of metal-on-metal hip articulations because of its hardness

and toughness.

PDF created with pdfFactory Pro trial version www.pdffactory.com

You might also like

- The Influence of Microalloying With Boron On Properties of Austenite Stainless Steel X8crnis18-9Document6 pagesThe Influence of Microalloying With Boron On Properties of Austenite Stainless Steel X8crnis18-9IJAR JOURNALNo ratings yet

- Classification of Hardfacing AlloysDocument5 pagesClassification of Hardfacing AlloyssainivijayNo ratings yet

- Consumo de Caucho en EafDocument9 pagesConsumo de Caucho en EafKatherine TamayoNo ratings yet

- Biomaterials Engineering (1154BT101)Document14 pagesBiomaterials Engineering (1154BT101)ronaldo magarNo ratings yet

- Strollberg LEO WorkshopDocument54 pagesStrollberg LEO WorkshopBinod Kumar PadhiNo ratings yet

- S.G IronDocument6 pagesS.G IronQasim BarkatNo ratings yet

- 8 - Unit IIDocument14 pages8 - Unit IIronaldo magarNo ratings yet

- Improvement in Mechanical Properties of Standard 1Document8 pagesImprovement in Mechanical Properties of Standard 1Karthik RaoNo ratings yet

- Metals: Sci 401 Lecture 8Document54 pagesMetals: Sci 401 Lecture 8Niña Viaña BinayNo ratings yet

- Lecture 8 MetalsDocument53 pagesLecture 8 MetalsManga 01No ratings yet

- Metalography and Microstructures of Stainless Steels and Maraging SteelsDocument32 pagesMetalography and Microstructures of Stainless Steels and Maraging SteelsChaguy VergaraNo ratings yet

- Report - Bikramdev Padhi - PGCSL 2 - BRO TS 19044Document10 pagesReport - Bikramdev Padhi - PGCSL 2 - BRO TS 19044BikramdevPadhiNo ratings yet

- Metallic Implant MaterialsDocument39 pagesMetallic Implant MaterialsRecep VatanseverNo ratings yet

- Design & Process of Steel Bloom: Manganese Chromium TungstenDocument10 pagesDesign & Process of Steel Bloom: Manganese Chromium Tungstenulul farichinNo ratings yet

- Sims 1969Document16 pagesSims 1969Brrr BrrrNo ratings yet

- Introduction in Alloys and Influence of Elements: Alloys and Melting 01 - Alloys - and - Melting - EN - Docx 1/13Document13 pagesIntroduction in Alloys and Influence of Elements: Alloys and Melting 01 - Alloys - and - Melting - EN - Docx 1/13luisA1923No ratings yet

- C Staehle Kalt Datenblatt EN 1511Document7 pagesC Staehle Kalt Datenblatt EN 1511pierocarnelociNo ratings yet

- Corrosion Resistance of Nickel Containing Alloys in Organic Acids and Related CompoundsDocument0 pagesCorrosion Resistance of Nickel Containing Alloys in Organic Acids and Related CompoundsrickrobbinsNo ratings yet

- Theory of AlloysDocument19 pagesTheory of AlloysNeel PatelNo ratings yet

- Nickle Based SuperalloyDocument25 pagesNickle Based SuperalloyLavesh Kumar100% (1)

- Base Metal AlloysDocument85 pagesBase Metal AlloysmeghaNo ratings yet

- 1-S2.0-S1044580315000157-Main Microstructure Characterization of Heat Affected Zone After Welding inDocument8 pages1-S2.0-S1044580315000157-Main Microstructure Characterization of Heat Affected Zone After Welding inRamesh EthirajanNo ratings yet

- Test 2 Material SelectionDocument6 pagesTest 2 Material Selectionsilent spritsNo ratings yet

- Metallograpgy & Microstructure SSDocument31 pagesMetallograpgy & Microstructure SSKatellin BermudezNo ratings yet

- Wire Rod of Boron-Bearing Low-Carbon Steel For Direct Deep DrawingDocument9 pagesWire Rod of Boron-Bearing Low-Carbon Steel For Direct Deep DrawingNicolas ValleNo ratings yet

- Slag in SteelmakingDocument18 pagesSlag in Steelmakingamit KumarNo ratings yet

- pp043-049 ms18Document6 pagespp043-049 ms18Srikanth SrikantiNo ratings yet

- Introduction To Rolling Element Bearing Manufacturing ProcessDocument18 pagesIntroduction To Rolling Element Bearing Manufacturing ProcessRamakanth P JoshiNo ratings yet

- Ksp-Instrument Impulse Piping & TubingDocument18 pagesKsp-Instrument Impulse Piping & TubingZulfequar R. Ali KhanNo ratings yet

- Case-Hardening Steel: Everything That Moves Needs Case-Hardened GearsDocument5 pagesCase-Hardening Steel: Everything That Moves Needs Case-Hardened GearsjeyakumarNo ratings yet

- Steel Making PresentationDocument80 pagesSteel Making PresentationAlvin Garcia PalancaNo ratings yet

- Steel and Other Alloying ElementDocument62 pagesSteel and Other Alloying ElementJoby Jobzz SebellinoNo ratings yet

- Jresv9n1p9 A2bDocument19 pagesJresv9n1p9 A2bMatteo CarusoNo ratings yet

- Module 21Document82 pagesModule 21Nirav ParmarNo ratings yet

- Effects of Al, Si and Mo On Passivation Characteristics of Fe-10Cr Alloys !Document8 pagesEffects of Al, Si and Mo On Passivation Characteristics of Fe-10Cr Alloys !Steve OoiNo ratings yet

- C Staehle Kalt Datenblatt en 1511Document7 pagesC Staehle Kalt Datenblatt en 1511Yokesh SamannanNo ratings yet

- Co Based AlloysDocument32 pagesCo Based AlloysNookang SeaSunNo ratings yet

- Sci 401pptDocument107 pagesSci 401pptNiña Viaña BinayNo ratings yet

- Inclusions in SteelsDocument31 pagesInclusions in SteelsJatin BangaliNo ratings yet

- Materials 11 01935 PDFDocument17 pagesMaterials 11 01935 PDFVartika UpretyNo ratings yet

- Metallography and Microstructures of Stainless Steel Vandervoort Met-Of-SS-Vol-9Document31 pagesMetallography and Microstructures of Stainless Steel Vandervoort Met-Of-SS-Vol-9Andrea CalderaNo ratings yet

- Week 1 Lecture Material - WatermarkDocument88 pagesWeek 1 Lecture Material - Watermarkchristi SNo ratings yet

- Duplex Stainless Steel 2205 PDFDocument1 pageDuplex Stainless Steel 2205 PDFSalmanNo ratings yet

- Alloy Steel Castings Table 1Document16 pagesAlloy Steel Castings Table 1takumi_zNo ratings yet

- NB Mo Ti MNDocument7 pagesNB Mo Ti MNHICHAM SBAITINo ratings yet

- Chemical Compositions, Microstructure and Mechanical  Properties of Roll Core Used Ductile Iron in Centrifugal Casting Composite Rolls PDFDocument6 pagesChemical Compositions, Microstructure and Mechanical  Properties of Roll Core Used Ductile Iron in Centrifugal Casting Composite Rolls PDFShankey JAlanNo ratings yet

- Wrought IronDocument32 pagesWrought IronHicham KorichiNo ratings yet

- COBALT - FACTS-Metallurgical - UsesDocument15 pagesCOBALT - FACTS-Metallurgical - UsesMarlon BombiNo ratings yet

- Exotic Materials: Static EquipmentDocument12 pagesExotic Materials: Static EquipmentVishaka ThekkedathNo ratings yet

- Pellet, Iron Ore Concentrste, Sintered Iron Ore - Buy From Metinvest ManufacturerDocument4 pagesPellet, Iron Ore Concentrste, Sintered Iron Ore - Buy From Metinvest ManufacturerMAHESH CHANDNo ratings yet

- Friction 2004Document20 pagesFriction 2004Dule JovanovicNo ratings yet

- Welding Stainless SteelDocument4 pagesWelding Stainless SteelJohan ZraghozNo ratings yet

- Inclusion Characterization of Complex De-Oxidation of Si-Killed SteelDocument13 pagesInclusion Characterization of Complex De-Oxidation of Si-Killed SteelKanan SahooNo ratings yet

- Arc Welding Cracks SolidificationDocument3 pagesArc Welding Cracks SolidificationShaher YarNo ratings yet

- MonelDocument3 pagesMonelnurarifiantoNo ratings yet

- 1 - Demir Ve Celik Uretimi - 2021 - 1Document99 pages1 - Demir Ve Celik Uretimi - 2021 - 1atilla kayangilNo ratings yet

- Solid SiFe Anode (DATA SHEET)Document2 pagesSolid SiFe Anode (DATA SHEET)Fareed KhanNo ratings yet

- 7 Tool Steels1Document12 pages7 Tool Steels1ontc0109No ratings yet

- Rsa 2 PDFDocument5 pagesRsa 2 PDFPinto PintoNo ratings yet

- Evolution of Ethereum: A Temporal Graph Perspective: Qianlan Bai, Chao Zhang, Yuedong Xu, Xiaowei Chen, Xin WangDocument9 pagesEvolution of Ethereum: A Temporal Graph Perspective: Qianlan Bai, Chao Zhang, Yuedong Xu, Xiaowei Chen, Xin WangPinto PintoNo ratings yet

- UniFi Controller V4 UG PDFDocument132 pagesUniFi Controller V4 UG PDFryaneschultzhotmail.comNo ratings yet

- Specific Heat Capacities of Metals: Experiment 9Document4 pagesSpecific Heat Capacities of Metals: Experiment 9Pinto PintoNo ratings yet

- NanoBeam 5AC-Gen2 QSGDocument28 pagesNanoBeam 5AC-Gen2 QSGpedroNo ratings yet

- Evolution of Ethereum: A Temporal Graph Perspective: Qianlan Bai, Chao Zhang, Yuedong Xu, Xiaowei Chen, Xin WangDocument9 pagesEvolution of Ethereum: A Temporal Graph Perspective: Qianlan Bai, Chao Zhang, Yuedong Xu, Xiaowei Chen, Xin WangPinto PintoNo ratings yet

- Management of Failed Metal-On-Metal Total Hip ArthroplastyDocument5 pagesManagement of Failed Metal-On-Metal Total Hip ArthroplastyPinto PintoNo ratings yet

- Basic Lectures On Cryptography: (With Sage Programs)Document91 pagesBasic Lectures On Cryptography: (With Sage Programs)Pinto PintoNo ratings yet

- RoadStatusReport PDFDocument2 pagesRoadStatusReport PDFPinto PintoNo ratings yet

- Pros and Cons of Starting A Specialty Food Business: Fact Sheets For The Small Scale Food EntrepreneurDocument2 pagesPros and Cons of Starting A Specialty Food Business: Fact Sheets For The Small Scale Food EntrepreneurPinto PintoNo ratings yet

- How Does Heat Flow From One Object To Another?: 32 Thermal Energy and HeatDocument24 pagesHow Does Heat Flow From One Object To Another?: 32 Thermal Energy and HeatPinto PintoNo ratings yet

- 1-Sample T-Test: Interpreting The ResultsDocument1 page1-Sample T-Test: Interpreting The ResultsPinto PintoNo ratings yet

- Rsa 2 PDFDocument5 pagesRsa 2 PDFPinto PintoNo ratings yet

- Media Multitasking Is Associated With Symptoms of Depression and Social AnxietyDocument4 pagesMedia Multitasking Is Associated With Symptoms of Depression and Social AnxietyPinto PintoNo ratings yet

- Performance MeasurementDocument15 pagesPerformance MeasurementrhodaNo ratings yet

- 3.5 Balancing A Closed TraverseDocument5 pages3.5 Balancing A Closed Traverseabdullahiomar2020No ratings yet

- As and A Level Chemistry Core Practical 8 Hess Law (Student, Teacher, Technician Worksheets)Document5 pagesAs and A Level Chemistry Core Practical 8 Hess Law (Student, Teacher, Technician Worksheets)Namira Shameem0% (1)

- Performance MeasurementDocument15 pagesPerformance MeasurementrhodaNo ratings yet

- Corrosion at The Head-Neck Taper As A Cause For Adverse Local Tissue Reactions After Total Hip ArthroplastyDocument7 pagesCorrosion at The Head-Neck Taper As A Cause For Adverse Local Tissue Reactions After Total Hip ArthroplastyPinto PintoNo ratings yet

- Adverse Local Tissue Reaction Arising From Corrosion at The Femoral Neck-Body Junction in A Dual-Taper Stem With A Cobalt-Chromium Modular NeckDocument8 pagesAdverse Local Tissue Reaction Arising From Corrosion at The Femoral Neck-Body Junction in A Dual-Taper Stem With A Cobalt-Chromium Modular NeckPinto PintoNo ratings yet

- Traversing: Lester E. Carter, JR., PLS City of San DiegoDocument12 pagesTraversing: Lester E. Carter, JR., PLS City of San DiegoHamza Al-SharifNo ratings yet

- Process Safety Management of Highly Hazardous & Explosive ChemicalDocument32 pagesProcess Safety Management of Highly Hazardous & Explosive ChemicalPinto Pinto100% (1)

- Apoptosis Dna Fragmentation Analysis ProtocolDocument1 pageApoptosis Dna Fragmentation Analysis ProtocolPinto PintoNo ratings yet

- 2 Levelling Theory 2014 PDFDocument76 pages2 Levelling Theory 2014 PDFPinto PintoNo ratings yet

- Eddy Wiki PDFDocument7 pagesEddy Wiki PDFMuhammad SulaimanNo ratings yet

- Jiang JDocument16 pagesJiang JmuhamedNo ratings yet

- Training T Test 16 enDocument50 pagesTraining T Test 16 enRaúl Moreno GómezNo ratings yet

- Helicopter PerfomanceDocument24 pagesHelicopter PerfomancePinto PintoNo ratings yet

- Section 1.8: X: Learning ObjectivesDocument26 pagesSection 1.8: X: Learning ObjectivesPinto PintoNo ratings yet

- Products of Chemistry: RayonDocument7 pagesProducts of Chemistry: RayonLaura Perez NiñoNo ratings yet

- Chapter5 PDFDocument18 pagesChapter5 PDFAli HassanNo ratings yet

- 4th SeminarDocument70 pages4th SeminarVeena Goud100% (1)

- Senseor For T50Document100 pagesSenseor For T50hienda09hhNo ratings yet

- WPS PQR-02Document8 pagesWPS PQR-02Ranjan Kumar100% (1)

- Paints, Varnishes, and Related Products: Bailey's Industrial Oil and Fat Products, Sixth Edition, Six Volume SetDocument45 pagesPaints, Varnishes, and Related Products: Bailey's Industrial Oil and Fat Products, Sixth Edition, Six Volume SetAbbas AliNo ratings yet

- Zinnabu TassewDocument105 pagesZinnabu TassewTeklit GebrerufaelNo ratings yet

- Optimal Processing Parameters of Electrostatic Crude Oil DesaltingDocument7 pagesOptimal Processing Parameters of Electrostatic Crude Oil DesaltingElbahi DjaalabNo ratings yet

- t2 Chem Revision Ex 6 - Answer SchemeDocument9 pagest2 Chem Revision Ex 6 - Answer SchemeNicholas OwNo ratings yet

- High Performance Liquid Chromatography (HPLC)Document11 pagesHigh Performance Liquid Chromatography (HPLC)Benjamin DanielNo ratings yet

- Benzene Homework QuestionsDocument4 pagesBenzene Homework Questionskemi.sklNo ratings yet

- Water Analysis ReportDocument4 pagesWater Analysis ReportAamirMalikNo ratings yet

- Synthesis of Piperitone Epoxide and P-Menthane-8-Thiol-3-One From Essential OilsDocument6 pagesSynthesis of Piperitone Epoxide and P-Menthane-8-Thiol-3-One From Essential OilsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Is0l4tion of 4lk4l0ids fr0m Te4Document9 pagesIs0l4tion of 4lk4l0ids fr0m Te4Timothy DrakeNo ratings yet

- Science Worksheet Grade - 7Document4 pagesScience Worksheet Grade - 7Srinivas_3181No ratings yet

- Minerals PPT 2023-2024Document46 pagesMinerals PPT 2023-2024nicoleclarostudentNo ratings yet

- Amphiphilic Mixtures Versus Surfactant Structures With Smooth Polarity Transition Across Interface To Improve Solubilization PerformanceDocument9 pagesAmphiphilic Mixtures Versus Surfactant Structures With Smooth Polarity Transition Across Interface To Improve Solubilization Performancelab biofarcoNo ratings yet

- Cosmetic Ingredients and Their Functions PDFDocument35 pagesCosmetic Ingredients and Their Functions PDFChris Jerick MenesesNo ratings yet

- FoldernamesDocument10 pagesFoldernamesLEADER VISANo ratings yet

- Matrices: Dr. J. Ramkumar Professor Dept of Mechanical & Design Program IIT Kanpur, IndiaDocument27 pagesMatrices: Dr. J. Ramkumar Professor Dept of Mechanical & Design Program IIT Kanpur, IndiaMahesh RajaNo ratings yet

- 3-AAP Analysis ReportDocument11 pages3-AAP Analysis ReportPinjala AnoopNo ratings yet

- Solutions HHW WorksheetDocument10 pagesSolutions HHW WorksheetPriyanshi -No ratings yet

- Steel Guide V1.2Document1 pageSteel Guide V1.2Manga DeviNo ratings yet

- OREAS 603 CertificateDocument16 pagesOREAS 603 CertificateDenis Alvarez RiveraNo ratings yet

- Solidification and Liquation CrackingDocument6 pagesSolidification and Liquation CrackingNnamdi Celestine Nnamdi100% (2)

- MTRL494 2019 - Assignment #1 - SolutionsDocument6 pagesMTRL494 2019 - Assignment #1 - SolutionsitzelNo ratings yet

- CPP & Cqa PDFDocument71 pagesCPP & Cqa PDFanon_695264516100% (1)

- Precautions in Handling, Acceptance and Fixation of SpecimenDocument5 pagesPrecautions in Handling, Acceptance and Fixation of SpecimenMary ChristelleNo ratings yet

- KBR's Transport Gasifier (TRIG) - An Advanced Gasification Technology For SNG Production From Low-Rank CoalsDocument19 pagesKBR's Transport Gasifier (TRIG) - An Advanced Gasification Technology For SNG Production From Low-Rank Coalsrecsco2No ratings yet

- Topical Application of (L.) : Formulation and Evaluation of Hydrophilic Cream With Antioxidant ActivityDocument10 pagesTopical Application of (L.) : Formulation and Evaluation of Hydrophilic Cream With Antioxidant ActivityFika Rasita SariNo ratings yet